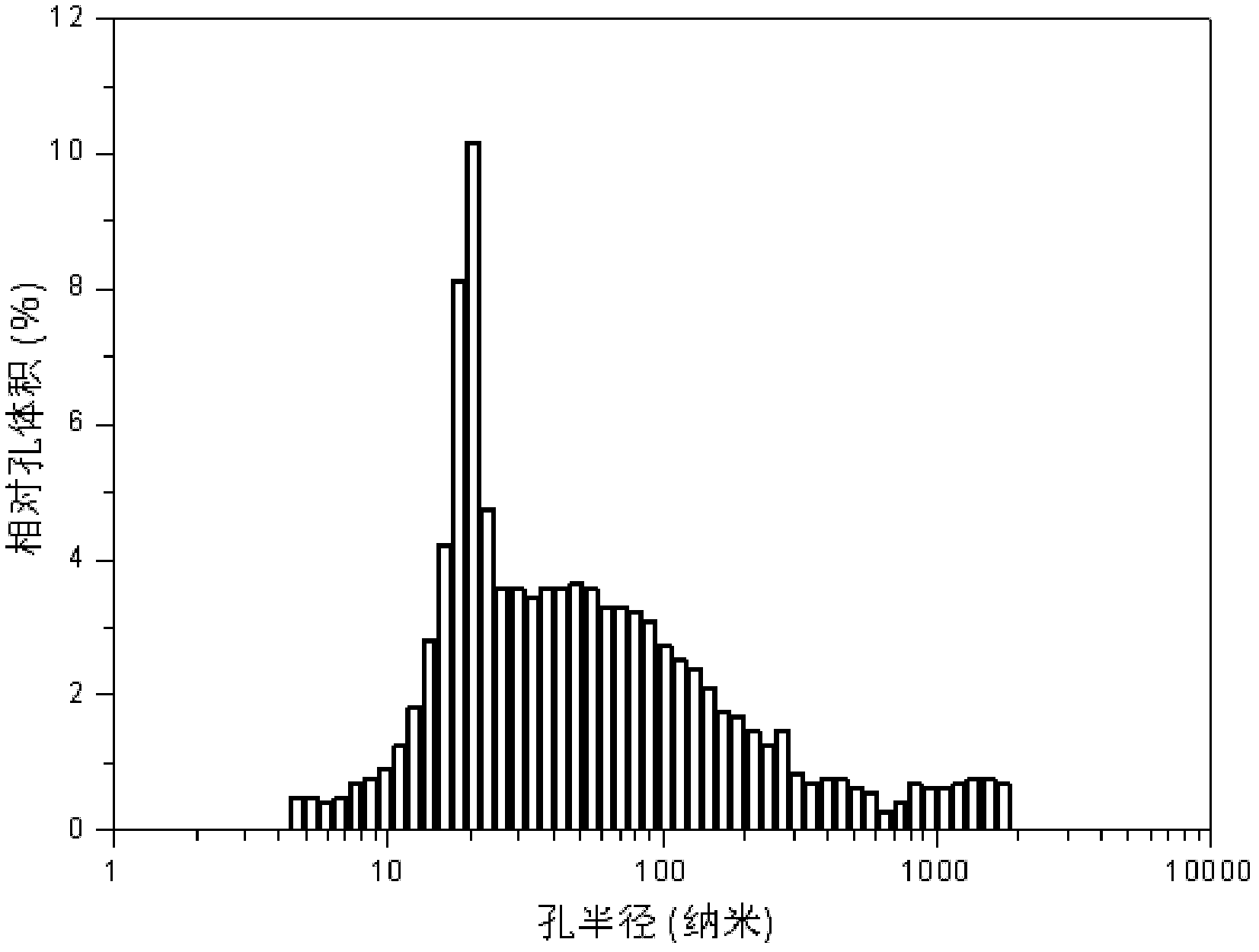

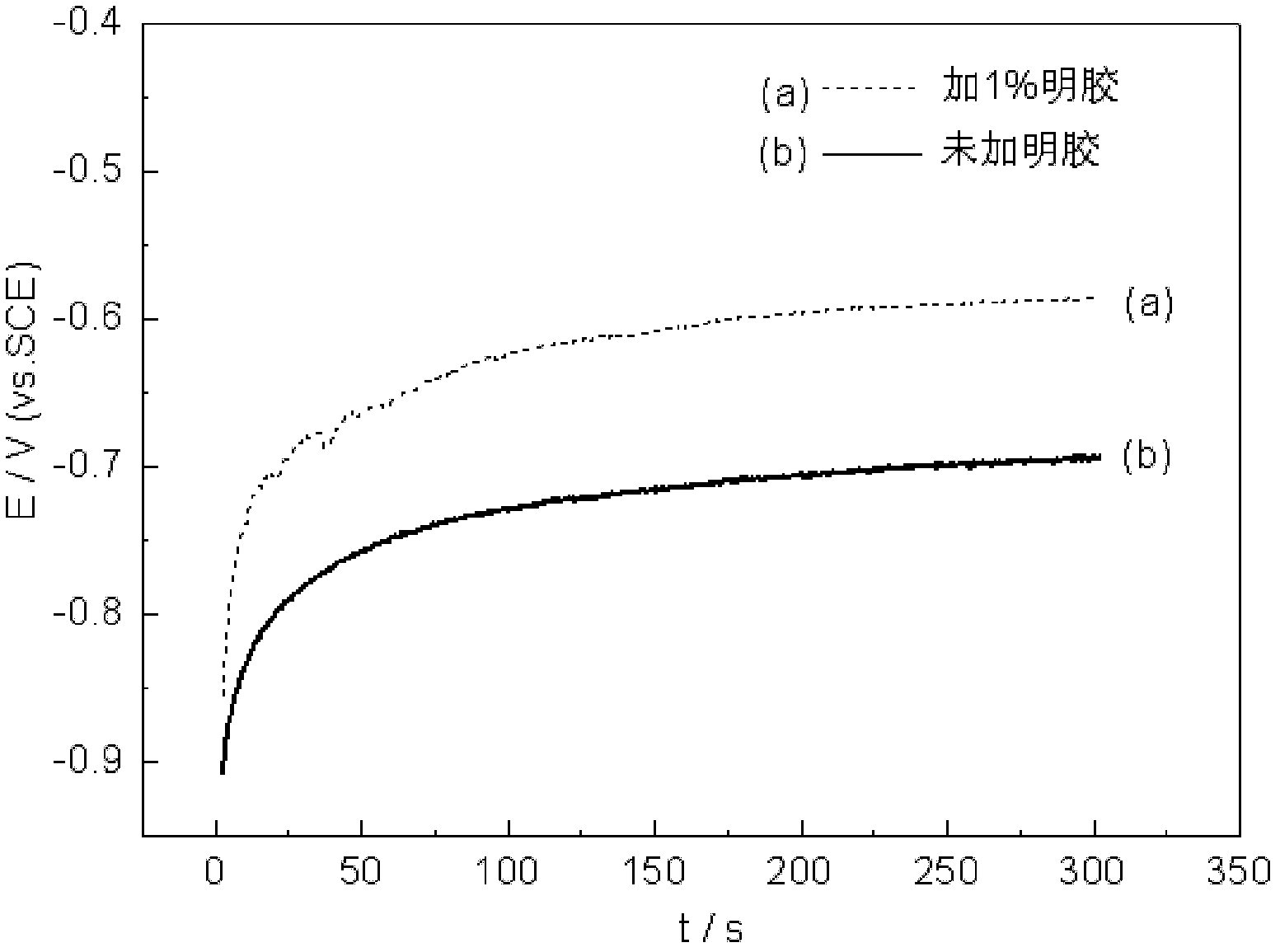

Gelatin hole forming method for gas diffusion electrodes

A gas diffusion electrode, gelatin technology, applied in the direction of electrode shape/type, etc., can solve the problems of damage to electrode performance and life, long time consumption, low decomposition temperature of ammonium salt, etc. Uniform and stable electrode structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add gelatin preparation process, wherein the mass ratio of gelatin and carbon black in the electrode component is 1%:

[0023] (1) Preparation of the diffusion layer: Add 20 mL of triton aqueous solution with a mass concentration of 4%, 1 mL of a gelatin aqueous solution with a mass fraction of 2%, 20 mL of isopropanol, and 2 g of hydrophobic carbon black in a beaker, and ultrasonically disperse the three to mix evenly , then add 2mL of 60% PTFE emulsion, use a homogenizer to shear and disperse for 0.5h, and then use a cell pulverizer to disperse ultrasonically for 10min to form a uniform slurry, coat the obtained slurry on the nickel foam and bake it at 60-80°C Cold pressing after 0.5 hours to obtain a diffusion layer;

[0024] (2) Preparation of catalytic layer: first add 10mL 4% triton aqueous solution, 0.5mL mass fraction 2% gelatin aqueous solution, 20mL isopropanol in the container successively, ultrasonic dispersion makes the three mix uniformly, then add 1g prop...

Embodiment 2

[0027] Add gelatin preparation process, wherein in the electrode component, the mass ratio of gelatin and carbon black is 2%:

