Patents

Literature

112results about How to "Controllable pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength lamellar Al-based metal ceramic composite material and preparation method thereof

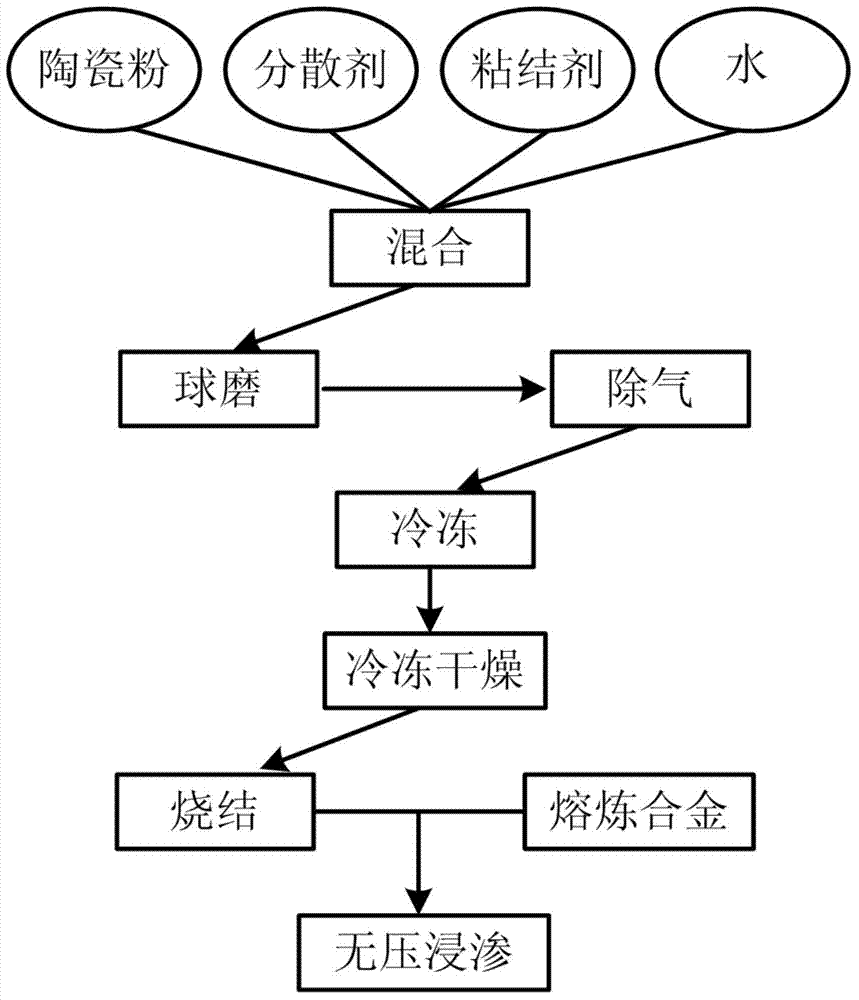

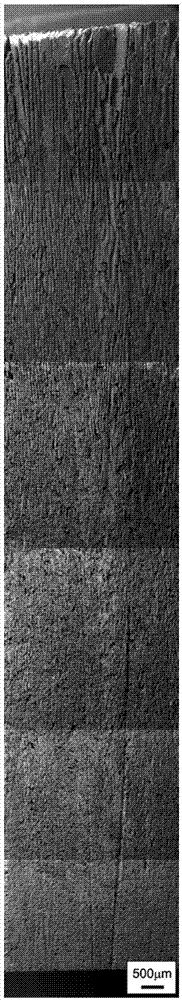

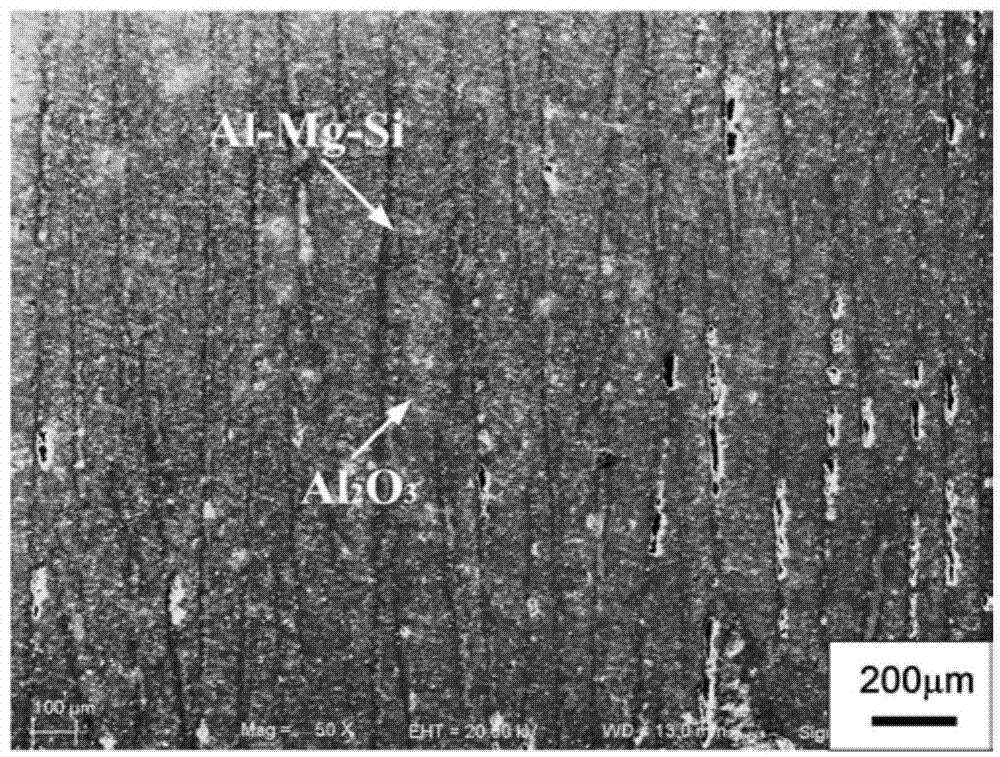

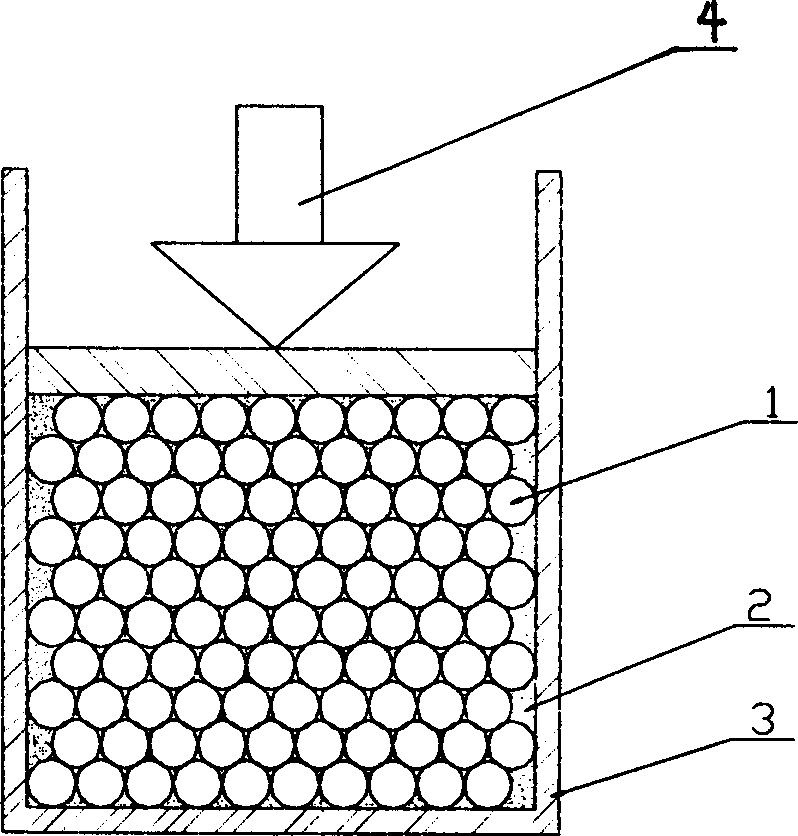

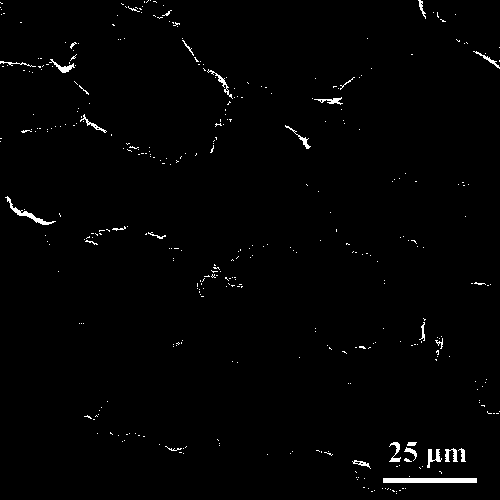

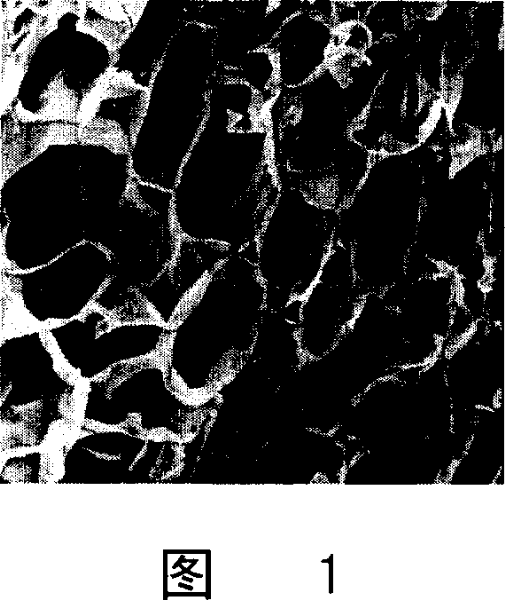

InactiveCN103895285ANot easy to sinterEasy to manufactureCeramicwareMetal layered productsWater basedMass ratio

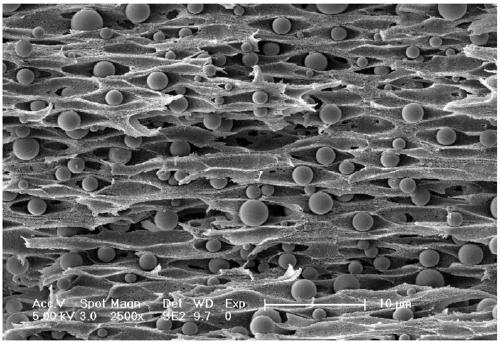

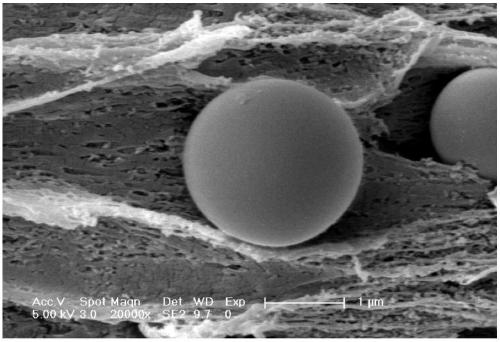

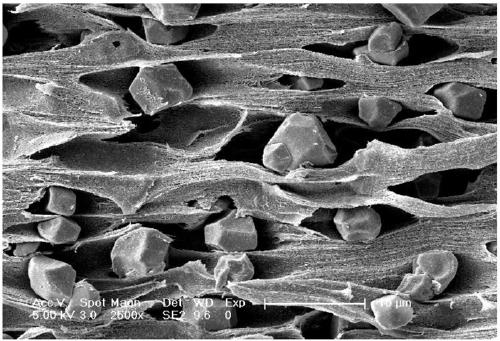

The invention discloses a high-strength lamellar Al-based metal ceramic composite material and a preparation method thereof, aiming at solving the problems of high preparation cost, complex operation, single type of reinforcement ceramic and low strength. The high-strength lamellar Al-based metal ceramic composite material, i.e., high-strength lamellar structure Al-Si-Mg / (Al2O3, SiC, TiC) composite material comprises ceramic powder and Al-Si-Mg alloy. The volume fraction of ceramic powder is 20%-40vol%; the volume fraction of Al-Si-Mg alloy is 80%-60vol%; the mass ratio of aluminum in the Al-Si-Mg alloy is 75-84wt%; the mass ratio of silicon is 10-15wt%; the mass ratio of magnesium is 6-10wt%. The preparation method of the high-strength lamellar Al-based metal ceramic composite material comprises the following steps: preparation of water-based ceramic slurry; directional solidification; freezing and drying; sintering of blanks; smelting of alloy; and non-pressure infiltration.

Owner:JILIN UNIV

Process for preparing porous ceramic by water-based gel injection moulding method

InactiveCN1456535AHigh apparent porosityControllable pore structureCeramicwareWater basedPolymer science

An injection moulding process for preparing porous ceramics from water-base gel includes such steps as preparing the stable suspension from organic monomer, cross-linking agent, trigger, disperser and ceramic powder, proportionally adding surface treated pore-forming agent while applying pressure, proportionally adding catalyst, slowly heating to 60-80 deg.C holding the temp for at least 30 min for solidifying, demoulding, drying and sintering.

