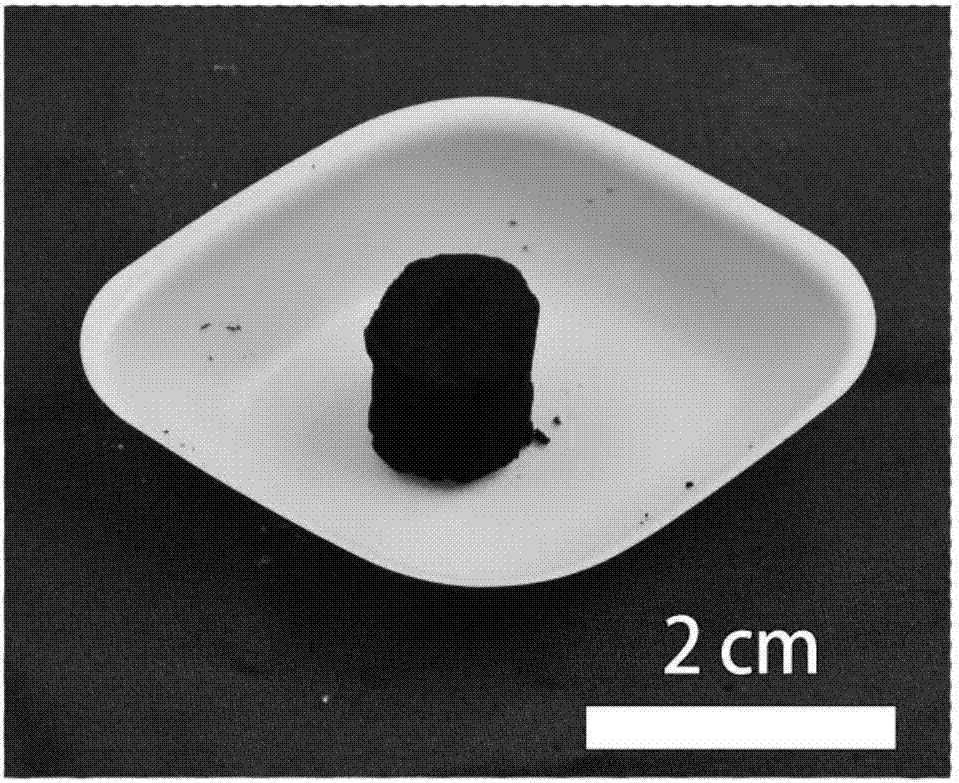

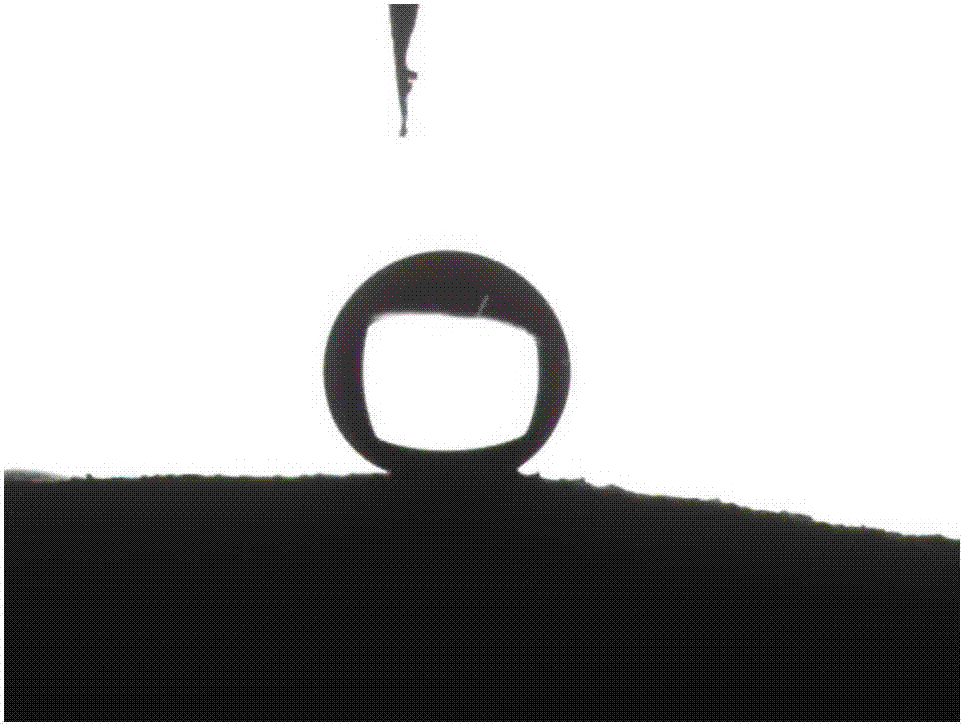

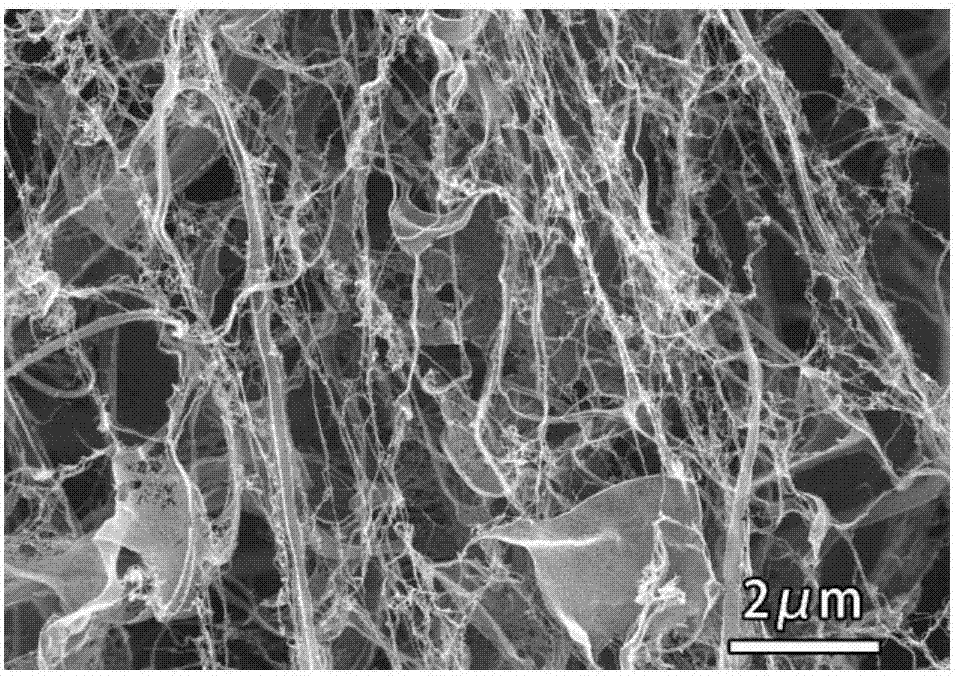

Three-dimensionalgraphene composite aerogel and preparation method thereof

A graphene composite and aerogel technology, applied in the directions of gel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of high cost of preparation methods, single structure, complicated operation, etc., and achieve rich porosity and simple equipment. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Rinse the bamboo purchased in the market, dry it and crush it through an 80-mesh sieve to obtain bamboo powder; take 1 g of the crushed bamboo powder, extract it with phenylethyl alcohol at a ratio of 1:2, remove some organic matter, and then adjust it with glacial acetic acid Add 1wt% NaClO under the condition of pH 4.5 2 Bleach by heating at 75°C for 1 hour;

[0047] 2. The bamboo powder after the bleaching is prepared as a 1wt% dispersion, and then the nanofiber dispersion is obtained by mechanical processing;

[0048] 3. Stir the 1wt% nanofiber solution obtained in step 2 on a magnetic stirrer at 500 rpm at room temperature and pressure for 10 minutes, and then use an ultrasonic pulverizer at 1000W for 20 minutes to obtain a uniformly dispersed nanofiber dispersion;

[0049] 4. The uniformly dispersed nanofibers obtained in step 3 are used for ion exchange and mechanical treatment, so that the surface of the nanofibers is grafted with positively charged PEI to o...

Embodiment 2

[0056] 1. The eucalyptus pulp purchased in the market is dried and pulverized through an 80-mesh sieve to obtain eucalyptus pulp powder; take 1 g of pulverized eucalyptus pulp powder, use phenylethyl alcohol to extract by 1:2, remove some organic matter, and then Use glacial acetic acid to adjust the pH to 4.5 and add 1wt% NaClO 2 Bleach by heating at 75°C for 1 hour;

