Core cell structure, core with porous structure and sandwich energy absorption structure

A technology of porous structure and energy-absorbing structure, which is applied in the direction of layered products, metal layered products, transportation and packaging, etc., can solve the problems of impact resistance, shock absorption and buffering, and insufficient energy absorption, and achieve light weight, easy control, Good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

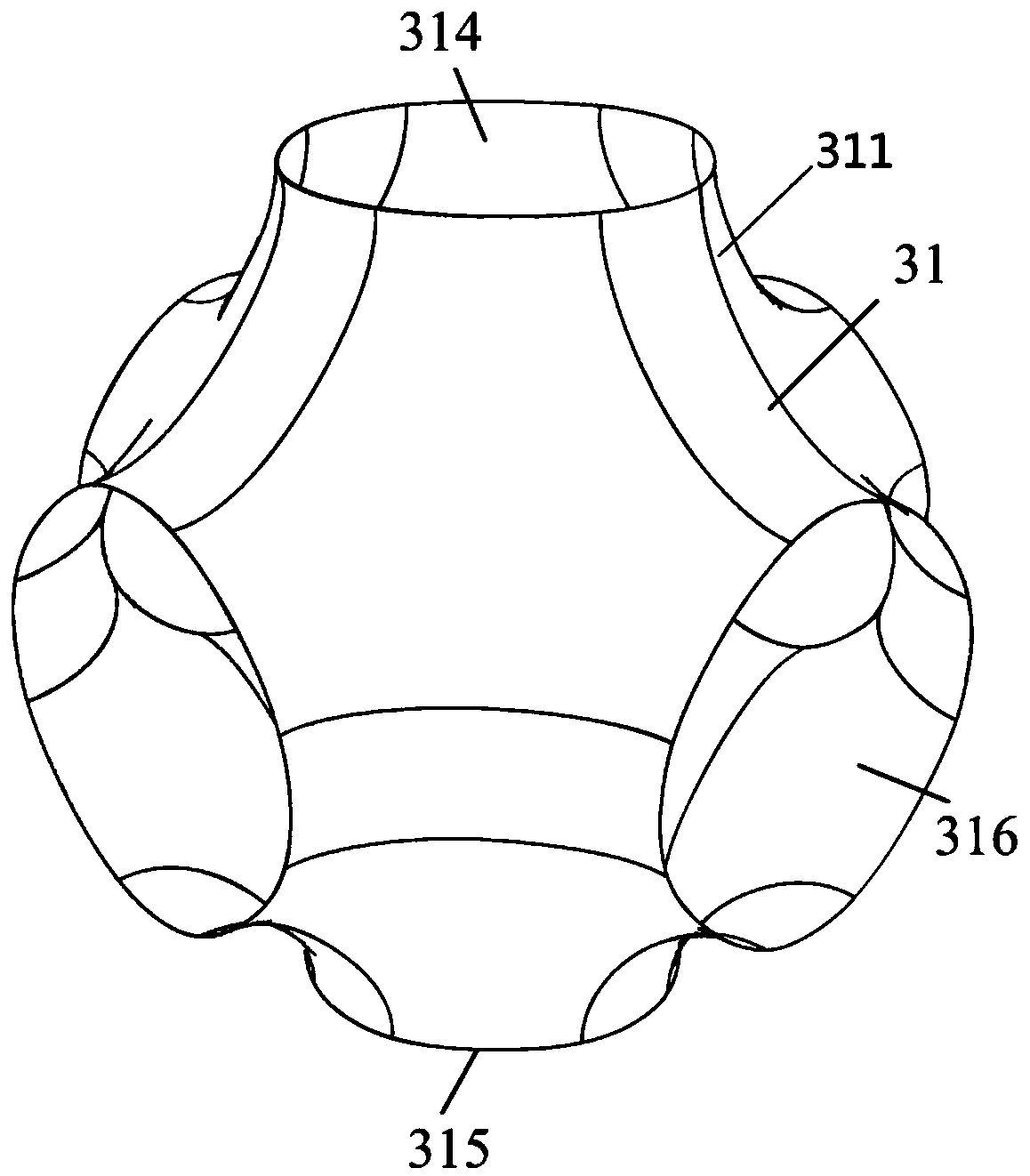

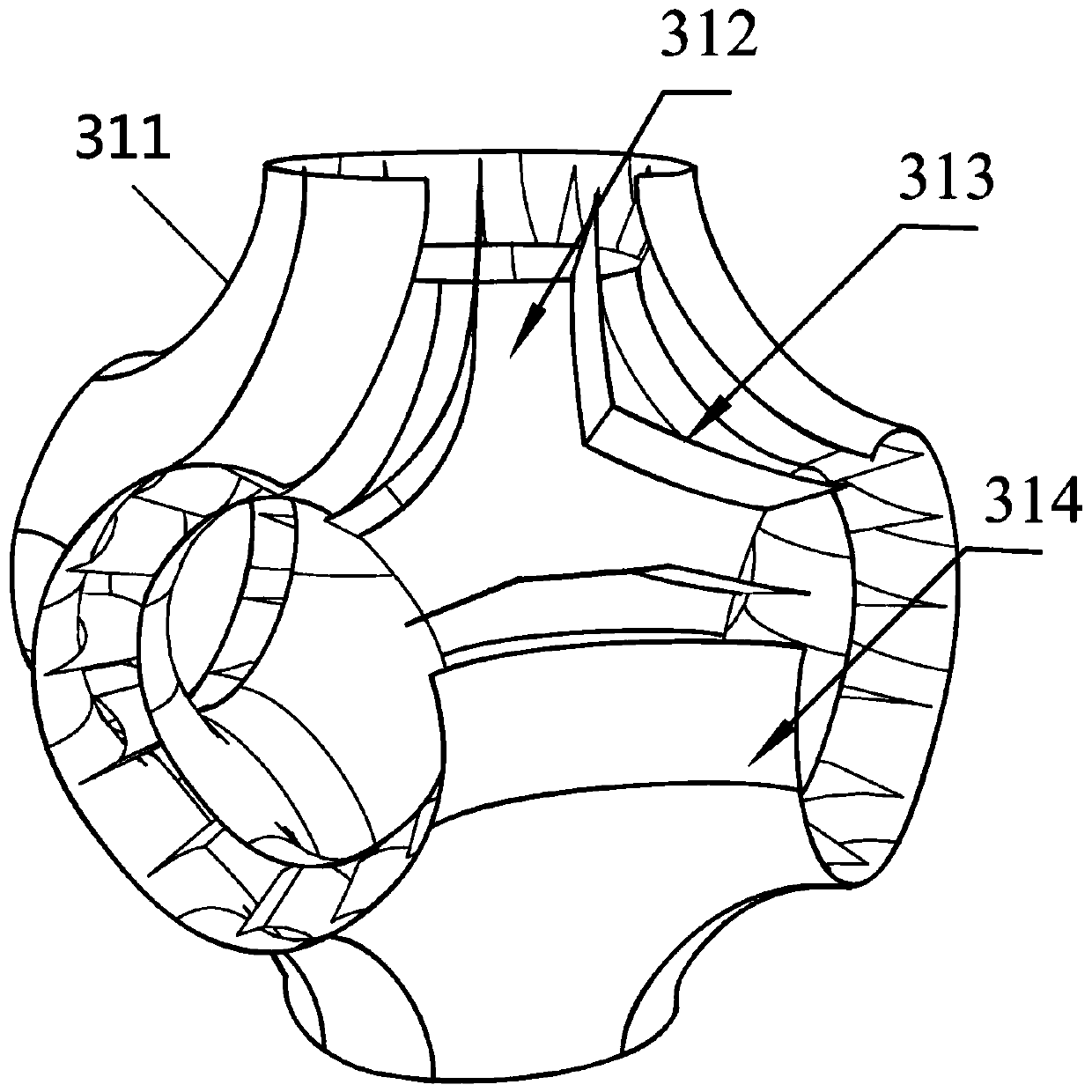

[0034] Such as figure 2 and image 3 As shown, the core cell structure of the present embodiment includes an outer layer 311 and an inner layer 312, and both the outer layer 311 and the inner layer 312 are three-period minimal curved surfaces (the three-period minimal curved surfaces are the average curvature extended to three-dimensional space zero surface, referred to as TPMS, where the three-period refers to the dimension extending to the surrounding space), a cavity is formed between the outer layer 311 and the inner layer 312, and a connection connecting the outer layer 311 and the inner layer 312 is provided in the cavity Plate 313 (such as a rib plate, which plays a role in connection and support); the outer layer 311 and the inner layer 312 are provided with an upper opening 314 and a lower opening 315 extending outward from the cavity, and the upper opening 314 and the lower opening 315 are arranged oppositely. Four side openings 316 extending out of the cavity are ...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 lies in the specific shapes of the first interlayer 1 and the second interlayer 2, such as Figure 5 As shown, in this embodiment, both the first interlayer 1 and the second interlayer 2 use curved panels, which are conveniently applicable to fields such as automobiles and aerospace. Of course, when the overall structure satisfies the energy absorption performance, the weight of the overall structure can be effectively reduced by increasing the weight reducing holes 4 and reducing the thickness of each interlayer. Other contents not described are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 lies in the specific shapes of the first interlayer 1 and the second interlayer 2, such as Figure 6 and Figure 7 As shown, in this embodiment, both the first interlayer 1 and the second interlayer 2 are circular tubes, and the porous structure core 3 is pasted between the outer tube and the inner tube. Other contents not described are the same as those in Embodiment 1, and will not be repeated here.

[0044] In summary, the porous structure core of the present invention (i.e. double-layer curved surface porous structure) makes sandwich structures such as sandwich flat panels, sandwich curved panels and sandwich pipes have higher energy absorption efficiency, thermal insulation, heat insulation performance, and sound insulation performance. Better, more multifunctional and comprehensive, which can meet the needs of high-tech industries such as aerospace and navigation. Of course, such a porous structure core bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com