Patents

Literature

37 results about "Calcium hexaboride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium hexaboride (sometimes calcium boride) is a compound of calcium and boron with the chemical formula CaB₆. It is an important material due to its high electrical conductivity, hardness, chemical stability, and melting point. It is a black, lustrous, chemically inert powder with a low density. It has the cubic structure typical for metal hexaborides, with octahedral units of 6 boron atoms combined with calcium atoms. CaB₆ and lanthanum-doped CaB₆ both show weak ferromagnetic properties, which is a remarkable fact because calcium and boron are neither magnetic, nor have inner 3d or 4f electronic shells, which are usually required for ferromagnetism.

High-purity high-conductivity oxygen-free copper rod and processing method thereof

InactiveCN106180616AImprove craftsmanshipSolve the problem of the utilization of renewable resourcesLithium oxideInsulation layer

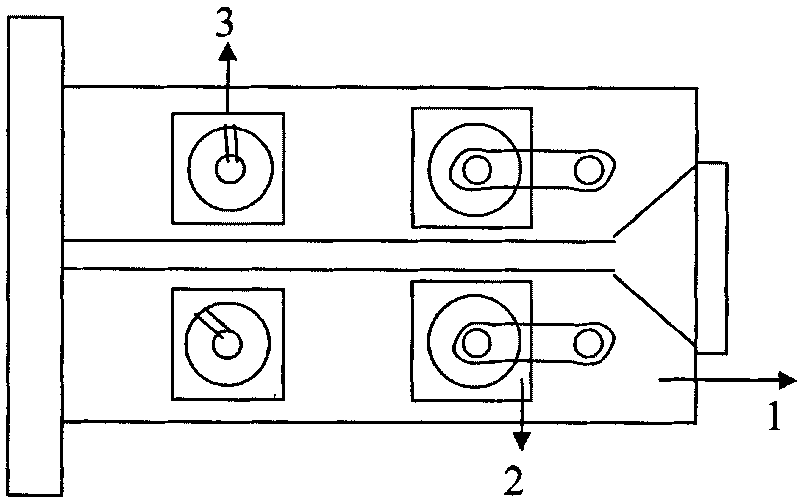

The invention discloses a processing method of a high-purity high-conductivity oxygen-free copper rod. The processing method comprises the following steps of S1 melting a copper material so as to form copper liquid, refining so as to remove impurities, and then adding deoxidant in batches, wherein the deoxidant is prepared from the following components in parts by weight: 40 to 45 parts of lanthanum, 20 to 25 parts of cerium, 5 to 10 parts of praseodymium, 15 to 30 parts of calcium hexaboride and 15 to 30 parts of lithium oxide; S2 leading the copper liquid in a smelting furnace to a holding furnace, controlling the temperature of the holding furnace to 1150 to 1160 DEG C, and covering an oxygen insulation layer on the surface of the copper liquid in the holding furnace; and S3 leading high-purity nitrogen below the liquid level of the copper liquid in the holding furnace for boiling degassing, and then adopting up-drawn continuous casting so as to obtain the high-purity high-conductivity oxygen-free copper rod. According to the processing method of the high-purity high-conductivity oxygen-free copper rod, the oxygen content of the high-purity high-conductivity oxygen-free copper rod is less than or equal to 20 PPM, the conductivity of the high-purity high-conductivity oxygen-free copper rod is greater than or equal to 0.064, and the whole process has the advantages of simple conditions, wide application range and less pollution.

Owner:安徽晋源铜业有限公司

Heat and sound insulation explosion preventing film and production method and application thereof

InactiveCN101700707AExcellent heat and sound insulationGood heat insulationSynthetic resin layered productsAntioxidantUltraviolet

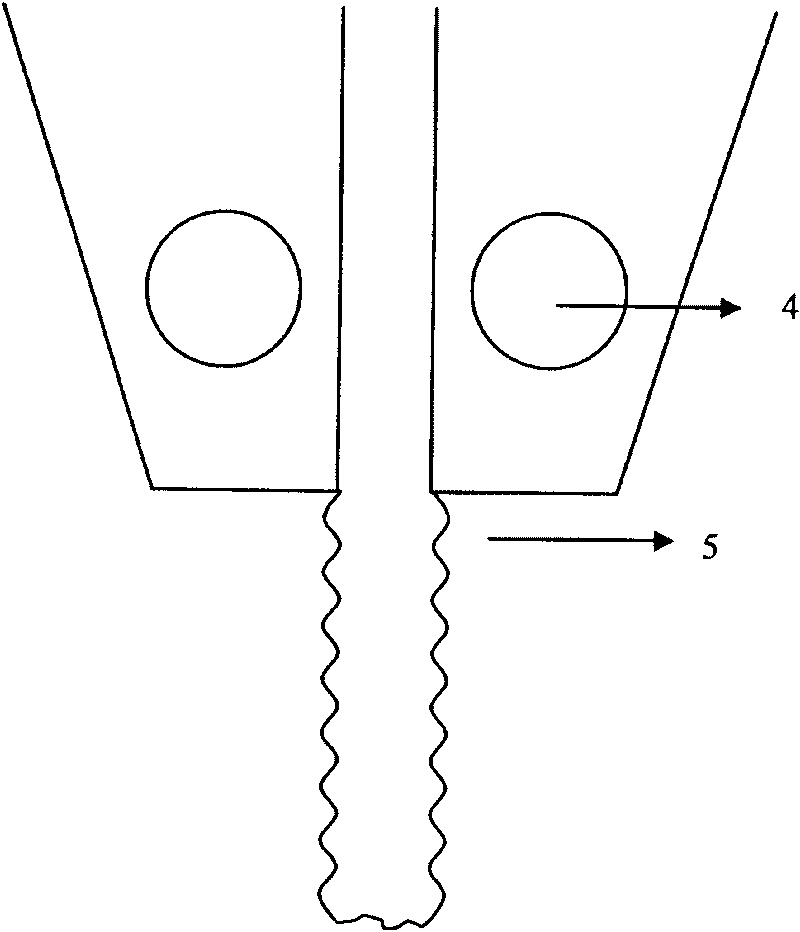

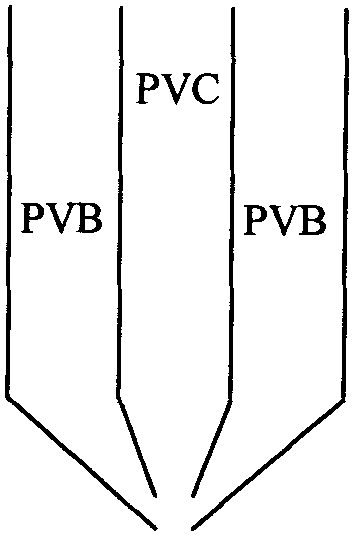

The invention relates to a heat and sound insulating material, in particular to a production method and application of a heat and sound insulation explosion preventing film. The heat and sound insulation explosion preventing film comprises three layers of materials, wherein the middle layer is polyvinyl chloride, and both side layers are polyvinyl butyral; an infrared absorbing agent, an ultra-violet absorbing agent, a hindered amine light stabilizer and an antioxidant are respectively added into the middle layer and both side layers; and the infrared absorbing agent is a mixture of nano titanium dioxide and nano calcium hexaboride. In the preparation method, the film is obtained on the basis of a multi-layer coextrusion casting film extruding technology by optimizing the process condition. The heat and sound insulation explosion preventing film is mainly used for being made into laminated glass. The explosion preventing film has favorable heat and sound insulating function and overcomes the defect of easy shrinkage and deformation in the production of traditional plastic films.

