A preparation method of a segmented National VI natural gas equivalence ratio catalyst

A natural gas and equivalent ratio technology, which is applied in the preparation of segmented National VI natural gas equivalent ratio catalysts and the preparation of natural gas equivalent ratio catalysts, can solve the problem of inability to improve catalyst performance, low utilization rate of precious metals, and complicated coating processes. and other problems, to achieve the effect of reducing poisoning effect, widening air-fuel ratio window, improving catalyst performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation of A catalyst

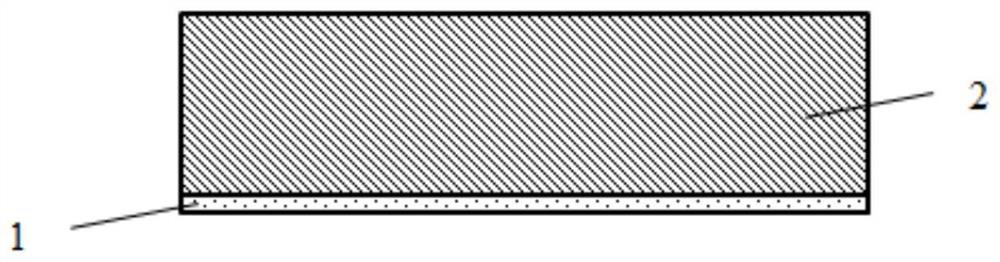

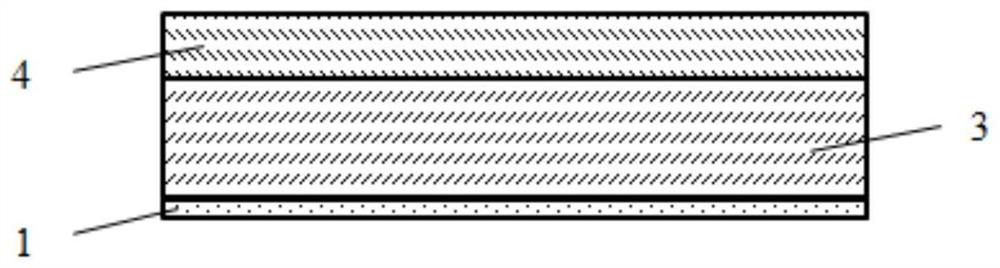

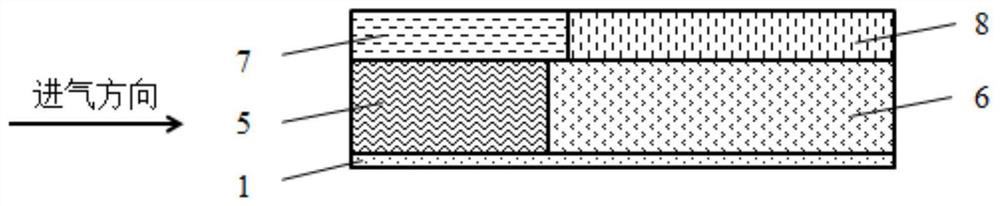

[0031] Using the catalyst slurry, the catalyst carrier 1 is coated in two layers with a special negative pressure coating machine. The air pressure of the special negative pressure coating machine is -20~-80kPa. Each layer of coating is divided into two parts: the front end of the lower coating layer. (air intake end) is the first formula coating 5, the rear end of the lower coating layer (air outlet) is the second formula coating 6, the front end of the upper coating layer is the third formula coating 7, the rear end of the upper coating layer Coat 8 for the fourth recipe. The catalyst carrier 1 can be a cordierite honeycomb ceramic with a mesh number of 400-600 mesh and a wall thickness of 3-6 mils.

[0032] After each coating of the slurry, the catalyst needs to be dried. The drying temperature is 150°C to 180°C and the drying time is 3h to 4h until the catalyst quality is no longer reduced. After drying, the catalyst needs to be calcine...

Embodiment A1

[0039]The coating weight of the first formula coating 5 and the second formula coating 6 is 150g / L, the coating weight of the third formula coating 7 and the fourth formula coating 8 is 65g / L, and the precious metal is 150g / L. ft3 (Pt:Pd:Rh=50:90:10); the precious metal content ratio in the first formula coating 5 and the second formula coating 6 is 2:1, the first formula coating 5 and the second formula coating 6 The length ratio of 1:1; the length ratio of the third formula coating 7 and the fourth formula coating 8 is 1:1.

Embodiment A2

[0041] The coating weight of the first formula coating 5 and the second formula coating 6 is 150g / L, the coating weight of the third formula coating 7 and the fourth formula coating 8 is 65g / L, and the precious metal is 150g / L. ft3 (Pt:Pd:Rh=50:90:10); the precious metal content ratio in the first formula coating 5 and the second formula coating 6 is 6:1, the first formula coating 5 and the second formula coating 6 The length ratio of 1:1.5; the length ratio of the third formula coating 7 and the fourth formula coating 8 is 1:1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com