Hierarchical porous polylactic acid material and preparation method thereof

A polylactic acid and multi-level porous technology, which is applied in the field of polylactic acid multi-level porous materials and their preparation, can solve the problems of difficult control of pore structure, poor mechanical strength, poor connectivity, etc., and achieves increased porosity, low production cost, and improved The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of polylactic acid hierarchical porous material of the present invention, comprises the following steps:

[0032] Step 1. Composite polylactic acid, micron particles and inorganic nanoparticles to obtain a polylactic acid composite material, wherein the mass percent of polylactic acid is 40-70wt%, and the mass percent of micron particles is 10-57wt%, preferably 10-45wt% %, inorganic nanoparticles 3-20wt%;

[0033] Step 2. Stretch the polylactic acid composite material obtained in step 1 through unidirectional or biaxial stretching, the stretching temperature is 55-70°C, the unidirectional stretching ratio is 2.0-4.5 times, and the bidirectional stretching ratio is (1×1) -(3 * 3), obtain polylactic acid hierarchical porous material;

[0034] When uniaxially stretched, a polylactic acid hierarchically porous material in the form of olive-shaped hierarchical pores is obtained, and when biaxially stretched, a polylactic acid hierarchically poro...

Embodiment 1

[0043]PLA (trade name is Natureworks 4032D, D-type lactic acid unit content is 2%, weight average molecular weight is 207KDa), micron silica (average particle diameter is 2μm) and nanometer silica (primary particle average particle diameter is 15nm) According to the weight ratio of 50 / 40 / 10, at 175 ° C, melt blending in an internal mixer at a speed of 60 rpm for 10 minutes, and then made into a sheet, in a universal tensile testing machine at 65 ° C, with a thickness of 5 mm / min rate, stretched 2.7 times, the obtained pore shape is olive-shaped PLA hierarchical porous material.

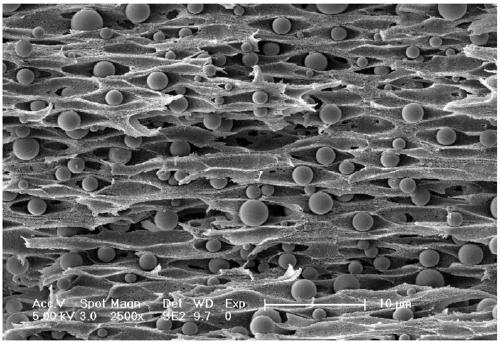

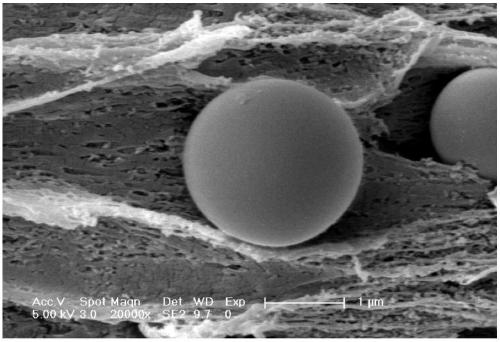

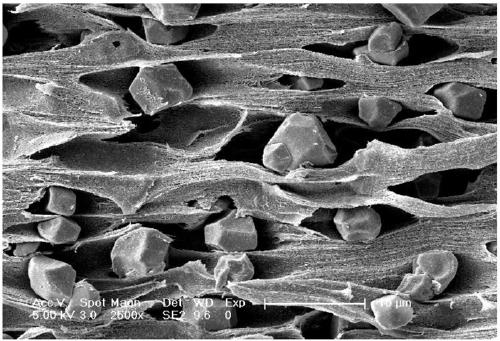

[0044] After the brittle section of the PLA hierarchical porous material obtained in Example 1 is sprayed with gold, the morphology of the hierarchical porous material obtained by SEM observation is as follows: figure 1 with figure 2 shown. It can be seen from the figure that olive-shaped macropores with a long axis of 5 μm are formed around the microparticles, and olive-shaped micropores with a l...

Embodiment 2

[0046] PLA (trade name is Natureworks 4032D, D-type lactic acid unit content is 2%, weight-average molecular weight is 207KDa), micron calcium carbonate (average particle diameter is 5 μm) and nano silicon dioxide (primary particle average particle diameter is 15nm) by The weight ratio is 60 / 30 / 10, at 175°C, melt blending at a speed of 60 rpm in an internal mixer for 10 minutes, and then made into a sheet, at 65°C in a universal tensile testing machine, at 5mm / The rate of min is stretched 2.7 times, and the pore shape is olive-shaped PLA hierarchical porous material with a porosity of 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com