Method for preparing three-dimensional network nanoporous copper

A nanoporous copper, three-dimensional network technology, applied in nanotechnology and other directions, can solve the problems of too large pore size of nanoporous copper, failure to obtain nanoporous copper, long dealloying time, etc., to achieve simple operation, suitable for large-scale Industrial production, the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

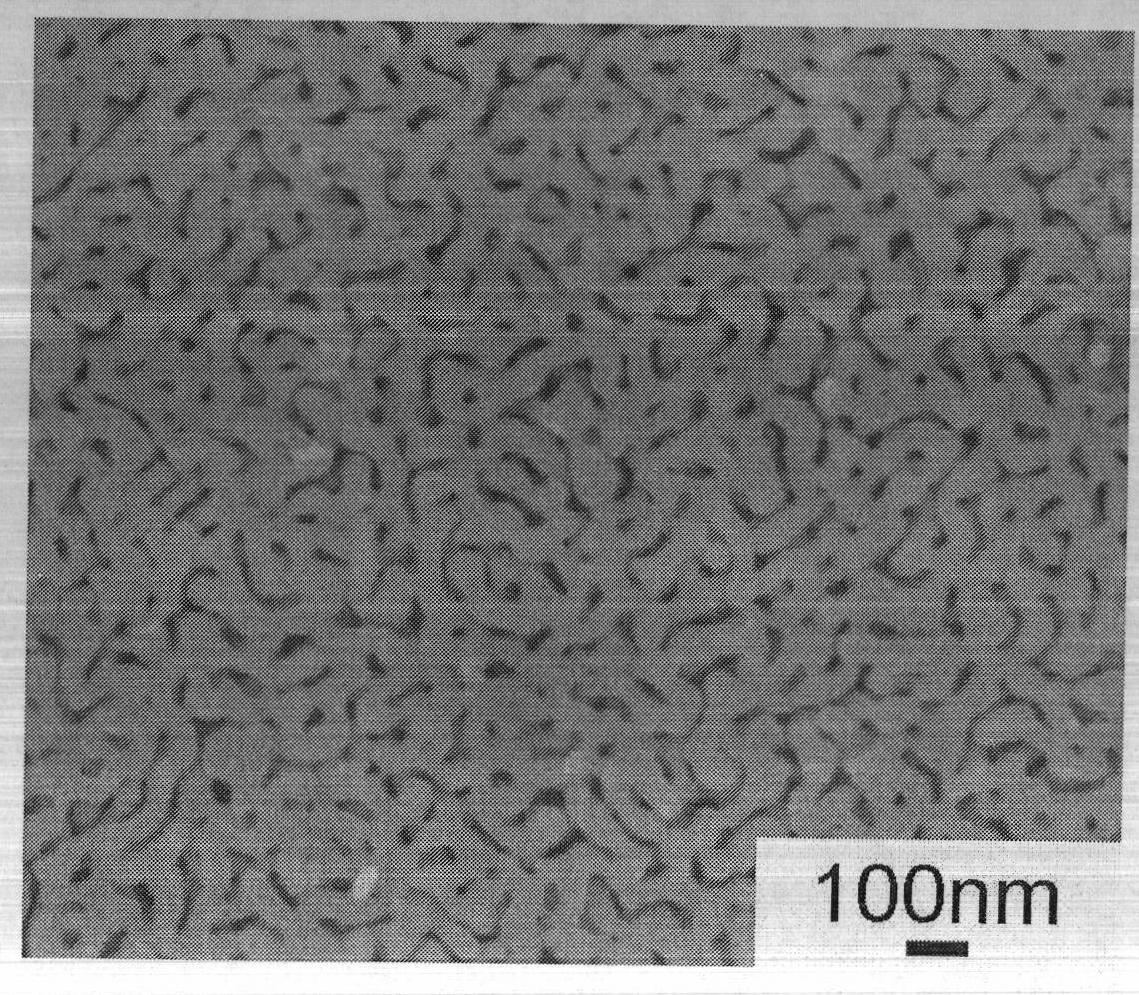

[0019] In terms of atomic percentage, Mn is 80%, Cu is 20%, and the raw materials are in powder form. Weigh the corresponding quality, mix the weighed powder in a planetary ball mill for 5 hours, then place the mixed material in a copper mold equipped with a copper substrate and press it into a blank under a pressure of 60MPa with a press, Melted into a master alloy in a vacuum arc melting furnace. The alloy is re-melted, and the molten metal is blown out with argon gas at a pressure of 0.5Mpa, and rapidly cooled on a high-speed rotating copper roller to obtain an alloy thin strip with a thickness of about 25μm, a width of 2-4mm, and a length of 10-100mm . After reacting with 0.3mol / L hydrochloric acid solution at room temperature for 4 hours, no air bubbles were generated. Rinse it several times with distilled water, then soak it in distilled water for 4 hours, take it out and put it in a vacuum drying oven for drying. Porous copper with uniform structure can be obtained. ...