Owner:深圳市宝龙盈捷光电科技有限公司

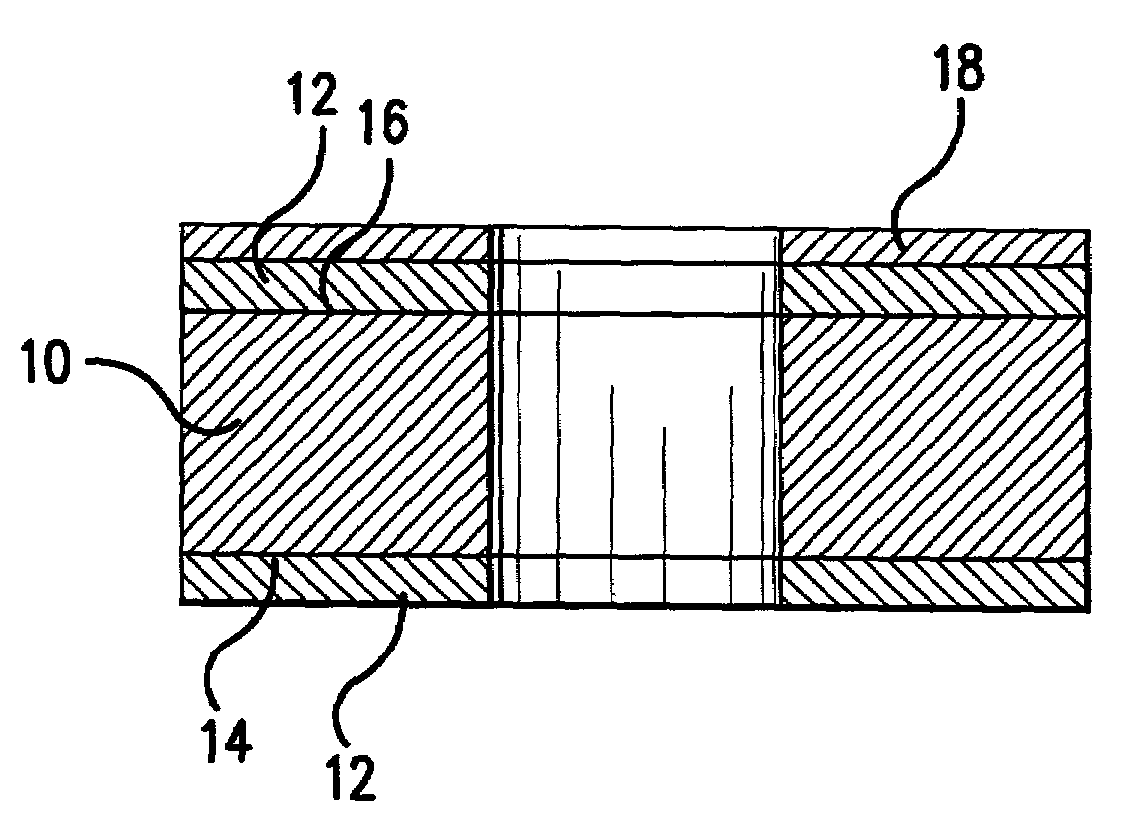

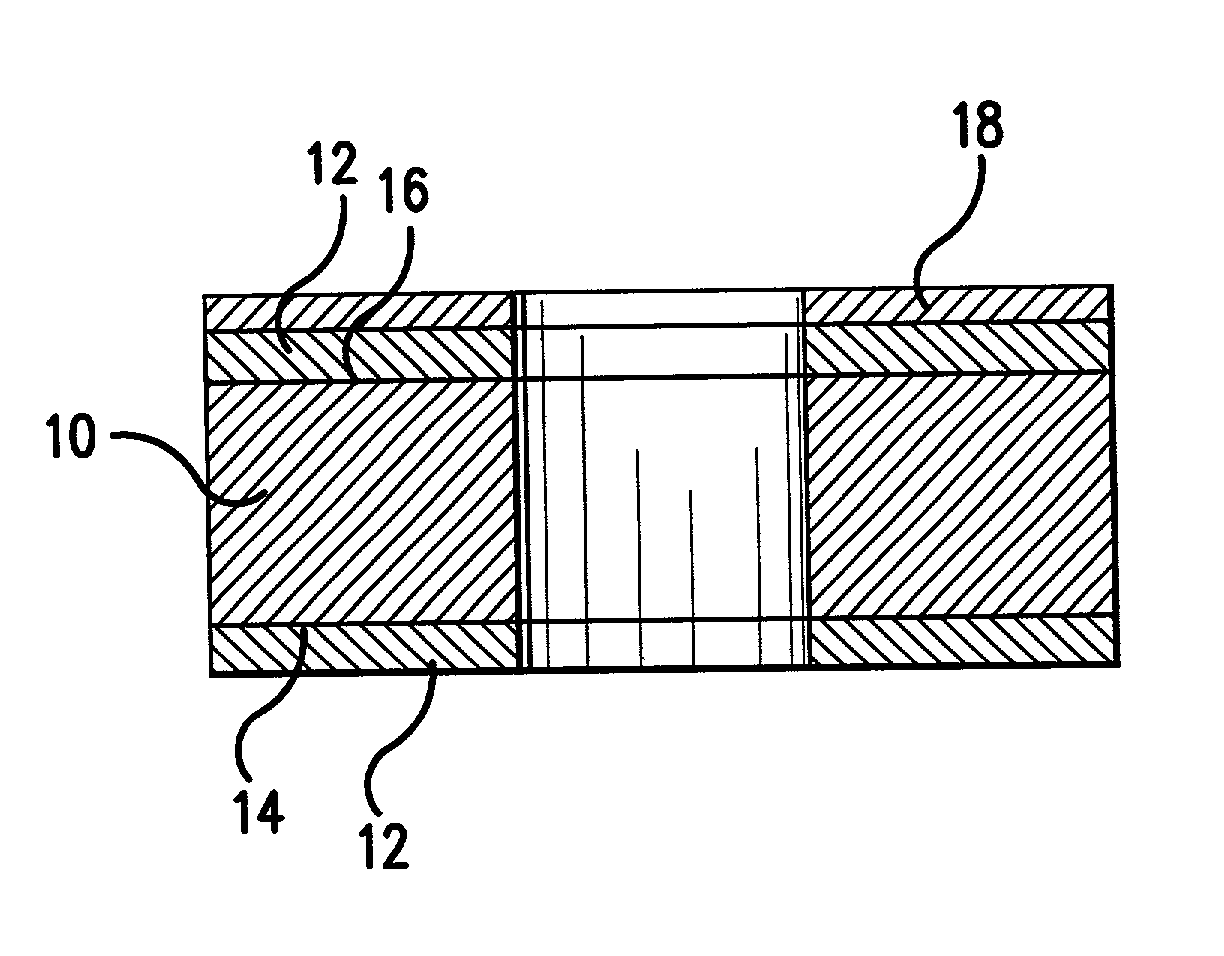

Metal matrix composites of aluminum, magnesium and titanium using silicon hexaboride, calcium hexaboride, silicon tetraboride, and calcium tetraboride

InactiveUS7160503B2Improve ductilityDriving/moving recording headsBase layers for recording layersThermal coefficientCalcium peroxide