Owner:WUHAN UNIV OF TECH

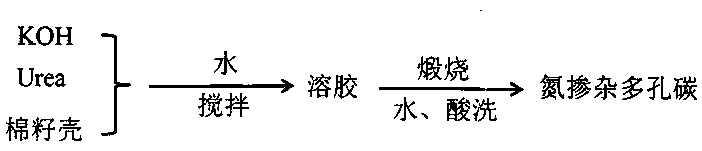

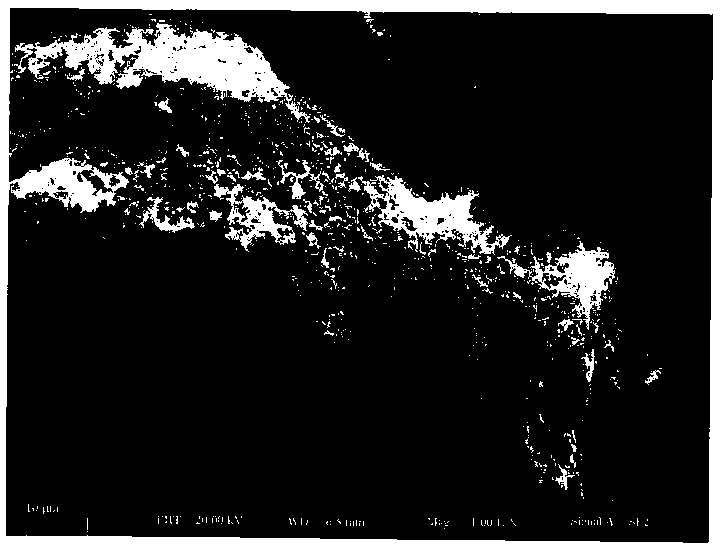

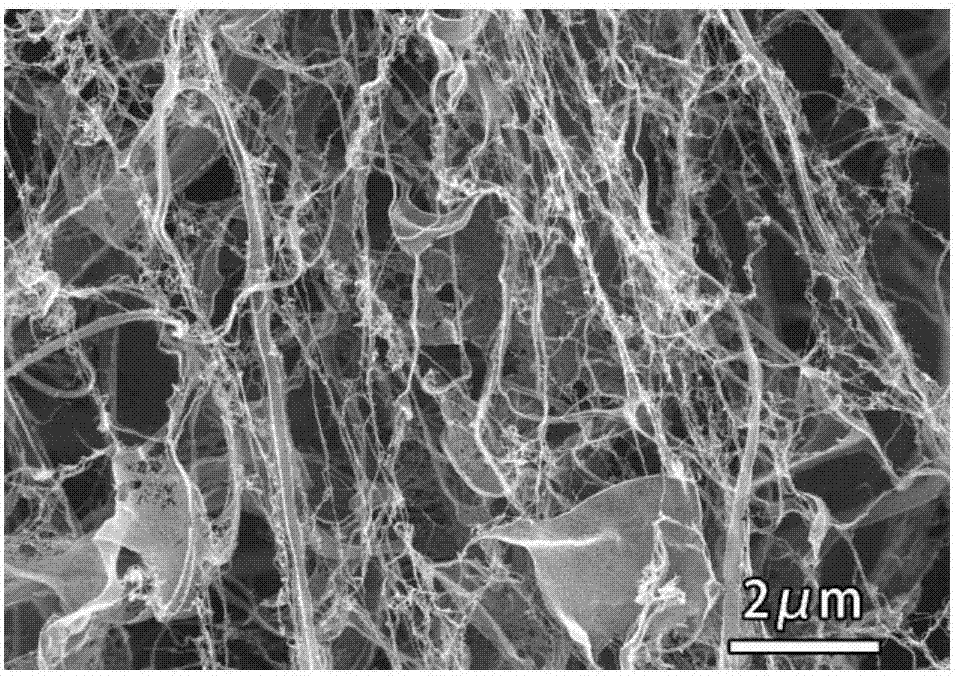

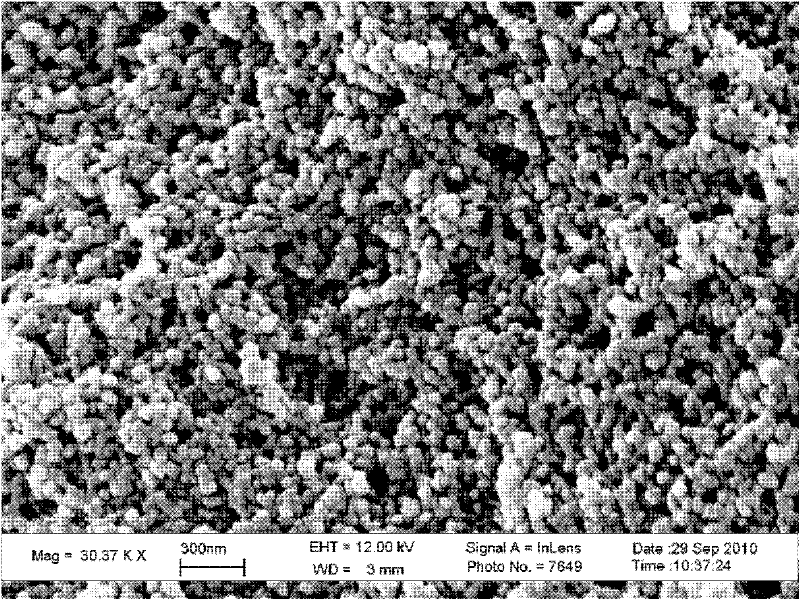

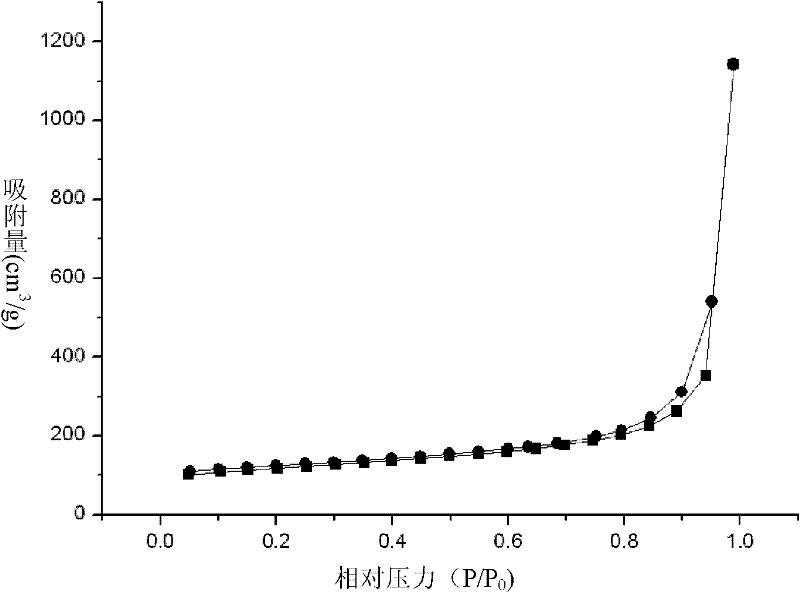

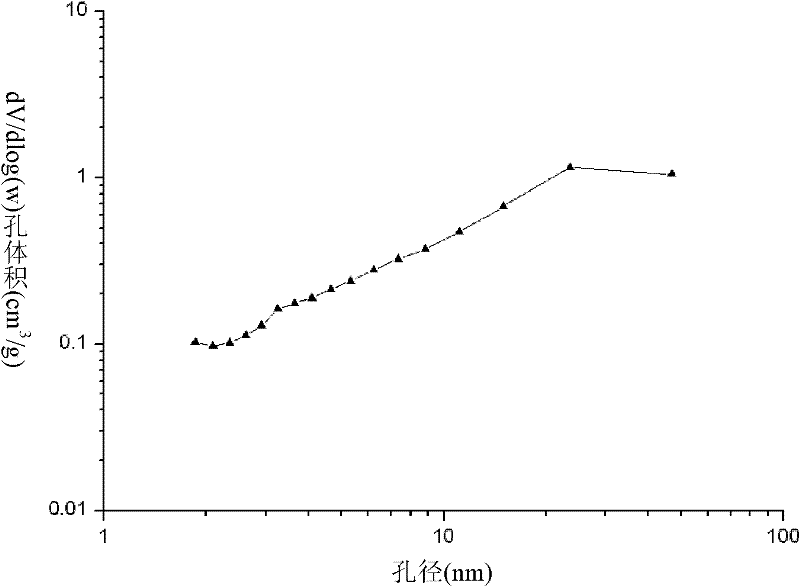

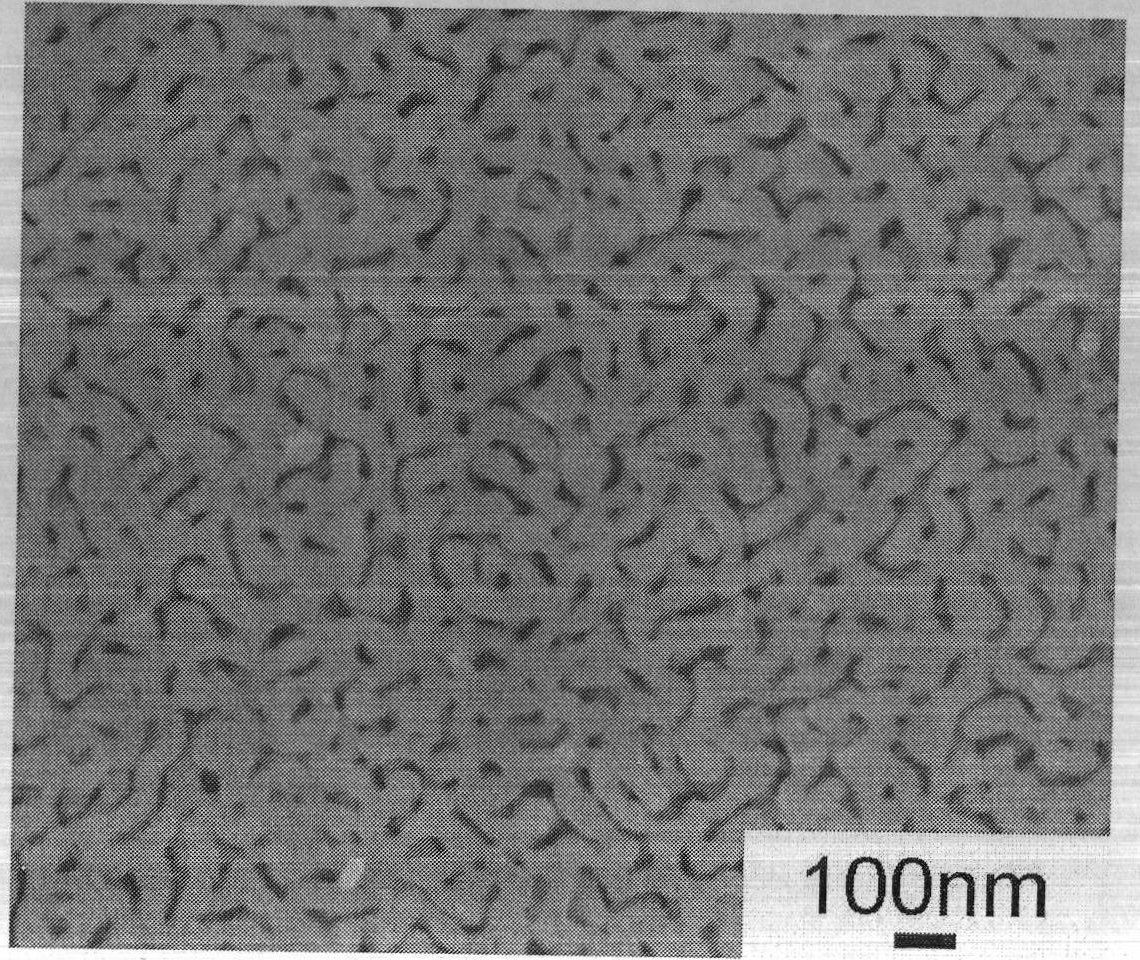

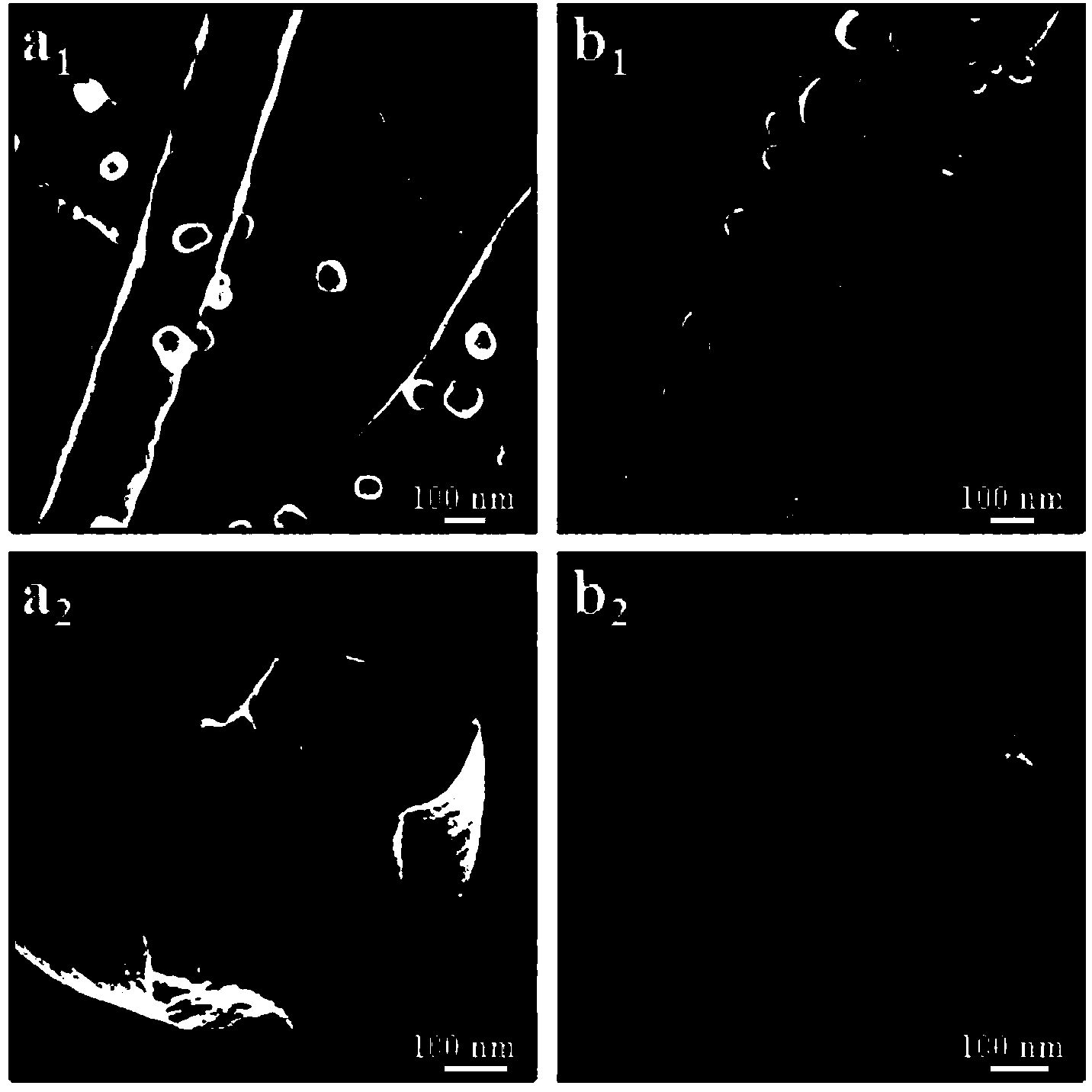

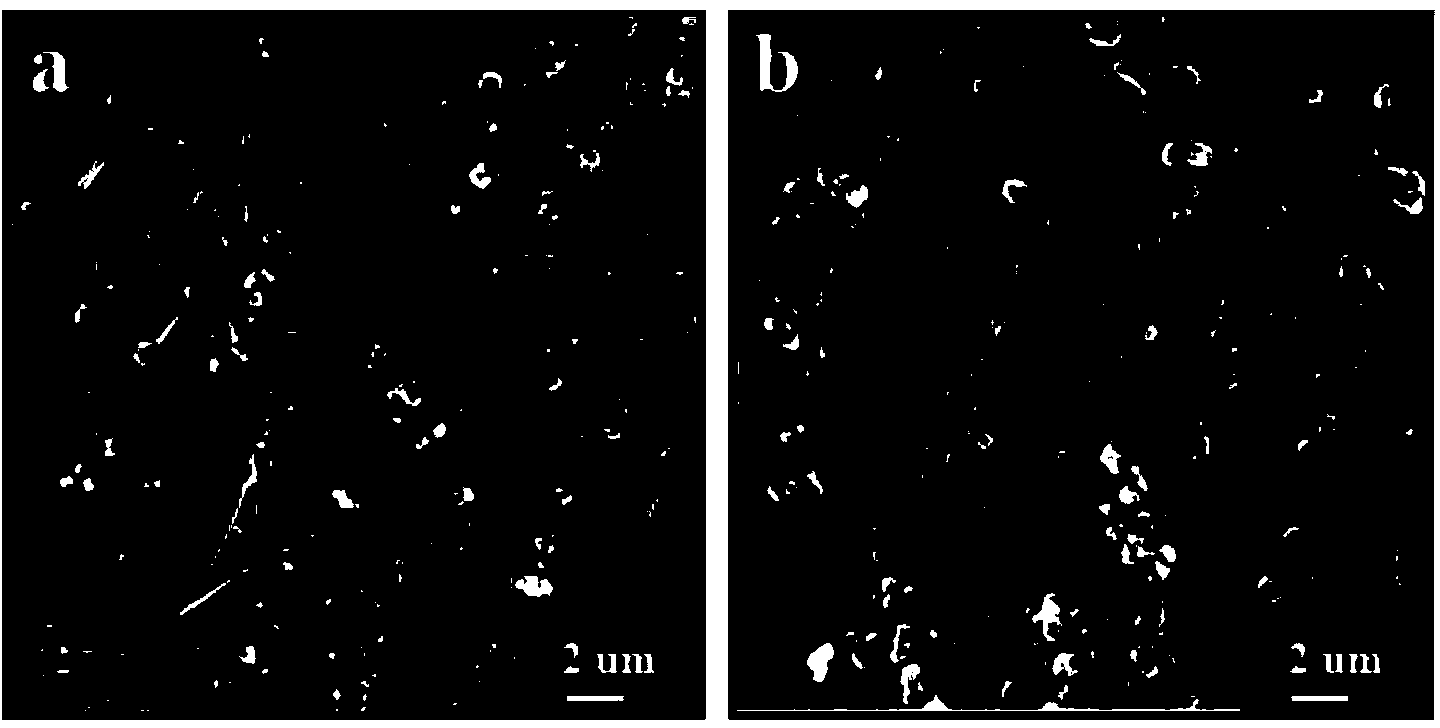

Method for preparing nitrogen-doped porous carbon by taking cottonseed hull as raw material and application

InactiveCN108455597AWide range of resource sourcesLow costCarbon preparation/purificationCapacitancePorous carbon

The invention discloses a method for preparing nitrogen-doped porous carbon by taking cottonseed hull as a raw material and application. The method is characterized in that the nitrogen-doped porous carbon material is prepared by taking the cottonseed hull as a raw material and urea as a nitrogen source, stirring and uniformly mixing the substances with a sodium hydroxide solution, and then carrying out high-temperature carbonization and activation. An electron microscope photo shows that the prepared nitrogen-doped porous carbon material is of a three-dimensional inner cross-linking network structure. XPS and elemental analysis show that the nitrogen element is successively and uniformly doped in a carbon matrix; the XPS analysis shows that the nitrogen content is 1.84 to 7.35%; the elemental analysis shows that the nitrogen content is 2.07 to 6.52 % and the specific surface area is 1010 to 2500m<2> / g. The super-capacitor experiment shows that the prepared nitrogen-doped porous carbonmaterial has good electrochemical properties and the specific capacitance can reach 320 to 340F / g (current density is 0.5A / g). The method has the advantages of simplicity in preparation, wide range of renewable resources as raw materials, low price, low cost, easiness in large-scale industrialization application and capability of being applied to the field of energy storage.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

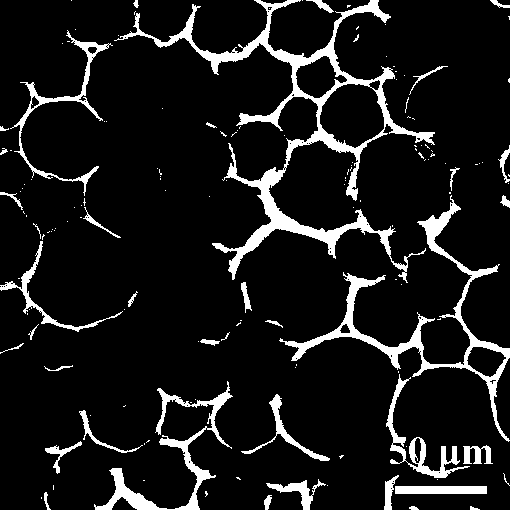

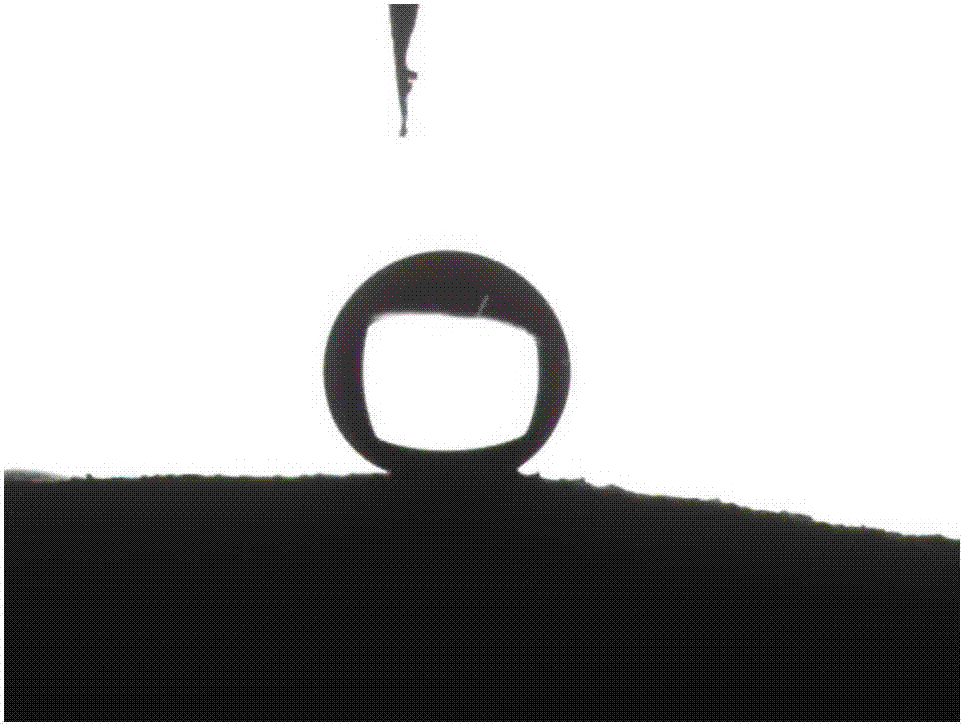

Preparation method of porous graphene-polymer composite material

InactiveCN103408786AControllable pore structureLarge specific surface areaPorous grapheneFoaming agent

The invention belongs to the technical field of materials and particularly relates to a preparation method of a porous graphene-polymer composite material. According to the preparation method, a surface active agent is adopted to modify graphene oxide (GO); the modified graphene oxide is taken as a stabilizer of a Pickering emulsion; then, monomer, a cross-linking agent, an initiator and a pore-foaming agent are added into the modified graphene oxide; continuous phases are polymerized to prepare the graphene oxide / graphene-polymer composite material with a porous structure; polymer matrixes are removed through calcination to obtain porous graphene. The preparation method has the advantages that the process is simple, the cost is lower, and the porous graphene-polymer composite material prepared according to the preparation method is controllable in the hole structure (each hole diameter is 2-120 mum) and high in specific surface area.

Owner:FUDAN UNIV

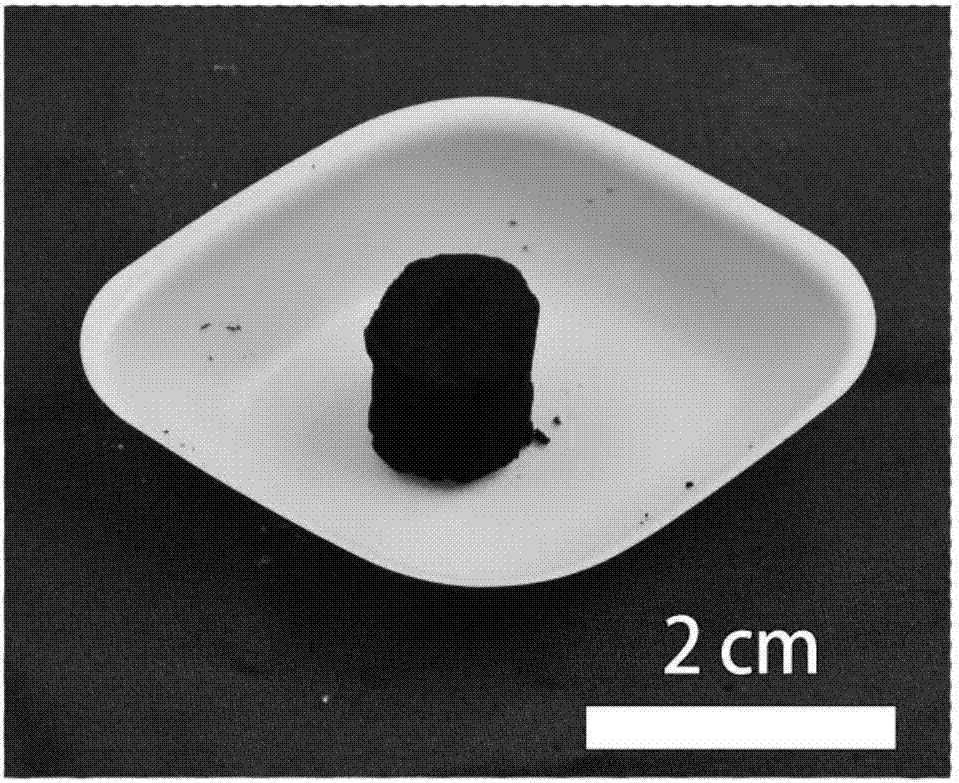

Three-dimensionalgraphene composite aerogel and preparation method thereof

ActiveCN106890605ASimple methodGood lookingOther chemical processesWater contaminantsCvd grapheneGraphite oxide

The invention discloses three-dimensionalgraphene composite aerogel. High-molecular material nano fiber with a biomass polysaccharide structure is compounded with oxidized graphene through a surface electrostatic-force effect, and then the composite aerogelis prepared by utilizing hydrazine hydrate reduction and a method for high-temperature pyrolysis in an inert atmosphere. The invention further discloses a preparation method of the three-dimensionalgraphene composite aerogel. The method for preparing the three-dimensionalgraphene composite aerogel is simple, easy to operate, large in specific surface area, uniform in pore size distribution and good in electrical conductivity, and the chemical reactivity is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Degradable biphase ceramics bone frame with high-strength and phosphate cement containing strontium and the preparing method

InactiveCN101041087AMeet the requirements for growthImprove pore structureBone implantSlurryCompressive strength

The invention discloses a high-strength degradable strontium phosphate dual-phase ceramic bone skeleton and relative preparation, wherein the initial material is calciprivia fermorite bone cement, whose solid phase powder is the mixture of Ca4(PO4)2O, SrHPO4, CaHPO4, and the liquid phase is 0.1mol / L-1mol / L H3PO4 water solution. The invention uses skeleton structure to controllably quickly print and shape RP optical sensitive resin as concave mold, to irrigate slurry, solidify, and thermally remove mold and following sinter to obtain the strontium phosphate dual-phase ceramic bone support with adjustable phases. The total porous rate of skeleton is 42.5-75%, the size of macro hole is 300mum-600mum, the volume of macro hole is 0-50%, the size of micro hole is 2-10mum, and the compression strength is 3.15MPa-21.53MPa, with wide application.

