Preparation method of multi-element rare earth oxygen storage and release material in three-effect catalyst of automobile emission purification

A technology for purifying catalysts and automobile exhaust, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. , the difficulty of catalytic coating and other problems, to achieve the effect of convenient industrial production, large specific surface, and reducing the amount of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Solution configuration:

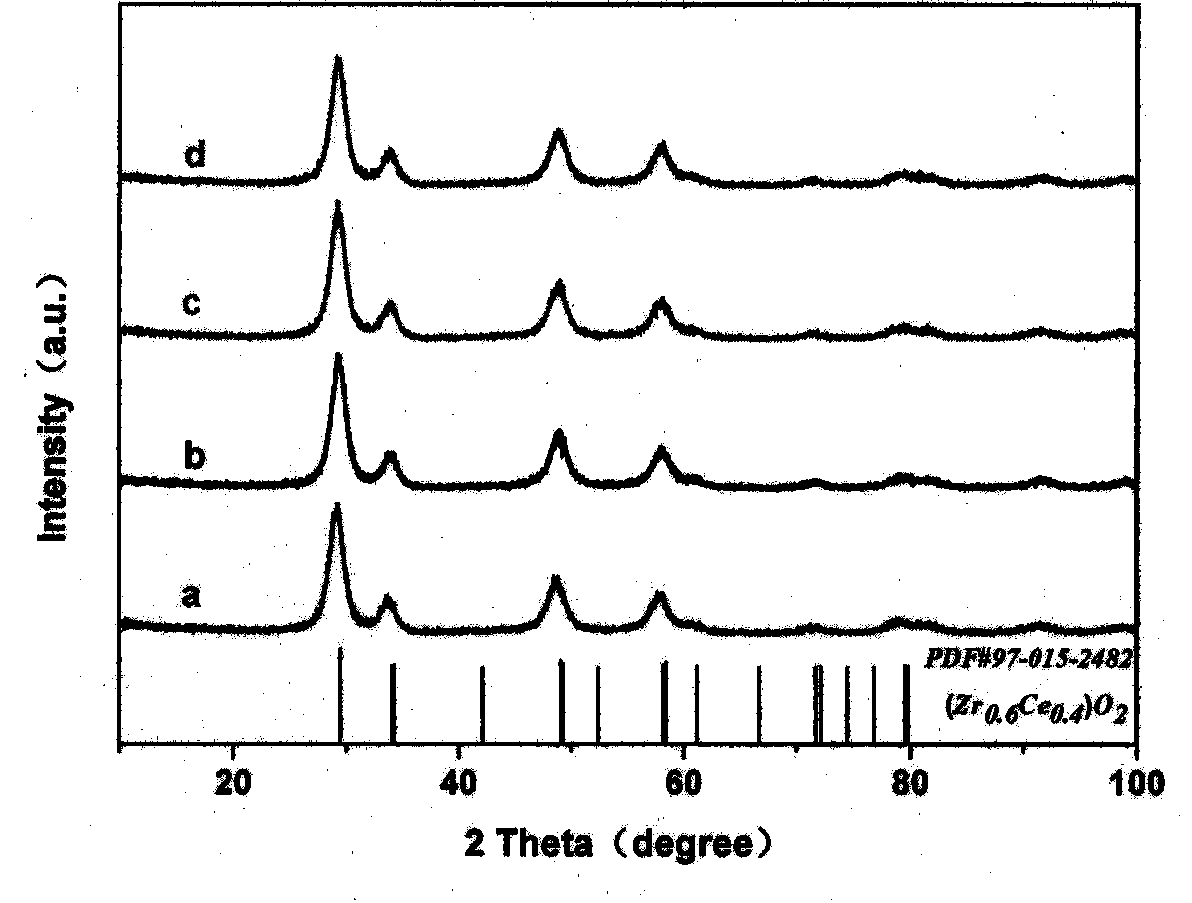

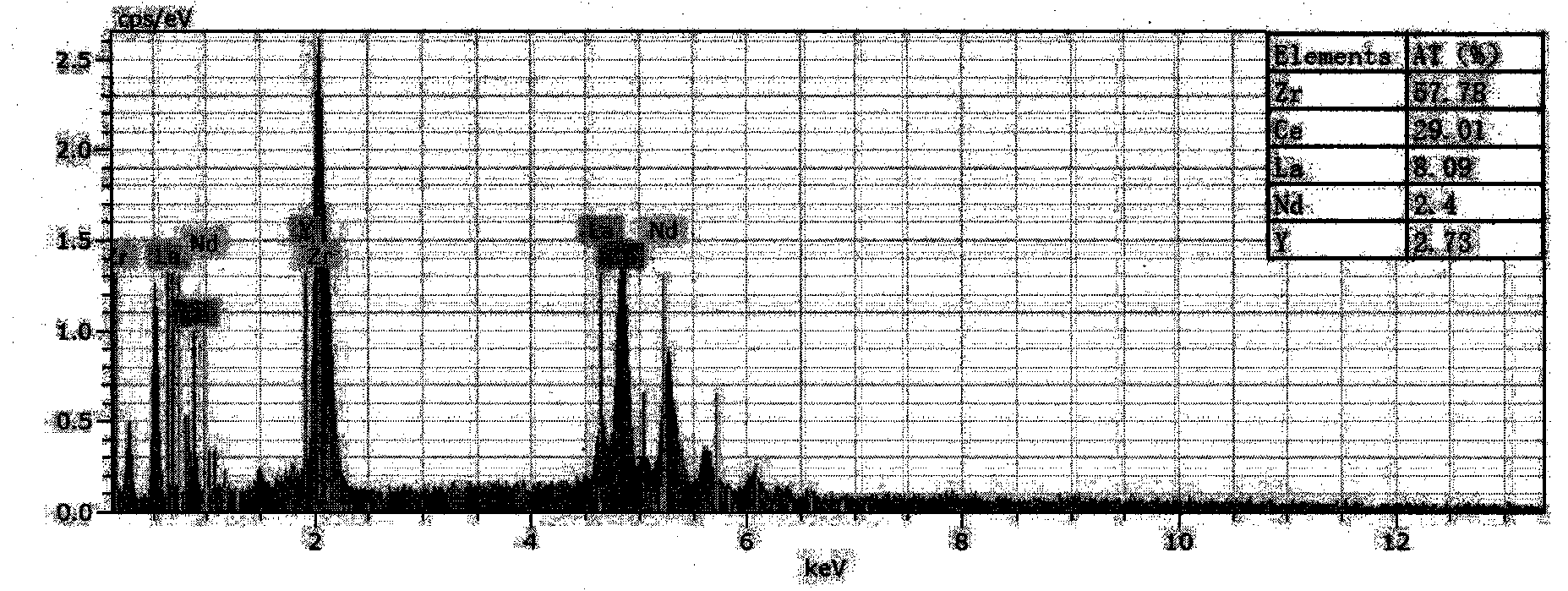

[0032] It is preliminarily estimated to synthesize 20g of multi-component rare earth cerium-zirconium solid solution, and the mass fractions of each rare earth oxide are: ZrO 2 (wt): 49.40%, CeO 2 (wt): 35.8%, La 2 o 3 (wt): 9.76%, Nd 2 o 3 (wt): 3.28%, Y 2 o 3 (wt): 1.76%, according to the proportion, the preparation of Zr(NO 3 ) 4 The concentration of the solution is 1.88mol / L, the preparation of Ce(NO 3 ) 3 The concentration of the solution is 1.10mol / L, and La(NO 3 ) 3 The concentration of the solution is 0.423mol / L, Y(NO 3 ) 3 The molar concentration is 0.54mol / L, the preparation of Nd(NO 3 ) 3 The molar concentration is 0.417mol / L;

[0033] Take Zr(NO 3 ) 4 The volume of solution is V1=42.66ml, Ce(NO 3 ) 3 The volume of solution is V2=37.82mL, La(NO 3 ) 3 The volume of the solution is V3=28.32mL, Y(NO 3 ) 3 The volume of solution is V4=5.78mL, Nd(NO 3 ) 3The volume of solution is V3=9.35mL, these five kinds o...

Embodiment 2

[0038] (1) Solution configuration:

[0039] It is preliminarily estimated to synthesize 20g of multi-component rare earth cerium-zirconium solid solution, and the mass fractions of each rare earth oxide are: ZrO 2 (wt): 49.40%, CeO 2 (wt): 35.8%, La 2 o 3 (wt): 9.76%, Nd 2 o 3 (wt): 3.28%, Y 2 o 3 (wt): 1.76%, according to the proportion, the preparation of Zr(NO 3 ) 4 The concentration of the solution is 1.88mol / L, the preparation of Ce(NO 3 ) 3 The concentration of the solution is 1.10mol / L, and La(NO 3 ) 3 The concentration of the solution is 0.423mol / L, Y(NO 3 ) 3 The molar concentration is 0.54mol / L, the preparation of Nd(NO 3 ) 3 The molar concentration is 0.417mol / L;

[0040] Take Zr(NO 3 ) 4 The volume of solution is V1=42.66ml, Ce(NO 3 ) 3 The volume of solution is V2=37.82mL, La(NO 3 ) 3 The volume of the solution is V3=28.32mL, Y(NO 3 ) 3 The volume of solution is V4=5.78mL, Nd(NO 3 ) 3 The volume of solution is V3=9.35mL, these five kinds ...

Embodiment 3

[0045] (1) Solution configuration:

[0046] It is preliminarily estimated to synthesize 20g of multi-component rare earth cerium-zirconium solid solution, and the mass fractions of each rare earth oxide are: ZrO 2 (wt): 49.40%, CeO 2 (wt): 35.8%, La 2 o 3 (wt): 9.76%, Nd 2 o 3 (wt): 3.28%, Y 2 o 3 (wt): 1.76%, according to the proportion, the preparation of Zr(NO 3 ) 4 The concentration of the solution is 1.88mol / L, the preparation of Ce(NO 3 ) 3 The concentration of the solution is 1.10mol / L, and La(NO 3 ) 3 The concentration of the solution is 0.423mol / L, Y(NO 3 ) 3 The molar concentration is 0.54mol / L, the preparation of Nd(NO 3 ) 3 The molar concentration is 0.417mol / L;

[0047] Take Zr(NO 3 ) 4 The volume of solution is V1=42.66ml, Ce(NO 3 ) 3 The volume of solution is V2=37.82mL, La(NO 3 ) 3 The volume of the solution is V3=28.32mL, Y(NO 3 ) 3 The volume of solution is V4=5.78mL, Nd(NO 3 ) 3 The volume of solution is V3=9.35mL, these five kinds ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com