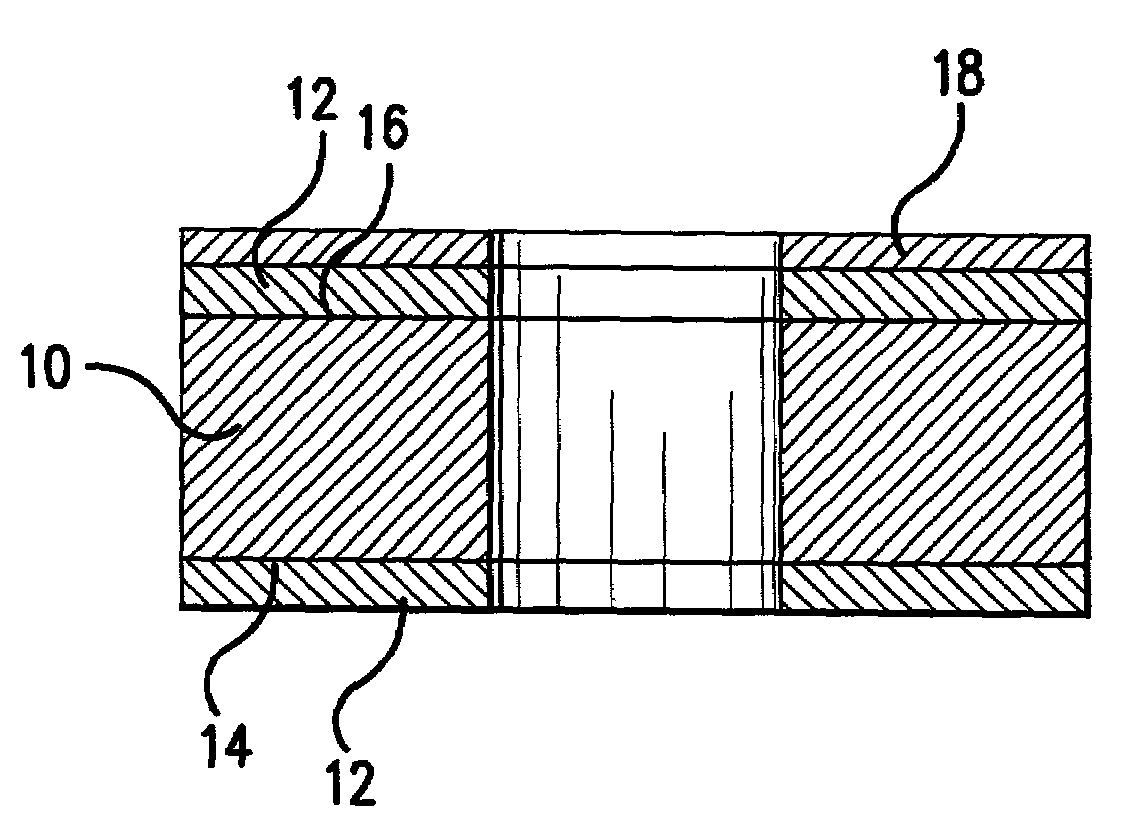

A metal matrix composite was fabricated by adding particles of calcium hexaboride to a metal of aluminum, magnesium or titanium and their alloys. The resulting metal matrix composite is light weight has improved strength, increased elastic modulus and reduced thermal coefficient of expansion, thus making the metal matrix composite more useful in industry. A metal matrix composite is also formed by mixing particles of aluminum, magnesium, titanium or combinations thereof with particles of silicon lexaboride, calcium hexaboride, silicon tetraboride, calcium tetraboride or combinations thereof. The blended particles are processed according to powder metallurgical techniques to produce a metal matrix composite material.