Owner:XI AN JIAOTONG UNIV

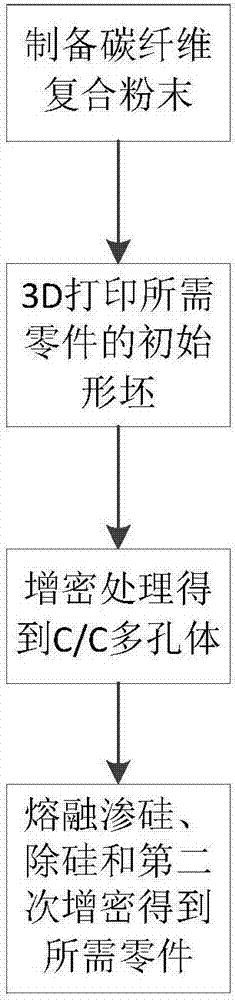

Method for preparing C/C-SiC composite part and product prepared through method

ActiveCN106927846AEvenly distributedAvoid damageAdditive manufacturing apparatusFiberSolvent evaporation

The invention belongs to the field of composites, and discloses a method for preparing a C / C-SiC composite part and a product prepared through the method. The method comprises the following steps that firstly, carbon fiber / phenolic resin composite powder is prepared by using a solvent evaporation method; secondly, according to a three-dimensional model of the part, the carbon fiber composite powder is molded into an initial molded blank by means of the 3D printing technology; thirdly, the initial molded blank is subjected primary densification and a C / C porous body is obtained; fourthly, the C / C porous body is subjected to a molten silicon infiltration reaction, high-temperature desilication and secondary densificaiton, and the final C / C-SiC part is obtained. By means of the method, the C / C-SiC composite part with a complex structure can be shaped in a near-net mode, the method is short in production period and low in cost, and the C / C-SiC composite part obtained through the method is low in residual silicon content and has excellent performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of blocky silicon-carbon composite aerogel

ActiveCN102343285ARich network structureStable network structureCatalyst carriersCarbon compositesSupercritical drying

The invention provides a preparation method of blocky silicon-carbon composite aerogel. The preparation method comprises the steps of: by taking resorcinol, formaldehyde and tetraethyl orthosilicate as reactants, respectively preparing silica sol and organic sol, mixing the silica sol and the organic sol, then reacting at constant temperature to obtain wet gel, performing low-temperature carbon dioxide supercritical drying and high-heat treatment processes on the wet gel to obtain the blocky silicon-carbon composite aerogel. The blocky silicon-carbon composite aerogel prepared by adopting thepreparation method provided by the invention has the characteristics of high strength, large specific surface area, low density and thermostability, can be used at the temperature as high as more than 1000 DEG C, and is beneficial to overcoming of the defects of low strength, difficult in forming and poor thermostability of the aerogel.

Owner:NANJING UNIV OF TECH

Catalyst for synthesizing dimethyl ether one-step with synthesis gas as well as its preparing method

InactiveCN101157038ASimple processGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsEther preparationMolecular sieveSyngas

The invention relates to catalyst synthesizing dimethyl ether with synthetic gas in one step and the preparation method thereof, and belongs to the catalyst preparation technical field. The invention is characterized in that a methanol synthetic component and a methanol dehydration component are prepared in a one pot way under the same condition, active components of Cu and Zn are added in the liquid phase condition, and Si-Al oxide, molecular sieve, and a silica resource, an aluminum resource, and template agent required by organic-inorganic hybrids of Si or Si-Al are formed under the liquid phase completely, and thus slurried catalyst with the general formula which is CuZnMSiAl (M is auxiliary agent) is prepared. The environmental change and the phase change are not required during the preparing process, the operation is simple, the repeatability is good, the pore structure can be controlled, the activity is high, and the preparation method is especially suitable for preparing the catalyst used by a slurry bed reactor.

Owner:TAIYUAN UNIV OF TECH

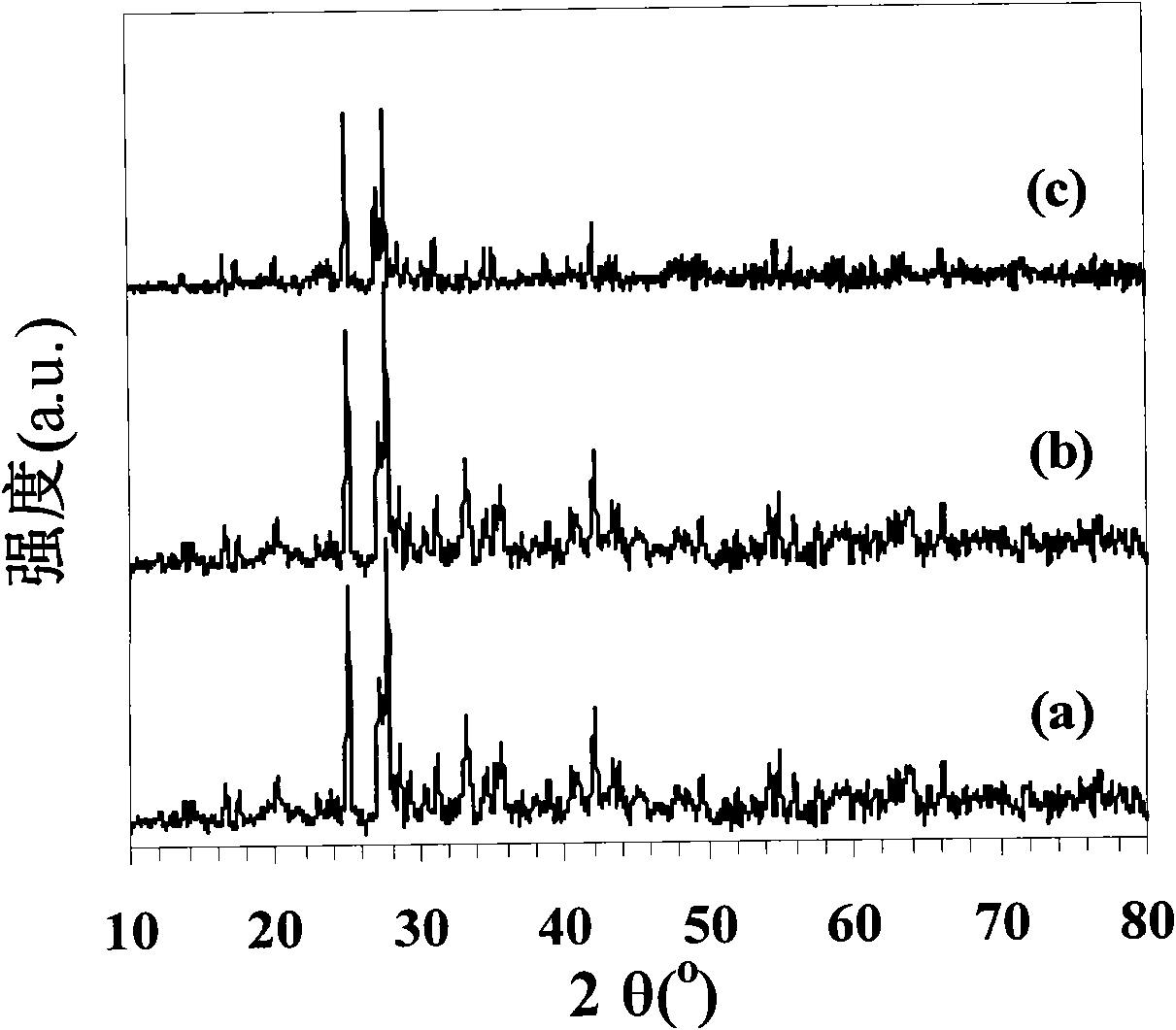

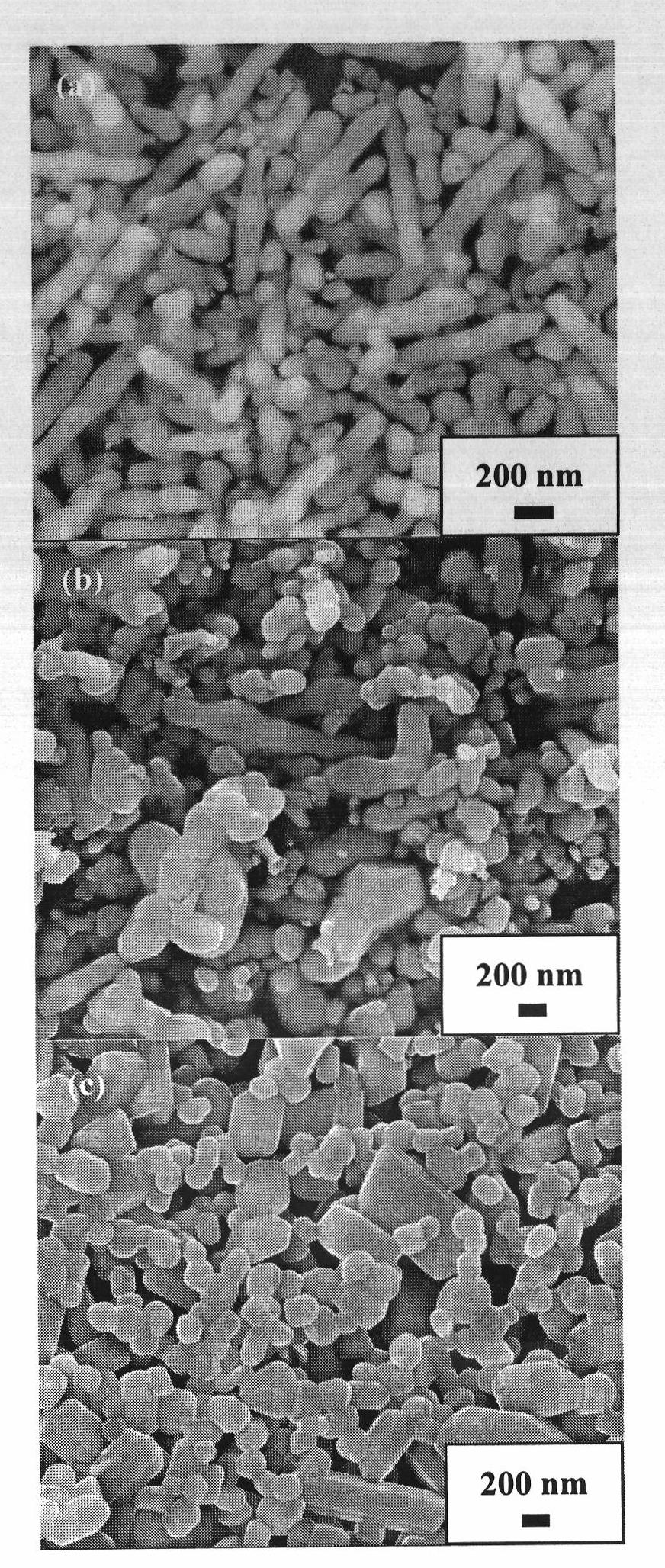

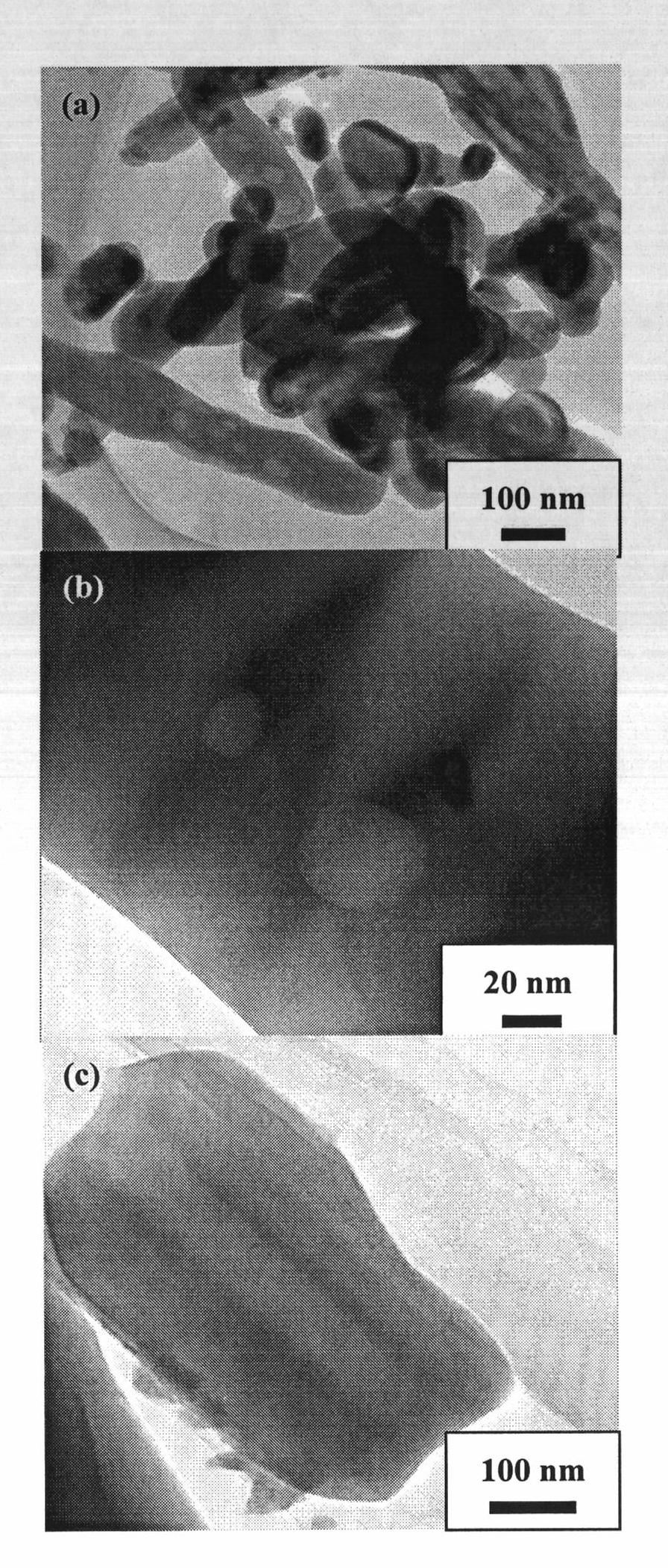

Hydrothermal method for preparing triclinic-phase FeVO4 micro particles

The invention discloses a hydrothermal method for preparing triclinic-phase FeVO4 micro particles. The method comprises the following steps of: mixing ferric nitrate nonahydrate, ammonium metavanadate and nitric acid solution in a molar ratio of 1:1:10, adjusting the pH value to 4 or 7 by using 14 weight percent of aqueous ammonia, transferring the solution to a stainless steel self-pressure kettle of which a lining is made of polytetrafluoroethylene, treating the solution for 2 or 6 hours at the constant temperature of 180 DEG C, filtering the solution, washing and drying the filtrate, and heating the filtrate to 600 DEG C from room temperature at the speed of 1 DEG C per minute under air atmosphere and keeping the temperature for 6 hours, wherein when the pH is 4 or 7 and the hydrothermal treatment is performed for 6 hours, the obtained product is a triclinic-phase FeVO4 mesoporous micro bar, and when the pH is 4 and the hydrothermal treatment is performed for 2 hours, the obtained product is a triclinic-phase FeVO4 imperforate micro block. The method is convenient to operate, the raw materials are cheap, and the topography, crystalline phase structure and specific surface area of the target product particles are controllable.

Owner:BEIJING UNIV OF TECH

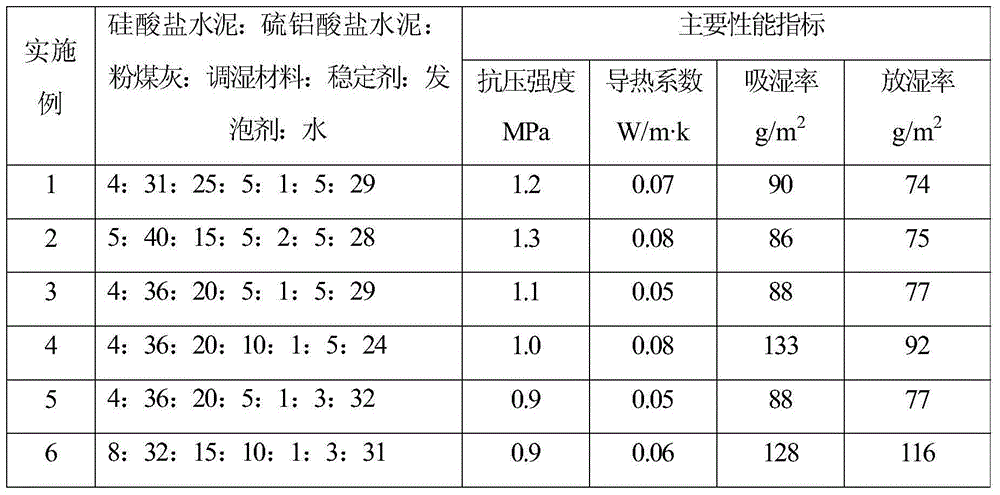

Thermal-insulation and humidity-regulating foam concrete material and preparation method thereof

ActiveCN104829199AGood humidity control and heat preservation performanceSimple preparation processSolid waste managementThermal insulationStabilizing Agents

The invention relates to a thermal-insulation and humidity-regulating foam concrete material which is characterized by being composed of following components, by weight: 35-45 parts of cement, 15-25 parts of fly ash, 5-10 parts of a humidity-regulating material, 1-2 parts of a stabilizing agent, 3-5 parts of a foaming agent and 24-32 parts of water. The thermal-insulation and humidity-regulating foam concrete material satisfies design requirements of technical indexes and has an excellent thermal-insulation and humidity-regulating performance.

