Composite material of micro-fiber encapsulated active carbon or active carbon catalyst and preparation method thereof

A composite material and activated carbon technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of no application reports, etc., and achieve easy manufacture, fast permeation speed, and low bed resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

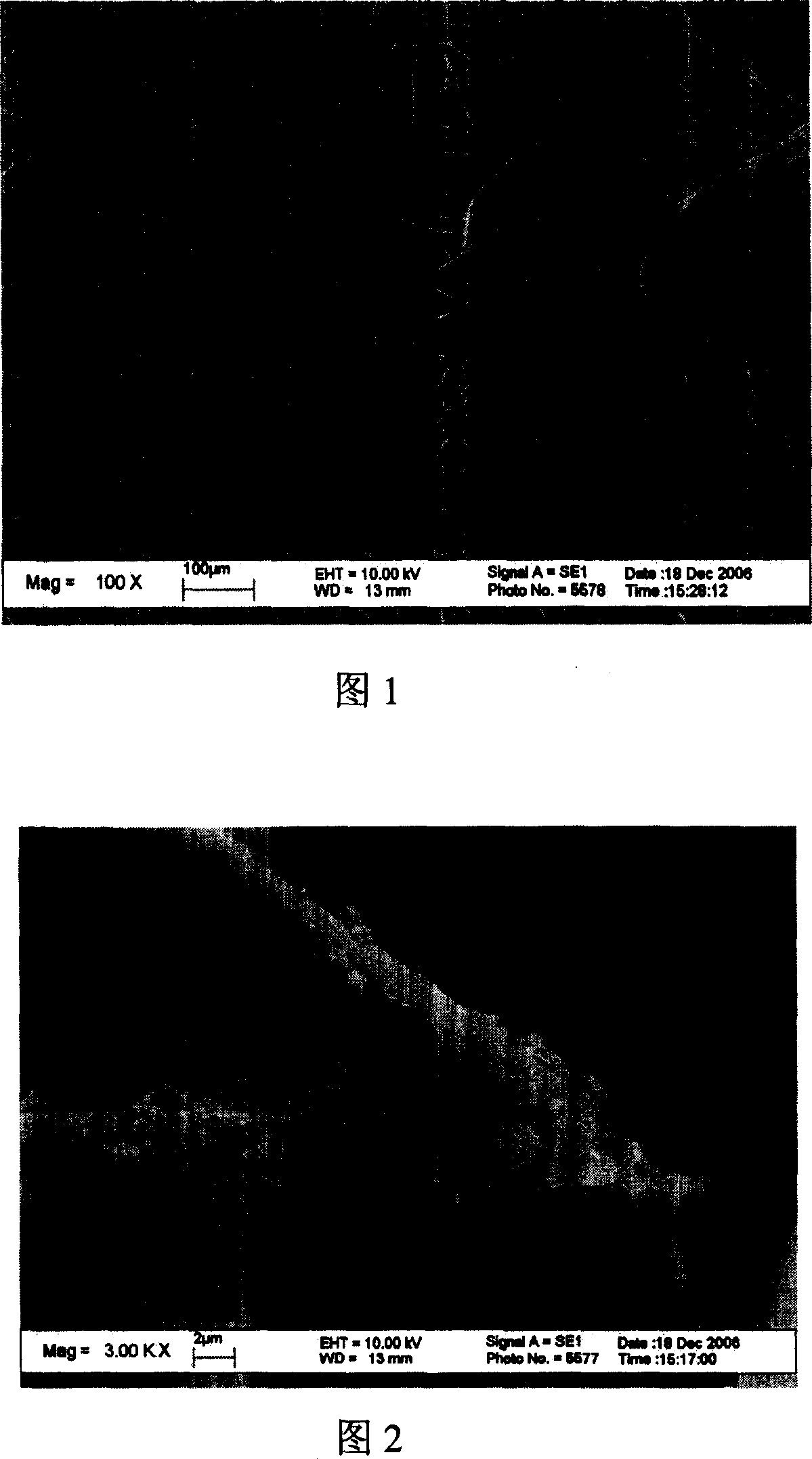

Embodiment 1

[0026] With 0.5g coniferous wood fiber and 0.5g carboxymethyl cellulose, 3.0g ceramic fiber (provided by Shandong Luyang Chemical Plant, hereinafter the same), 8g cyanogen chloride removal special activated carbon catalyst (provided by Shanxi Xinhua Chemical Plant, hereinafter the same) Add it into 1.5L of water, and stir with a high-speed mixer for 10 minutes to form a uniformly mixed slurry. Among them, the diameter of the ceramic fiber is 6.0 microns, and the particle size of the activated carbon is 105-150 microns. The uniformly mixed slurry is sliced by a slicer, and a wet filter cake is formed after water filtration. The wet cake was pressed at 4 bar, dried at 60°C for 40 minutes and then at 105°C for 24 hours. Put the dried composite material in N 2 Sintering was carried out at 950°C for 40 minutes under protection, and the gas flow rate was controlled at 200ml / min. The specific surface area of the original activated carbon measured by ASAP2020 static adsorption ...

Embodiment 2

[0029] Add 1 g of carboxymethyl cellulose, 1 g of stainless steel metal fiber (Hunan Huitong Metal Fiber Co., Ltd.), and 7 g of activated carbon into 1.5 L of water, and stir with a high-speed mixer for 10 min to form a uniformly mixed slurry. Among them, the diameter of the metal fiber is 50.0 microns, and the particle size of the activated carbon is 105-150 microns. The uniformly mixed slurry is sliced by a slicer, and a wet filter cake is formed after water filtration. The wet cake was pressed at 4 bar, dried at 60°C for 40 minutes and then at 150°C for 20 hours. Put the dried composite material in N 2 Sintering at 1400°C for 20 minutes under protection, with the gas flow rate controlled at 200ml / min. The specific surface area of the original activated carbon measured by ASAP2020 static adsorption instrument is 1320m 2 / g, the BET specific surface area of the material is 1258m 2 / g.

Embodiment 3

[0031] Add 0.5g of bamboo fiber, 0.5g of carboxymethyl cellulose, 3.5g of ceramic fiber and 9g of activated carbon into 1.5L of water, and stir with a high-speed mixer for 10min to form a uniformly mixed slurry. Among them, the diameter of the ceramic fiber is 0.5 micron, and the particle size of the activated carbon is 150-350 micron. The uniformly mixed slurry is sliced by a slicer, and a wet filter cake is formed after water filtration. The wet cake was pressed at 4 bar, dried at 60°C for 40 minutes and then at 200°C for 24 hours. The dried composite material was sintered at 1000° C. for 90 minutes under the protection of N2, and the gas flow rate was controlled at 200 ml / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com