Owner:SAFFIL

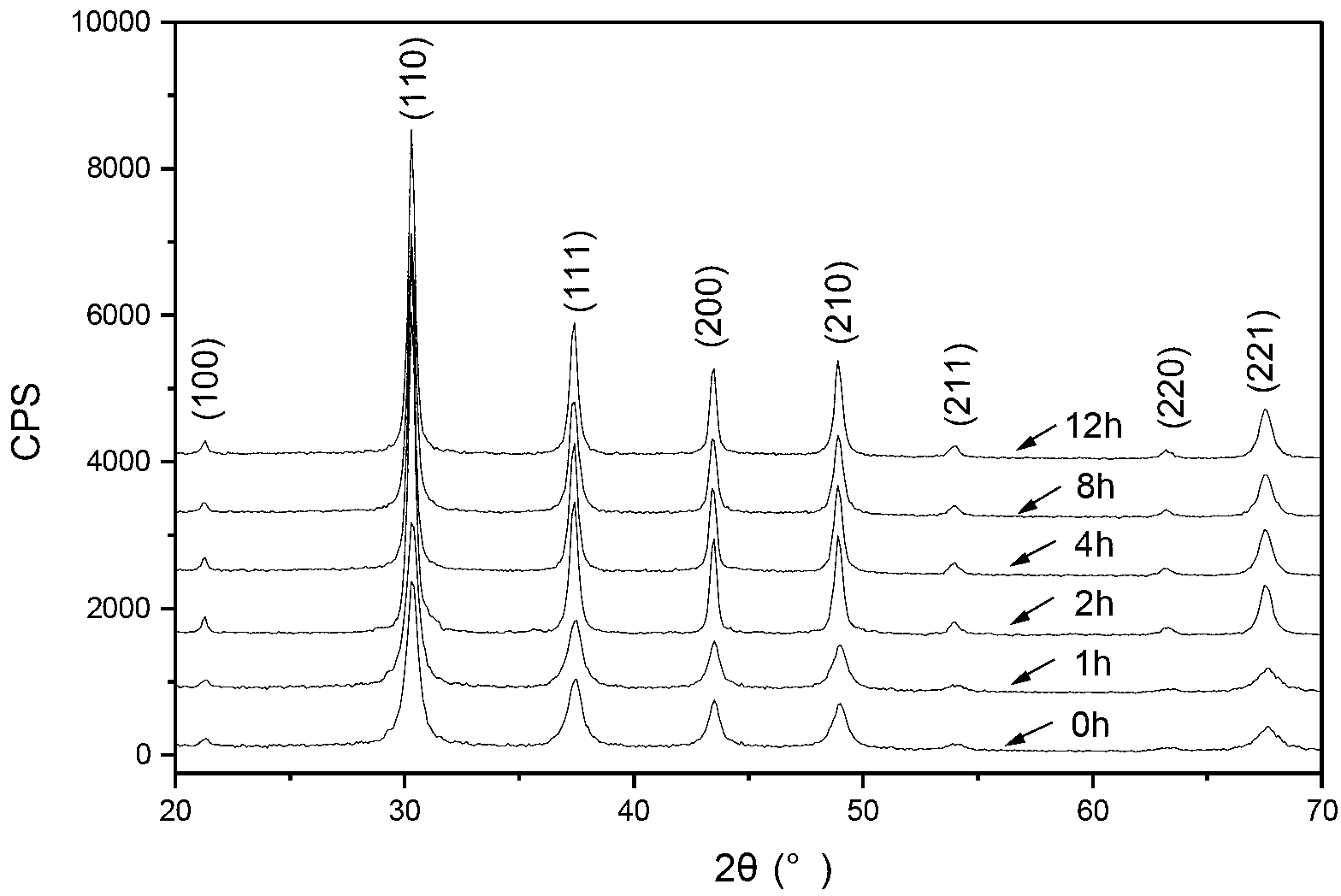

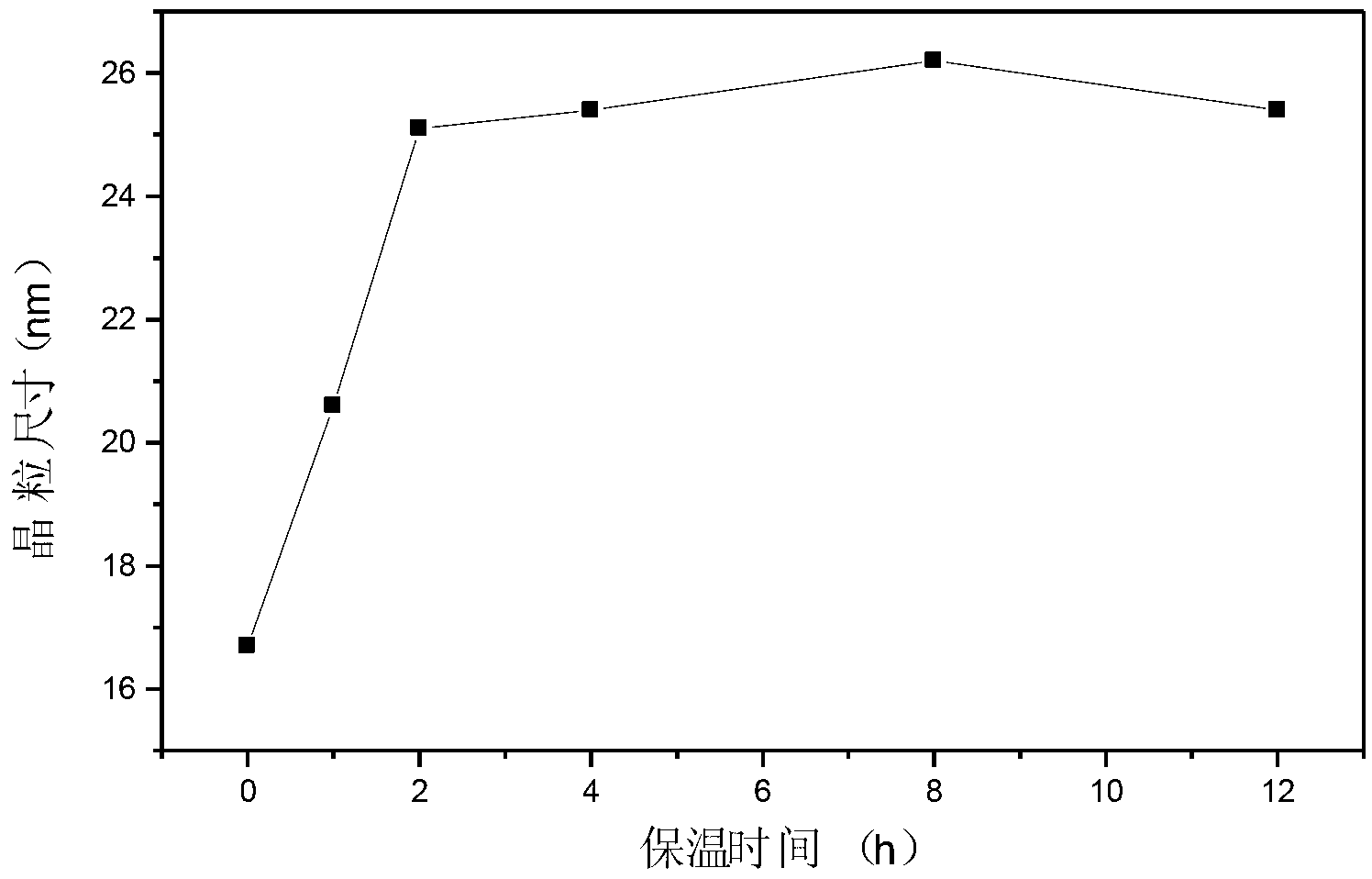

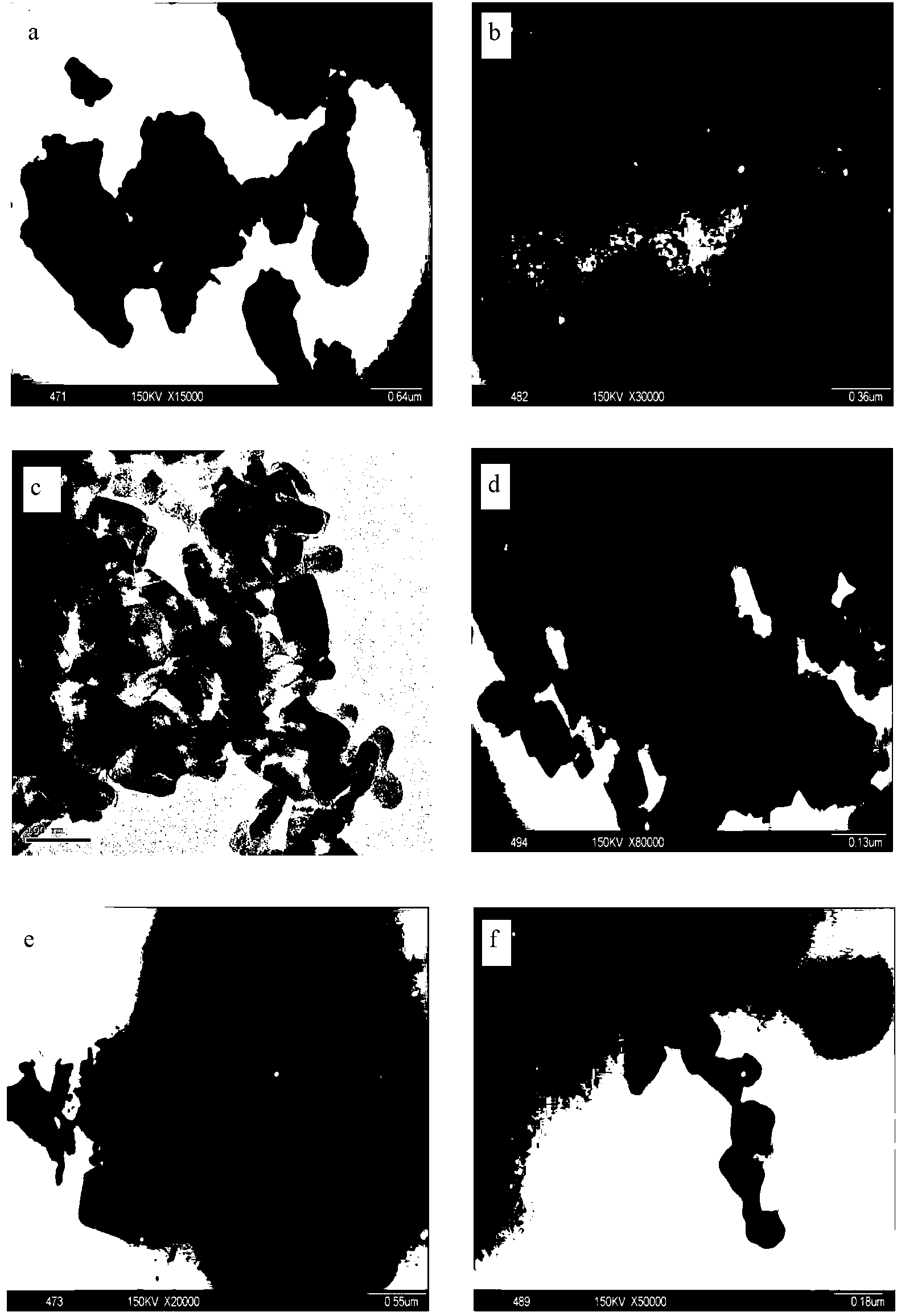

Preparation method of nanometer calcium hexaboride powder

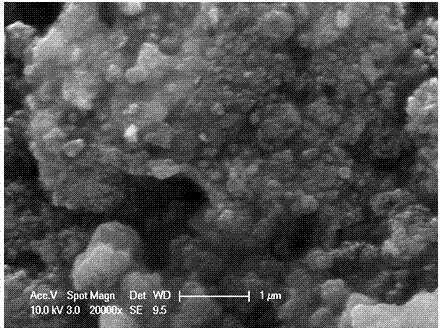

The invention relates to a preparation method of nanometer calcium hexaboride powder. The preparation method comprises the steps of: weighing calcium chloride and sodium borohydride according to the chemical mole ratio of 1:(6-12), grinding, and evenly mixing to place in a crucible; placing the crucible in a vacuum resistance furnace, keeping the working vacuum degree of 6.67*10<-2>Pa, heating to increase the temperature up to 480 DEG C-550 DEG C, preserving heat for 1-4 hours, and carrying out furnace cooling; taking out reactant and grinding, washing, purifying and drying to finally obtain final product. The grain size of the CaB6 prepared is distributed within 20nm to 30nm, the particle size is smaller than 100nm, the CaB6 is shaped like a cube, and the yield rate approaches 100%.

Owner:SHANDONG UNIV

Composite refining method for decreasing various impurity elements of brass alloy

InactiveCN110117726ATo achieve the purpose of purification and removal of impuritiesControl impurity contentSlagDolomite

The invention discloses a composite refining method for decreasing various impurity elements of a brass alloy, and belongs to the technical field of purifying of regenerated copper melts. The method comprises the main processes of preparing raw materials, crushing, sorting, melting, purifying and casting, wherein yellow brass like wastes are selected from wasted scrap copper material and then is crushed into small blocks being less than 50mm; impurities are sorted by ways such as a way of magnetic separating; a mixture of calcium hexaboride, dolomite, calcium carbonate, calcium fluoride and sodium fluoride are added after the yellow brass is molten in an induction furnace; the temperature is maintained for 15-30min; slag is removed; and then an ingot is obtained by casting. According to the method, lead, tin, iron and nickel contents in the ingot brass copper are correspondingly decreased by 10-60%, so that the contents of impurity elements in the regenerated brass alloy can be controlled; and the problem of difficulty in control of the impurity elements in the scrap copper material can be solved.

Owner:UNIV OF SCI & TECH BEIJING

Metal matrix composites of aluminum, magnesium and titanium using calcium hexaboride

InactiveUS20030056861A1Improve ductilityDriving/moving recording headsBase layers for recording layersThermal coefficientTitanium

A metal matrix composite was fabricated by adding particles of calcium hexaboride to a metal of aluminum, magnesium or titanium and their alloys. The resulting metal matrix composite is light weight has improved strength, increased elastic modulus and reduced thermal coefficient of expansion, thus making the metal matrix composite more useful in industry.

