Macroporous hydrogel as well as preparation method and application thereof

A hydrogel and gelatin technology, applied in the field of macroporous hydrogel and its preparation, can solve the problems of difficult to prepare hydrogel with super large pore size, unfavorable material biocompatibility, lack of uniform pore structure, etc., and achieve good application Prospects, excellent biocompatibility and degradability, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: a kind of hydrogel and preparation method thereof:

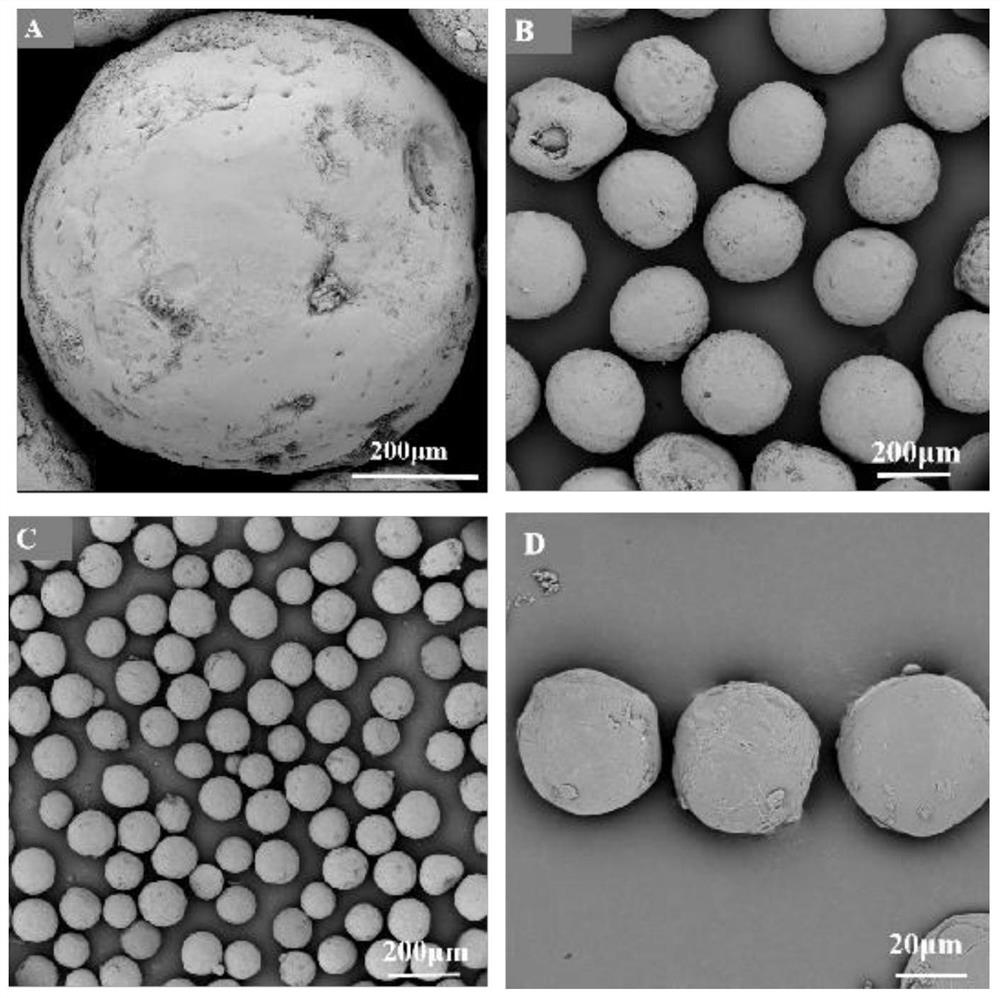

[0050] (1) Get 0.3g of gelatin microspheres with a particle size of about 230 μm and place them in a polytetrafluoroethylene mold, and gently tap the mold to make the gelatin microspheres tightly packed and smooth on the surface;

[0051] (2) Inject the ethanol solution into the stacked gelatin microspheres, and inject about 1 mL of ethanol solution with a volume concentration of 80% per gram of gelatin microspheres;

