Thermal-insulation and humidity-regulating foam concrete material and preparation method thereof

A technology of foam concrete and humidity control materials, applied in the field of building materials, can solve problems such as insufficient range of humidity adjustment, no evaluation of humidity control effect, weak humidity control ability of gypsum, etc., achieve good humidity control and heat preservation performance, and easy pore structure The effect of simple control and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

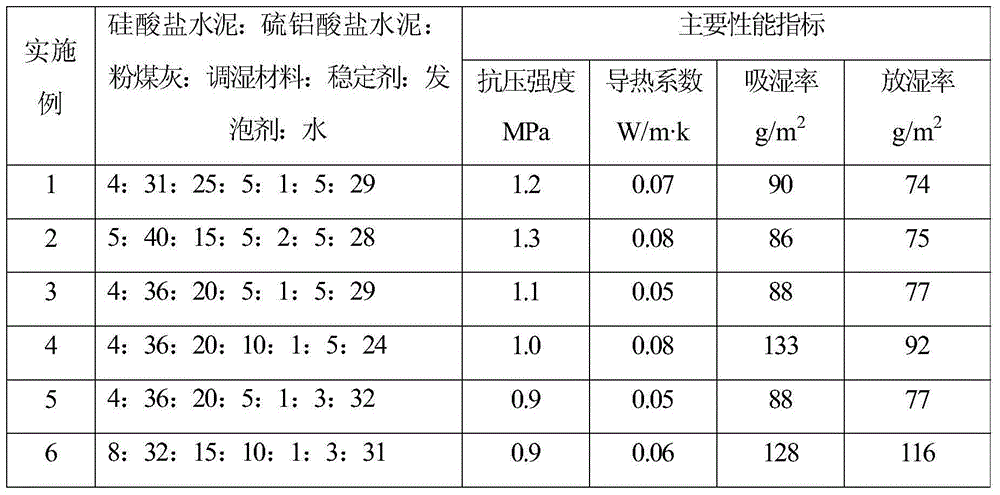

[0025] Humidity-adjusting and heat-insulating foam concrete is composed of cement, fly ash, humidity-adjusting material, foaming agent, stabilizer and water, and the parts by weight of each component are shown in Table 1.

[0026] In the raw material that following embodiment adopts:

[0027] The strength grade of ordinary Portland cement is not less than 42.5;

[0028] The humidity control material is zeolite powder with a fineness of 100-200 mesh.

[0029] The stabilizer is calcium lauryl sulfate, chemically pure.

[0030] Its preparation comprises the following steps:

[0031] 1) immersing the humidity-conditioning material in the foaming agent to saturation to obtain a pre-treated humidity-conditioning material that pre-absorbs the foaming agent;

[0032] 2) Mix cement, fly ash, and stabilizer evenly, then add water and stir evenly to form a uniform slurry, then add pretreatment humidity-adjusting materials, stir evenly, let stand for foaming, and release the mold after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com