Owner:HUBEI UNIV OF TECH

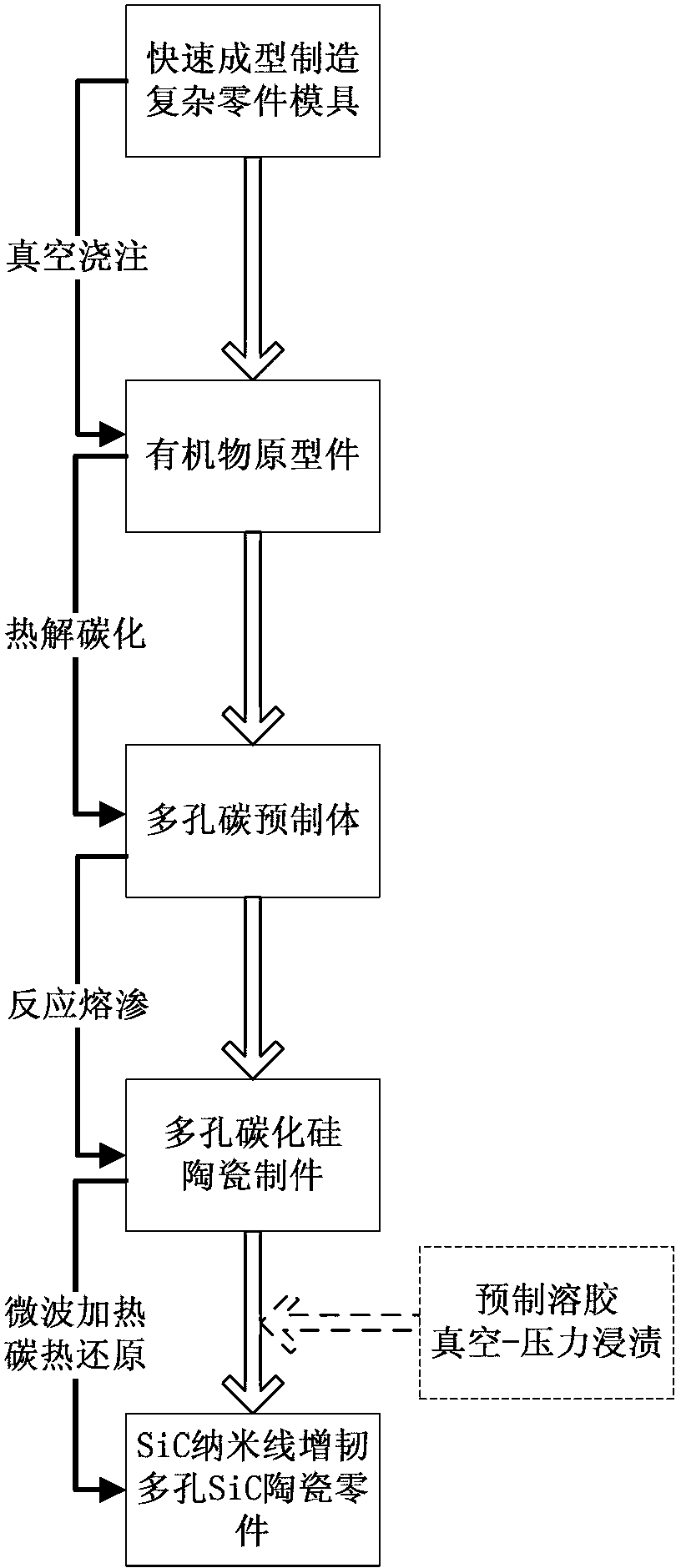

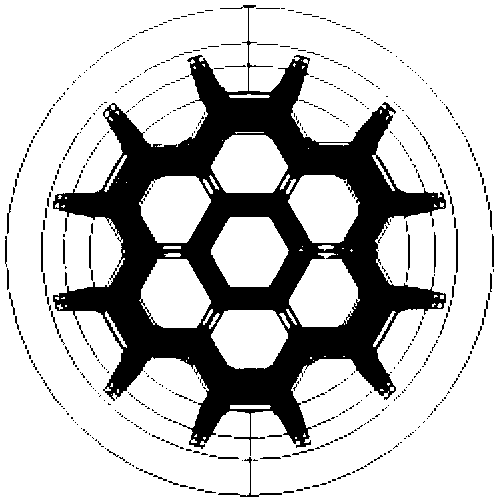

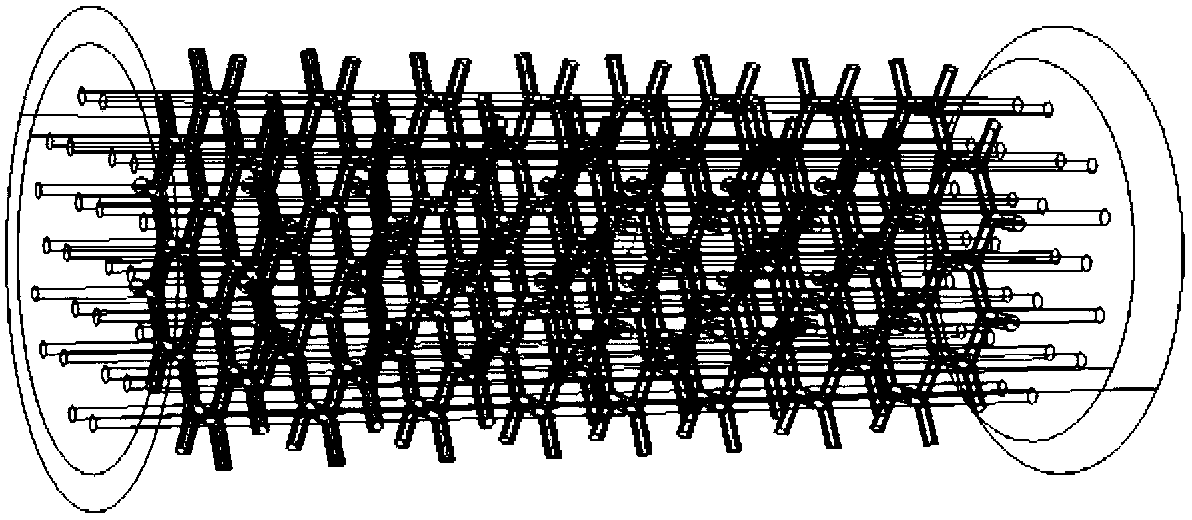

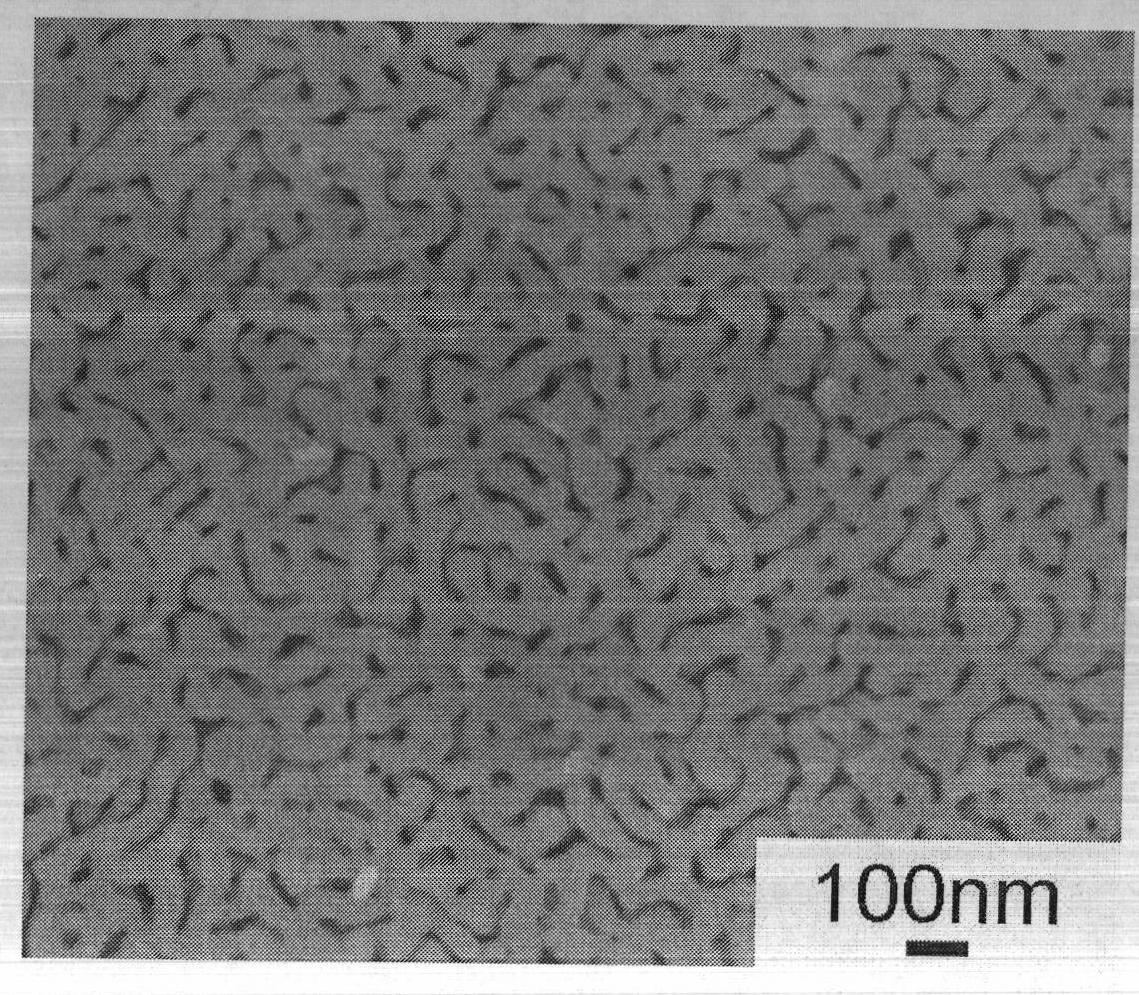

Making method of high-toughness porous SiC ceramic complex part

InactiveCN103130525AImprove part performanceExcellent flexural strengthCeramicwareTemperature resistanceOxidation resistant

The invention discloses a making method of a high-toughness porous SiC ceramic complex part. A light-cured rapid forming technology is adopted to make a resin die of the complex part, a high-residual carbon resin slurry is casted, cured and pyrolyzed to make a porous carbon perform, silicon-carbon reaction sintering and high-temperature vacuum silicon discharge technologies are adopted to make a porous SiC complex part, and matrix aperture internal SiC nanowires are made through a microwave heating process to realize the toughening purpose. The method has the advantages of free forming of the complex structure, uniform and controllable aperture, high specific surface area, high fracture toughness, high-temperature resistance, anti-oxidation and the like.

Owner:XI AN JIAOTONG UNIV

Method for preparing three-dimensional network nanoporous copper

InactiveCN102628112AReduce manufacturing costShort reaction timeNanotechnologyMolten stateStrong acids

A method for preparing three-dimensional network nanoporous copper comprises the following steps of: (1) mixing a Cu powder and a Mn powder with Cu atomic percent being 20-60% and the other being Mn, and carrying out arc melting to form mother alloy; (2) heating the obtained alloy in a bottom open-ended quartz test tube to a molten state, rapidly blowing out the molten alloy by the use of an inert gas, and rapidly solidifying the molten liquid alloy on a copper roller which is rotating at high speed so as to obtain an alloy ribbon; (3) placing the obtained alloy ribbon into an acid or strong acid and weak base salt solution for dealloying, namely placing the alloy ribbon into a hydrochloric acid solution of 0.01-10mol / L to react at 0-99 DEG C for 0.1-100 hours; and (4) repeatedly flushing the three-dimensional network nanoporous copper ribbon obtained after completely dealloying by the use of distilled water until pH value is neutral, carrying out vacuum drying and preserving.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

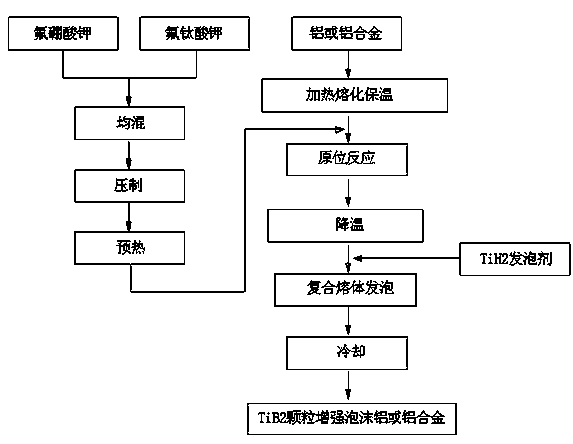

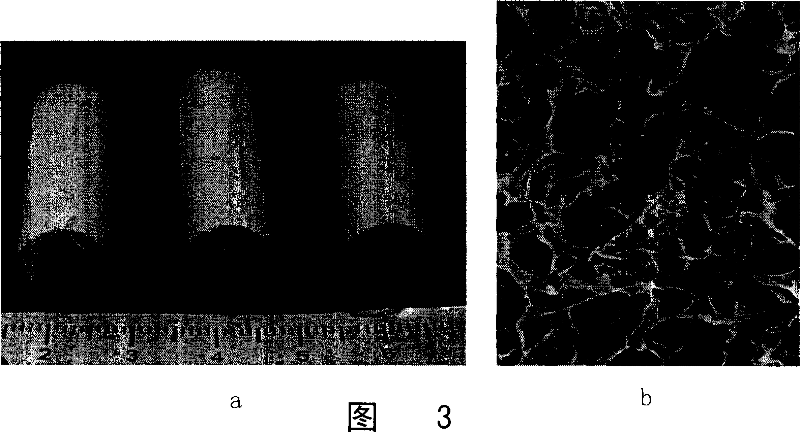

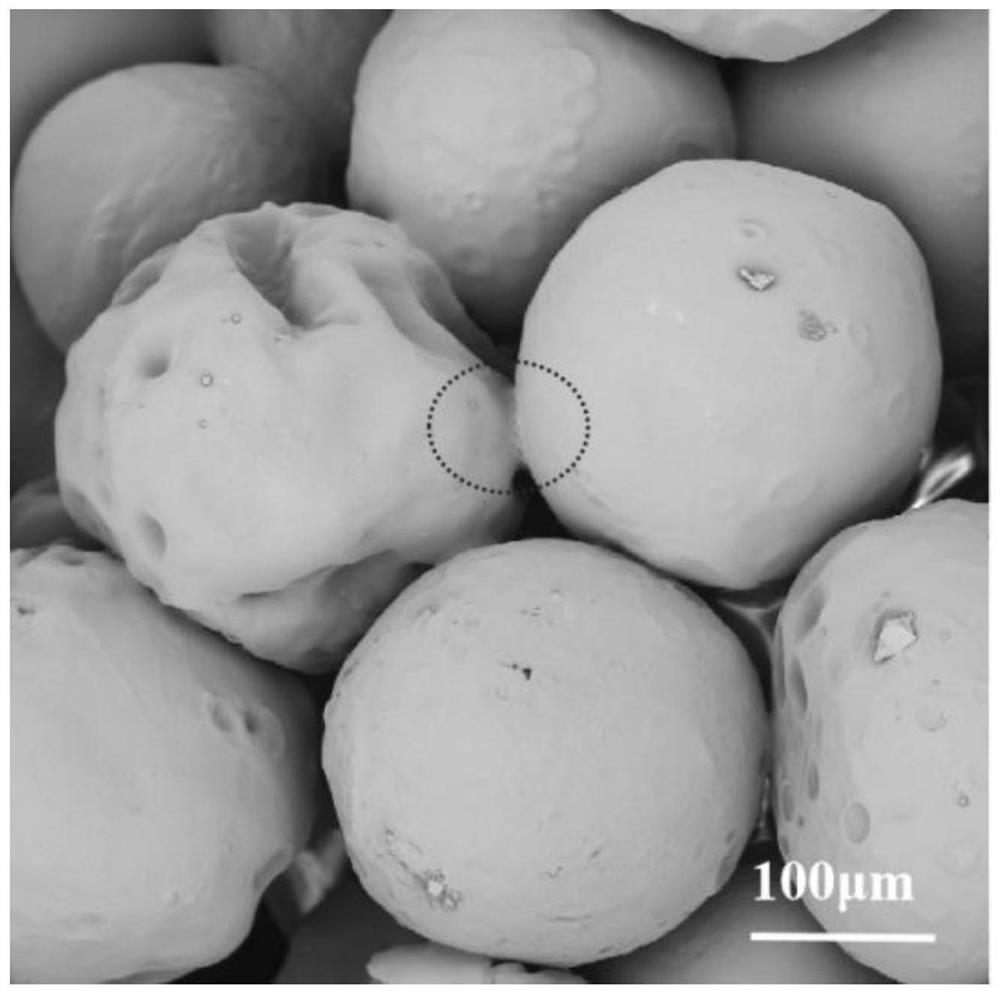

Preparing method of TiB2 particle reinforced foamed aluminium/aluminium alloy

The invention relates to a preparing method of TiB2 particle reinforced foamed aluminium / aluminium alloy, and belongs to the technical field of porous materials. The method includes: melting aluminium / aluminium alloy by heating, adding potassium fluoborate and potassium fluotitanate, performing an in-situ reaction to generate TiB2 particles, adding TiH2, foaming, allowing the melt and foam to be cooled and cured to obtain the TiB2 particle reinforced foamed aluminium / aluminium alloy. The TiB2 particles have double functions, namely a function of tackifying an aluminium / aluminium alloy melt and a function of particle reinforcing. The method has characteristics of high strength of the foamed aluminium / aluminium alloy, controllable pore structures, and simple preparation process, and can achieve industrial production.

