Carbon carrier for hydrogenation catalyst and preparation method thereof and palladium-system-supported hydrogenation catalyst and application thereof

A hydrogenation catalyst and carbon carrier technology, applied in the field of palladium-based supported hydrogenation catalysts, can solve the problems of complex methods and high costs, and achieve the effects of simple methods, low production costs, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This example is used to illustrate the carbon carrier of the present invention and its preparation method.

[0063] Mix 300g of phenolic resin, 30g of hexamethylenetetramine and 100g of starch into a kneader, then add 80mL of deionized water and knead for 10 minutes, and then extrude into a gear shape to obtain a carbon carrier precursor. The carbon carrier precursor was aged in air at room temperature for 12 hours, then dried at 80°C for 6 hours, then cured at 150°C for 12 hours, and finally carbonized at 650°C for 3 hours in a nitrogen atmosphere , so as to obtain the carbon support. The specific surface area of the carbon carrier is 465.61m 2 / g, the average pore diameter is 3.26nm. The strength of the carbon support is 83.5N / particle, and the total surface acidity is 0.19mmol / g.

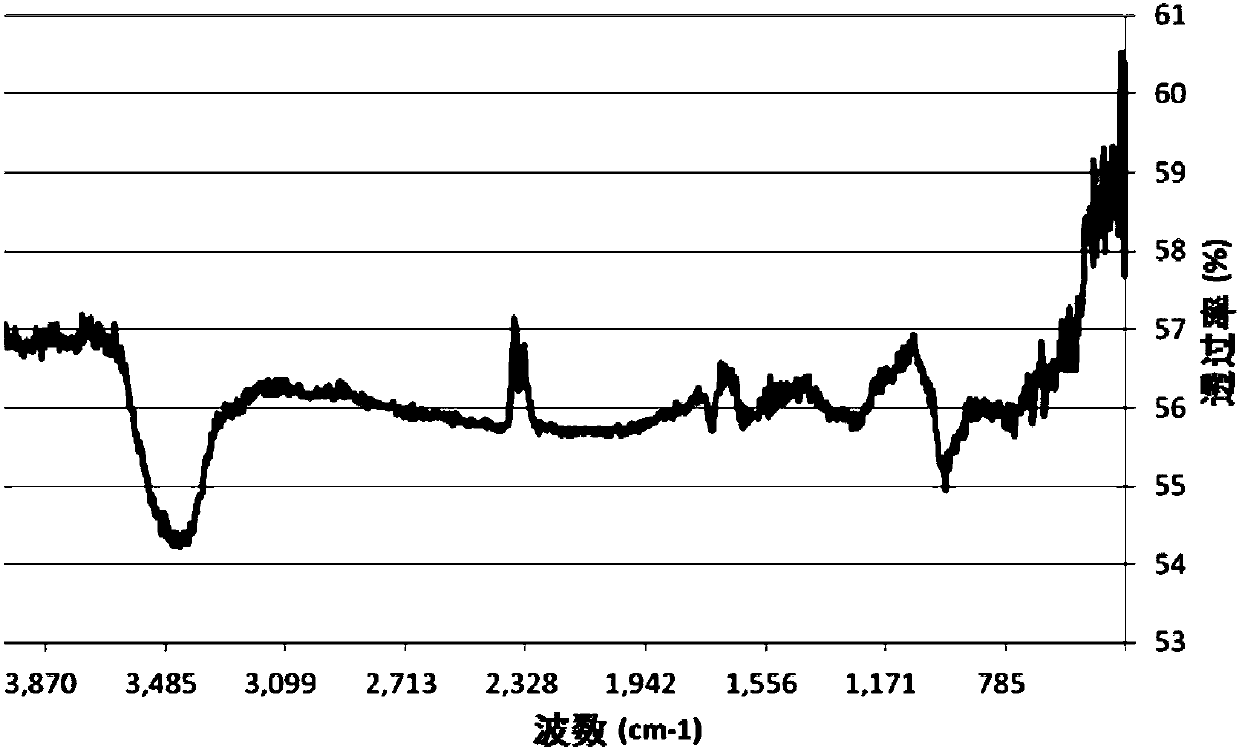

[0064] Using infrared spectroscopy to analyze the surface functional groups of the carrier, the results are as follows figure 1 As shown, as can be seen from the figure, the surface ...

Embodiment 2

[0066] This example is used to illustrate the carbon carrier of the present invention and its preparation method.

[0067] Weigh 240g of phenolic resin, 30g of hexamethylenetetramine, 60g of melamine formaldehyde resin and 60g of starch and mix them evenly into a kneader, then add 90mL of deionized water and knead for 5-15 minutes, and then extrude into a gear shape. Aging in air at room temperature for 12 hours, drying at 80°C for 6 hours, curing at 150°C for 12 hours, and carbonization at 650°C for 3 hours in a nitrogen atmosphere to obtain a carbon support. The specific surface area of the obtained carbon support is 414.10m 2 / g, the average pore diameter is 3.26nm; the measured strength of the carbon carrier is 96.4N / particle, and the total surface acidity is 0.17mmol / g.

Embodiment 3

[0069] This example is used to illustrate the palladium-based supported hydrogenation catalyst of the present invention.

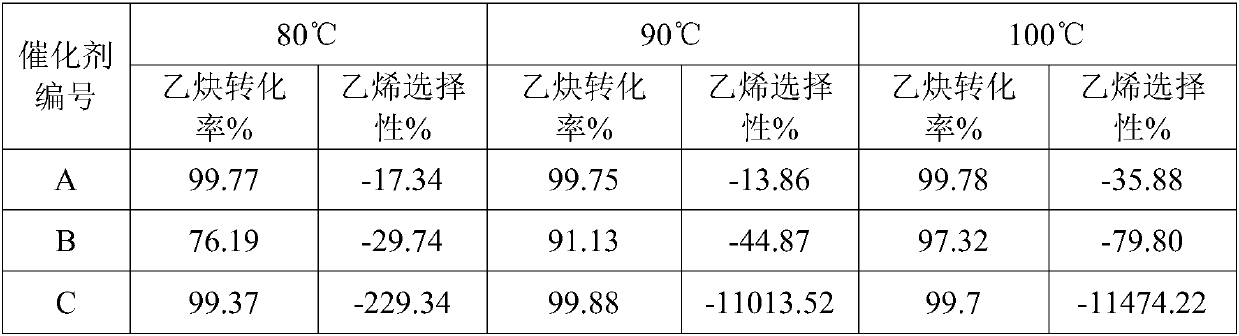

[0070] The carbon support 100g that adopts embodiment 1 to make, specific surface is 465.61m 2 / g. Measure 50mL of palladium nitrate solution containing 0.6mg / mL of palladium, mix it with 5mL of potassium lauryl polyoxyethylene ether phosphate glue containing 1wt% surfactant, and then impregnate it on the carbon support, and heat it at 120°C After drying for 12 hours, catalyst A was obtained, and the Pd content determined by atomic absorption spectrometry was 0.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com