Polyacrylonitrile/polyacrylic acid nanofiber lithium sulfur battery diaphragm with controllable pore structure

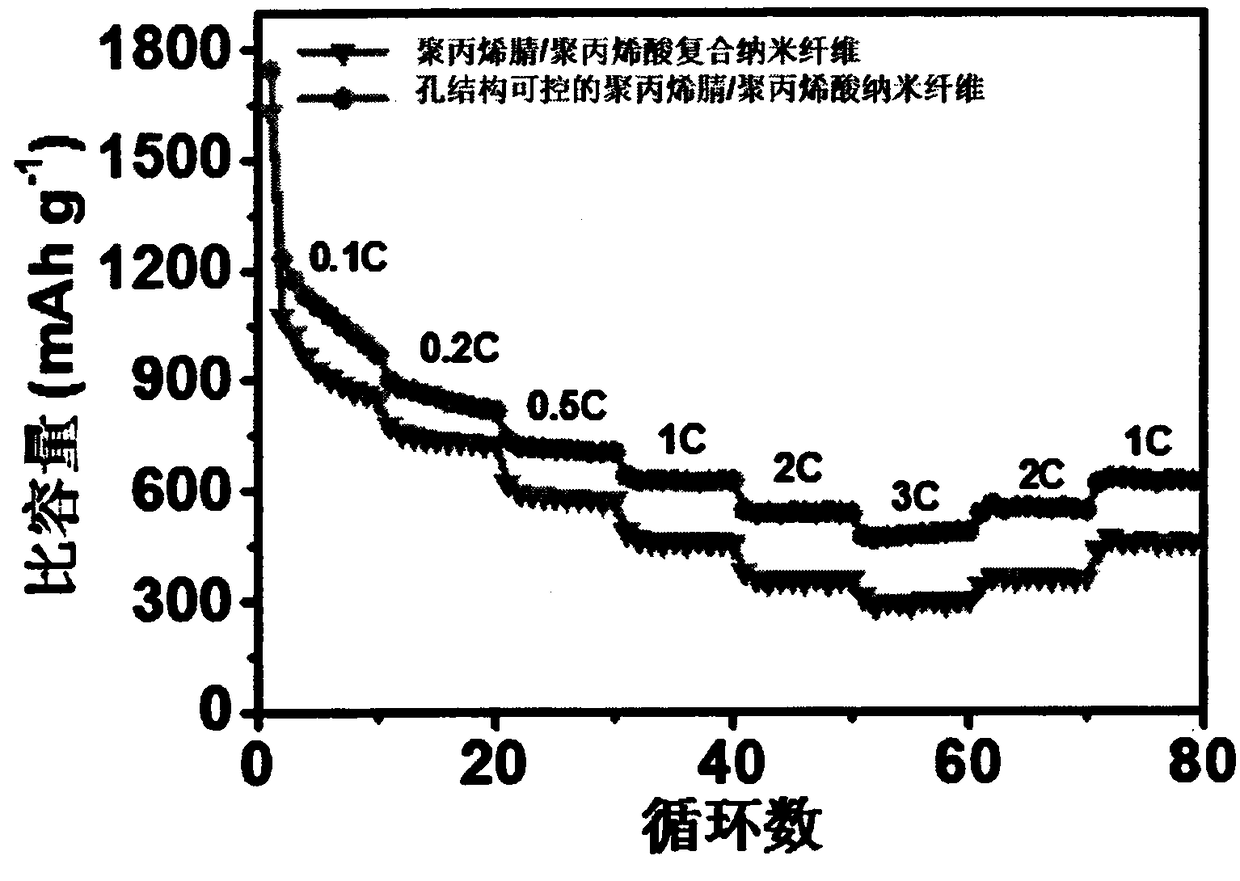

A technology of polyacrylonitrile and polyacrylic acid, applied in the direction of nanotechnology, fiber type, structural parts, etc., can solve the problems of polysulfides not having a good inhibitory effect, capacity decay and poor cycle stability, etc., to achieve fast and effective The preparation method, the pore size distribution can be adjusted, and the effect of small density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A polyacrylonitrile / polyacrylic acid nanofiber lithium-sulfur battery separator with controllable pore structure, the preparation method of which is as follows:

[0038]Step 1: Prepare an electrospun polyacrylonitrile / polyacrylic acid composite nanofiber membrane by electrospinning: use N,N-dimethylformamide (Shanghai Lingfeng Chemical Reagent Co., Ltd., ≥99.5%) as a solvent, Weigh polyacrylonitrile (sigma-aldrich, 181315-100G), polyacrylic acid (sigma-aldrich, 181285-100G) and N,N-dimethylformamide in a mass ratio of 6:4:90, and polyacrylonitrile 1. Add polyacrylic acid to N, N-dimethylformamide, place it on a stirring table and stir and dissolve at room temperature (25° C.) at a speed of 700 rpm for 12 hours to obtain a mixed spinning solution; at an ambient temperature of 25 ± 2 degrees Celsius, under the condition of 35 ± 3% air humidity, take 5 milliliters of mixed spinning solution and pour it into a 5 milliliter syringe to control the amount of spun fibers; the s...

Embodiment 2

[0045] Similar to the polyacrylonitrile / polyacrylic acid composite nanofiber with controllable pore structure of Example 1, the difference is: the ratio of polyacrylonitrile, polyacrylic acid and N, N-dimethylformamide in Example 1 is changed to 8:2:90, the obtained product is labeled as polyacrylonitrile / polyacrylic acid composite nanofiber with controllable pore structure-1.