[0052] (3) Move the mold to a 70°C oven for 8 minutes;

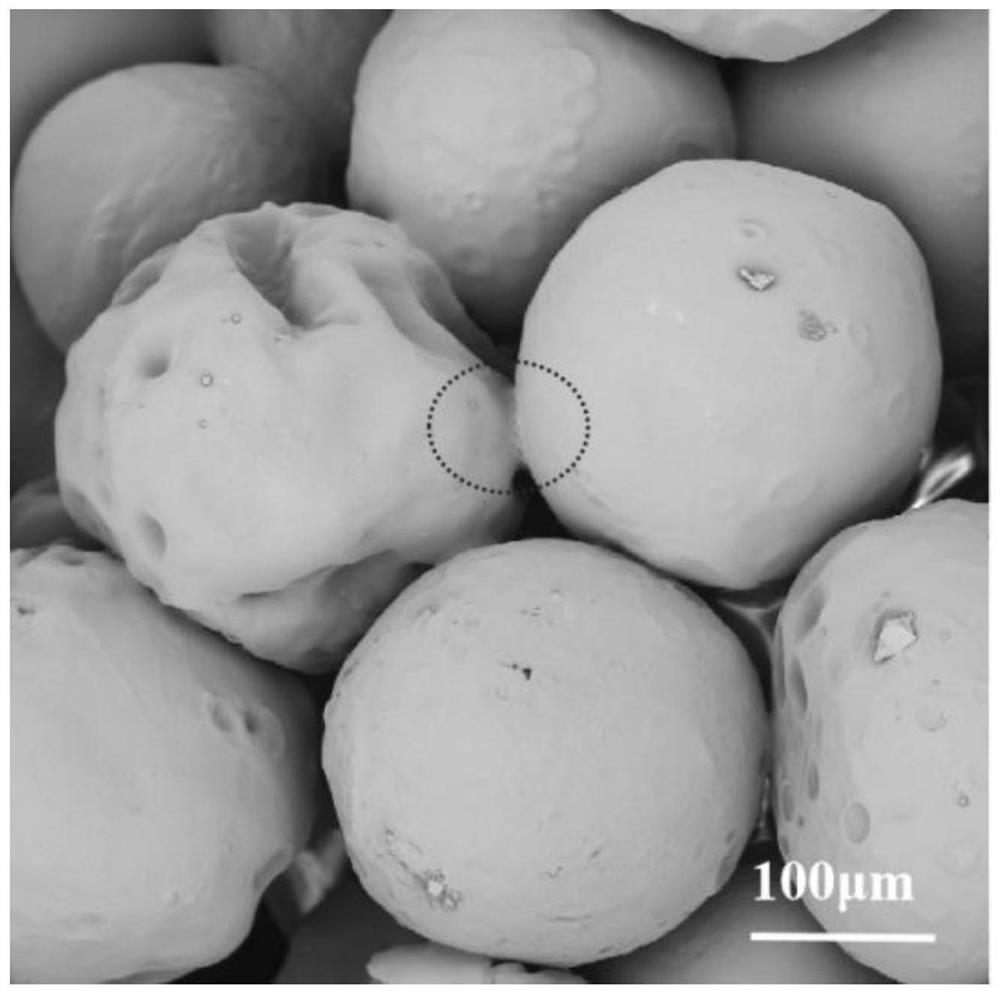

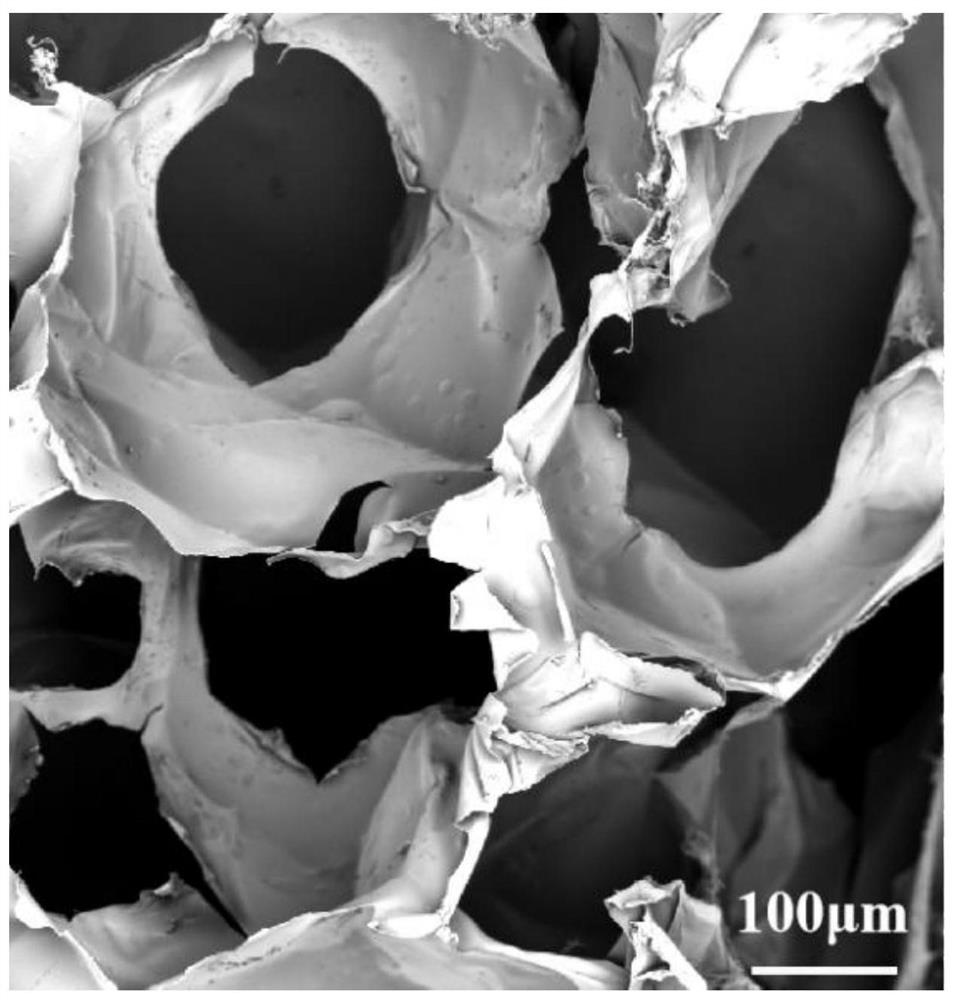

[0053] (4) Take out the mold and freeze-dry to obtain the mutually bonded gelatin microsphere template, and its SEM image is as follows figure 2 As shown, the adjacent microspheres are slightly bonded at the interface, forming a mutually bonded gelatin microsphere template;

[0054] (5) Put the gelatin microsphere template of step (4) into 1 mL of 2% bis In the bonded hyaluronic acid solution, under the condition of -0.08MPa, the...

Embodiment 2

[0056] Embodiment 2: a kind of hydrogel and preparation method thereof:

[0057] (1) Sieve out gelatin microspheres with a particle size of about 100 μm, take 0.2 g of gelatin microspheres with a particle size of about 100 μm and place them in a polytetrafluoroethylene mold, tap the mold gently to make the gelatin microspheres tightly packed and the surface smooth ;

[0058] (2) Inject the ethanol solution into the stacked gelatin microspheres, and inject about 1 mL of ethanol solution with a volume concentration of 80% per gram of gelatin microspheres;

[0059] (3) Move the mold to an oven at 80°C for 5 minutes;

[0060] (4) Take out the mold and freeze-dry to obtain interconnected gelatin microsphere templates;

[0061] (5) Mix 1% double-bond hyaluronic acid solution and 10% double-bond gelatin solution at a volume ratio of 10:1, add 0.1% phenyl-2,4,6-trimethylbenzoylphosphinic acid Lithium, to obtain a mixed solution; the gelatin microsphere template of step (4) is put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com