Nickel-based composite anode material of solid oxide fuel cell and application thereof

A technology of solid oxide and composite anode, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of ceramic skeleton and electrolyte cracks, poor nickel dispersion, and battery performance failure, so as to improve interface contact and improve resistance. Cycling redox performance, effect of reducing volume expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

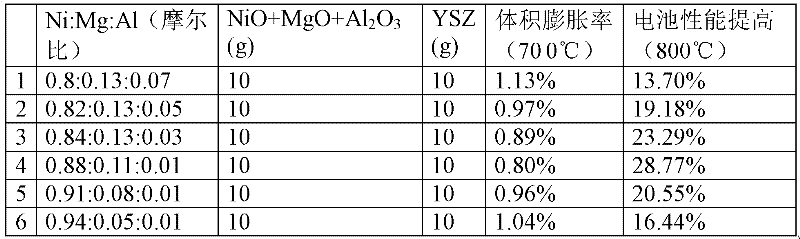

Examples

Embodiment 1

[0041] Using the method of nitrate co-decomposition, a total of 1.624g of magnesium nitrate (Mg(NO 3 ) 2 ·6H 2 O), 0.125g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 17.450g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) mixture to obtain magnesium oxide and aluminum oxide modified nickel oxide-based anode material. Select magnesium oxide and alumina-modified nickel oxide as the anode catalyst material (wherein Ni: Mg: Al=0.9: 0.095: 0.005, molar ratio), mix (by weight) with 8YSZ (the molar content of yttrium oxide in YSZ is 8%) Ratio 60:40), add an organic adhesive (such as PVB and n-butanol (1:1 by weight) solvent, the amount is 30% of the total weight of the anode) to the powder, mix and grind thoroughly.

[0042] After drying, it is pressed at 100MPa, and then fired at 1350°C for 4 hours in an air atmosphere. The prepared strip-shaped composite anode material with a size of 1.5×4×20mm was used to investigate the volume expansion rate during the cyclic redox process. With hig...

Embodiment 2

[0045] Using the method of co-decomposition of nitrate, a total of 2.052g of magnesium nitrate (Mg(NO 3 ) 2 ·6H 2 O), 1.001g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 16.285g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) mixture to obtain magnesium oxide and aluminum oxide modified nickel oxide-based anode material. The nickel oxide modified by magnesium oxide and aluminum oxide is used as the anode catalyst material (wherein Ni: Mg: Al=0.85: 0.11: 0.04, molar ratio), mixed with 8YSZ (the molar content of yttrium oxide in YSZ is 8%) (by weight Ratio 50:50), add an organic adhesive (such as PVB and n-butanol (1:1 by weight) solvent, the amount is 30% of the total weight of the anode) to the powder, mix and grind thoroughly.

[0046] After drying, it is pressed at 100MPa, and then fired at 1500°C for 3 hours in an air atmosphere. The strip-shaped composite anode material with a size of about 1.5×4×20mm was prepared to investigate the volume expansion rate during the cyclic redox...

Embodiment 3

[0049] A solid-state reaction method was used to directly mix magnesium oxide, aluminum oxide, nickel oxide and 8YSZ to prepare magnesium oxide and aluminum oxide-modified nickel oxide-based anode materials. Fully mix and grind all the oxides according to the corresponding proportion, then add an organic adhesive (such as PVB and n-butanol (1:1 by weight) solvent, the dosage is 30% of the total weight of the anode) to the powder and mix evenly.

[0050] After drying, press at 100MPa, and then bake at 1450°C for 3.5h in an air atmosphere. The strip-shaped composite anode material with a size of about 1.5×4×20mm was prepared to investigate the volume expansion rate during the cyclic redox process. When high-purity hydrogen is used as the reducing gas and air is used as the oxidizing gas, the oxidation and reduction processes are carried out at 700°C for 3 hours.

[0051] Composite anode substrates with a thickness of 800 μm were prepared by dry pressing and fired at 1450°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com