Method for preparing high titanium slag through low temperature reduction and separation of titanium-containing iron ore

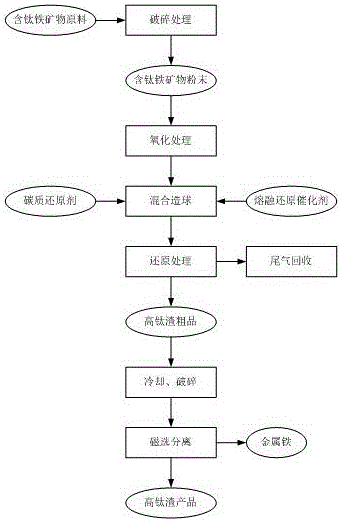

A high-titanium slag and ferrotitanium technology, applied in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of low production efficiency, complex process, high cost, etc., and achieve fast reduction speed, complex solution process, and recovery rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] This embodiment adopts TiO 2 Titanium concentrate with a mass percentage of 35% is used as the titanium-iron mineral raw material, graphite is used as the carbonaceous reducing agent, Na 2 SO 4 As a smelting reduction catalyst, high titanium slag is prepared by reducing according to the method of the present invention, and the specific steps are as follows:

[0050] 1) The ilmenite concentrate is crushed to obtain ilmenite-containing mineral powder for later use, and the particle size of the obtained ilmenite mineral powder is less than 100 mesh, accounting for 83% of the total weight.

[0051] 2) Put the titanium-iron mineral powder into a muffle furnace and oxidize it at 600° C. for 80 minutes to obtain the titanium-iron mineral powder oxide.

[0052] 3) Add graphite and Na to titanium-iron mineral powder oxide 2 SO 4 , wherein, after calculation, the ratio of the molar content of carbon in the added graphite to the molar content of oxygen in the iron oxide contai...

example 2

[0057] This embodiment adopts TiO 2 Ilmenite with a mass percentage content of 32% is used as the ilmenite-containing mineral raw material, coal dust is used as the carbonaceous reducing agent, and FeS is used as the smelting reduction catalyst. The high-titanium slag is prepared by reduction according to the method of the present invention. The specific steps are as follows:

[0058] 1) Crushing the ilmenite ore to obtain ilmenite-containing mineral powder for later use. Particles with a particle size of less than 100 mesh in the obtained ilmenite mineral powder account for 85% of the total weight.

[0059] 2) Put the titanium-iron mineral powder into a muffle furnace and oxidize it at 1100° C. for 20 minutes to obtain the titanium-iron mineral powder oxide.

[0060] 3) Add coal powder and FeS to the titanium-iron mineral powder oxide, wherein, after calculation, the molar content of carbon in the added coal powder is added to the oxygen in the iron oxide contained in the tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com