High-strength lamellar Al-based metal ceramic composite material and preparation method thereof

A ceramic composite material and high-strength layer technology, which is applied in the direction of ceramic products, metal layered products, chemical instruments and methods, etc., can solve the problems of high cost of composite material preparation, single types of reinforced ceramics, cumbersome operation, etc., and achieve equipment The effect of low requirements, low manufacturing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

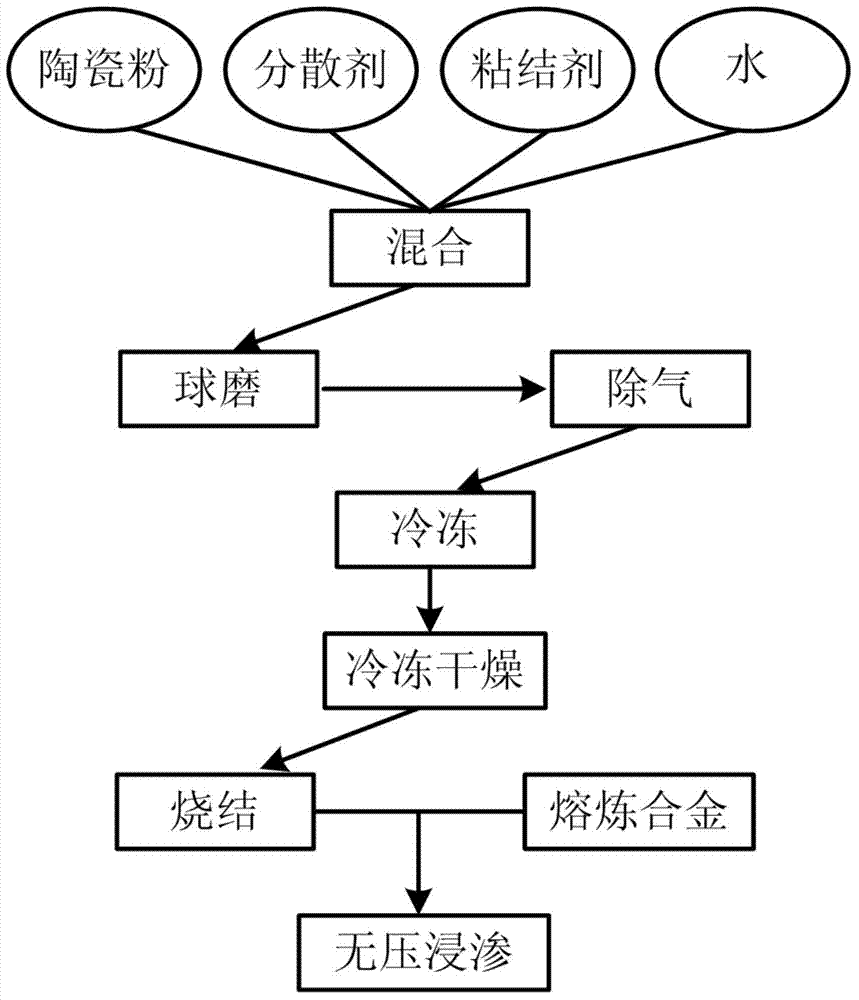

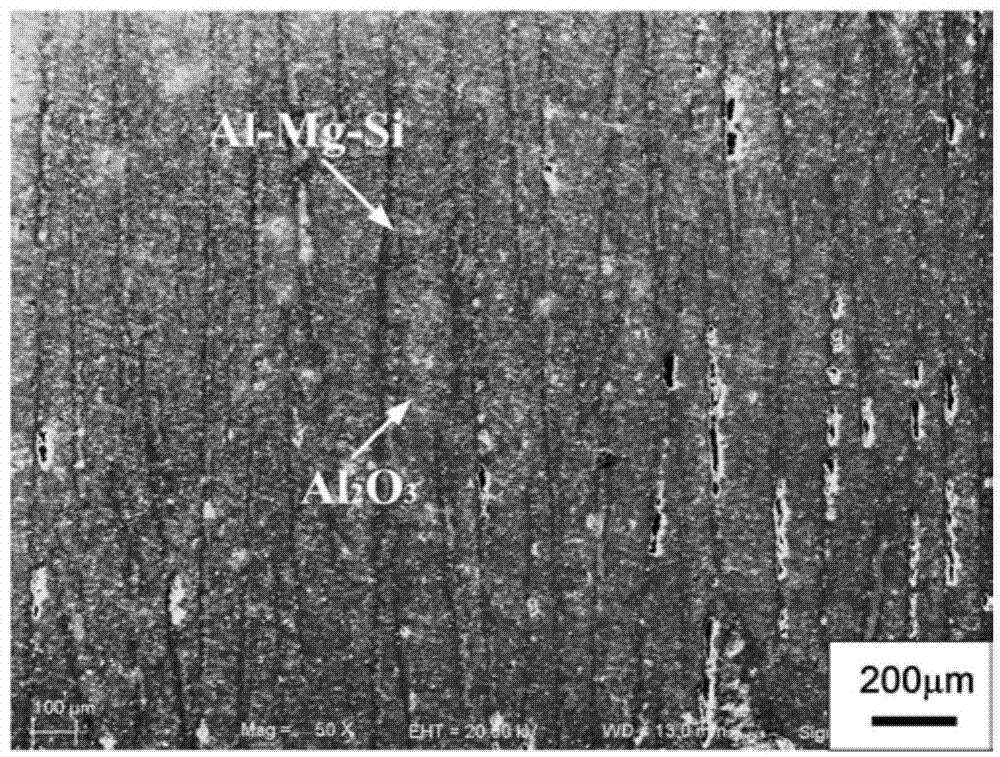

[0051] High-strength layered structure Al-Si-Mg / (Al 2 o 3 , SiC, TiC) the steps of composite material preparation method are as follows:

[0052] 1. Preparation of water-based ceramic slurry:

[0053] Dissolve the dispersant (ammonium polyacrylate or sodium polymethacrylate or sodium carboxymethyl cellulose) and binder (polyvinyl alcohol) in deionized aqueous solution at 60°C, and then mix with ceramic Al 2 o 3 or ceramic SiC or ceramic TiC powder, and use a planetary ball mill with a rotation speed of 100r / min to perform ball milling for 12h to make a ceramic slurry, wherein the solid phase ceramic (Al 2 o 3 or SiC or TiC) powder accounts for 20-40% of the volume of the entire slurry, and the dispersant content is solid phase ceramics (Al 2 o 3 or SiC or TiC) powder mass of 0.8 to 2%, the binder content is solid phase ceramics (Al 2 o 3 or SiC or TiC) powder mass of 0.5-2%, the slurry after ball milling is then vacuum stirred and degassed for 20min, and the stirring s...

Embodiment 1

[0065] 1. Preparation of water-based ceramic slurry:

