Carbon nanotube/polypropylene composite powder material and preparation method for sls

A carbon nanotube composite and carbon nanotube technology, applied in the direction of additive processing, can solve the problems of irregular composite powder morphology, affecting the performance of SLS parts, and inability to uniformly disperse nano-fillers, and achieve good laser absorption rate. and thermal conductivity, improved laser sintering performance, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

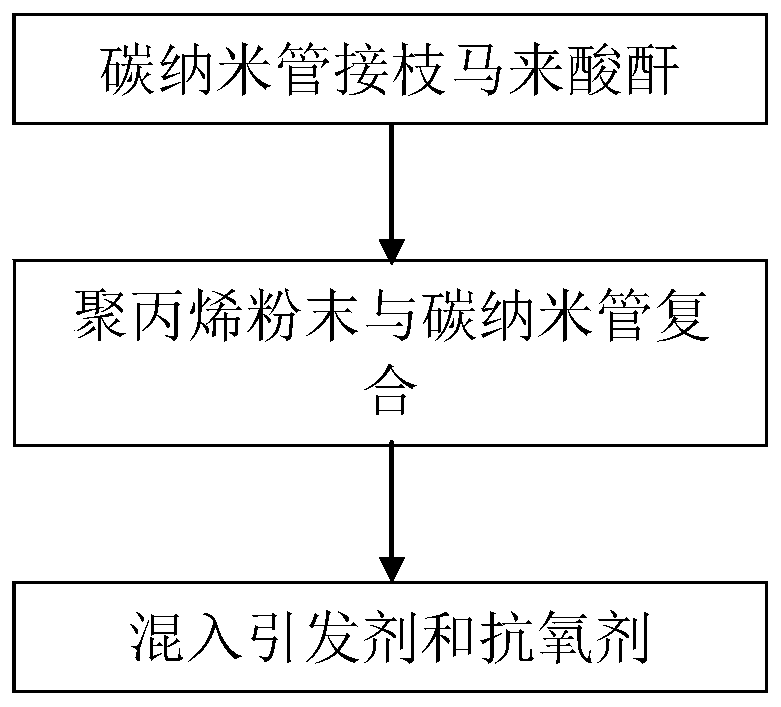

[0032] A method for preparing carbon nanotube / polypropylene composite powder for selective laser sintering provided by the present invention comprises the following steps:

[0033] 1) carbon nanotube grafted maleic anhydride treatment

[0034] Put hydroxylated carbon nanotubes, solvent ethyl acetate, maleic anhydride and catalyst perchloric acid into a three-necked flask at a ratio of 0.1g: 100mL: 1g: 10mL, use an ultrasonic disperser such as a bath type, and disperse ultrasonically in a water bath for 40 minutes , power 40-120W, then stirred and condensed and refluxed at 60°C for 4h at a stirring speed of 100-300rpm, filtered the product, washed with deionized water until neutral, and vacuum-dried at 50°C to constant weight.

[0035] The above-mentioned carbon nanotubes are hydroxylated multi-walled carbon nanotubes, the hydroxyl content is 1-5 wt%, and the purity is >95%.

[0036] 2) Composite polypropylene powder and carbon nanotubes

[0037]First, use an ultrasonic dispe...

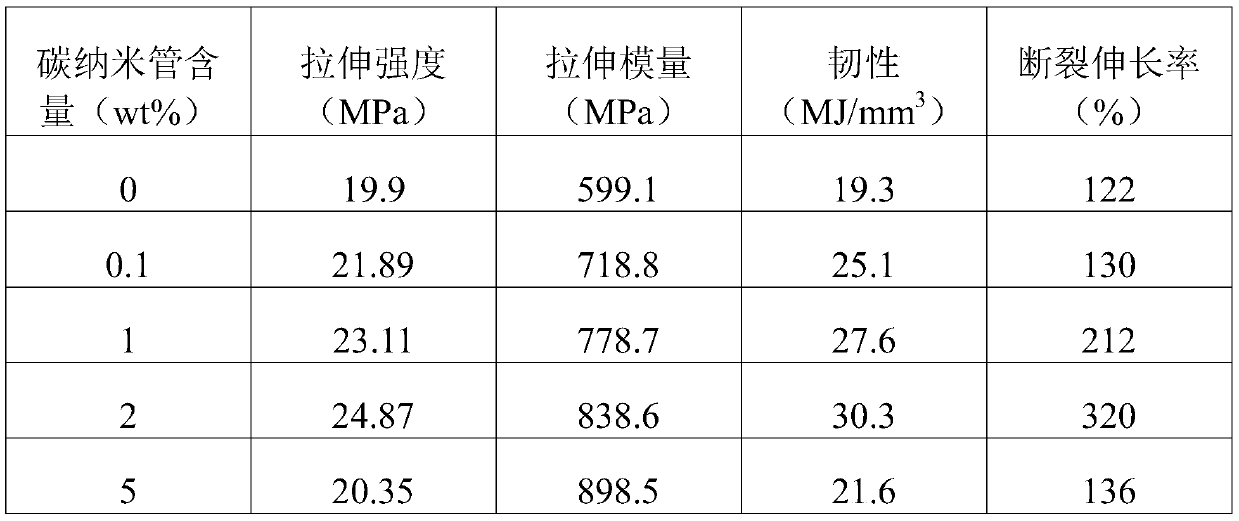

Embodiment 1

[0043] Embodiment 1: (the carbon nanotube mass fraction is the carbon nanotube / polypropylene composite powder of 0.1wt%)

[0044] 1) Put hydroxylated carbon nanotubes (1g), solvent ethyl acetate (1000mL), maleic anhydride (10g) and catalyst perchloric acid (100mL) into a three-necked flask, using an ultrasonic disperser (bath type), water bath Ultrasonic dispersion for 40min, power 40W; then stirring and condensing at 60°C for reflux for 4h at a stirring speed of 100rpm, the product was filtered, washed with deionized water, and vacuum-dried at 50°C to a constant weight state.

[0045] 2) Use an ultrasonic disperser (Tip type) to uniformly disperse the above 1g nanotubes in absolute ethanol, the concentration of carbon nanotubes is 1:5g / L, the power is 100W, and the ultrasonic treatment time is 30min; the particle size of 993g is 10μm polypropylene powder is slowly poured into the dispersed carbon nanotube solution at a speed of 6g / s, while stirring rapidly with a mechanical s...

Embodiment 2

[0048] Embodiment 2: (the carbon nanotube mass fraction is the carbon nanotube / polypropylene composite powder of 1wt%)

[0049] 1) Put hydroxylated carbon nanotubes (10g), solvent ethyl acetate (10000mL), maleic anhydride (100g) and catalyst perchloric acid (1000mL) into a three-necked flask, using an ultrasonic disperser (bath type), water bath Ultrasonic dispersion for 40min, power 80W; then stirring and condensing at 60°C for reflux for 4h at a stirring speed of 200rpm, filtering the product, washing with deionized water, and vacuum drying at 50°C;

[0050] 2) Use an ultrasonic disperser (Tip type) to uniformly disperse 10g of the above-mentioned carbon nanotubes in absolute ethanol, the concentration of carbon nanotubes is 1:2.5g / L, the power is 150W, and the ultrasonic treatment time is 30min; The polypropylene powder with a diameter of 90 μm is slowly poured into the dispersed carbon nanotube solution at a speed of 4 g / s, and at the same time, it is stirred rapidly by a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com