Making method of high-toughness porous SiC ceramic complex part

A complex part, high toughness technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of difficult to control pore shape, low porosity, low strength and toughness, etc., to achieve controllable structure and performance of parts, improve Parts performance, the effect of superior flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

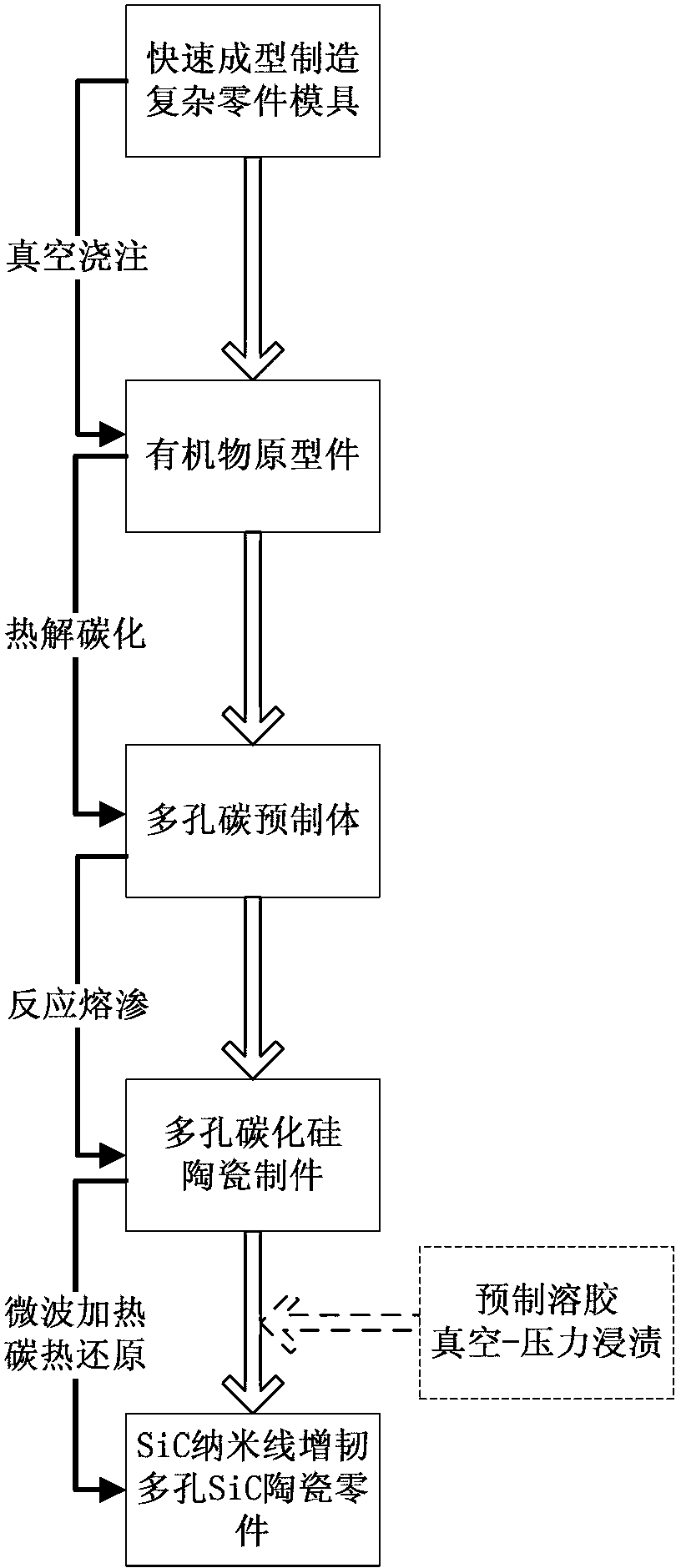

[0042] see figure 1 , a preparation method of high-toughness porous SiC ceramic complex parts, comprising the following steps:

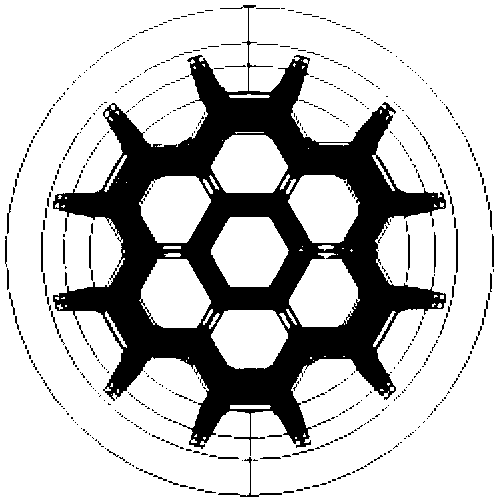

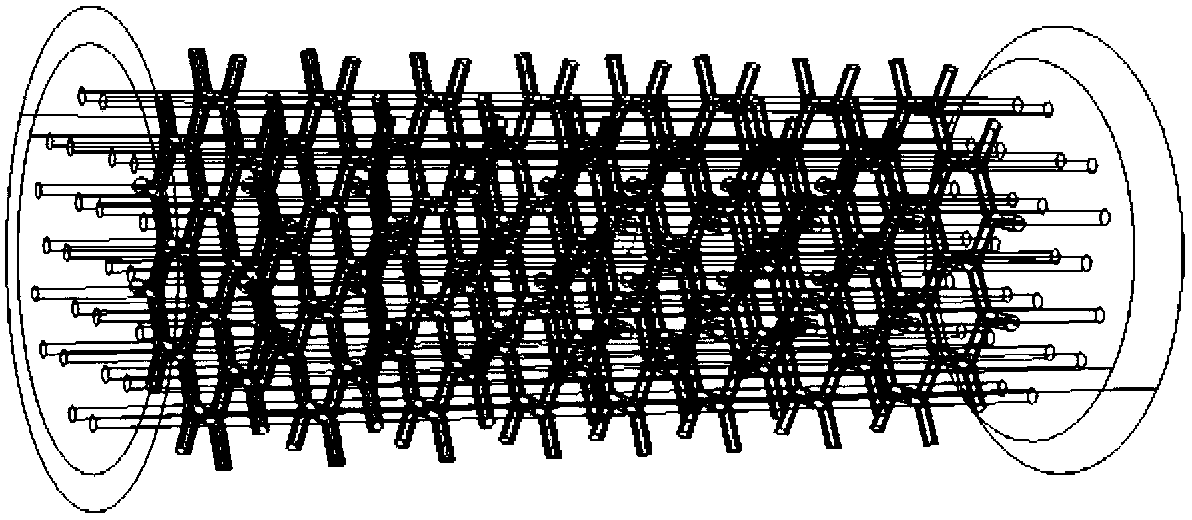

[0043] 1. Using light-curing rapid prototyping technology to realize the manufacture of negative molds for complex parts; Figure 2-1~2-2 Shown is the filter for the internal design topology network channel, image 3 Molds and prototypes for the prepared parts;

[0044] 2. Raw material preparation: Mix phenolic resin and pore-forming agent (triethylene glycol) uniformly in a mass ratio of 50:80~100 to obtain resin slurry (hereinafter referred to as slurry);

[0045] 3. Ball mill the prepared slurry for 30 minutes, add curing agent (benzenesulfonyl chloride), stir in vacuum for 30 minutes to remove foam, and inject the slurry into the resin mold in the vacuum injection molding machine, and then put the cast parts into Insulate in a drying oven at 60°C for 8 hours, then increase the temperature at a rate of 2°C / h to 160°C for curing. After the pheno...

Embodiment 2

[0053] A method for preparing a high-toughness porous SiC ceramic complex part, comprising the following steps:

[0054] 1. Using light-curing rapid prototyping technology to realize the manufacture of negative molds for complex parts;

[0055] 2. Raw material preparation: Mix phenolic resin and pore-forming agent (triethylene glycol) uniformly in a mass ratio of 50:60~70 to obtain resin slurry (hereinafter referred to as slurry);

[0056] 3. Ball mill the prepared slurry for 30 minutes, add curing agent (benzenesulfonyl chloride), stir in vacuum for 30 minutes to remove foam, and inject the slurry into the resin mold in the vacuum injection molding machine, and then put the cast parts into Insulate in a drying oven at 80°C for 5 hours, then increase the temperature at a rate of 2°C / h to 180°C for curing. After the phenolic resin is completely cured, put the parts into a 20wt% potassium hydroxide-ethanol solution (ethanol: water = 2 :6), the photosensitive resin mold was corr...

Embodiment 3

[0064] A method for preparing a high-toughness porous SiC ceramic complex part, comprising the following steps:

[0065] 1. Using light-curing rapid prototyping technology to realize the manufacture of negative molds for complex parts;

[0066] 2. Raw material preparation: Mix phenolic resin and pore-forming agent (triethylene glycol) uniformly in a mass ratio of 50:60~75 to obtain resin slurry (hereinafter referred to as slurry);

[0067] 3. Ball mill the prepared slurry for 30 minutes, add curing agent (benzenesulfonyl chloride), stir in vacuum for 30 minutes to remove foam, and inject the slurry into the resin mold in the vacuum injection molding machine, and then put the cast parts into Insulate in a drying oven at 80°C for 5 hours, then increase the temperature at a rate of 1.5°C / h to 150°C for curing. After the phenolic resin is completely cured, put the parts into a 15wt% potassium hydroxide-methanol solution (ethanol: water = 2 :3), the photosensitive resin mold was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com