Lithium battery separator and preparation method and application thereof

A separator and lithium battery technology, applied in the field of electrochemistry, can solve the problem that the airtightness and strength electrochemical performance of cellulose paper cannot meet the separator materials for secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

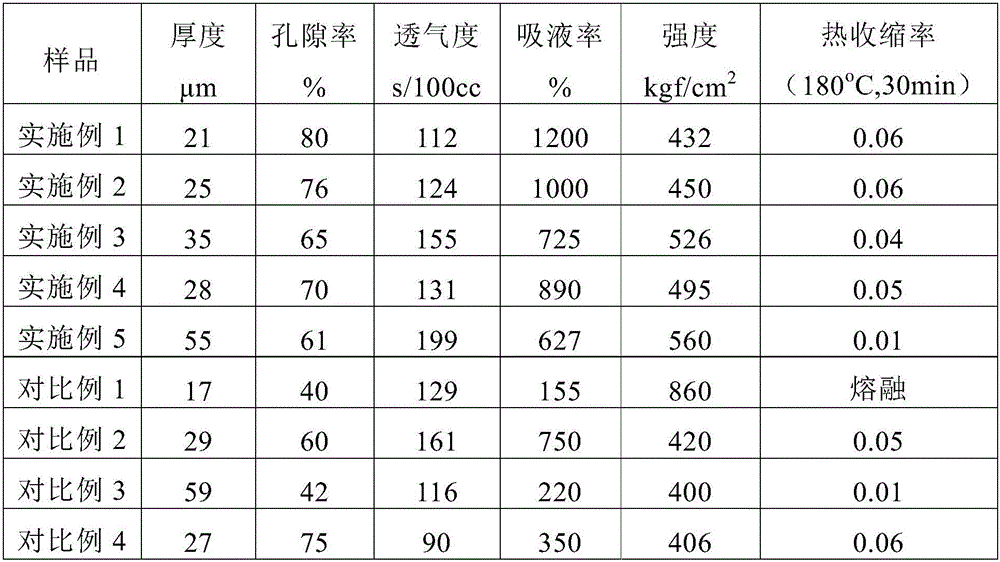

Examples

preparation example Construction

[0042] The preparation method of the separator provided by the invention comprises the following steps:

[0043] In the first step, the cellulose slurry, inorganic particles, binder and dispersion liquid are mixed to obtain a mixture;

[0044] In the second step, the mixture is made into paper to obtain a wet separator;

[0045] The third step is to remove moisture from the wet separator and then dry to obtain the separator provided by the present invention.

[0046]In the above-mentioned first step, the cellulose slurry is to soak at least one of cellulose acetate, cellulose nitrate, wood pulp, cotton pulp, hemp pulp, bamboo pulp and their composites in the dispersion Limited to 12-36 hours, preferably 20-30 hours) after high-speed grinding and beating. The speed of so-called high-speed grinding is 500-2000 rpm, preferably 1000-1500 rpm. The wood pulp, cotton pulp, hemp pulp or bamboo pulp can be obtained by conventional methods in the art, such as but not limited to chemi...

Embodiment 1

[0080] Preparation of separator

[0081] Add 1 liter of deionized water to 20g of bamboo pulp, after soaking, grind at a high speed and beating to make a hardwood plant fiber slurry with a concentration of 5wt%, the fiber cross-sectional diameter is 0.8 micron, and 2 grams of particle diameter is 500nm of carbon dioxide Disperse silicon in 100ml of water, add 0.2g of epoxy resin, and fully mix with cellulose slurry, make paper through a semi-automatic paper machine, squeeze the wet paper sheet with a press roller, remove excess water, and dry at 85°C , made of cellulose composite non-woven membrane.

Embodiment 2

[0083] Preparation of separator

[0084] Add 1 liter of deionized water to 20 g of cellulose acetate, after soaking, high-speed grinding and beating to make a cellulose acetate slurry with a concentration of 3 wt%, the cross-sectional diameter of the fiber is 0.6 micron, and 2 grams of trioxide Dialuminum is dispersed in 100 ml of water, 0.2 g of melamine formaldehyde resin is added, and fully mixed with cellulose slurry, paper is made by a semi-automatic paper machine, and the wet paper sheet is squeezed with a press roller to remove excess water. Dry at 85°C to make a cellulose composite nonwoven membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com