[0028] (1) Preparation of the diffusion layer: Add 20 mL of triton aqueous solution with a mass concentration of 4%, 2 mL of a gelatin aqueous solution with a mass fraction of 1%, 20 mL of isopropanol, and 2 g of hydrophobic carbon black in a beaker, and ultrasonically disperse the three to mix evenly , then add 2mL of 60% PTFE emulsion, use a homogenizer to shear and disperse for 0.5h, and then use a cell pulverizer to disperse ultrasonically for 10min to form a uniform slurry, coat the obtained slurry on the nickel foam and bake it at 60-80°C Cold pressing after 0.5 hours to obtain a diffusion layer;

[0029] (2) Preparation of catalytic layer: First add 10mL 4% triton aqueous solution, 1mL mass fraction 1% gelatin aqueous solution, 20mL isopropanol in the container, and ultrasonically disperse the three to mix evenly, then add 1g hydrophilic Carbo...

Embodiment 3

[0032] Add gelatin preparation process, wherein in the electrode component, the mass ratio of gelatin and carbon black is 3%:

[0033](1) Preparation of the diffusion layer: Add 20 mL of triton aqueous solution with a mass concentration of 4%, 3 mL of a gelatin aqueous solution with a mass fraction of 2%, 20 mL of isopropanol, and 2 g of hydrophobic carbon black in a beaker, and ultrasonically disperse the three to mix evenly , then add 2mL of 60% PTFE emulsion, use a homogenizer to shear and disperse for 0.5h, and then use a cell pulverizer to disperse ultrasonically for 10min to form a uniform slurry, coat the resulting slurry on the nickel foam and bake it at 60-80°C Cold pressing after 0.5 hours to obtain a diffusion layer;

[0034] (2) Preparation of catalytic layer: first add 10mL 4% triton aqueous solution, 1.5mL mass fraction 2% gelatin aqueous solution, 20mL isopropanol in the container successively, ultrasonic dispersion makes the three mix uniformly, then add 1g pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com