Owner:DYSON US HLDG

Preparation method and application of superfine calcium hexaboride

InactiveCN102242371AOvercome the shortcomings of high synthesis temperature, low yield and expensive raw materialsHigh melting pointElectrolysis componentsMetal boridesBorideElectrical conductor

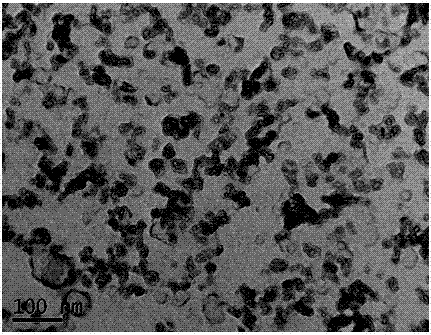

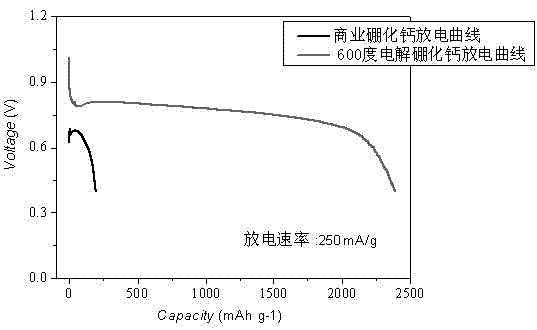

The invention discloses a preparation method and application of superfine calcium hexaboride to a battery. The preparation method comprises the steps of: carrying out electrolysis in a fused-salt electrolytic cell at a temperature of 500-750 DEG C through taking a composition of porous calcium borate and a metal current collector as the cathode and taking an insoluble conductor material as the anode, wherein fused-salt electrolyte contains a haloid corresponding to a metal capable of chemically reducing the calcium borate, and the voltage applied through the electrolysis is enough to reduce the calcium borate but not enough to resolve the fused-salt electrolyte; and taking out a reduction product on the cathode from the electrolytic cell, washing by using water and acid removing impurities, drying and then obtaining CaB6 powder. The obtained superfine calcium hexaboride can be used for a cathode material of a high-specific energy alkaline cell. By means of the method, the defects of high synthesis temperature, low yield and more expensive raw material of conventional boride are overcome and continuous production can be carried out.

Owner:WUHAN UNIV

Automobile steering-gear cylinder barrel

Provided is an automobile steering-gear cylinder barrel. The automobile steering-gear cylinder barrel is prepared from steel bond hard alloy raw material powder through the procedures of mixing, pressing and sintering, heating and forging, annealing, machining, quenching, tempering and nitriding. The hard phase of the automobile steering-gear cylinder barrel involves aluminium oxide, molybdenum carbide, aluminium nitride, calcium hexaboride and Co and improves the mechanical property of the material. The components of a steel base binder have high strength, and the strength of steel bond hard alloy is further improved under the action of the hard phase.

Owner:郭金艳

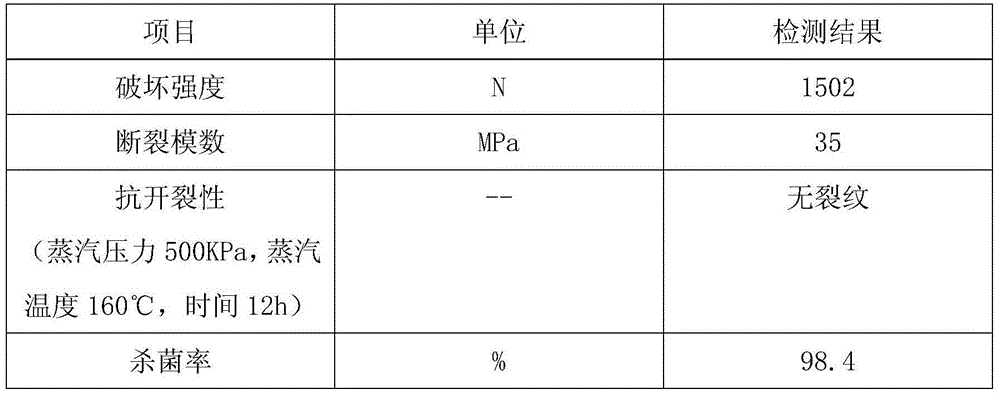

Ageing cracking resistant ceramic bowl and preparation method thereof

The invention discloses an ageing cracking resistant ceramic bowl and its preparation method. The ceramic bowl is prepared from the following raw materials, by weight, 33-47 parts of meerschaum, 25-35 parts of leucite, 22-33 parts of barite, 18-26 parts of nacrite, 15-25 parts of glass flake, 4-8 parts of tea dust, 3-6 parts of calcium hexaboride, 9-16 parts of konjaku flour, 4-7 parts of soya lecithin, 2-4 parts of disodium ethylene diamine tetraacetate, 3-5 parts of poly-aluminum ferric silicate sulfate, 2-3 parts of CITREM, 4-6 parts of alkali lignin and 8-10 parts of antimicrobial powder. With addition of glass flake, tea dust and calcium hexaboride, chemical corrosion resistance and ageing resistance of ceramic tiles can be enhanced. In addition, with addition of konjaku flour, soya lecithin, poly-aluminum ferric silicate sulfate and the like, adhesive stress among mineral particles can be raised, and ageing cracking of ceramic tiles can be prevented effectively. The prepared ceramic bowl has excellent heat resistance, corrosion resistance and ageing resistance, is not easy to crack or break and has long service life.

Owner:安徽省含山瓷业股份有限公司

High-strength and high-conductivity refining agent for smelting chromium-zirconium-copper alloy and application method for refining agent

The invention discloses a high-strength and high-conductivity refining agent for smelting a chromium-zirconium-copper alloy. The refining agent comprises a covering component and a purifying component, wherein the purifying component comprises calcium hexaboride, fluorotitanate, fluoborate, chlorine metal salt and rare earth. The invention further discloses an application method for the high-strength and high-conductivity refining agent for smelting the chromium-zirconium-copper alloy. According to the refining agent and the application method thereof, the cooperation function of the covering component and the purifying component is adopted so that the good impurity removal and purification effect on chromium-zirconium-copper alloy melt can be achieved, in addition, the oxidation burning loss in the smelting process can be effectively avoided, and therefore the strength and the conductivity of the material can be improved, and no pollution can be caused to the copper alloy melt.

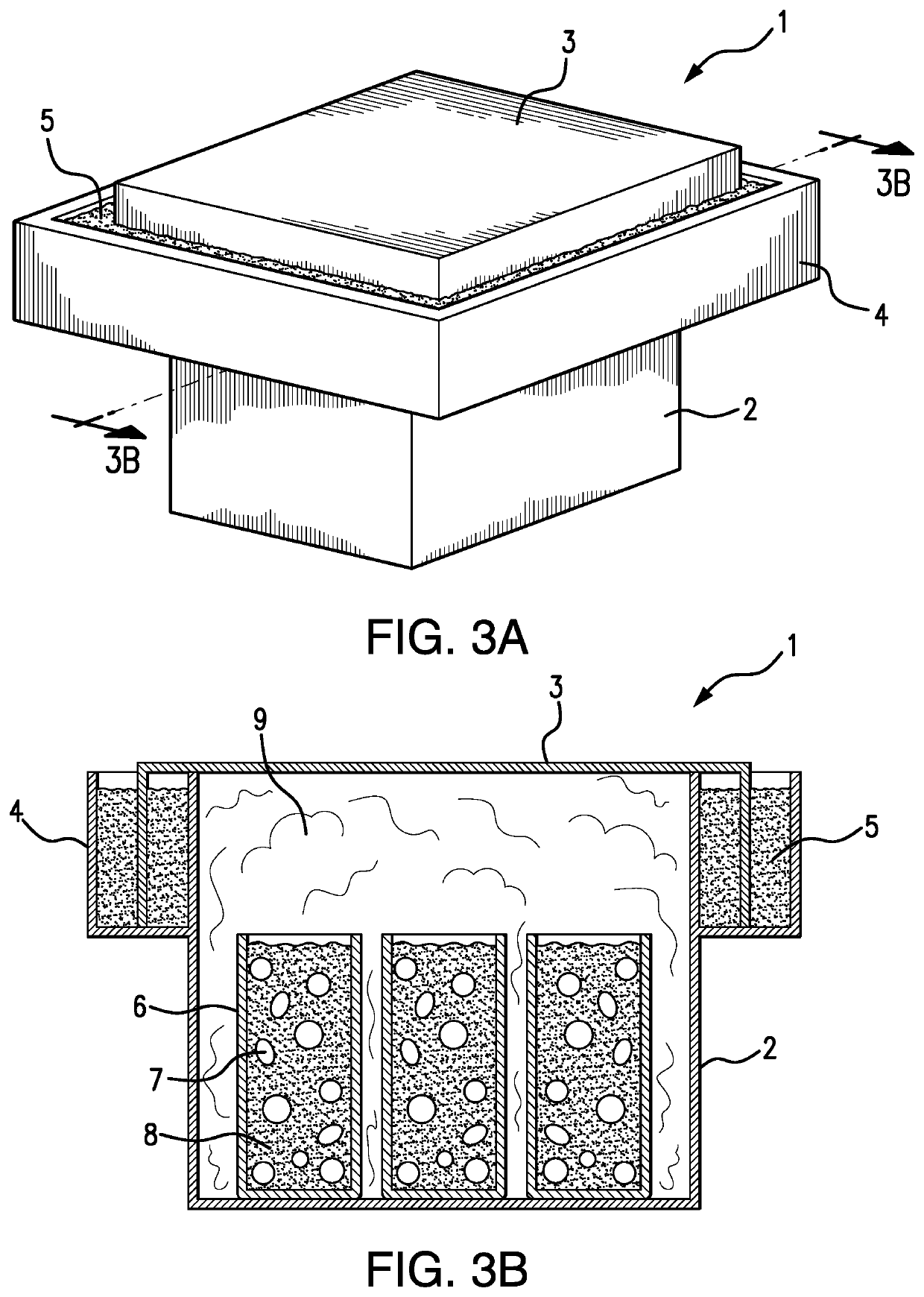

Boronizing powder compositions for improved boride layer quality in oil country tubular goods and other metal articles