Owner:KUNMING UNIV OF SCI & TECH

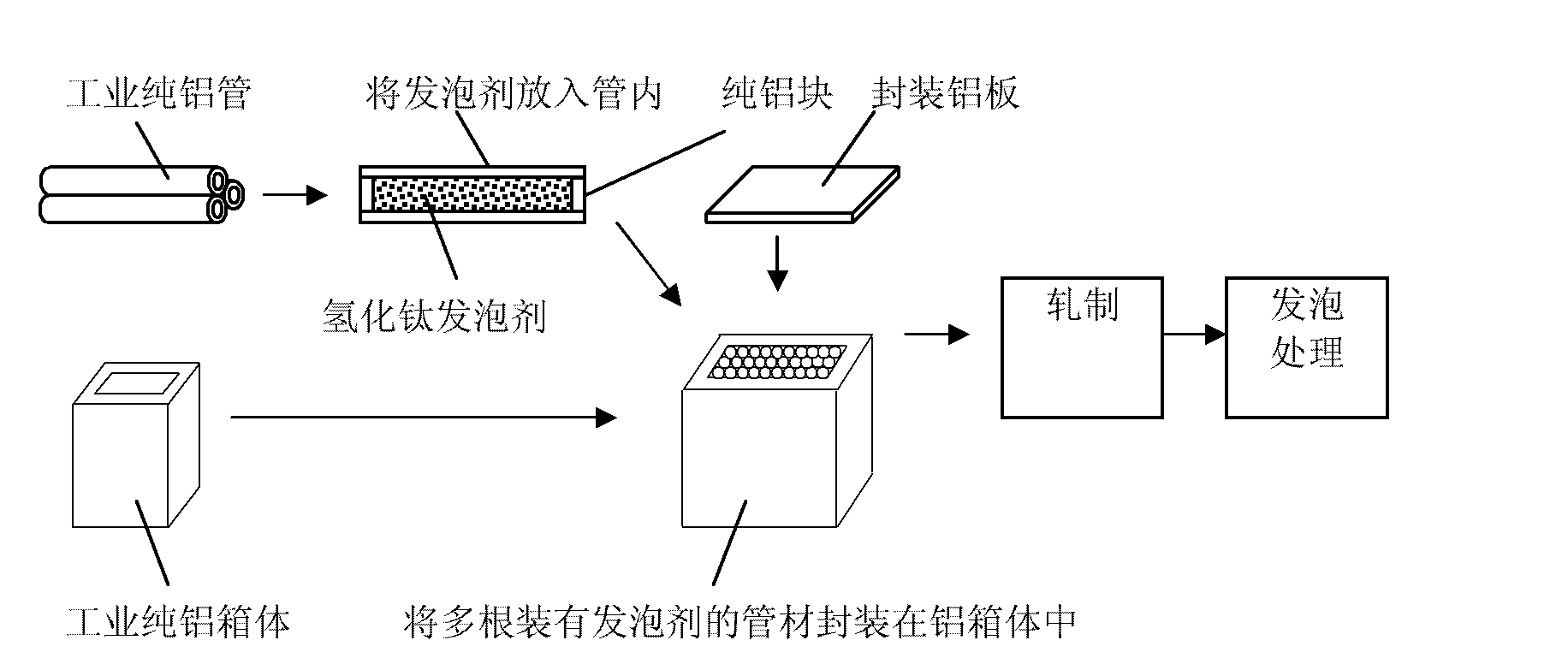

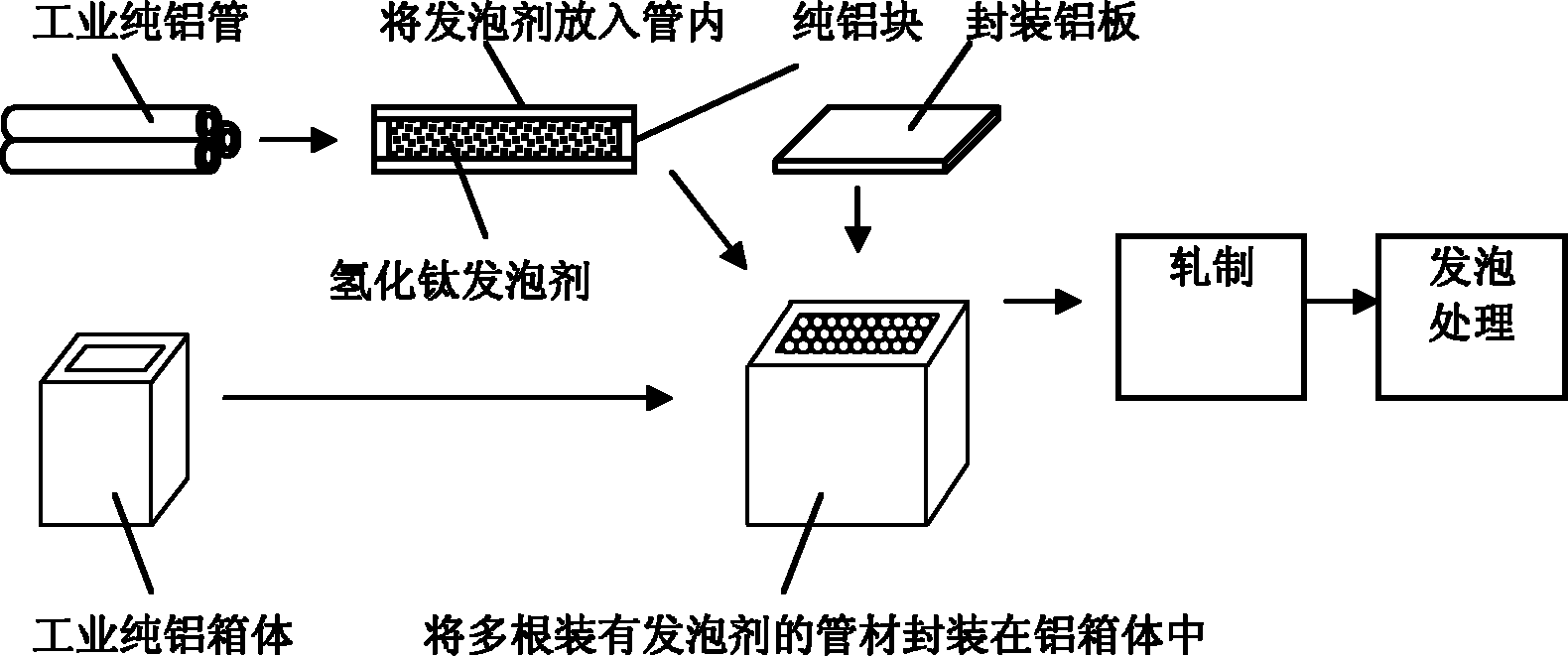

Method for manufacturing foamed aluminum board

The invention provides a method for manufacturing a foamed aluminum board. The method comprises the following steps of: putting titanium hydride powder containing 1 to 3 percent foaming agent into an aluminum or aluminum alloy pipe, sealing a plurality of aluminum or aluminum alloy pipes into which titanium hydride powder is filled in an aluminum or aluminum alloy box, performing mill processing and densifying, and foaming to prepare the foamed aluminum board. By the method, the defects that the pore structure is difficult to control in a casting method and preparation cost is high in a powder metallurgy method are overcome. Compared with an accumulative roll-bonding method, the method has the advantages that the foaming agent can be distributed uniformly, the pore volume can be controlled, the method is not limited by rolling reduction of a critical pass; by the method, the processing can be performed by a compound blank with a large section size, so that a foamed aluminum precursor can be manufactured under a low distortion temperature condition; and the method is convenient to operate and is low in cost.

Owner:UNIV OF SCI & TECH BEIJING

Bioactive porous hybrid carbon nanofiber material and preparation method thereof

ActiveCN103866424ALarge specific surface areaIncrease roughnessProsthesisArtifical filament manufactureWater bathsBiocompatibility Testing

The invention provides a bioactive porous hybrid carbon nanofiber material and a preparation method thereof, and belongs to the technical field of biological composite materials. The bioactive porous hybrid carbon nanofiber material is prepared by virtue of a process comprising the steps of evenly mixing a precursor sol-gel liquid of a bioactive substance, polyacrylonitrile, a pore-foaming agent and an organic solvent together under the conditions of heating in a water bath and ultrasonics, aging to obtain a spinning solution, forming a primary nanofiber film by virtue of an electrostatic spinning process, and then carrying out hot-stretching, pre-oxidating in heating stage by stage and carbonizing, and a preparation method of the bioactive porous hybrid carbon nanofiber material. Due to the bioactive nanoparticles existing on the surface of the material, the material has biocompatibility, bioactivity and biodegradability; due to existing regular-structure nano-scale pores, the material has the relatively high specific surface area, and therefore, the biological properties of the material are greatly improved. As a result, the bioactive porous hybrid carbon nanofiber material can be further used as a novel bone repair material or a bone tissue scaffold reinforcing material.

Owner:BEIJING UNIV OF CHEM TECH

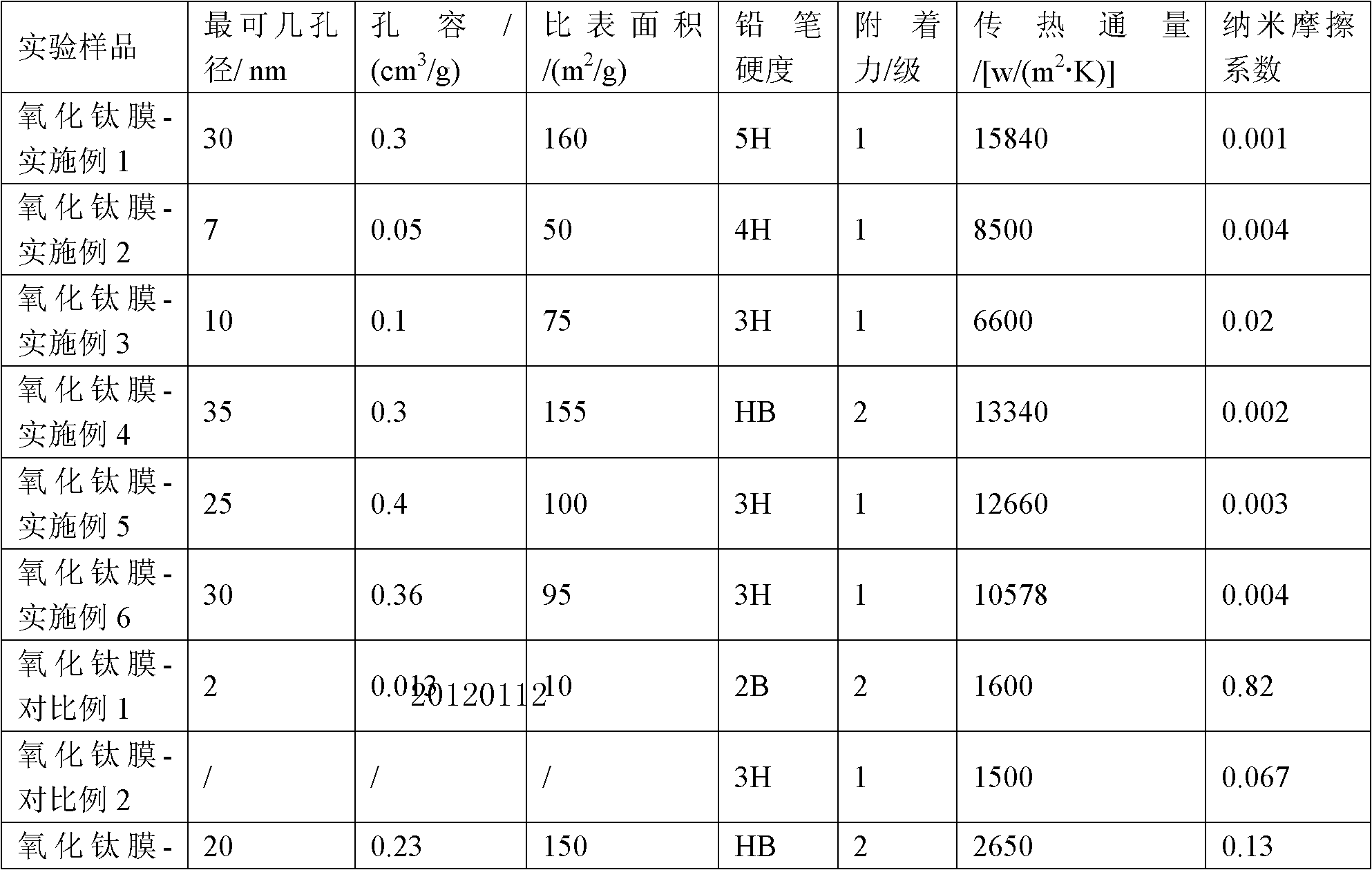

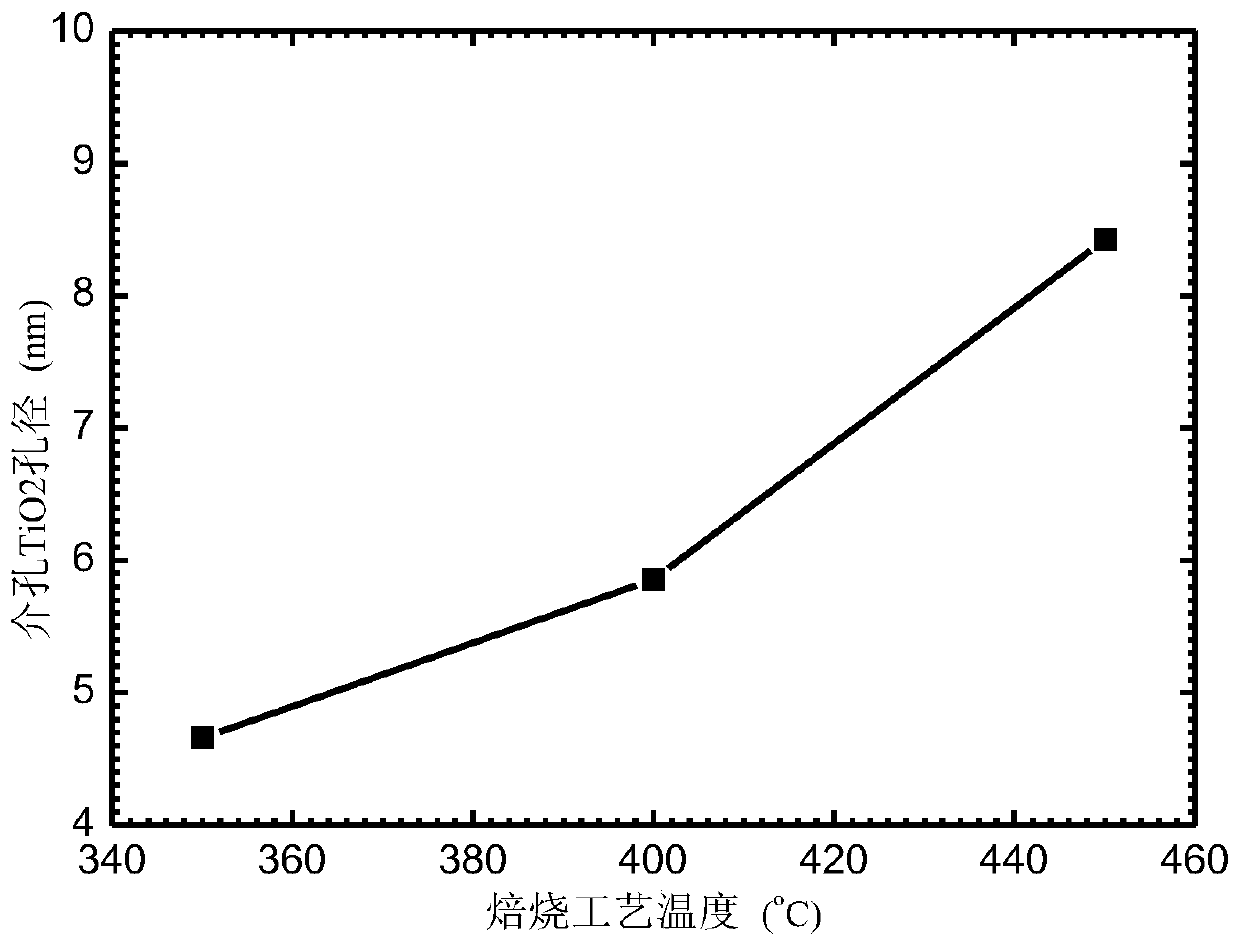

Method for preparing mesoporous titanium oxide film loaded on substrate

InactiveCN102534609AGood biocompatibilityReduce coefficient of frictionMetallic material coating processesSol-gelTitanium oxide

