A method for reducing iron oxide in steel slag and producing high-activity steel slag

A technology of iron oxide and high activity, which is applied in reducing iron oxide in steel slag and producing high-activity steel slag, improving the properties of iron oxide in steel slag, and can solve the problems of unfavorable promotion, increased grinding power consumption, and reduced economic performance. Effects of adding unevenness, improving reduction speed, and solving ease of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

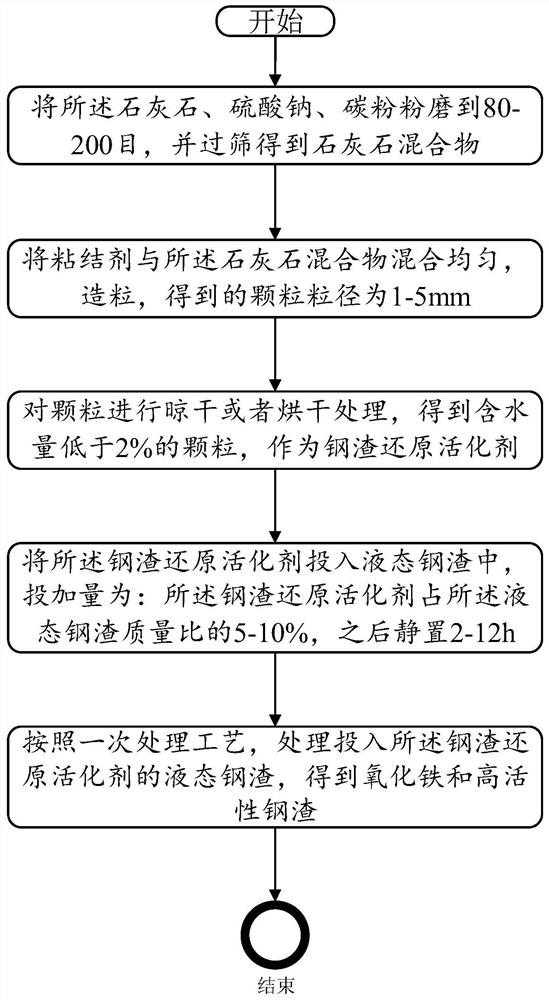

Method used

Image

Examples

Embodiment 1

[0036] Mix and grind 80 kg of limestone powder, 13 kg of baking soda desulfurization ash, 7 kg of coke bin dedusting ash, and 1 kg of sodium carboxymethyl cellulose to 150 mesh, add 6 kg of water and stir for 10 minutes, use Press it into granules with a size of 5mm by a tablet press, and dry until the water content is 2% for later use.

[0037] Add about 100 kg of the above reduction activator into an empty steel slag tank, pour about 2 tons of high-temperature liquid steel slag, and use the impact force to achieve the purpose of stirring. After leaving it for 3 hours, the steel slag is then heated and simmered, that is, water is drawn to cool and slag is simmered. High activity steel slag is obtained, and more metallic iron is magnetically separated at the same time.

Embodiment 2

[0039] Mix and grind 63 kg of limestone, 6 kg of baking soda desulfurization ash, 30 kg of blast furnace dust, and 1 kg of sodium carboxymethyl cellulose to 120 mesh, add 6 kg of water and stir for 10 minutes, and use a ball forming disc to make 5mm-sized particles , dried to a moisture content of 2% for later use.

[0040] Add about 50 kg of the above-mentioned reduction activator to the empty steel slag tank, pour about 1 ton of high-temperature liquid steel slag, add about 50 kg of the above-mentioned reduction activator, and then add about 0.5 tons of liquid steel slag, and use the impact force to achieve the purpose of stirring. After leaving it for 5 hours, heat the steel slag and other operations according to the normal procedure. High activity steel slag is obtained, and more metallic iron is magnetically separated at the same time.

[0041] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com