ActiveUS20180265364A1Reduced boriding potentialSurface boron concentrationBoron/boridesCorrosion preventionGraphiteChloride

A powder boronizing composition comprising:a. 0.5 to 4.5 wt % of a boron source selected from B4C, amorphous boron, calcium hexaboride, borax or mixtures thereof;b. 45.5 to 88.5 wt % of a diluent selected from SiC, alumina or mixtures thereof;c. 1.0 to 20.0 wt % of an activator selected from KBF4, ammonia chloride, cryolite or mixtures thereof; andd. 10.0 to 30.0 wt % of a sintering reduction agent selected from carbon black, graphite or mixtures thereof.

Owner:BWT LLC

Al2O3-TiO2-CaO based self-flow castable and preparation method thereof

The invention relates to Al2O3-TiO2-CaO based self-flow castable and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding aluminum sol which accounts for 4 weight percent to 6 weight percent of titanium-iron slag fine powder into the titanium-iron slag fine powder; granulating and drying; putting the dried titanium-iron slag raw material into a muffle furnace; carrying out heat treatment at 1350 DEG C to 1400 DEG C; cooling and sieving to obtain a heat treatment material A and a heat treatment material B, wherein the granularity of the heat treatment material A is 2mm to 4mm and the granularity of the heat treatment material B is 0.1mm to 1mm; preparing materials according to the ratio of the heat treatment material A to the heat treatment material B to rho-aluminum oxide micro-powder to calcium hexaboride micro-powder to calcium aluminate cement of 1 to (2 to 2.2) to (2.0 to 2.5) to (0.03 to 0.13) to (0.1 to 0.15) and mixing; adding sodium citrate and water into a mixture and stirring to obtain the Al2O3-TiO2-CaO based self-flow castable. The Al2O3-TiO2-CaO based self-flow castable and the preparation method thereof, provided by the invention, have the characteristics of low cost and simple process; the prepared Al2O3-TiO2-CaO based self-flow castable has high density, great cold-state compressive strength and good flowability.

Owner:锦州国泰实业有限公司

Mining cable high-strength oxygen free copper rod

InactiveCN109457129AImprove craftsmanshipSolve the problem of the utilization of renewable resourcesCable/conductor manufactureRare-earth elementLithium oxide

The invention discloses a mining cable high-strength oxygen free copper rod. In the burdening process, electrolytic copper raw materials are strictly screened, according to selection of copper, exceptfor the electrolytic copper, a certain amount of red copper waste is added, through refining impurity removal and deoxygenization, the standard of the cathode copper oxygen containing amount can be basically achieved, the problem about using of red copper waste renewable resources can be solved, and production cost is reduced; in the smelting process, through three-time refining, different refining reagents are selected, through layer-by-layer progressive operation, impurity metal like zinc, lead, tin, nickel, arsenic and the like can be removed to the maximum degree, through a composite deoxidant, lanthanum, cerium and praseodymium compound rare earth elements can be used for obviously improving the process property of the copper, and can make sufficient reaction with cuprous oxide in melt copper, the cuprous oxide is sufficiently reduced into copper, the compound deoxidant formed by calcium hexaboride and lithium oxide can further reduce the content of oxygen in the melt copper, andthe product oxygen containing amount can be further reduced.

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

Rotary kiln refractory material

The invention discloses a rotary kiln refractory material, comprising the following raw materials in parts by weight: 70-80 parts of bauxite, 1-3 parts of aluminum silicate fiber, 6-8 parts of silicondioxide, 3-6 parts of calcium hexaboride, 8-10 parts of water, and 6-12 parts of zirconium nitride. The rotary kiln refractory material proposed by the invention adopts bauxite as a main raw materialwhich is low in cost and convenient to obtain, and the bauxite has stable chemical properties and good physical properties. Aluminum silicate fiber is added as a raw material interstitial filler, hasgood thermal stability, thermal shock resistance and excellent sound absorption, and is conducive to silencing of a rotary kiln. Calcium hexaboride is added as an antioxidant to achieve the antioxidant effect of the refractory material and improve the corrosion resistance of the refractory material, and enables the refractor material to be stable in properties, and at the same time, to be non-flammable and non-toxic during application. Zirconium nitride is added to enhance the wear resistance and oxidation resistance of the refractory material and prolong the service life.

Owner:JIANGSU DELONG NICKEL IND CO LTD

Metal matrix composites of aluminum, magnesium and titanium using silicon hexaboride, calcium hexaboride, silicon tetraboride, and calcium tetraboride

InactiveUS20030059641A1Improve ductilityDriving/moving recording headsBase layers for recording layersThermal coefficientTitanium

A metal matrix composite was fabricated by adding particles of calcium hexaboride to a metal of aluminum, magnesium or titanium and their alloys. The resulting metal matrix composite is light weight has improved strength, increased elastic modulus and reduced thermal coefficient of expansion, thus making the metal matrix composite more useful in industry. A metal matrix composite is also formed by mixing particles of aluminum, magnesium, titanium or combinations thereof with particles of silicon lexaboride, calcium hexaboride, silicon tetraboride, calcium tetraboride or combinations thereof. The blended particles are processed according to powder metallurgical techniques to produce a metal matrix composite material.

Owner:SAFFIL

Preparation method of calcium-hexaboride-reinforced aluminum matrix composite

The invention belongs to the field of metal materials, and relates to a preparation method of a calcium-hexaboride-reinforced aluminum matrix composite. According to the preparation method, aluminum-boron intermediate alloy and pure calcium are used as the source of boron and calcium. The preparation method comprises the following steps of: firstly, smelting the aluminum-boron intermediate alloy in a smelting furnace, rising the temperature to 900-1300 DEG C, then adding pure calcium, insulating, carrying out mechanical agitation uniformly, and pouring directly to be ingot. The preparation method of the calcium-hexaboride-reinforced aluminum matrix composite is simple in process and low in cost. The prepared calcium-hexaboride-reinforced aluminum matrix composite has the advantages of low resistivity, low linear thermal expansion coefficient, high hardness, and the like.

Owner:SHANDONG UNIV

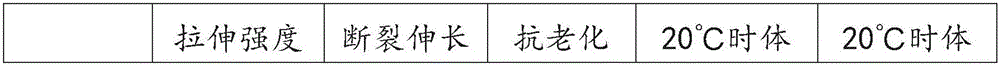

High-aging-resistance semiconductive shielding material for cables

The invention discloses a semi-conductive shielding material for cables with good aging resistance, which relates to the technical field of cable shielding materials and mainly consists of nitrile rubber, butadiene rubber, conductive carbon black, tricresyl phosphate, decabromodiphenyl ether, Diformyl peroxide, antioxidant 1076, zinc stearate, antioxidant MB, calcium hexaboride, antimony trioxide, nano-diamond, titanium dioxide, carbon fiber, epoxy soybean oil. The semi-conductive shielding material for cables of the present invention uses nitrile rubber and butadiene rubber as the main raw materials. Butadiene rubber makes up for the deficiency of nitrile rubber in terms of cold resistance. Excellent performance, antimony trioxide, nano-diamond, calcium hexaboride, carbon fiber and other ingredients improve the flame resistance, oxidation resistance, chemical corrosion resistance and strength of the material, thereby increasing the service life of the product.