Owner:NANJING UNIV OF TECH

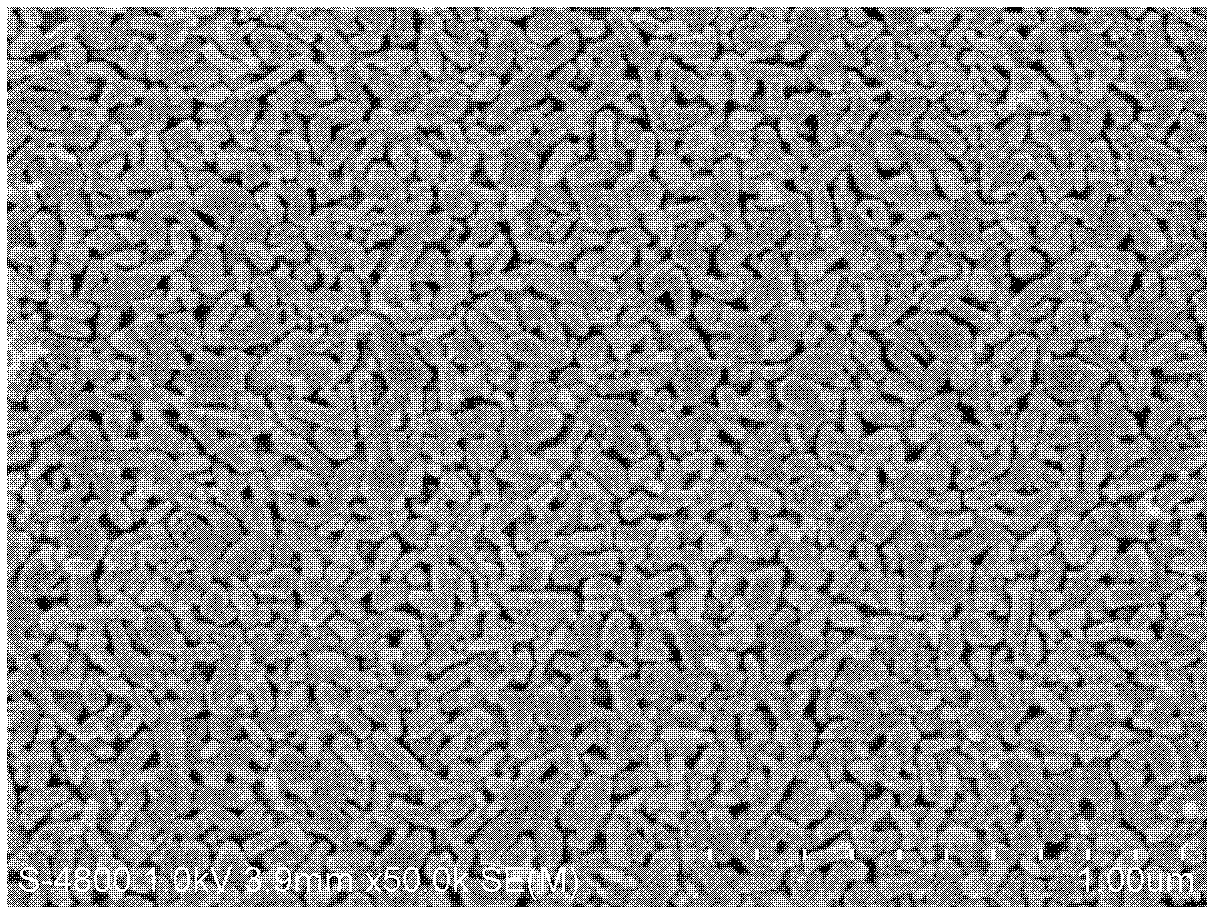

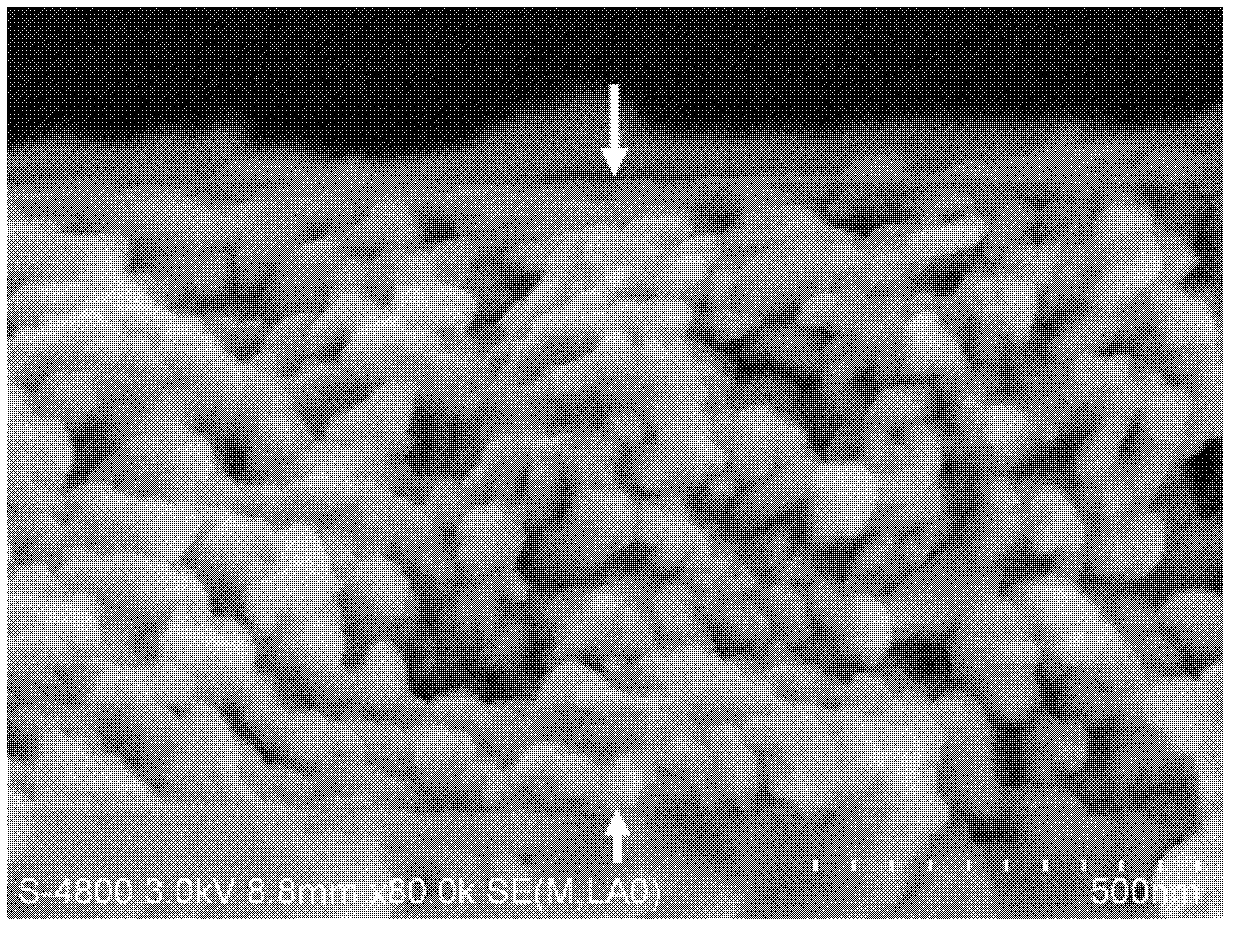

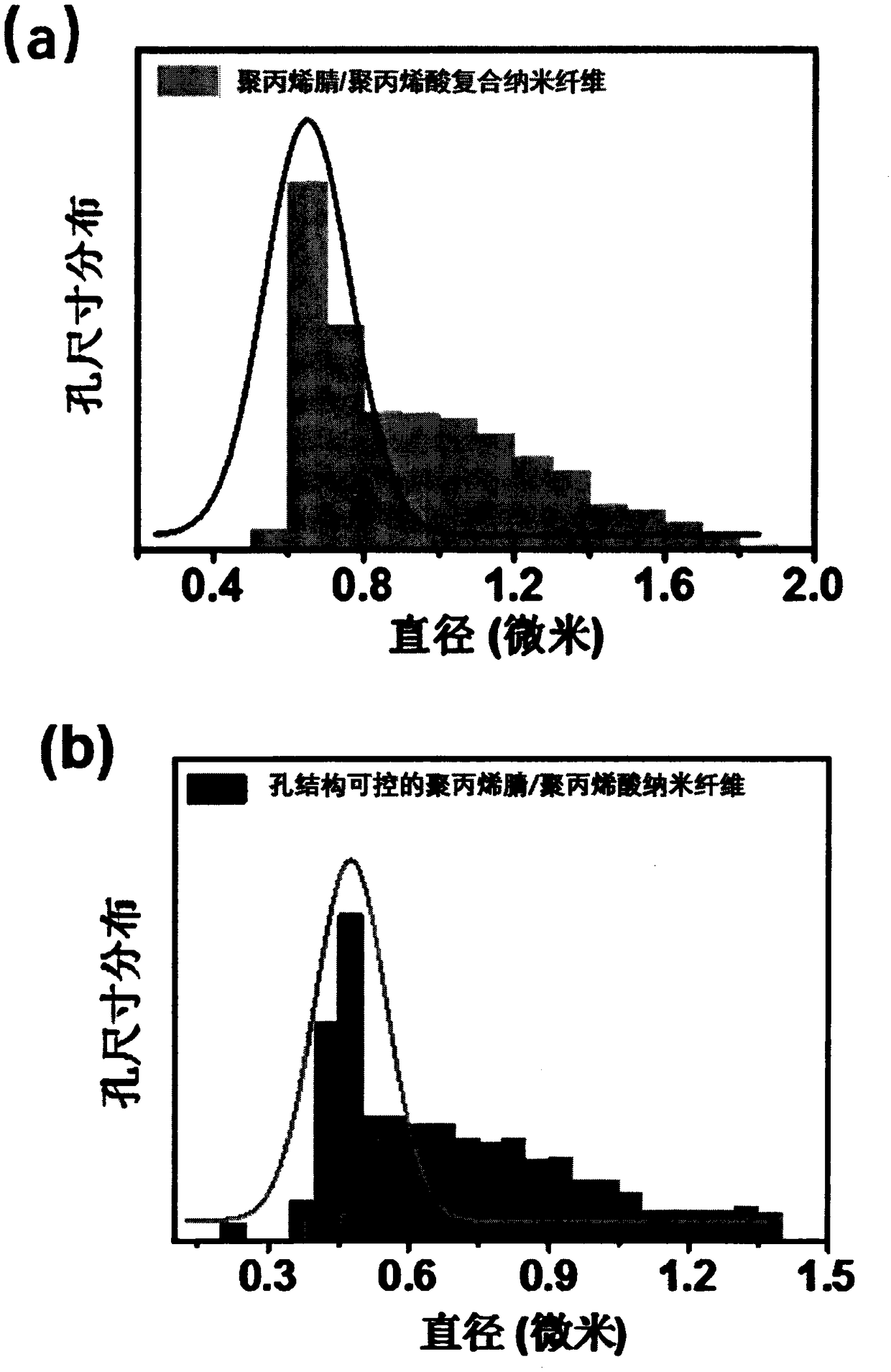

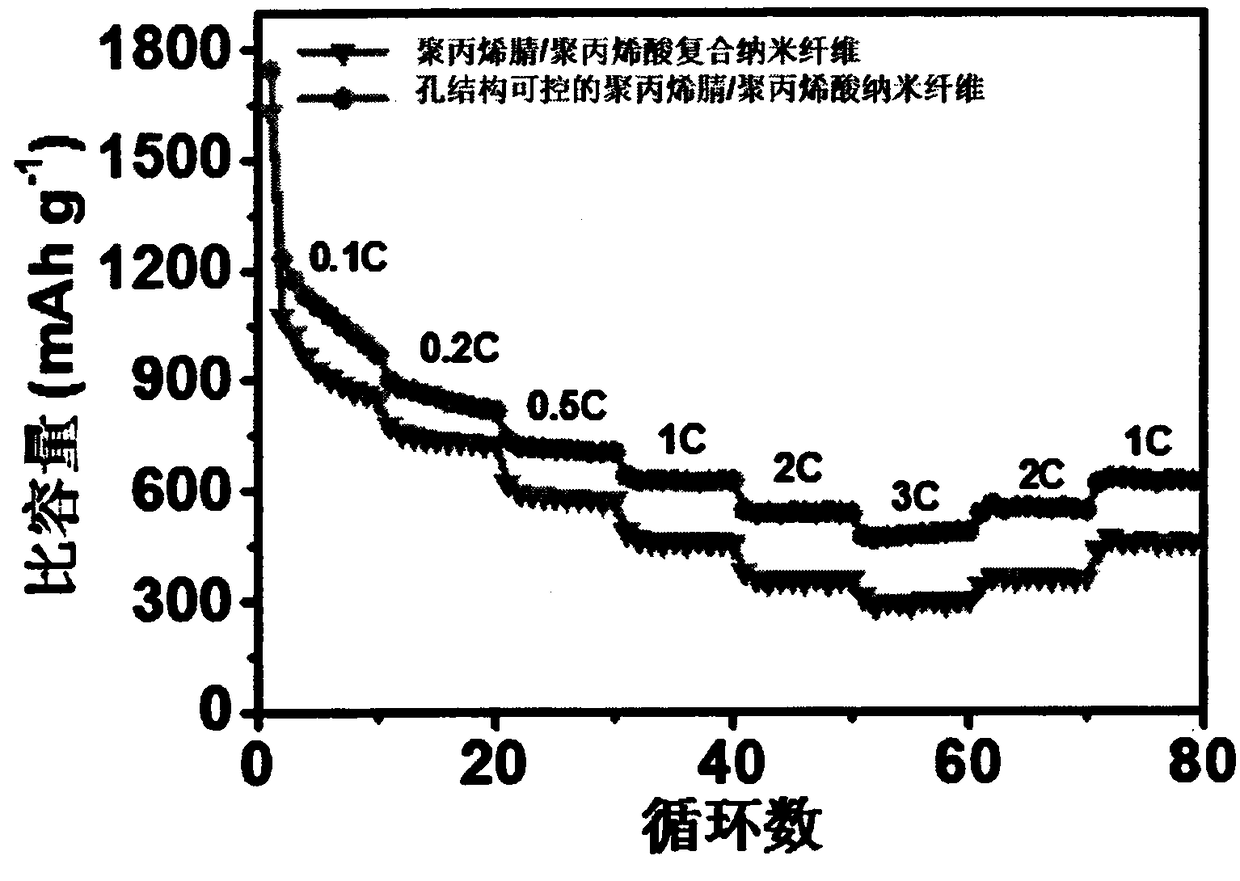

Polyacrylonitrile/polyacrylic acid nanofiber lithium sulfur battery diaphragm with controllable pore structure

InactiveCN108589034AUniform shapeControllable pore structureFibre typesElectro-spinningChemistryNanofiber

The invention provides a polyacrylonitrile / polyacrylic acid nanofiber lithium sulfur battery diaphragm with a controllable pore structure. A preparation method of the polyacrylonitrile / polyacrylic acid nanofiber lithium sulfur battery diaphragm with the controllable pore structure is characterized by comprising the following steps: preparing polyacrylonitrile / polyacrylic acid composite nanofibersby electrospinning; performing ethanol vapor treatment to obtain the polyacrylonitrile / polyacrylic acid composite nanofibers with the controllable pore structure. The prepared composite material has the characteristics of complete fiber morphology, uniform pore size distribution and the like. Polyacrylonitrile can act as a composite nanofiber framework while polyacrylic acid is used as a structurecontrol material of the composite nanofibers. The composite nanofiber diaphragm has the advantages of environmental friendliness, high efficiency, precise regulation of pore size and porosity, stablephysical and chemical properties and the like.

Owner:DONGHUA UNIV

Three-dimensional isinglass multi-hole bracket and the preparing method

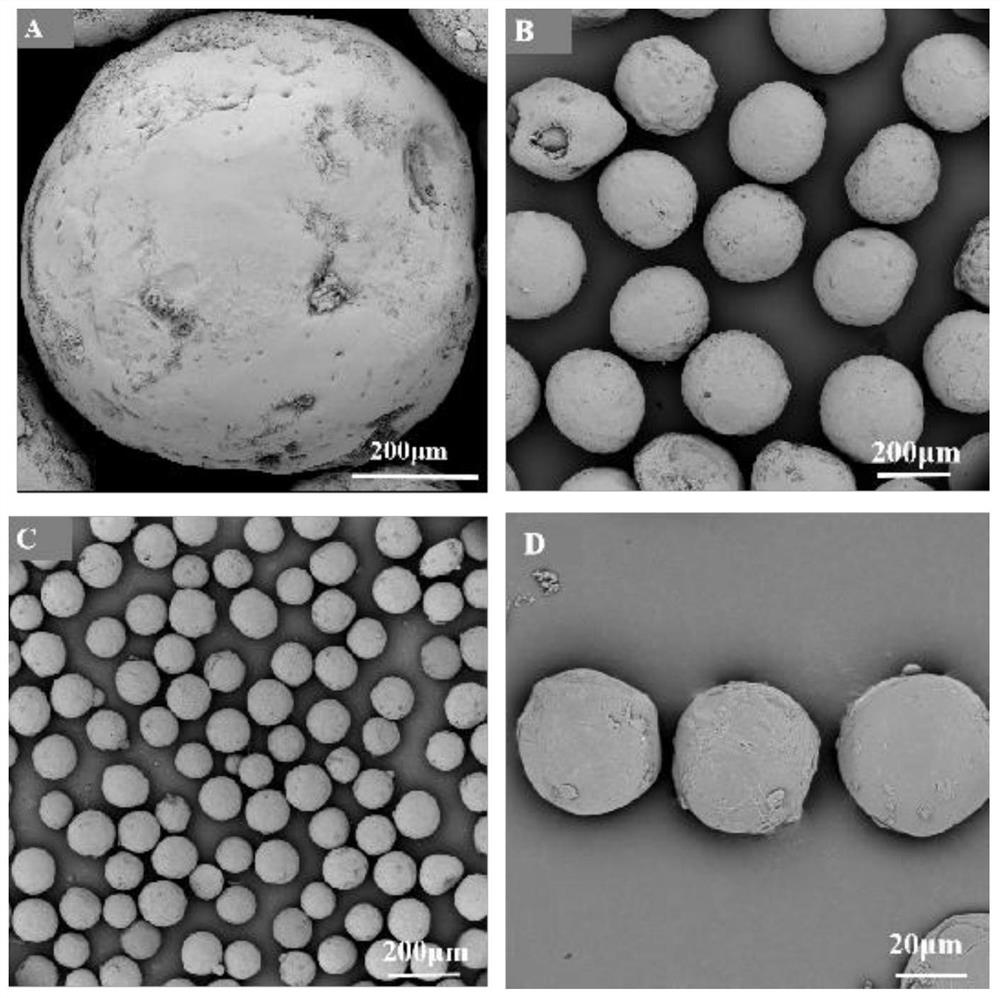

InactiveCN101036803AUniform pore structureControllable pore structureCoatingsProsthesisFreeze-dryingGelatin

The invention discloses 3D gelatin porous scaffold material, with features of homogeneous pore size and distribution, easily forming, resisting compression and resisting bending. The invention also discloses a method of 3D gelatin porous scaffold material using latex freeze drying method. The said 3D gelatin porous scaffold material is especiallu adapted for skin tissue scaffold material.

Owner:SHANGHAI TISSUE ENG LIFE SCI

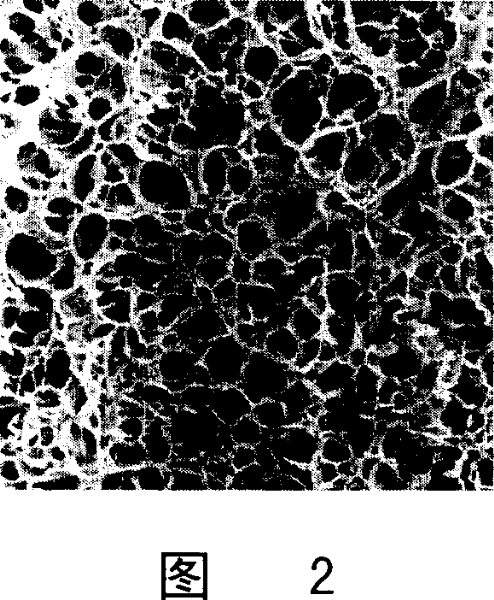

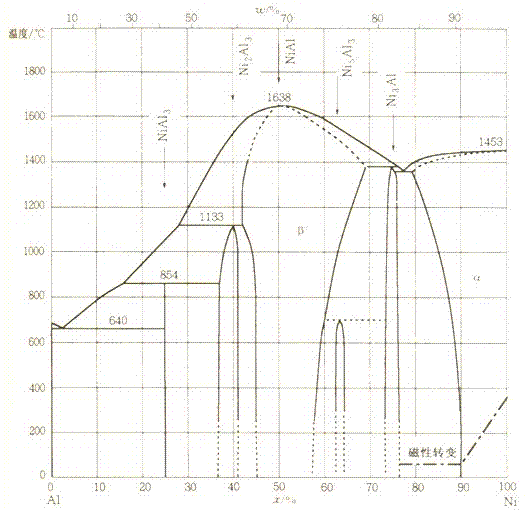

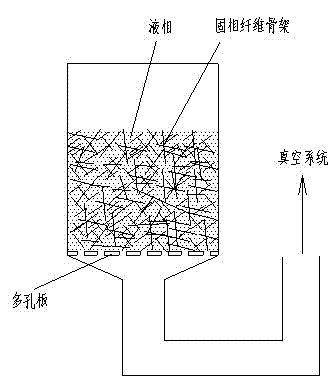

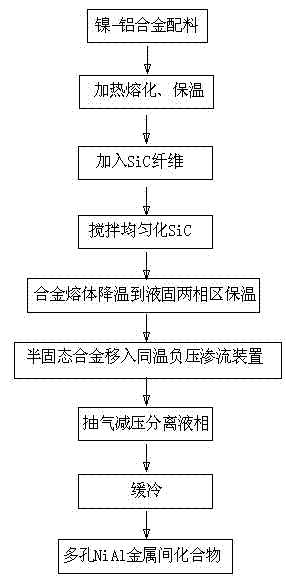

Preparation method for porous NiAl intermetallic compound

The invention discloses a preparation method for a porous NiAl intermetallic compound, and belongs to the field of porous materials. The method comprises the following steps of: dosing nickel-aluminum alloy according to a certain mass percentage; heating until the alloy is molten, preserving heat and then adding SiC fiber; then cooling the alloy melt to a liquid and solid two-phase region for thermal insulation; and finally, separating a liquid phase under reduced pressure from semi-solid alloy obtained by thermal insulation and cooling to obtain the porous NiAl intermetallic compound. A product has an easily controlled shape, a simple and uniform component of organization and a controllable pore structure. The preparation method provided by the invention has the characteristics of high efficiency, low cost and capability of realizing industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing porous carbon material from aluminum electrolysis waste cathode carbon

InactiveCN111792644AEasy to separateImprove etchabilityCarbon compoundsAluminium electrolysisEtching

The invention discloses a method for preparing a porous carbon material from aluminum electrolysis waste cathode carbon, wherein aluminum electrolysis waste cathode carbon is used as a raw material, and the purposes of fluorine fixation and etching are mainly realized through auxiliary treatment and reactant reaction, so that easy-to-separate porous carbon is obtained. According to the invention,soluble fluorine ions in waste cathode carbon are cured by utilizing calcium ions or magnesium ions in a calcium agent or a magnesium agent, oxygen ions and hydroxyl ions in the calcium agent or the magnesium agent are combined with sodium ions, potassium ions and lithium ions to form oxides and hydroxides with high etching property, so that in-situ hole etching is realized; water vapor generatedby auxiliary treatment or high-temperature decomposition of the calcium agent and the magnesium agent can react with insoluble aluminum fluoride and cryolite to generate hydrogen fluoride and aluminumoxide, so that the content of insoluble fluoride in the carbon is reduced; and air in auxiliary treatment can improve the etching property of a carbon skeleton, increase the wettability of a carbon interface and improve the separability of impurities, so that the content of the impurities in the carbon material is reduced.

Owner:ZHENGZHOU UNIV

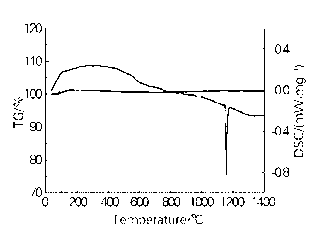

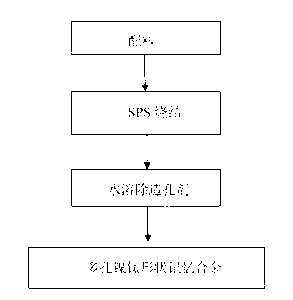

Preparation method of porous nickel titanium shape memory alloy

The invention provides a preparation method of a porous nickel titanium shape memory alloy, which comprises the following steps: determining volume V total porosity of the obtained porous nickel titanium shape memory alloy according to demands, calculating the mass m of every raw material according to the formula, weighing Ni powder, Ti powder and a pore forming agent, and mixing for 30-150 minutes; carrying out discharge plasma sintering at 750-1100 DEG C for 8-30 minutes to obtain a sintered body; and after cooling to room temperature, infusing with water for 30-180 minutes until the pore forming agent is completely dissolved or reacted, thereby obtaining the porous nickel titanium shape memory alloy. The porosity and pore size are controlled through and volume percent, and the reinforced sintering action of SPS and the removal of the soluble salt pore forming agent are utilized to implement the preparation of the controllable-pore-structure porous nickel titanium shape memory alloy. The porosity of the porous nickel titanium shape memory alloy is 40-70%, and the pore size is 75-1000 mu m. The porous nickel titanium shape memory alloy has the characteristics of low cost, controllable pore structure, and simple, stable and efficient technique, and can implement industrial production.