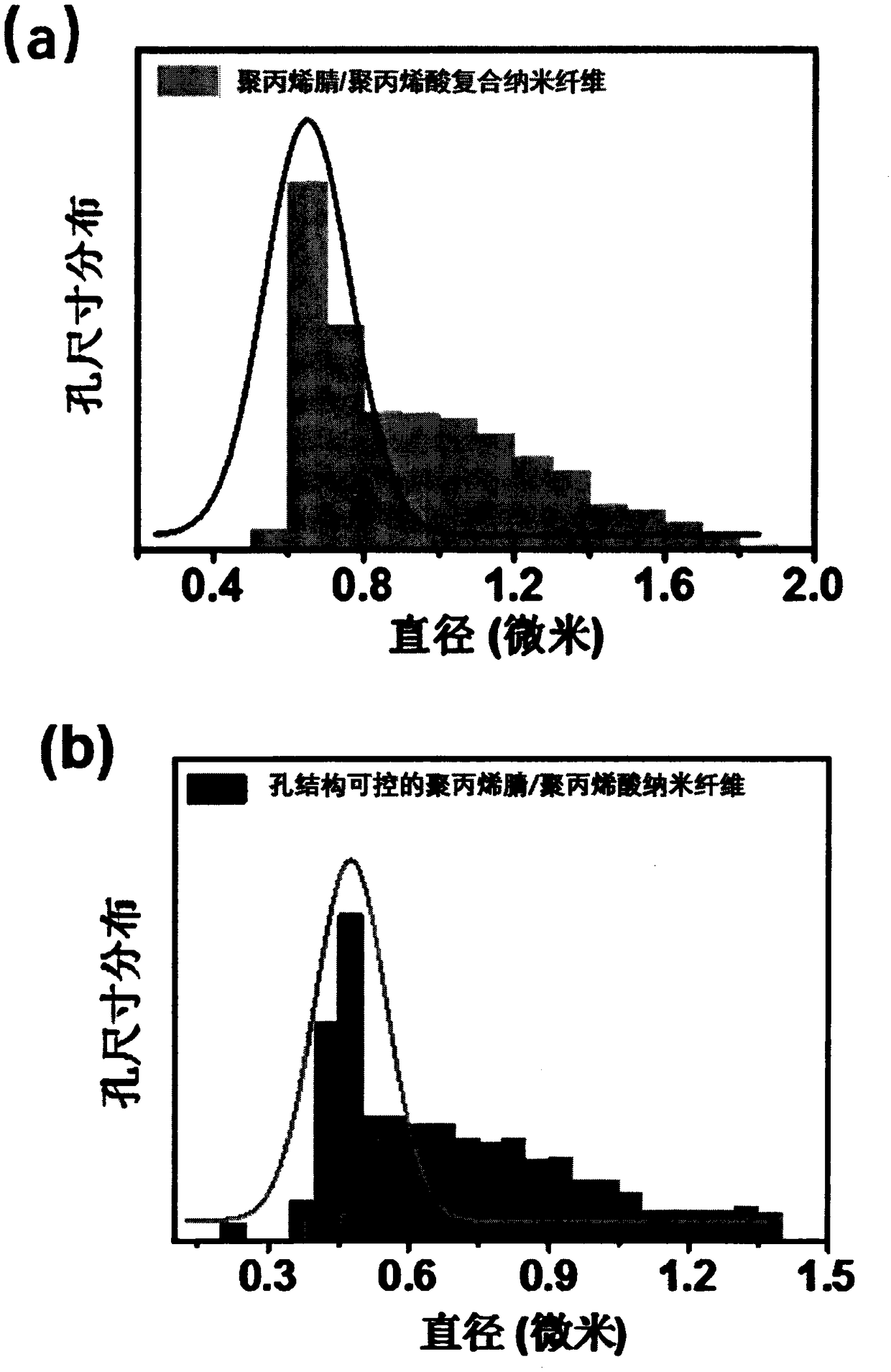

[0046] The fiber diameter of the electrospun polyacrylonitrile / polyacrylic acid composite nanofiber membrane is 0.4-0.5 microns, the porosity is 90.5%, and the pore size distribution of the fiber membrane is 0.4-2.0 microns. The polyacrylonitrile / polyacrylic acid nanofiber lithium-sulfur battery diaphragm with controllable pore structure has a fiber diameter of 0.3-0.8 microns, a porosity of 37.1%, and a fiber membrane pore size distribution of 0.4-1.3 microns.

Embodiment 3

[0048] Similar to the polyacrylonitrile / polyacrylic acid nanofiber with controllable pore structure of Example 1, the difference is: the ratio of polyacrylonitrile, polyacrylic acid and N,N-dimethylformamide in Example 1 is changed to 4 :6:90, the obtained product is labeled as polyacrylonitrile / polyacrylic acid nanofiber-3 with controllable pore structure.

[0049] The fiber diameter of the electrospun polyacrylonitrile / polyacrylic acid composite nanofiber membrane is 0.8-0.9 microns, the porosity is 83.9%, and the pore size distribution of the fiber membrane is 0.3-1.3 microns. The polyacrylonitrile / polyacrylic acid nanofiber lithium-sulfur battery diaphragm with controllable pore structure has a fiber diameter of 0.7-1.2 microns, a porosity of 19.6%, and a fiber membrane pore size distribution of 0.2-0.8 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com