Poly(p-phenylenebenzobisoxazole) porous membrane, preparation method and application thereof

A technology of benzobisoxazole and poly-p-phenylene, which is applied in the field of lithium-ion secondary batteries, can solve the problems of poor heat resistance and low strength of the separator, and achieve the effects of high tensile strength, uniform distribution and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

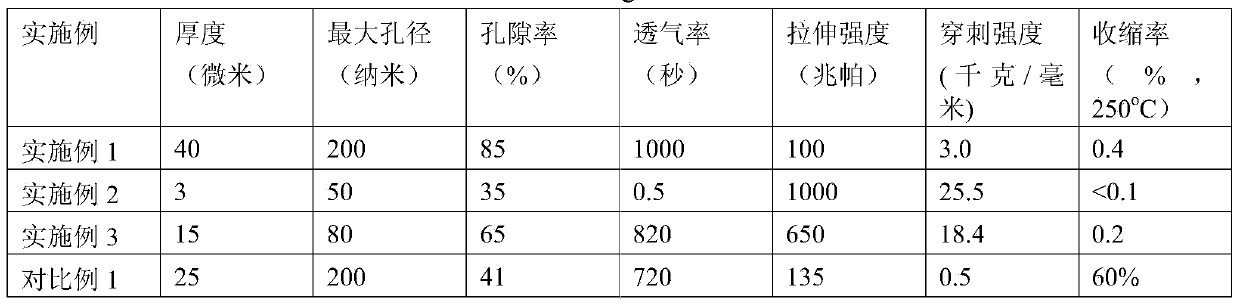

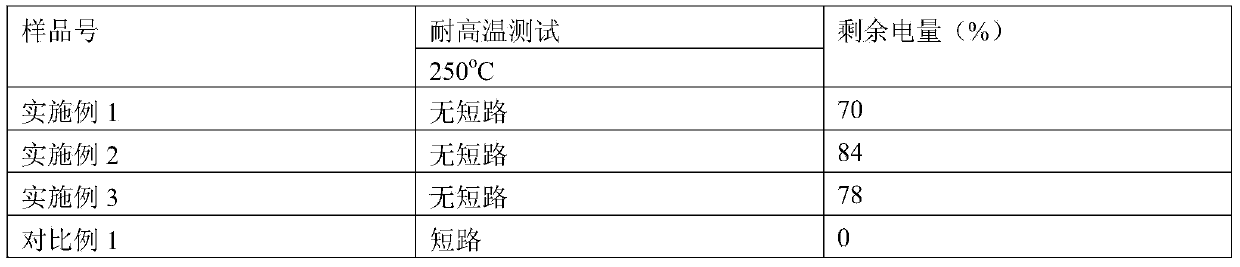

Embodiment 1

[0054] Step 1: Add poly-p-phenylenebenzobisoxazole fibers with a molecular weight of 105,000 to a mixed solvent of methanesulfonic acid (MSA) and trifluoroacetic acid (TFA) (the volume ratio of MSA and TFA is 7:3), Stir for one week under dry conditions at room temperature to form a 1% by mass poly-p-phenylenebenzobisoxazole solution.

[0055] Step 2: After the solution is subjected to vacuum defoaming treatment, it is cast into a film in an isopentane atmosphere to obtain a poly-p-phenylenebenzobisoxazole film blank.

[0056] Step 3: remove the film blank and immerse it in isopropanol at a temperature of -40°C for 4 hours, then take out the treated film blank and immerse it in deionized water at a temperature of 10°C for 4 hours to obtain Gel-state films of poly(p-phenylenebenzobisoxazole). Then the gel-state film was taken out and placed in a freezer at -50° C. for 4 hours, and vacuum-dried at this temperature for 12 hours to obtain a poly-p-phenylenebenzobisoxazole porous ...

Embodiment 2

[0059] Step 1: Add poly-p-phenylenebenzobisoxazole fibers with a molecular weight of 110,000 to a mixed solvent of methanesulfonic acid (MSA) and trifluoroacetic acid (TFA) (MSA and TFA volume ratio is 2:8), Stir for one week under dry conditions at room temperature to form a poly-p-phenylenebenzobisoxazole solution with a mass percentage of 15%.

[0060] Step 2: After the solution is subjected to vacuum defoaming treatment, it is cast into a film in an isopentane atmosphere to obtain a poly-p-phenylenebenzobisoxazole film blank.

[0061] Step 3: taking out the film blank and immersing it in deionized water at a temperature of 10° C. for 24 hours to obtain a gel-state film of poly-p-phenylenebenzobisoxazole. Then the gel-state film was taken out and placed in a freezer at -10° C. for 24 hours, and vacuum-dried at this temperature for 12 hours to obtain a poly-p-phenylenebenzobisoxazole porous film.

[0062] The obtained poly-p-phenylene benzobisoxazole porous membrane was cha...

Embodiment 3

[0064] Step 1: Add poly-p-phenylenebenzobisoxazole fibers with a molecular weight of 105,000 to a mixed solvent of methanesulfonic acid (MSA) and trifluoroacetic acid (TFA) (the volume ratio of MSA and TFA is 1:1), Stir for one week under dry conditions at room temperature to form a poly-p-phenylenebenzobisoxazole solution with a mass percentage of 10%.

[0065] Step 2: After the solution is subjected to vacuum defoaming treatment, it is cast into a film in an isopentane atmosphere to obtain a poly-p-phenylenebenzobisoxazole film blank.

[0066] Step 3: Take out the film blank and immerse it in a mixed solvent with a volume ratio of deionized water and ethanol of 1:1 for 12 hours, and the temperature of the mixed solvent is 10° C. colloidal film. Then the gel-state film was taken out and placed in a freezer at -50° C. for 24 hours, and vacuum-dried at this temperature for 16 hours to obtain a poly-p-phenylenebenzobisoxazole porous film.

[0067] The obtained poly-p-phenylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com