Hydrothermal method for preparing triclinic-phase FeVO4 micro particles

A technology of micron particles and triclinic phase, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., to achieve the effect of simple experimental steps, convenient operation, and regular appearance of target products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

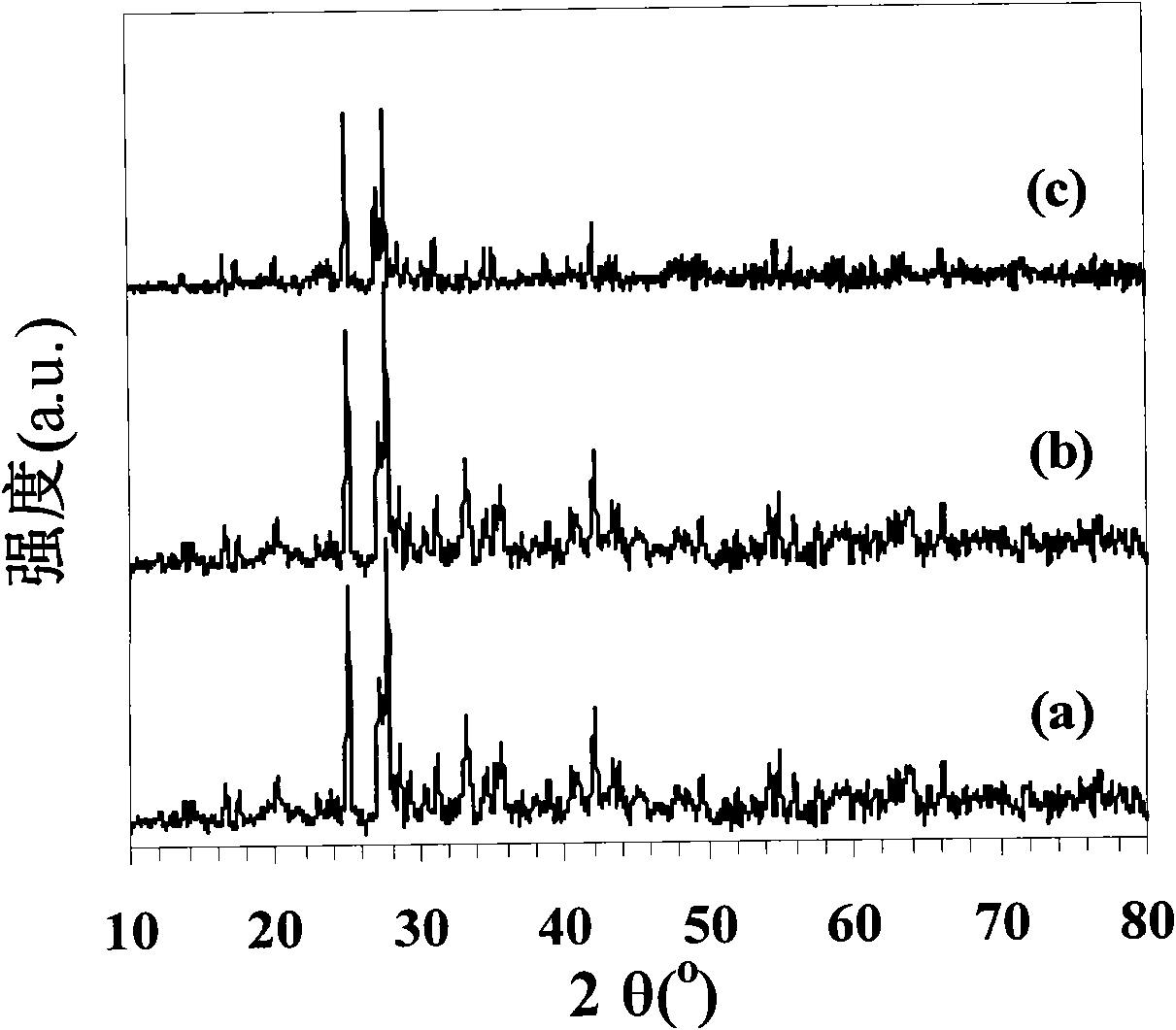

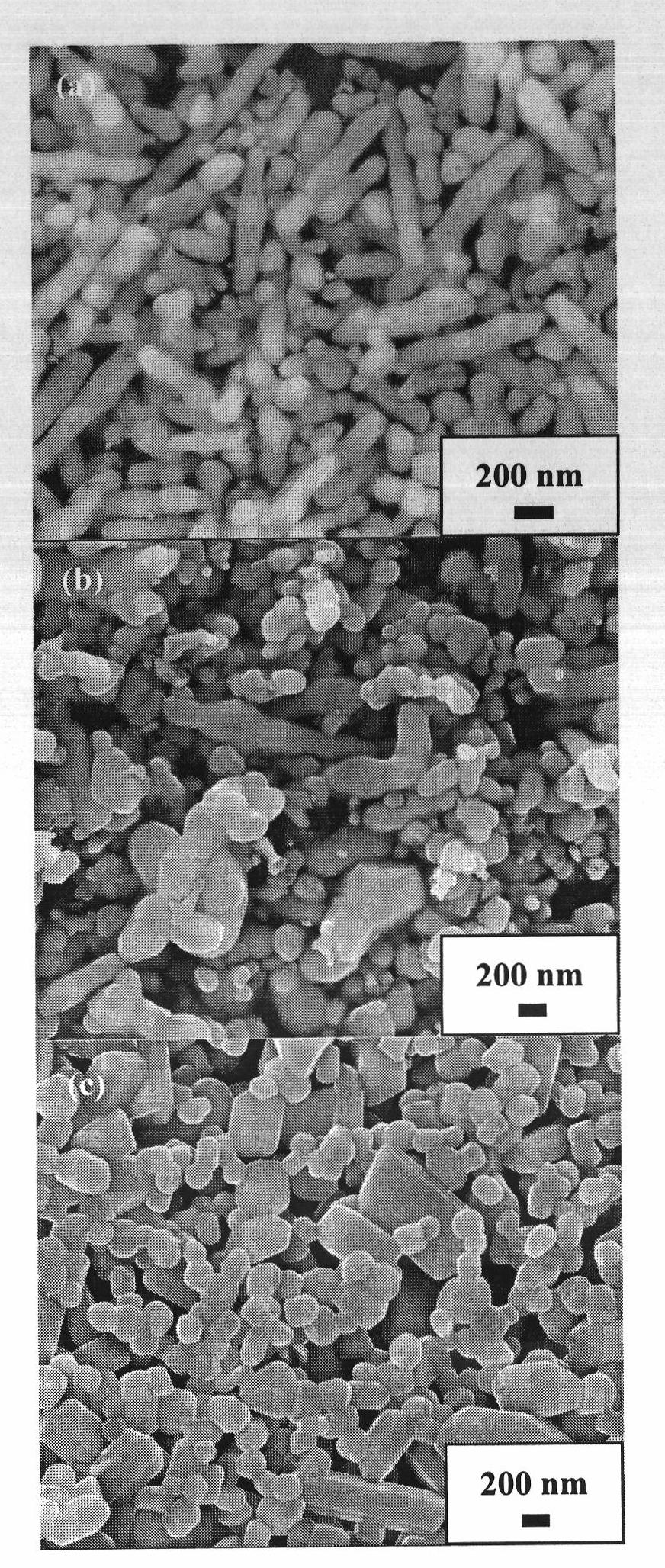

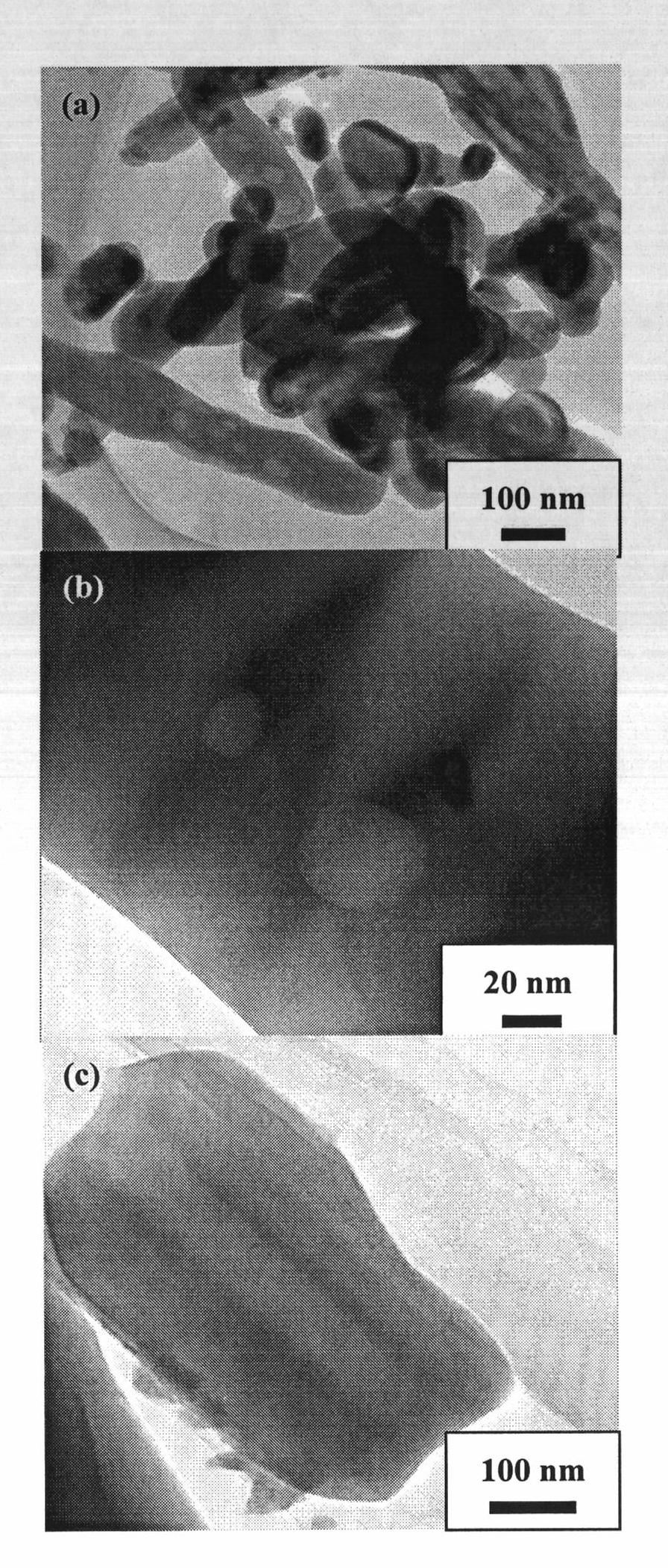

Embodiment 1

[0020] Embodiment 1: under stirring condition, 10mmol Fe(NO 3 ) 3 9H 2 O was added to 50mL HNO 3 Solution (concentration is 2mol / L), then add 10mmol NH 4 VO 3 , after being completely dissolved, a transparent brownish-yellow solution is obtained, and the pH value of the mixed solution is adjusted to 4 with 14wt% ammonia water, and the resulting suspension is transferred to an autoclave equipped with a polytetrafluoroethylene liner (volume is 100mL) (Volume filling degree 80%) was treated at a constant temperature of 180 ° C for 6 h, filtered by suction, washed with