Method for manufacturing foamed aluminum board

A foamed aluminum plate and manufacturing method technology, applied in the field of material processing, can solve the problems of limited product shape, inability to effectively control and arbitrarily adjust foamed metal structure parameters, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

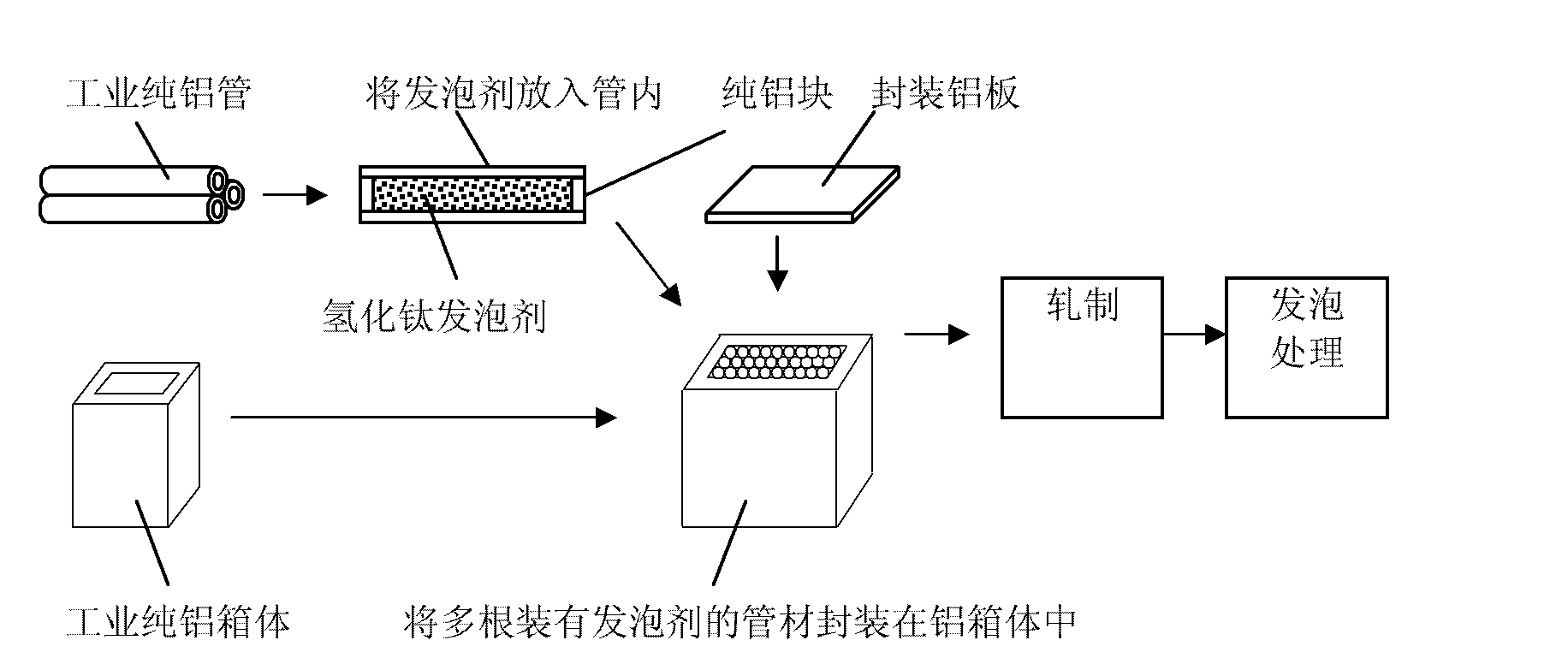

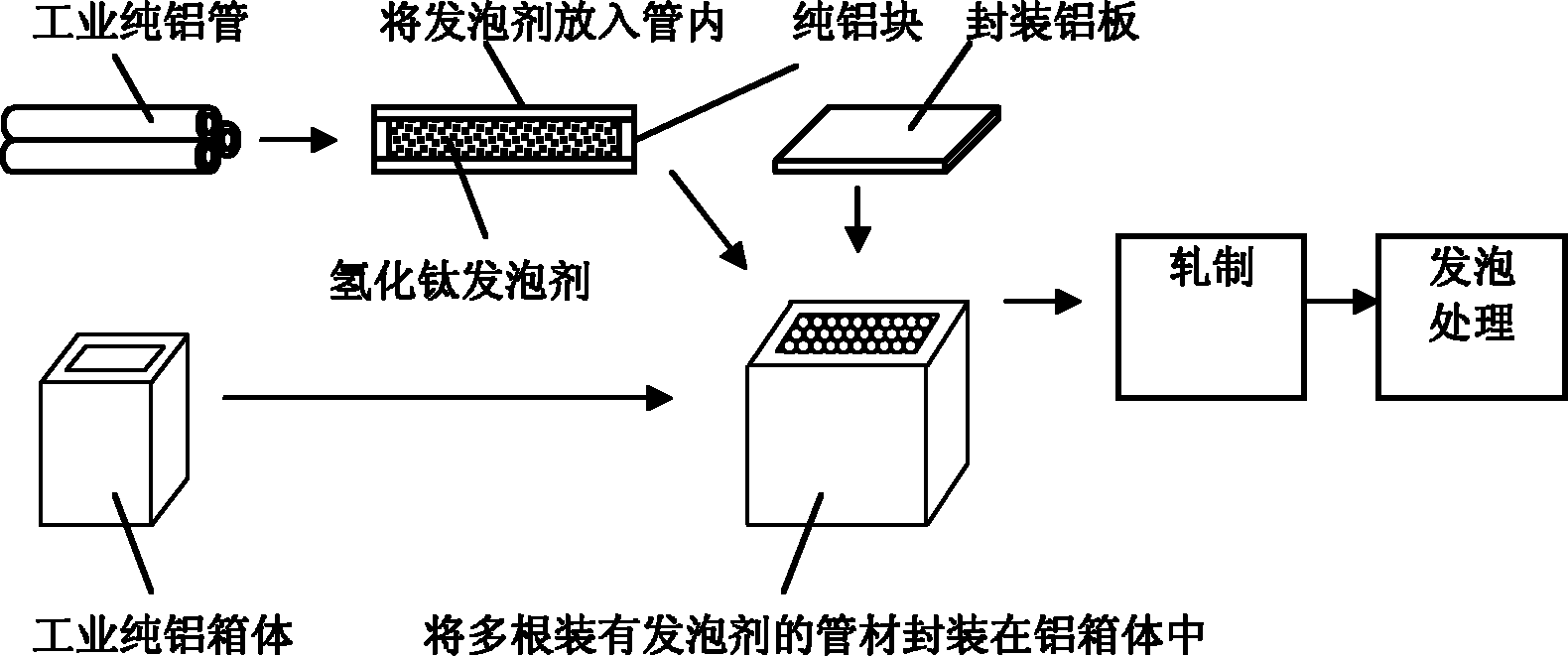

[0017] Embodiment 1: the manufacture of foamed aluminum sheet

[0018] 1. Chamber preparation

[0019] The industrial pure aluminum sheet with a thickness of 15mm is riveted to make an open box with an internal space of 900×500×300mm, and the cross-sectional size of the opening is 500×300mm.

[0020] 2. Encapsulate the blowing agent in the tube

[0021] Industrial pure aluminum pipe: inner diameter 10mm, wall thickness 5mm, cutting length 900mm. Seal one end of the pipe with an industrial pure aluminum block, the mass fraction of the foaming agent TiH2 is 2%, and the other is Al powder. Mix TiH2 and Al powder evenly at normal temperature and pressure and put them into the industrial pure aluminum pipe. After cold pressing, the foaming agent is sealed in the pipe with an ordinary aluminum block.

[0022] 3. Fabrication of aluminum foam precursor

[0023] Put 299 pieces of industrial pure aluminum pipes containing foaming agent titanium hydride powder into an open box made o...

Embodiment 2

[0026] Embodiment 2: the manufacture of foamed aluminum alloy plate

[0027] The difference from Example 1 is that the box body, pipe and pipe encapsulation materials are all 5083 aluminum alloy, and the heating temperature is 300°C when the aluminum alloy precursor is prepared by rolling method, and the foam is finally made into foam after foaming treatment Aluminum alloy sheet.

Embodiment 3

[0028] Example 3: Manufacture of 7075 aluminum alloy / foam aluminum / 7075 aluminum alloy sandwich composite plate

[0029] Compared with Example 1 and Example 2, the box material is 25mm thick 7075 aluminum alloy, the pipe and packaging materials are industrial pure aluminum, the heating temperature is 330°C, and the precursor with a thickness of 50mm is prepared by rolling method , and finally prepared into 7075 aluminum alloy / foam aluminum / 7075 aluminum alloy sandwich composite plate after foaming treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com