Owner:KUNMING UNIV OF SCI & TECH

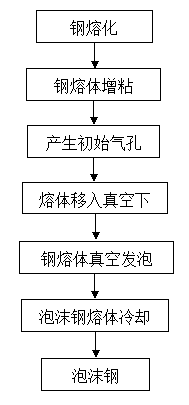

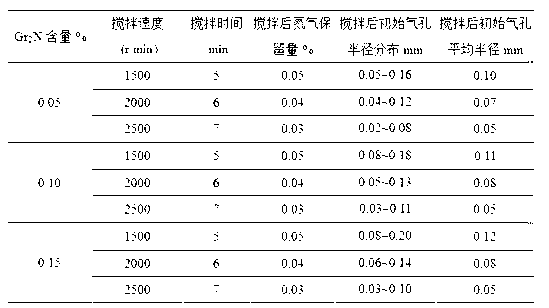

Vacuum foaming preparation method of blister steel

The invention provides a vacuum foaming preparation method of blister steel and belongs to the technical field of a foam metal material. The vacuum foaming preparation method comprises the following steps of: carrying out steel smelting, tackifying a steel melt, generating initial air pores in the steel melt, foaming in vacuum, and cooling a blister steel melt to finally obtain the blister steel with the porosity of 70-85% and the pore diameter of 0.5-5mm. According to the vacuum foaming preparation method disclosed by the invention, SiC is used as a tackifier to carry out tackifying treatment on the steel melt; and a small amount of Cr2N is added into the steel melt tackified by the SiC, and gas is generated by agitating and dispersing the Gr2N and decomposing the Gr2N, so that the initial air pores which are uniformly distributed, great in quantity and fine are generated in the steel melt, and the blister steel is prepared by foaming in the vacuum. The control of the distribution, the quantity, the size, the vacuum degree, the foaming time and the like of the generated initial air pores is carried out so as to control the porosity and the pore structure of the blister steel to prepare the blister steel with the excellent performance in short time. The vacuum foaming preparation method of the blister steel, disclosed by the invention, has the characteristics of high efficiency, simple process, controllable pore structure, stable process and the like, and can realize the industrial production.

Owner:KUNMING UNIV OF SCI & TECH

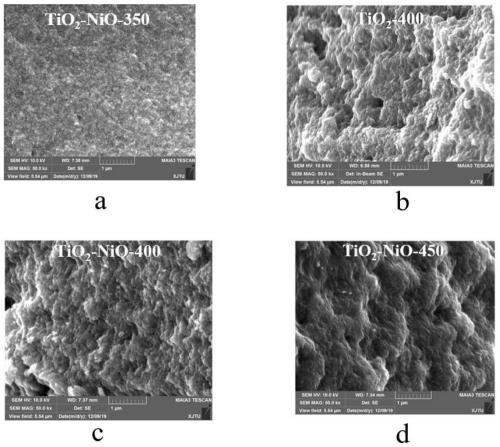

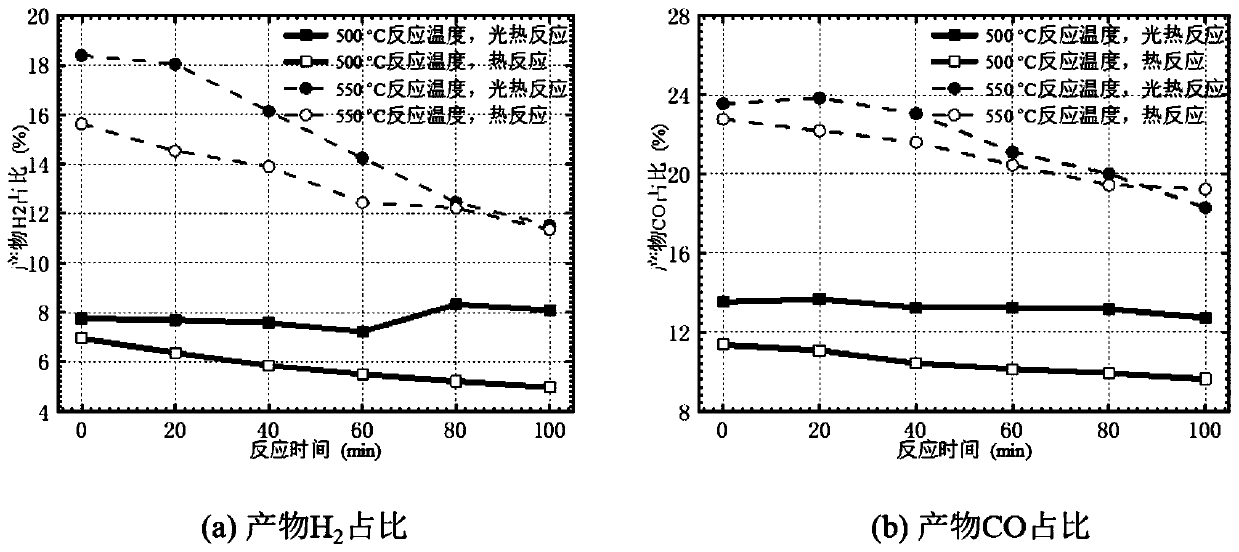

Mesoporous photo-thermal catalyst for dry reforming of medium-high temperature methane as well as preparation method and application thereof

InactiveCN111111669AControllable pore structureGood dispersionHydrogenCatalyst activation/preparationPtru catalystPhoto catalytic

The invention discloses a mesoporous photo-thermal catalyst for medium-high temperature methane dry reforming as well as a preparation method and application thereof. The preparation method belongs tothe field of solar photo-thermal conversion and photo-thermal catalyst preparation methods, and adopts an impregnation method to load a thermal catalyst Ni to the surface of a mesoporous TiO2 photocatalyst, so as to form the Ni-mesoporous TiO2 photo-thermal catalyst with nano Ni particles loaded on the surface of mesoporous TiO2. The medium-high temperature methane dry reforming photo-thermal synergistic catalyst provided by the invention is simple to prepare and easy to operate, has good photo-thermal synergistic catalytic activity at 400-600 DEG C, and has obviously improved activity compared with the traditional Ni-based thermal catalyst, so that the catalyst has higher industrial application level and prospect.

Owner:XI AN JIAOTONG UNIV

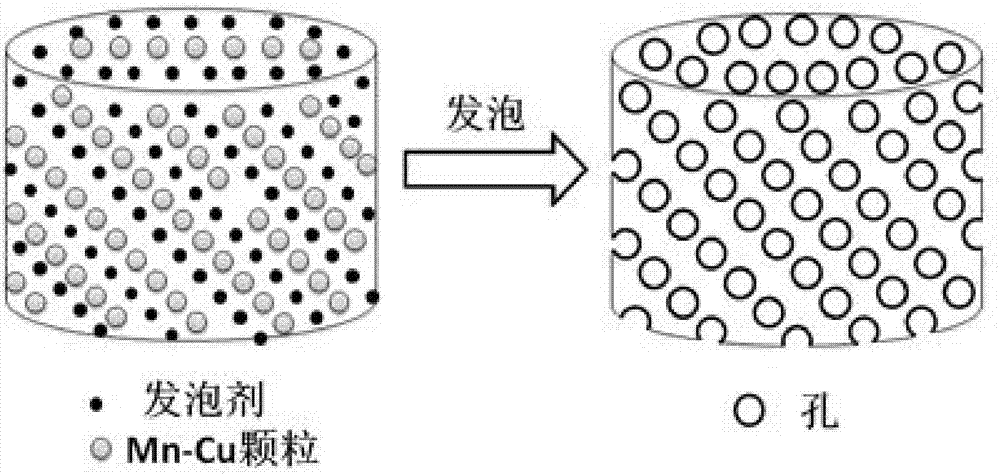

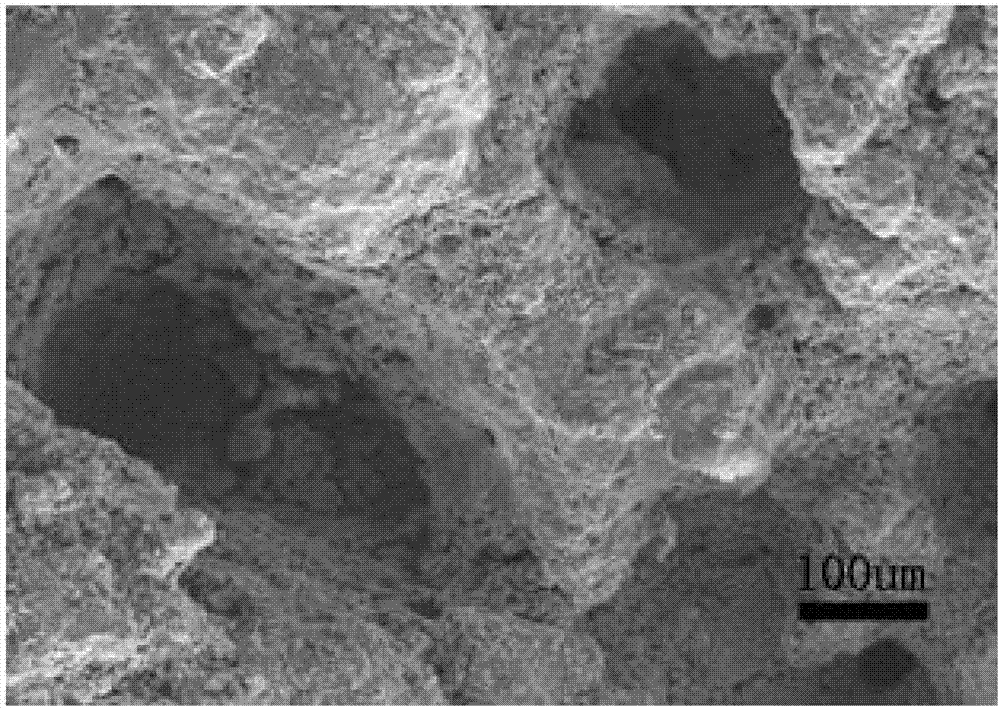

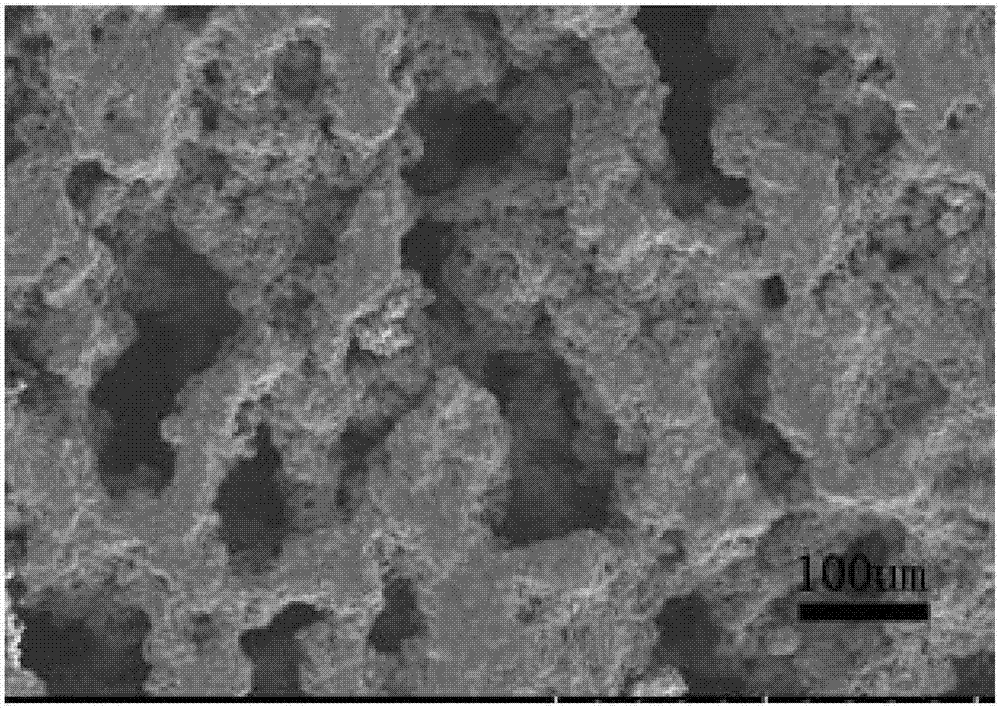

Light foam Mn-Cu alloy high-damping material and preparation method thereof

The invention discloses a light foam Mn-Cu alloy high-damping material. The light foam Mn-Cu alloy high-damping material is a binary alloy formed by metal manganese and copper or a multicomponent alloy formed by manganese, copper and one or more of iron, nickel and aluminum. A preparation method of the light foam Mn-Cu alloy high-damping material comprises the following steps of mixing Mn-Cu alloy particles and a foaming agent evenly; putting mixed powder into a mold and conducting cold-press molding to obtain a blank body for standby application; conducting hot-press molding on the blank body to obtain a high-compactness blank body with the density greater than 80%; putting the high-compactness blank body into the mold, conducting foaming and then cooling, and finally obtaining the foam Mn-Cu alloy high-damping material with the uniform aperture. By means of the light foam Mn-Cu alloy high-damping material and the preparation method thereof, the defect that the density of a traditional high-damping Mn-Cu alloy is large is overcome; the damping property of the Mn-Cu alloy is effectively improved through the porosity and the high-density defect around cavities. Besides, by means of the method, the problems that the foaming temperature is high, the size distribution of pores is non-uniform and the technological operation is difficult are solved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

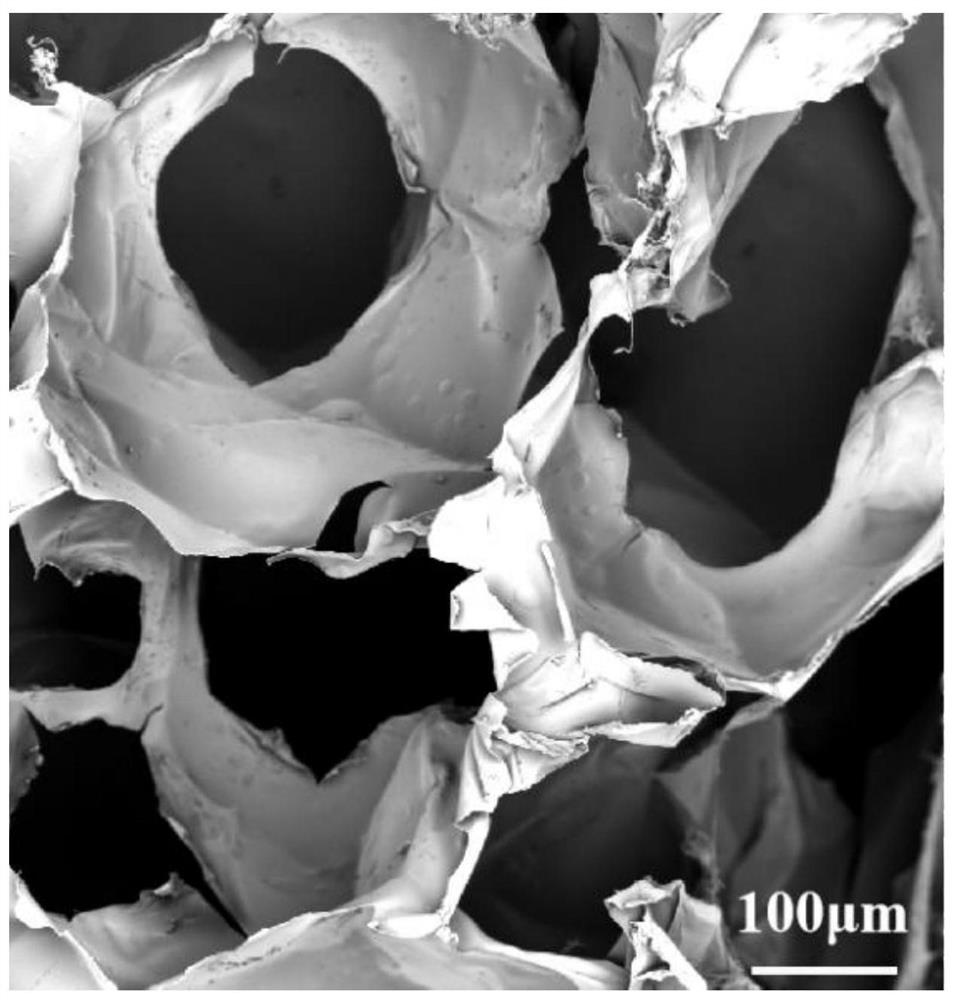

Hierarchical porous polylactic acid material and preparation method thereof

ActiveCN109370179AImprove connectivityImprove mechanical propertiesHierarchical porousMechanical property

The invention relates to a hierarchical porous polylactic acid material and a preparation method thereof, belongs to the technical field of biodegradable polymer porous materials and solves the technical problems that an existing porous polylactic acid material is single in pore diameter, poor in mechanical strength and poor connectivity among pores and a pore structure is difficult to control dueto the introduction of an organic solvent in a preparation method of the existing porous polylactic acid material. The hierarchical porous polylactic acid material disclosed by the invention is prepared by taking polylactic acid as a matrix, the matrix is irregularly distributed with a plurality of micropores and macropores which are in a form of olive-shaped pores or round pores, and long axes of the olive-shaped pores are parallel when both the micropores and the macropores are in the form of the olive-shaped pores. The porous polylactic acid material simultaneously has the micropores and the macropores, the connectivity among the pores is relatively good, the micropores can be interconnected with the macropores, the porosity can reach up to 80% or above, and the mechanical properties are good.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Macroporous hydrogel as well as preparation method and application thereof

ActiveCN111978588APerformance is not affectedGood biocompatibilityPharmaceutical delivery mechanismProsthesisGelatin microspheresFoaming agent

The invention provides macroporous hydrogel and a preparation method and application thereof. The preparation method comprises the steps that: water-soluble gelatin microspheres are adopted as a pore-foaming agent, gelatin microsphere interfaces are bonded with one another in a heating mode, a gelatin microsphere template is removed after crosslinking and gelling, and finally the macroporous hydrogel with controllable pore diameter and mutual communication is formed. Adhesion, migration and proliferation of cells and transportation of oxygen, nutrient substances and the like are facilitated, avascularization promoting gel stent is expected to be further developed, and application of the hydrogel in tissue engineering and regenerative medicine is expanded. Compared with macroporous hydrogel prepared by traditional methods, the macroporous hydrogel prepared by the method has the advantages that the gelation time is short, the gelation can be completed within a few seconds, the pore structure is controllable, uniform and mutually communicated, and the pore diameter range is 30-600 microns.

Owner:GUANGDONG PROV MEDICAL INSTR INST

Method for preparing lignin-based hierarchical pore activated carbon fibers

ActiveCN107604479ARich in holesLarge specific surface areaArtifical filament manufactureActivated carbonCarbon fibers

The invention discloses a method for preparing lignin-based hierarchical pore activated carbon fibers. The method comprises the following steps: alternately adding purified lignin and sodium alginateinto a sodium silicate aqueous solution at 60-80 DEG C, uniformly stirring, and adjusting the pH value to 1-2; performing rotary evaporation at reduced pressure to obtain a hybridized material; addingthe hybridized material into a melt spinning machine, and spinning at a temperature of 200-250 DEG C at a speed of 100-6000m / min to obtain hybridized fibers; heating the hybridized fibers in a high-temperature furnace to 280-300 DEG C at a speed of 0.01-3 DEG C, and insulating at a constant temperature for 1-6 hours; and heating to 1000-2000 DEG C at a speed of 1-5 DEG C / min, carbonizing for 0.5-12 hours, and activating and pickling to obtain porous activated carbon fibers. The method has the beneficial effects that the prepared carbon fibers have more pores, large specific surface and controllable pore structure.

