Vacuum foaming preparation method of blister steel

A technology of vacuum foaming and steel foam, which is applied in the field of metal foam materials, and can solve the problems of limited product size, high cost, and difficult control of pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

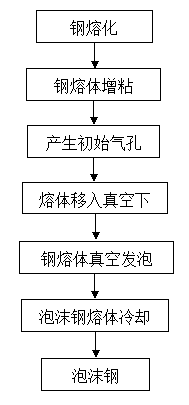

Method used

Image

Examples

Embodiment 1

[0063] (1) Heat carbon steel with a carbon content of 0.45% and a melting point of 1530-1480°C to 1560°C and keep it warm for 2 hours;

[0064] (2) First heat SiC to 1500°C and keep it warm for 3 hours, then add 15% of the steel volume SiC (particle size is 10 μm) to the molten steel after step (1) heat preservation, and then stir at a stirring speed of 2500r / min Viscosification 8min;

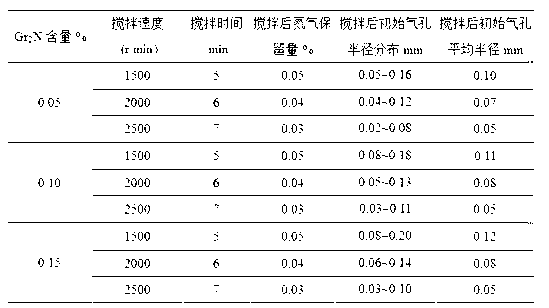

[0065] (3) Add Gr by 0.1% of the steel mass to the steel melt after step (2) viscosity increasing 2 N (particle size is 20μm), and then stirred at a stirring rate of 1500r / min for 5min to produce uniformly distributed, large number of initial pores with a pore size of 0.08-0.18mm in the steel melt;

[0066] (4) Cover and seal the melt obtained in step (3) and vacuumize it, and perform vacuum foaming at a vacuum degree of 5Pa for 10s;

[0067] (5) Cooling and solidifying the foamed steel melt after vacuum foaming in step (4) under vacuum conditions to finally obtain foamed steel with a porosit...

Embodiment 2

[0069] (1) Heat carbon steel with a carbon content of 0.20% and a melting point of 1530-1480°C to 1580°C and keep it warm for 2 hours;

[0070] (2) First heat SiC to 1500°C and keep it warm for 3 hours, then add SiC with 13% steel volume (particle size is 10 μm) to the molten steel after step (1) and keep it warm, and then stir at a stirring speed of 2000r / min Viscosification for 10 minutes;

[0071] (3) Add Gr by 0.15% of the steel mass to the steel melt after step (2) viscosity increasing 2 N (particle size is 20μm), and then stirred at a stirring rate of 2000r / min for 6min to produce uniformly distributed, large number of initial pores with a pore size of 0.05-0.13mm in the steel melt;

[0072] (4) Cover and seal the melt obtained in step (3) and vacuumize it, and perform vacuum foaming at a vacuum degree of 1Pa for 25s;

[0073] (5) Cooling and solidifying the foamed steel melt after vacuum foaming in step (4) under vacuum conditions to finally obtain foamed steel with a...

Embodiment 3

[0075] (1) Heat eutectoid carbon steel with a carbon content of 0.77% and a melting point of 1530-1480°C to 1530°C and keep it warm for 2 hours;

[0076] (2) First heat SiC to 1500°C and keep it warm for 3 hours, then add 10% of the steel volume SiC (particle size is 10μm) to the molten steel after step (1) and keep it warm, and then stir at a stirring speed of 1500r / min Viscosification for 15 minutes;

[0077] (3) Add Gr by 0.05% of the steel mass to the steel melt after step (2) viscosity increasing 2 N (particle size is 20μm), and then stirred at a stirring rate of 2500r / min for 8min to produce uniformly distributed, large number of initial pores with a pore size of 0.03-0.11mm in the steel melt;

[0078] (4) Cover and seal the melt obtained in step (3) and vacuumize it, and perform vacuum foaming at a vacuum degree of 10 Pa for 5 seconds;

[0079] (5) cooling and solidifying the foamed steel melt after vacuum foaming in step (4) under vacuum conditions to finally obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com