Powder X-ray diffraction method for determining magnesium aluminate spinel phase content in catalyst

A magnesia-aluminum spinel, X-ray technology, applied in the direction of material analysis using radiation diffraction, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following embodiments, the following The experimental method that does not indicate specific condition in the embodiment, generally according to routine condition.

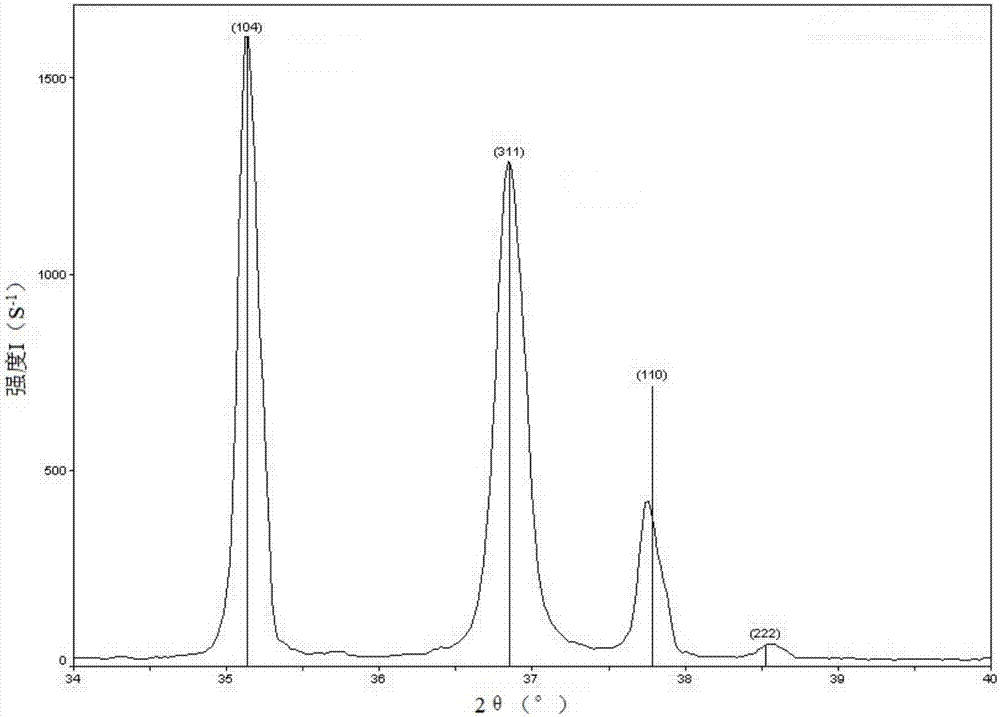

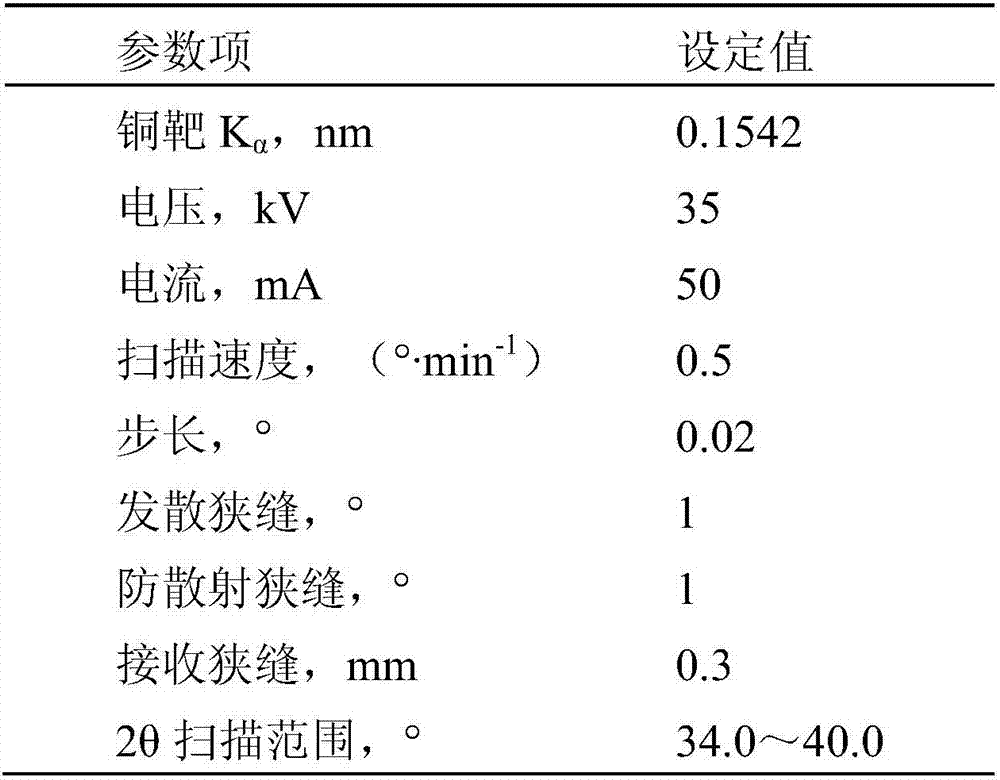

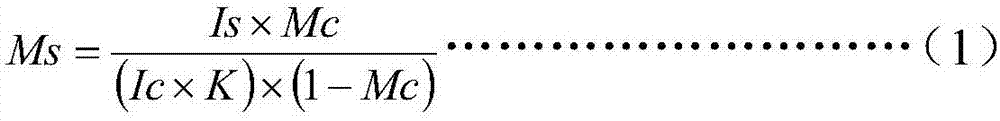

[0045] combine figure 1 , and further specifically describe the powder X-ray diffraction process for determining the content of the magnesium-aluminum spinel phase in the biofuel hydrogenation catalyst through the examples, including:

[0046] 1. Sample preparation

[0047] Take about 1.0 g of the sample to be tested, grind it finely, and sieve it (10 μm ~ 15 μm). Take about 0.5 g of 10 μm ~ 15 μm sieve for later use.

[0048] Preparation of mixed standard samples: Take 0.5 g of the standard sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com