Owner:SUZHOU SHUANGHU SCI & TECH CO LTD

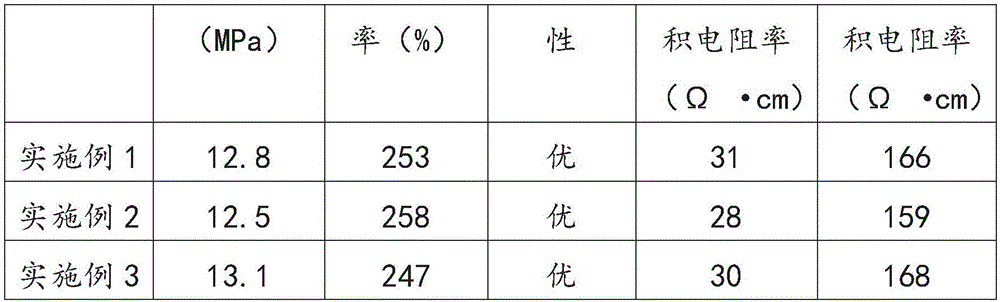

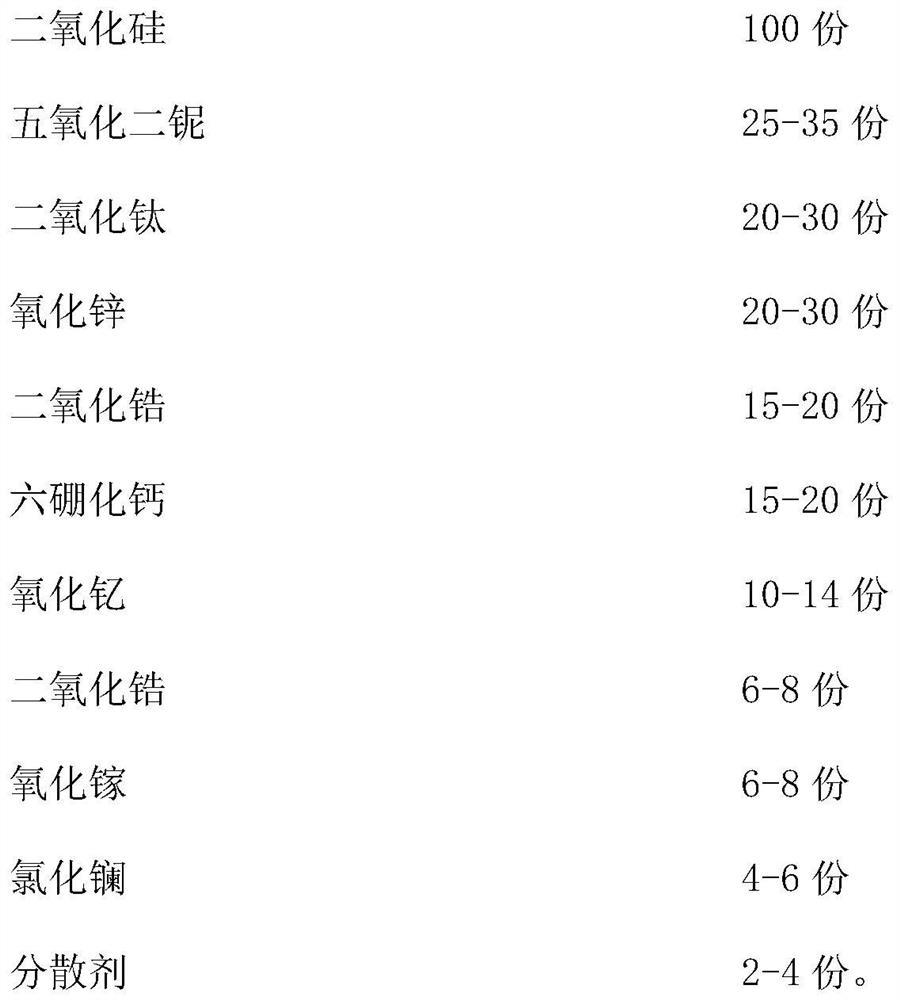

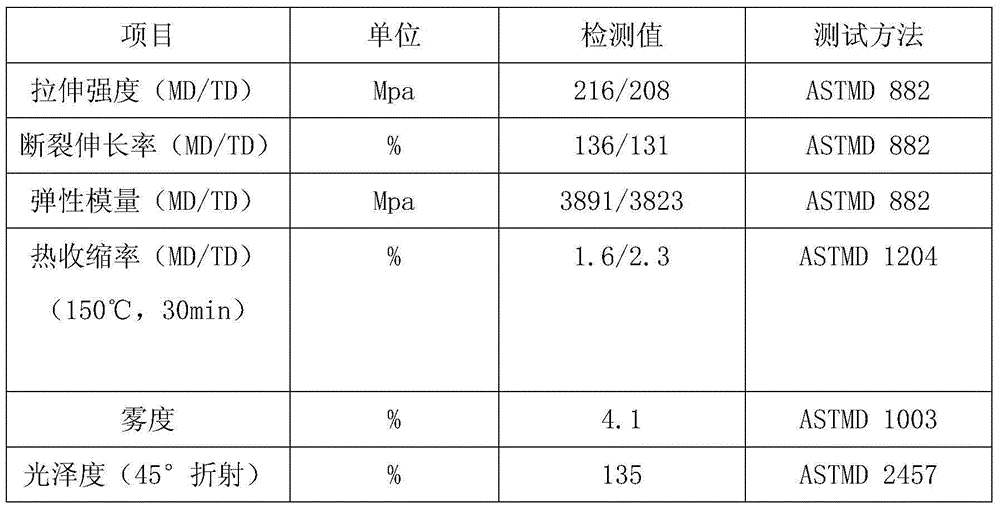

High-refractive-index optical glass and preparation method thereof

InactiveCN113698096AHigh refractive indexGood chemical stabilityGlass shaping apparatusRefractive indexLanthanum(III) chloride

The invention belongs to the field of preparation of high-refractive-index optical glass, and particularly discloses high-refractive-index optical glass and a preparation method thereof. The high-refractive-index optical glass is prepared from the following raw materials in parts by weight: 100 parts of silicon dioxide, 20-40 parts of niobium pentoxide, 15-30 parts of titanium dioxide, 15-30 parts of zinc oxide, 10-20 parts of zirconium dioxide, 10-20 parts of calcium hexaboride, 8-16 parts of yttrium oxide, 5-10 parts of zirconium dioxide, 5-10 parts of gallium oxide, 3-7 parts of lanthanum chloride and 2-4 parts of a dispersing agent. The high-refractive-index optical glass disclosed by the invention is high in refractive index, good in chemical temperature property, short in preparation process and suitable for large-scale application.

Owner:XINYI DONGFANG SHUOHUA OPTICAL MATERIALS CO LTD

Glass bead for engineering-grade reflective film and preparation method thereof

InactiveCN105005105AImprove thermal stabilityHigh mechanical strengthGlass shaping apparatusOptical elementsPhosphatePhosphoric acid

The invention discloses a glass bead for an engineering-grade reflective film and a preparation method thereof. The glass bead is composed of the following components by weight: 41-53 parts of natural sea rock, 37-49 parts of diopside, 22-33 parts of tungsten tailings, 29-43 parts of magnesite, 21-32 parts of nacrite, 7-14 parts of boron phosphate, 5-10 parts of calcium hexaboride, 4-7 parts of sorbitan monopalmitate, 6-9 parts of triethanolamine polyoxyethylene dodecyl mono phosphate, 5-10 parts of cation hydroxy silicone oil, 3-6 parts of polyoxyethylene lanolin ether and 12-14 parts of additive. The glass beam is provided with the natural sea roc, the tungsten tailings and the magnesite which match the boron phosphate and the calcium hexaboride. Not only can thermal stability and mechanical strength of the glass beam be improved, but also wear resistance, high-temperature resistance, aging resistance and solvent resistance can be improved. The prepared glass beam has an excellent comprehensive performance and can be widely applied for the engineering-grade reflective film.

Owner:ANHUI TIANTANG WEIGAO PLASTIC TECH

Boronizing powder compositions for improved boride layer quality in oil country tubular goods and other metal articles

A powder boronizing composition comprising:a. 0.5 to 4.5 wt % of a boron source selected from B4C, amorphous boron, calcium hexaboride, borax or mixtures thereof;b. 45.5 to 88.5 wt % of a diluent selected from SiC, alumina or mixtures thereof;c. 1.0 to 20.0 wt % of an activator selected from KBF4, ammonia chloride, cryolite or mixtures thereof; andd. 10.0 to 30.0 wt % of a sintering reduction agent selected from carbon black, graphite or mixtures thereof.