[0057] 2. The bamboo powder after the bleaching is prepared as a 1wt% dispersion, and then the nanofiber dispersion is obtained by mechanical processing;

[0058] 3. Stir the 1wt% nanofiber solution obtained in step 2 on a magnetic stirrer at 500 rpm at room temperature and pressure for 5 minutes, and then process it with an ultrasonic pulverizer at 1200W for 10 minutes to obtain a uniformly dispersed nanofiber dispersion;

[0059] 4. The uniformly dispersed nanofibers obtained in step 3 are subjected to ion exchange and mechanical treatment, and the surface active agent CTAB is used to modify the surface with...

Embodiment 3

[0066] 1. Dried industrial waste crab shells and crushed them through an 80-mesh sieve to obtain crab shell powder; take 1g of crushed crab shell powder and extract them with phenylethyl alcohol at a ratio of 1:2 to remove some organic matter, and then use glacial acetic acid Adjust the pH to 4.5 by adding 1wt% NaClO 2 Bleach by heating at 75°C for 1 hour;

[0067] 2. Prepare the bleached crab shell powder as a dispersion with a weight fraction of 1 wt%, and then process it mechanically in combination with TEMPO pre-oxidation to obtain a nanofiber dispersion;

[0068] 3. Stir the 1wt% nanofiber solution obtained in step 2 on a magnetic stirrer at 300 rpm at room temperature and pressure for 5 minutes, and then process it with an ultrasonic pulverizer at 1200W for 10 minutes to obtain a uniformly dispersed nanofiber dispersion;

[0069] 4. The uniformly dispersed nanofibers obtained in step 3 are subjected to ion exchange and mechanical treatment, and the surfactant CTAB is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com