Continuous equal-thickness paving method for curved surface forming, formed part and application

A technology of surface forming and equal thickness, applied in the field of composite material processing and forming, can solve the problems of reducing the performance of parts, destroying the continuity of layup, uneven fiber distribution, etc., and improving the performance of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

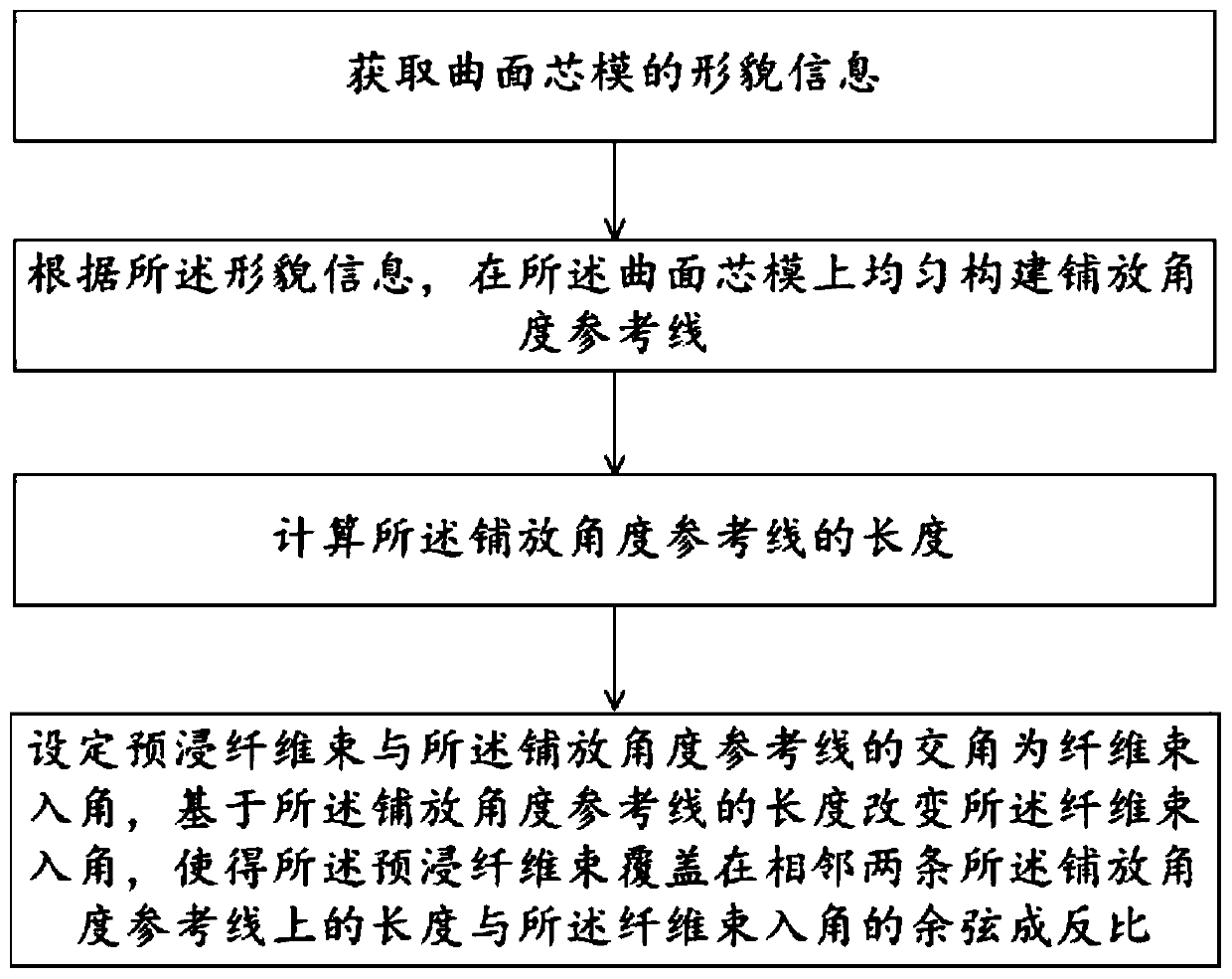

[0035] In this embodiment, a method for continuous equal-thickness layup of curved surface molding is provided, see figure 1 , including the following steps:

