A kind of azo printing and dyeing wastewater treatment process

A technology for treating process, printing and dyeing wastewater, applied in textile industry wastewater treatment, water/sewage treatment, water treatment parameter control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

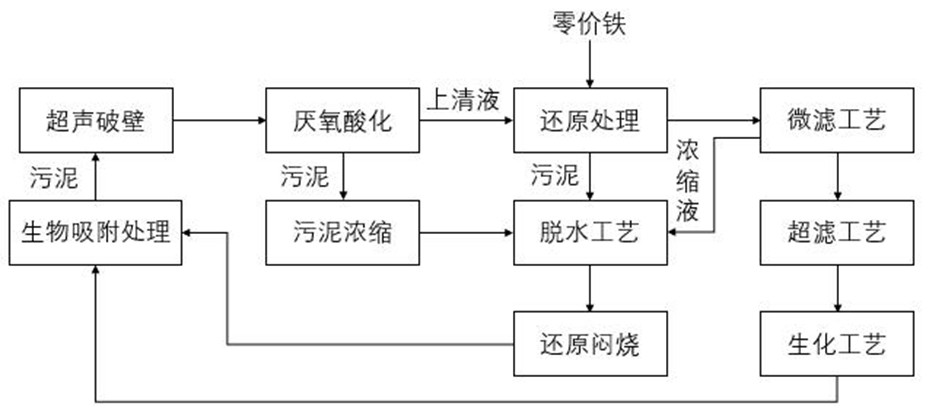

Method used

Image

Examples

Embodiment 1

[0034] Take a certain printing and dyeing wastewater, pH9.3, chroma 970, CODcr1400mg / L, methyl orange 9.16×10 -5 mol / L;

[0035] (1) Biological adsorption treatment: sludge load is 6kgBOD 5 / (kgMLSS·d), sludge concentration 3000mg·L -1 , hydraulic retention time 0.5h;

[0036] (2) Broken wall treatment

[0037] The sludge discharged from the biological adsorption tank is transported to the wall-breaking treatment process, and the sludge is subjected to wall-breaking treatment. 2 10 minutes under the acoustic energy density;

[0038] (3) Anaerobic acidification

[0039] The sludge treated by wall breaking is transported to the anaerobic acidification process for acidification treatment, and after controlling its pH to be maintained between 4.5-5, the reaction conditions are maintained for 1 hour;

[0040] (4) Reduction treatment

[0041] The supernatant of the anaerobic acidification process and the effluent of the biosorption treatment process are transported to the r...

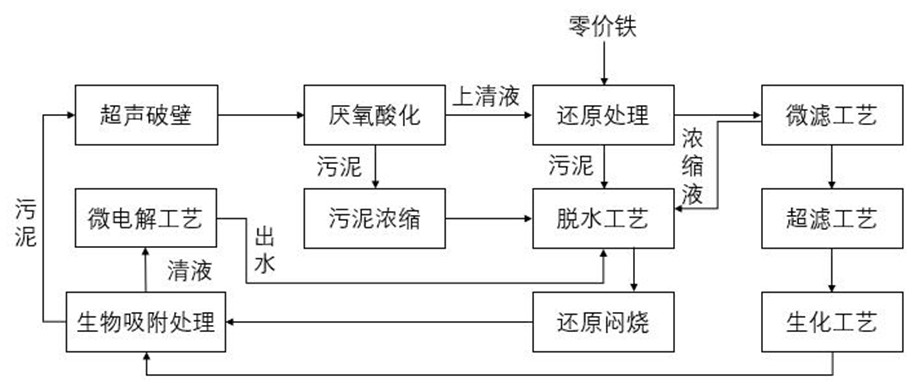

Embodiment 2

[0046] On the basis of Example 1, the effluent from the biosorption treatment was sent to the micro-electrolysis process, and the effluent from the micro-electrolysis process was sent to the dehydration process for dehydration treatment.

[0047] Effluent water quality: pH7.1, chroma 29, CODcr53 mg / L, methyl orange was not detected.

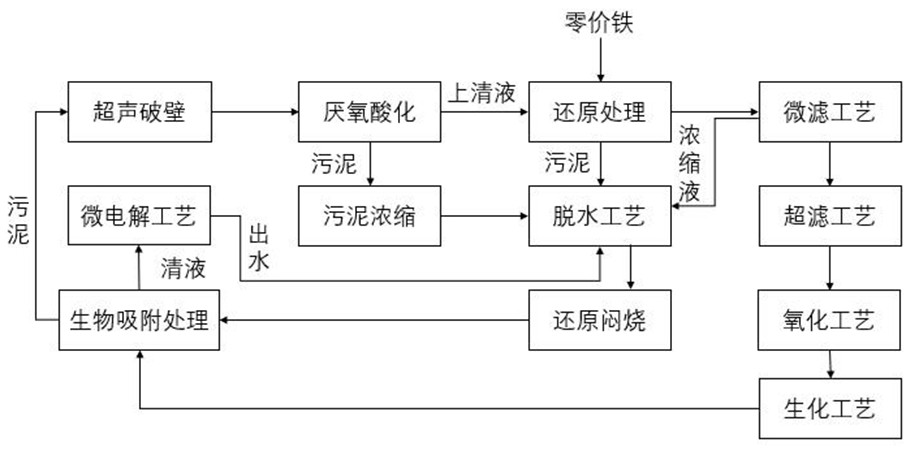

Embodiment 3

[0049] On the basis of Example 2, the concentrated solution of the ultrafiltration process is subjected to oxidation treatment before entering the biochemical process, and the oxidation treatment is a Fenton oxidation process.

[0050] Effluent water quality: pH 7.1, chroma 18, CODcr 35 mg / L, methyl orange was not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com