deionized water and absolute ethanol three times and dried at 100 ° C for 12 h, and then placed in a muffle furnace at 1 ° C / The rate of min is increased from room temperature to 600 °C and maintained at this temperature for 6 h, that is, the triclinic phase FeVO 4 Mesoporous microrods.

Embodiment 2

[0021] Embodiment 2: under stirring condition, 10mmol Fe(NO 3 ) 3 9H 2 O was added to 50mL HNO 3 Solution (concentration is 2mol / L), then add 10mmol NH 4 VO 3 , after being completely dissolved, a transparent brown-yellow solution is obtained, and the pH value of the mixed solution is adjusted to 7 with 14wt% ammonia water, and the resulting suspension is transferred to an autoclave equipped with a polytetrafluoroethylene liner (a volume of 100 mL) (Volume filling degree 80%) was treated at a constant temperature of 180 ° C for 6 h, filtered by suction, washed with deionized water and absolute ethanol three times and dried at 100 ° C for 12 h, and then placed in a muffle furnace at 1 ° C / The rate of min is increased from room temperature to 600 °C and maintained at this temperature for 6 h, that is, the triclinic phase FeVO 4 Mesoporous microrods.

Embodiment 3

[0022] Embodiment 3: under stirring condition, 10mmol Fe(NO 3 ) 3 9H 2 O was added to 50mL HNO 3 Solution (concentration is 2mol / L), then add 10mmol NH 4 VO 3 , after being completely dissolved, a transparent brownish-yellow solution is obtained, and the pH value of the mixed solution is adjusted to 4 with 14wt% ammonia water, and the resulting suspension is transferred to an autoclave equipped with a polytetrafluoroethylene liner (volume is 100mL) (Volume filling degree 80%) was treated at a constant temperature of 180 ° C for 2 h, filtered by suction, washed with deionized water and absolute ethanol three times and dried at 100 ° C for 12 h, and then placed in a muffle furnace under an air atmosphere at 1 ° C / The rate of min is increased from room temperature to 600 °C and maintained at this temperature for 6 h, that is, the triclinic phase FeVO 4 Non-porous micron block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com