Preparation method for porous NiAl intermetallic compound

A technology of intermetallic compounds and alloys, applied in the field of porous materials, to achieve the effects of easy shape control, excellent high temperature oxidation resistance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

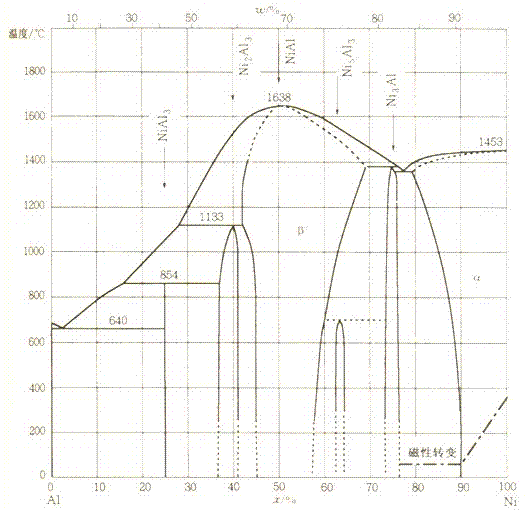

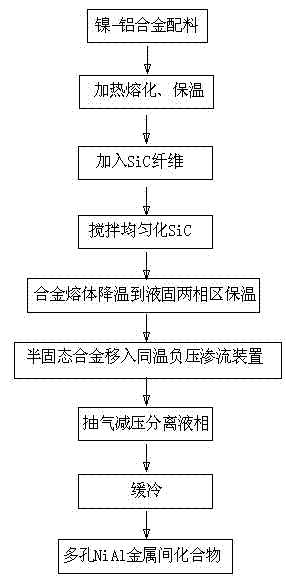

[0033] (1) Preparation of nickel-aluminum alloy melt: adopt industrial pure nickel and industrial pure aluminum as raw materials, prepare nickel-aluminum alloy according to the mass percentage of industrial pure nickel as 66%, and the mass percentage of industrial pure aluminum as 34%. The industrially pure nickel and industrially pure aluminum after batching are heated to 1640°C for melting and kept for 30 minutes to obtain a nickel-aluminum alloy melt;

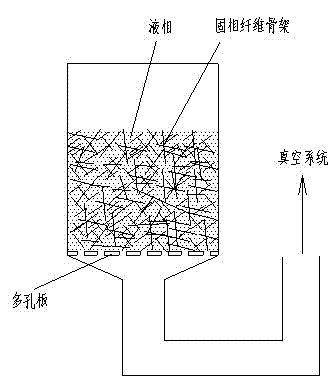

[0034] (2) Liquid-solid phase control of the nickel-aluminum alloy melt: add SiC fibers with a melt volume content of 2% to the nickel-aluminum alloy melt prepared in step (1) (the diameter of the SiC fiber is 0.5 μm, and the SiC fiber The length of the fiber is 1cm), and stirred for 3 minutes at a stirring speed of 1000 rpm, so that the SiC fibers were evenly dispersed in the nickel-aluminum alloy melt; the temperature of the nickel-aluminum alloy melt containing the SiC fiber was reduced to 1585 ° C and After 20 minutes of...

Embodiment 2

[0037] (1) Preparation of nickel-aluminum alloy melt: using industrial pure nickel and industrial pure aluminum as raw materials, according to the mass percentage of industrial pure nickel is 68%, the mass percentage of industrial pure aluminum is 32% to prepare nickel-aluminum alloy, will After batching, the industrial pure nickel and industrial pure aluminum are heated to 1650°C for melting and kept for 30 minutes to obtain a nickel-aluminum alloy melt;

[0038] (2) Liquid-solid phase control of the nickel-aluminum alloy melt: Add SiC fibers with a melt volume content of 3% to the nickel-aluminum alloy melt prepared in step (1) (the diameter of the SiC fiber is 1 μm, and the SiC fiber length of 2cm), stirred at a stirring speed of 700 rpm for 4 minutes, so that the SiC fibers were evenly dispersed in the nickel-aluminum alloy melt; the temperature of the nickel-aluminum alloy melt containing SiC fibers was reduced to 1615°C and kept In 20 minutes, the β′ solid phase (NiAl ph...

Embodiment 3

[0041] (1) Preparation of nickel-aluminum alloy melt: adopt industrial pure nickel and industrial pure aluminum as raw materials, prepare nickel-aluminum alloy according to the mass percentage of industrial pure nickel as 73%, and the mass percentage of industrial pure aluminum as 34%. After batching, the industrial pure nickel and industrial pure aluminum are heated to 1720°C for melting and kept for 30 minutes to obtain a nickel-aluminum alloy melt;

[0042](2) Liquid-solid phase control of the nickel-aluminum alloy melt: Add SiC fibers with a melt volume content of 4% to the nickel-aluminum alloy melt prepared in step (1) (the diameter of the SiC fiber is 2 μm, and the SiC fiber length is 3cm), stirred at a stirring speed of 500 rpm for 5 minutes, so that the SiC fibers were evenly dispersed in the nickel-aluminum alloy melt; the temperature of the nickel-aluminum alloy melt containing SiC fibers was reduced to 1600°C and kept In 20 minutes, the β′ solid phase (NiAl phase) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com