Owner:QINGDAO UNIV

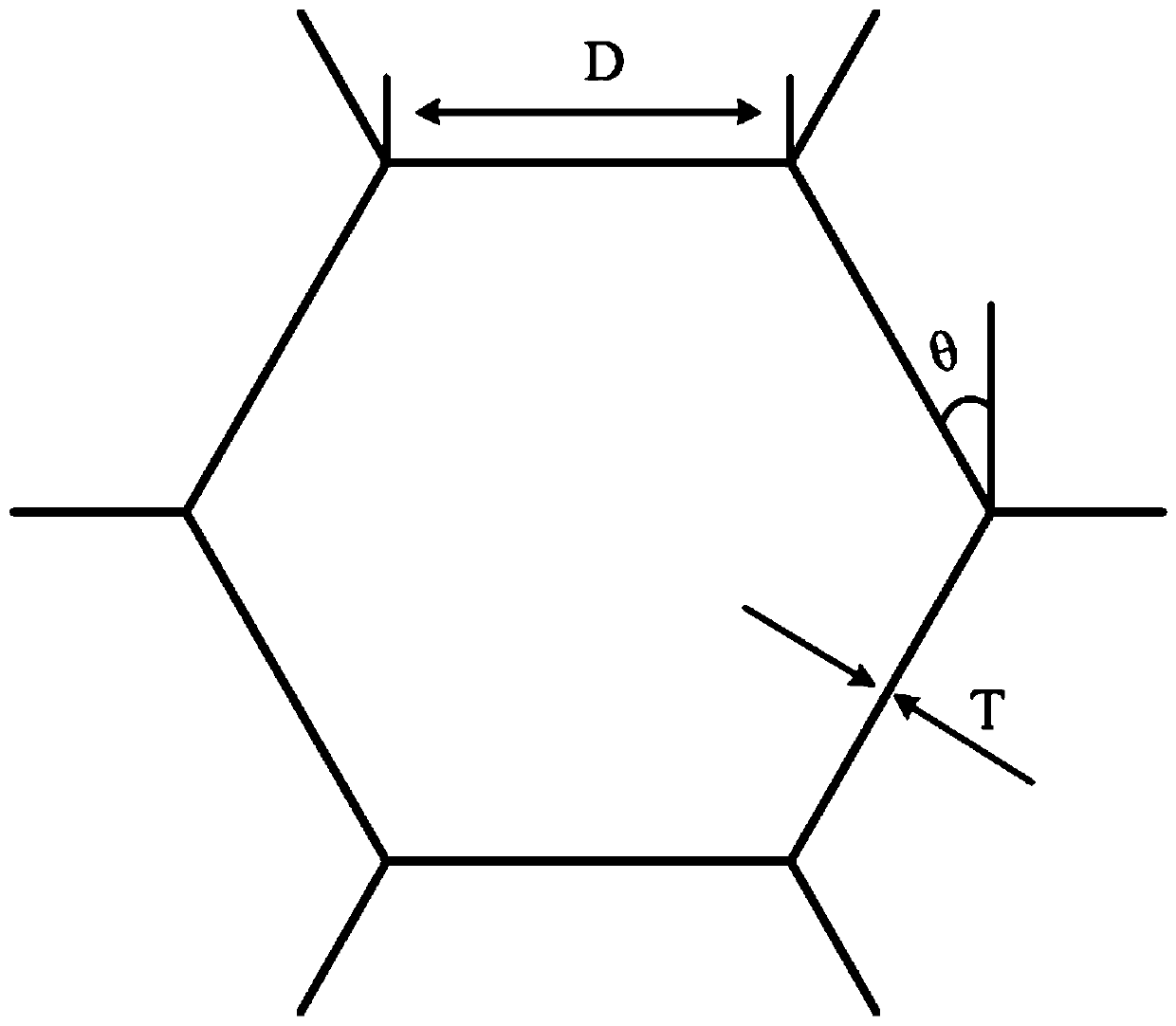

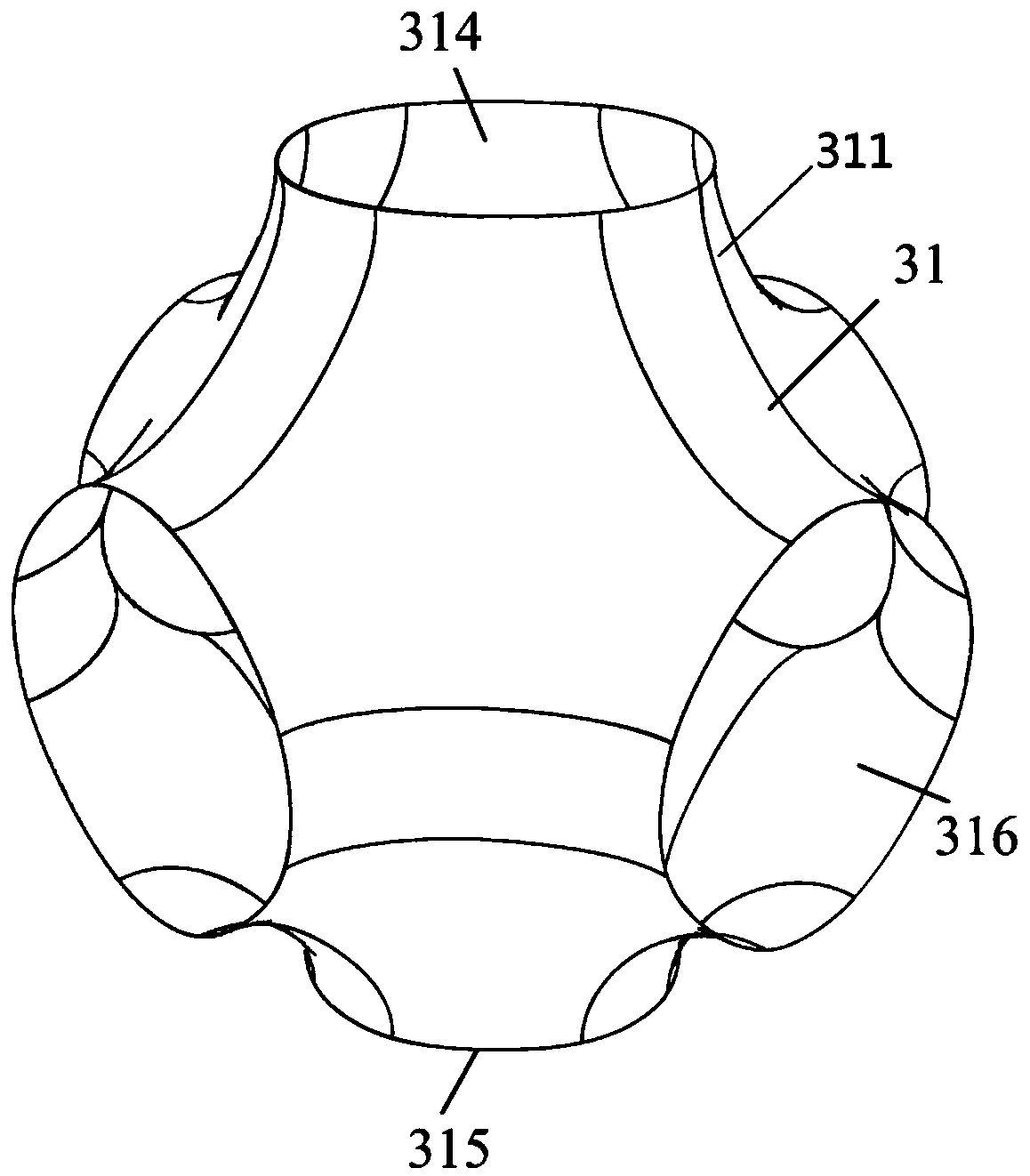

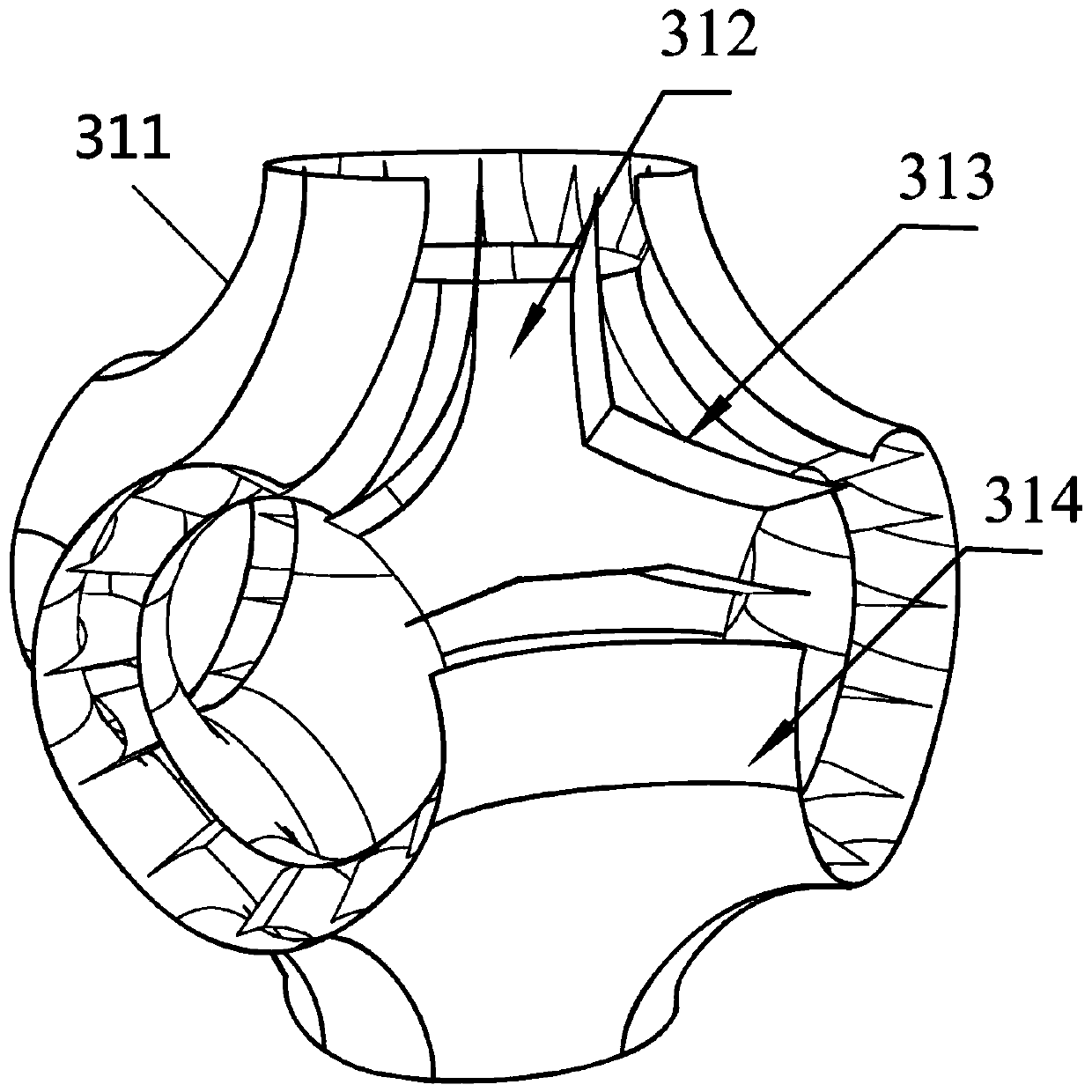

Core cell structure, core with porous structure and sandwich energy absorption structure

ActiveCN110497656ASimple structureLight in massVehicle componentsMetal layered productsHigh energyEngineering

The invention discloses a core cell structure. The core cell structure comprises an outer layer and an inner layer, wherein both the outer layer and the inner layer are three-period minimal curved surfaces; a cavity is formed between the outer layer and the inner layer; a connecting plate for connecting the outer layer with the inner layer is arranged in the cavity; an upper opening and a lower opening which extend to the outside of the cavity and are opposite to each other are formed in each of the outer layer and the inner layer; and a plurality of lateral openings which extend to the outside of the cavity are formed in the peripheral side of each of the outer layer and the inner layer. The invention also discloses a core with a porous structure. The core with the porous structure comprises the core cell structures, wherein the adjacent core cell structures are in butt joint with each other through the corresponding opening, and the outer layers and the inner layers of the core cellstructures form a continuous curved surface. The invention also discloses a sandwich energy absorption structure which comprises a first interlayer, a second interlayer and the core with the porous structure, and the core with the porous structure is clamped between the first interlayer and the second interlayer. The core cell structure, the core with the porous structure and the sandwich energy absorption structure have the advantages of simple structure, high energy absorption efficiency and the like.

Owner:HUNAN UNIV

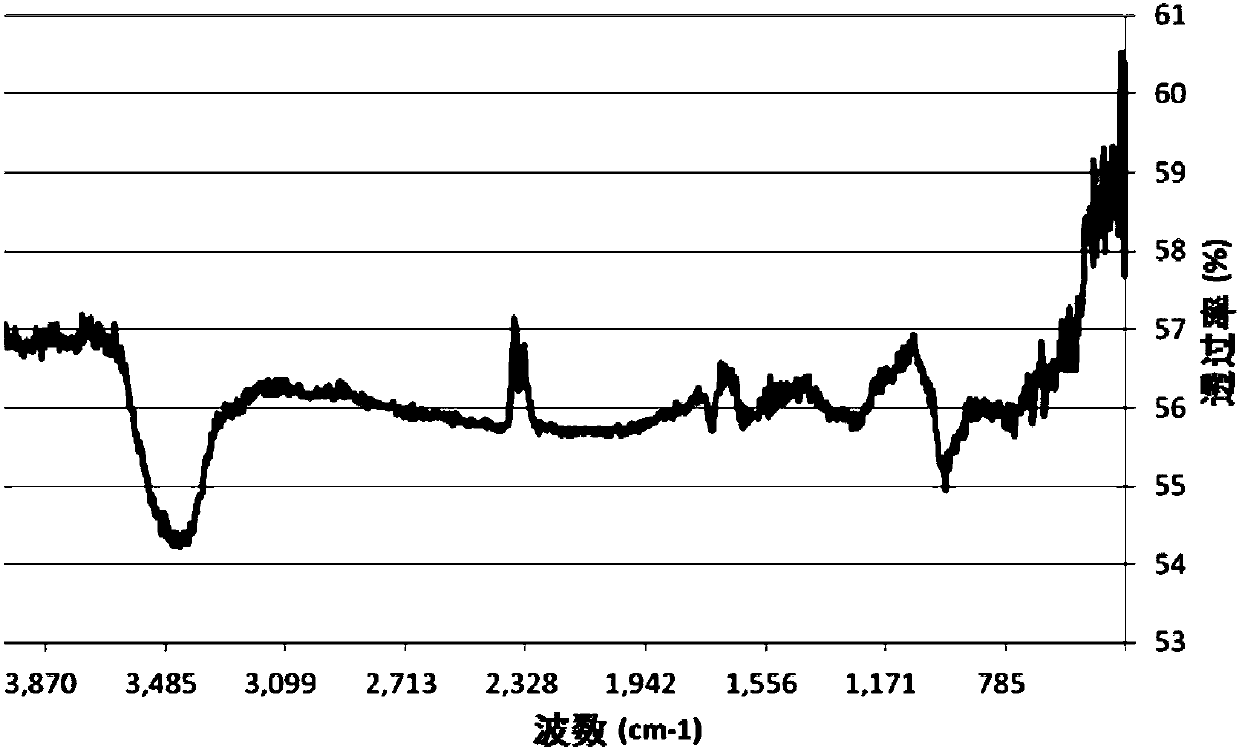

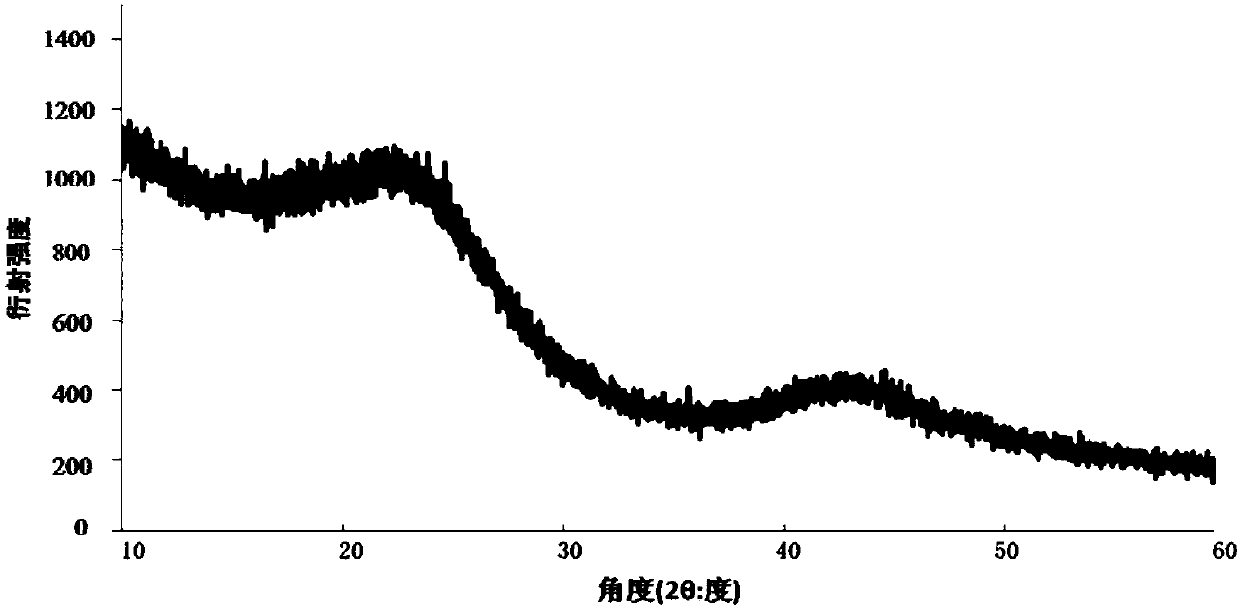

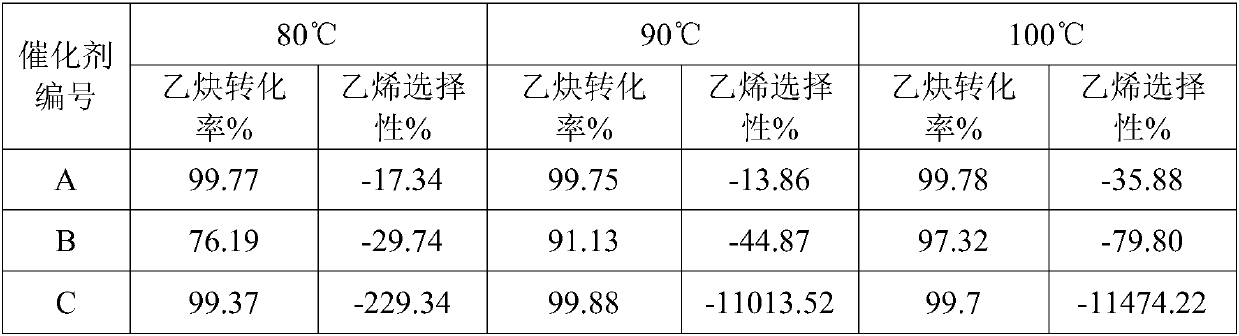

Carbon carrier for hydrogenation catalyst and preparation method thereof and palladium-system-supported hydrogenation catalyst and application thereof

ActiveCN108014777ALow impurity contentLess side effectsHydrocarbon by hydrogenationCatalystsChemistryHigh polymer

The invention provides a carbon carrier for a hydrogenation catalyst and a preparation method thereof and a palladium-system-supported hydrogenation catalyst and application thereof. The surface of the carbon carrier has oxygen-containing groups, and the strength of the carbon carrier is 70-120N / particle, and the specific surface area of the carbon carrier is 1-2000m<2> / g, and the average poresize is 2-10nm. The preparation method of the carbon carrier for the hydrogenation catalyst includes 1) even mixing of an organic polymer compound and a curing accelerator to obtain a curing system;2) mixing of the curing system with water, and successive kneading and forming of the obtained mixture to obtain a carbon carrier precursor; and 3) successive aging, drying, curing and carbonization of the obtained carbon carrier precursor to obtain the carbon carrier. The carbon carrier prepared by the method has large specific surface area, high strength, less impurity and easily-controlled shape. The preparation method of the carbon carrier is simple and practical, and is suitable for large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com