[0066] Using sodium polymethacrylate as a dispersant and polyvinyl alcohol as a binder, they were dissolved in deionized aqueous solution at 60°C, and then mixed with ceramics (Al 2 o 3 ) powders, and use a planetary ball mill with a rotating speed of 100r / min to perform ball milling for 12h to make a slurry, in which the solid phase ceramics (Al 2 o 3 ) powder accounts for 20% of the volume of the entire slurry, and the dispersant content is solid phase ceramics (Al 2 o 3 ) 2.0% of the powder mass, the binder content is solid phase ceramics (Al 2 o 3 ) 2.0% of the mass of the powder, the slurry after ball milling was vacuum stirred and degassed for 20 minutes, the stirring speed was 80-100r / min, and the water-based ceramics (Al 2 o 3 ) slurry.

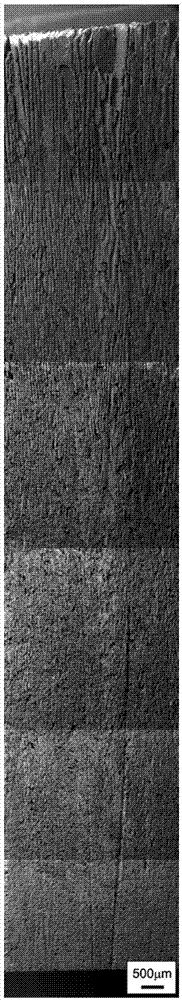

[0067] 2. Directional solidification:

[0068] Water-based ceramics (Al 2 o 3 ) slurry is injected into the polytetrafluoroethylene mold, and directional solidification...

Embodiment 2

[0078] 1. Preparation of water-based ceramic slurry:

[0079] Using sodium polymethacrylate as a dispersant and polyvinyl alcohol as a binder, they were dissolved in deionized aqueous solution at 60°C, and then mixed with ceramics (Al 2 o 3 ) powders, and use a planetary ball mill with a rotating speed of 100r / min to perform ball milling for 12h to make a slurry, in which the solid phase ceramics (Al 2 o 3 ) powder accounts for 40% of the volume of the entire slurry, and the dispersant content is solid phase ceramics (Al 2 o 3 ) 2.0% of the mass, the binder content is solid phase ceramics (Al 2 o 3 ) 2.0% of the mass of the powder, the slurry after ball milling was vacuum stirred and degassed for 20 minutes, the stirring speed was 80-100r / min, and the water-based ceramics (Al 2 o 3 ) slurry.

[0080] 2. Directional solidification:

[0081] Water-based ceramics (Al 2 o 3 ) slurry was poured into a polytetrafluoroethylene mold and directional solidified in a low-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com