Embodiment 2

[0021] In terms of atomic percentage, Mn is 50%, Cu is 50%, and the raw materials are in powder form. Weigh the corresponding quality, mix the weighed powder in a planetary ball mill for 5 hours, then place the mixed material in a copper mold equipped with a copper substrate and press it into a blank under a pressure of 60MPa with a press, Melted into a master alloy in a vacuum arc melting furnace. The alloy is re-melted, and the molten metal is blown out with argon gas at a pressure of 0.5Mpa, and rapidly cooled on a high-speed rotating copper roller to obtain an alloy thin strip with a thickness of about 25μm, a width of 2-4mm, and a length of 10-100mm . After reacting with 0.5mol / L hydrochloric acid solution at room temperature for 8 hours, no air bubbles are generated. Rinse it several times with distilled water, then soak it in distilled water for 4 hours, take it out and put it in a vacuum drying oven for drying. Porous copper with uniform structure can be obtained. T...

Embodiment 3

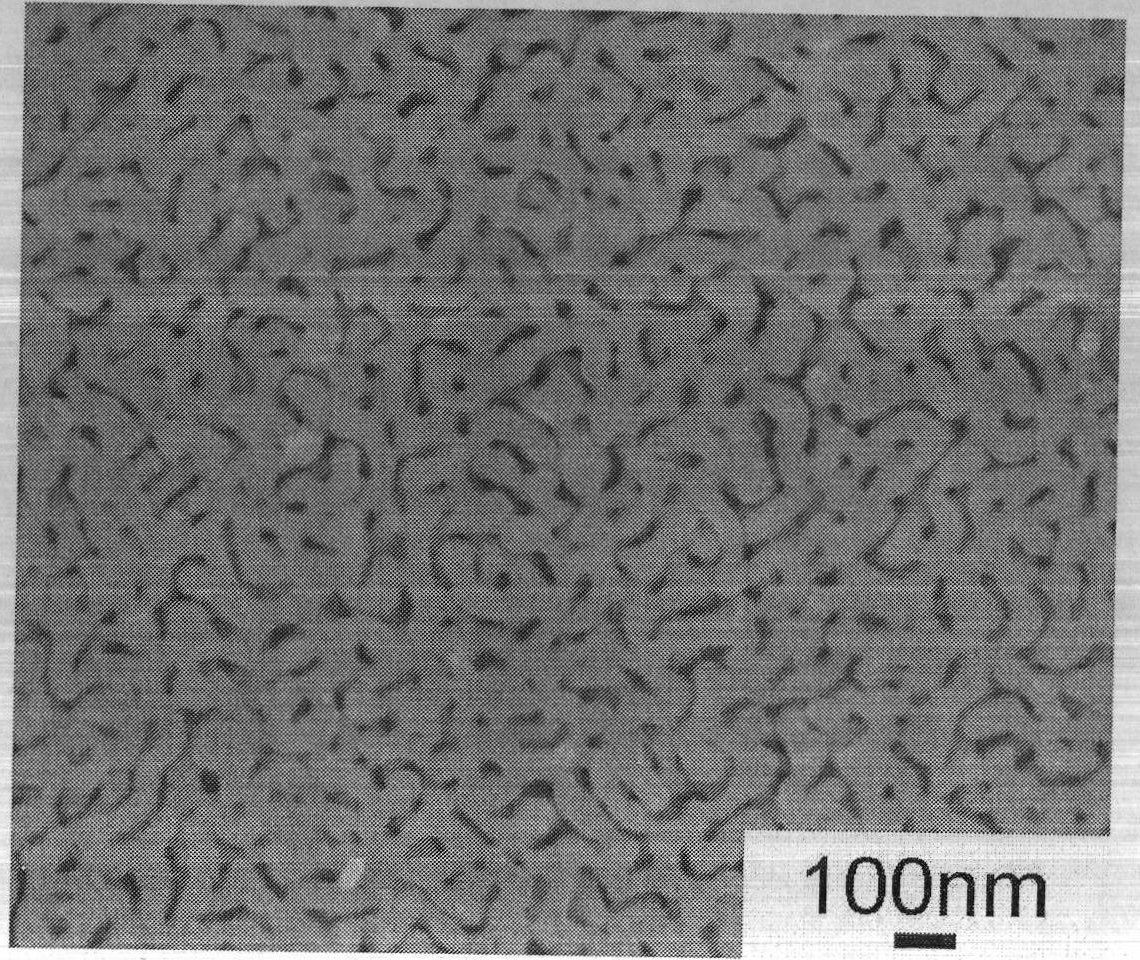

[0023] In terms of atomic percentage, Mn is 80%, Cu is 20%, and the raw materials are in powder form. Weigh the corresponding quality, mix the weighed powder in a planetary ball mill for 5 hours, then place the mixed material in a copper mold equipped with a copper substrate and press it into a blank under a pressure of 60MPa with a press, Melted into a master alloy in a vacuum arc melting furnace. The alloy is re-melted, and the molten metal is blown out with argon gas at a pressure of 0.5Mpa, and rapidly cooled on a high-speed rotating copper roller to obtain an alloy thin strip with a thickness of about 25μm, a width of 2-4mm, and a length of 10-100mm . After reacting with 0.3mol / L hydrochloric acid solution at 90±5°C for 8 hours, no air bubbles will be generated. Rinse with distilled water several times, then soak in distilled water for 4 hours, take it out and put it in a vacuum drying oven to dry. Porous copper with uniform structure can be obtained. The aperture liga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com