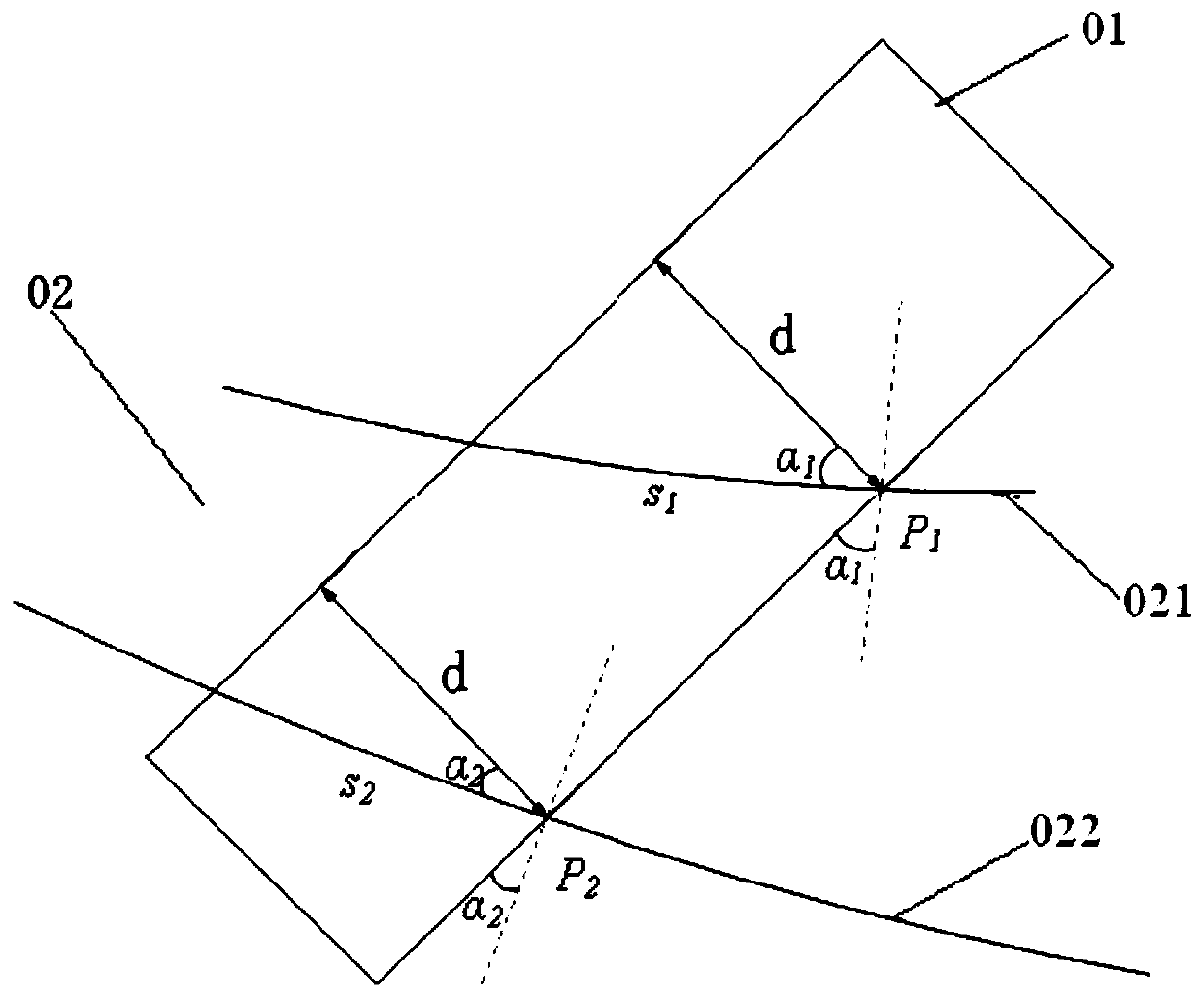

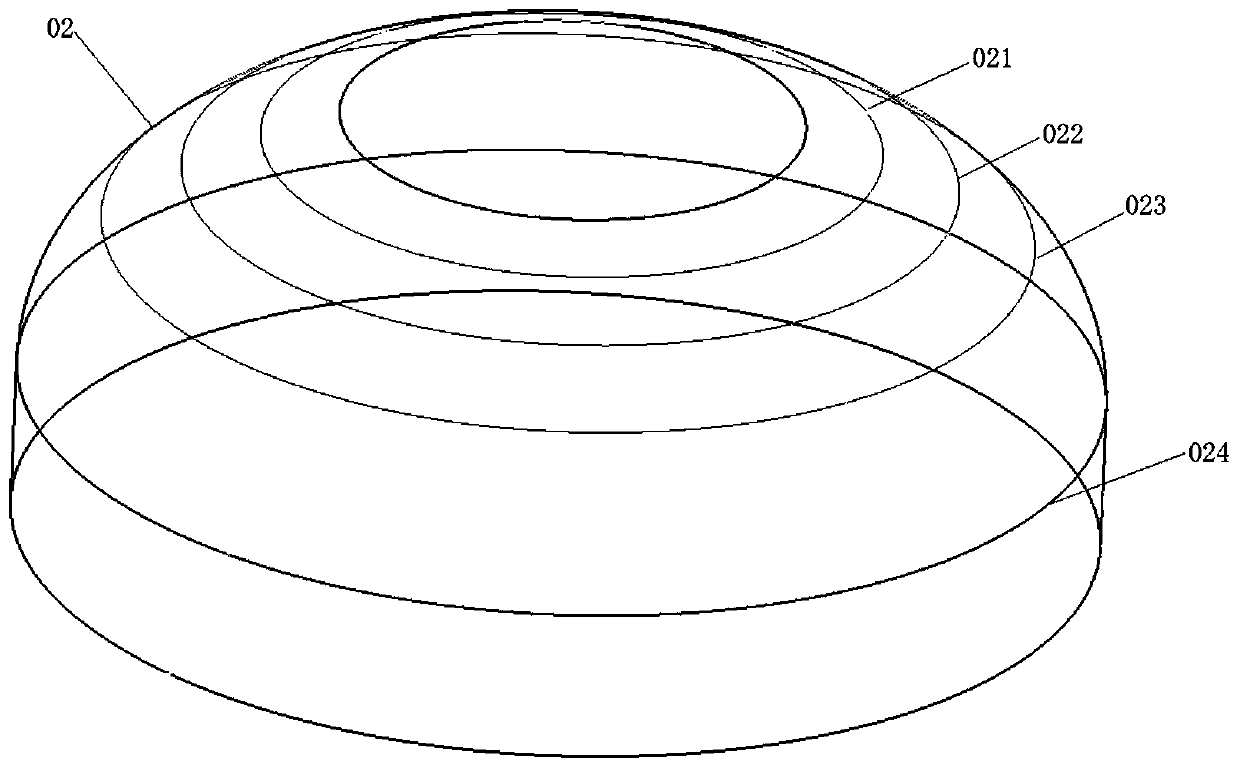

[0036] Obtain the shape information of the curved surface mandrel; according to the shape information, uniformly construct the laying angle reference line on the curved surface mandrel; calculate the length of the laying angle reference line; set the intersection angle between the prepreg fiber bundle and the laying angle reference line is the fiber bundle entry angle, and the fiber bundle entry angle is changed based on the length of the laying angle reference line, so that the length of the prepreg fiber bundle covering two adjacent laying angle reference lines is inversely proportional to the cosine of the fiber bundle entry angle.

[0037] The continuous equal-thickness layup method for curved surface molding in this embodiment is to construct a laying angle reference line on the curved surface of the curved surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com