Owner:BWT LLC

A kind of preparation method of refractory metal boride

ActiveCN109516469BLow costThe method is flexible and convenientMetal boridesRefractory metalsRaw material

Owner:UNIV OF SCI & TECH BEIJING

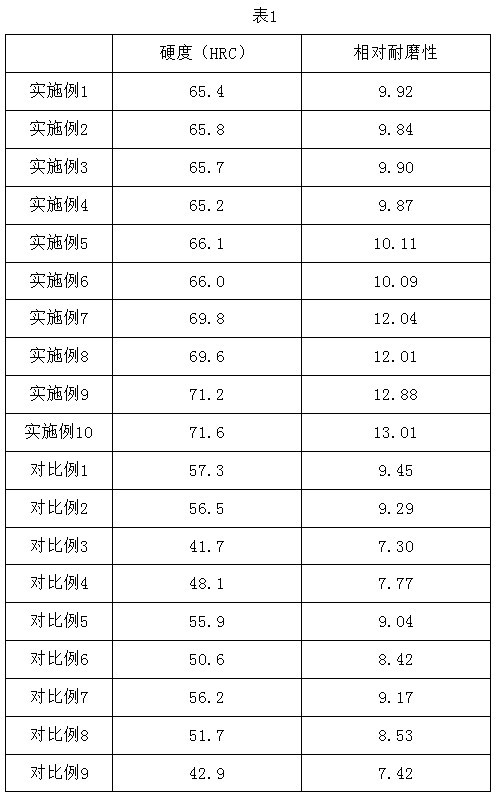

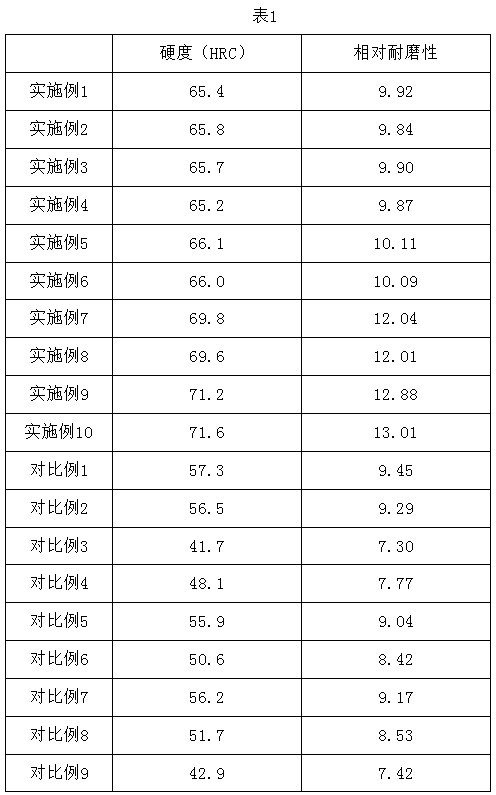

A kind of self-shielded surfacing flux-cored welding wire and preparation method thereof

ActiveCN112872655BHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconCerium

The application discloses a self-shielded surfacing flux-cored welding wire and a preparation method, which belong to the field of welding materials. The flux-cored welding wire includes a wire skin material and a flux, the flux is filled in the welding wire skin material, and the flux includes the following components by weight: 30-40% of chromium carbide, 15-25% of ferromanganese, and 7.5-9.5% of ferrotantalum %, tungsten carbide 3‑8%, calcium hexaboride 1‑5%, graphite 6‑8%, cerium oxide 0.5‑1%, rare earth magnesium ferrosilicon alloy 10‑15%, fluorspar 3‑5%, silica 4‑ 7%, Li 2 CO 3 1-2%, marble 2-3%; the filling rate of the flux in the welding wire skin material is 30-45%. In this application, by selecting each component in the flux and optimizing the addition amount of each component, the hardness and wear resistance of the surfacing metal can be significantly improved, so that the service life of the repair material can be prolonged, and the mechanical properties of the surfacing metal in special fields can be satisfied. Require.

Owner:江苏东南焊材有限公司

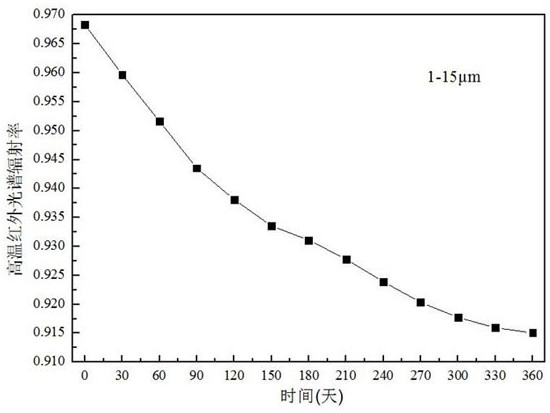

A kind of antiaging agent for high temperature resistant infrared coating and preparation method thereof

An antiaging agent for high-temperature resistant infrared coatings and a preparation method thereof, characterized in that: a. In parts by weight, 20-50 parts of silicon dioxide, 15-32 parts of silicon hexaboride, 15-32 parts of hexaboron Calcium chloride, 1-8 parts of boron trioxide, 3-12 parts of borosilicate glass are mixed and then added to the mixing tank for pre-mixing for 5-30 minutes; b. Then the mixture is added to the fluidized bed jet mill for shaping and mixing, and the classifier 1200~2300r / min, to obtain mixed powder with an average particle size of 0.1~4μm; c. The mixed powder is placed in a high-temperature furnace, heated to 850~1100℃ at 2~7℃ / min, kept for 1~3h, and sintered with furnace cooling d. The sintered material is crushed to an average particle size of 0.5-5mm, added to a fluidized bed jet mill for ultra-fine, and the classifier is 2400-3000r / min to obtain a high-temperature-resistant infrared coating with an average particle size of 0.1-2μm. Aging agent. The invention has simple composition and convenient preparation steps; it is stable and has good high-temperature infrared radiation ability, anti-oxidation ability and anti-washing ability in high-temperature complex atmosphere.

Owner:SHENZHEN TRIUMPH TECH ENG +1

Refining agent for smelting high-strength and high-conductivity chromium-zirconium-copper alloy and using method thereof

Owner:安徽晋源铜业有限公司

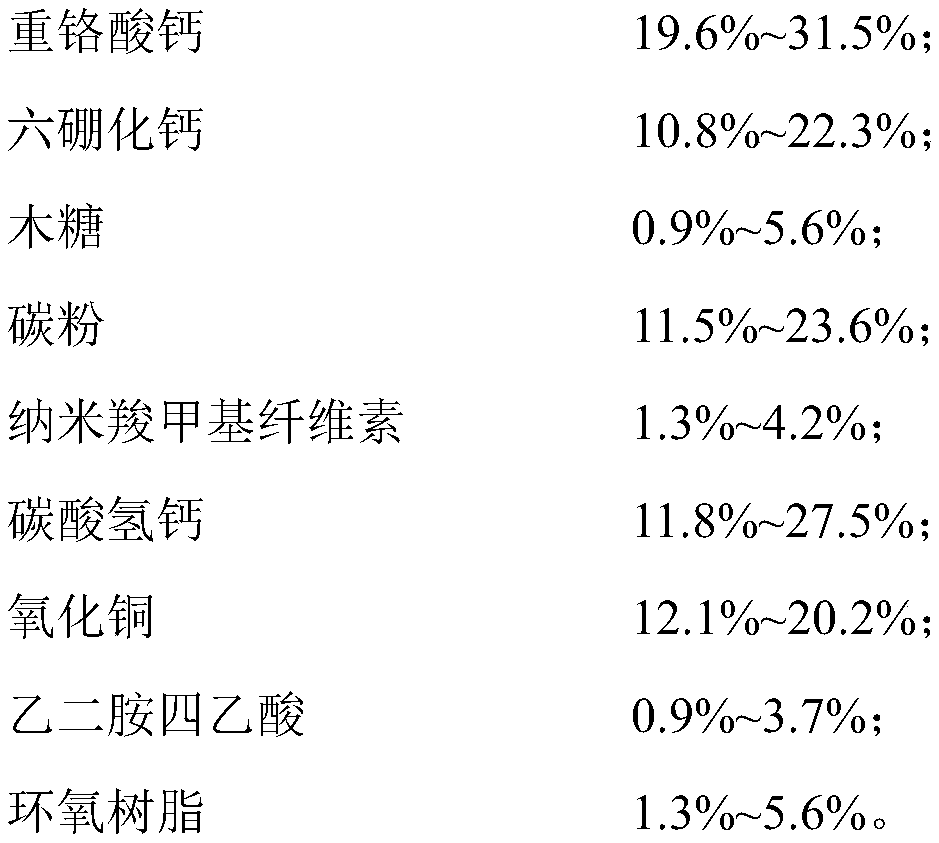

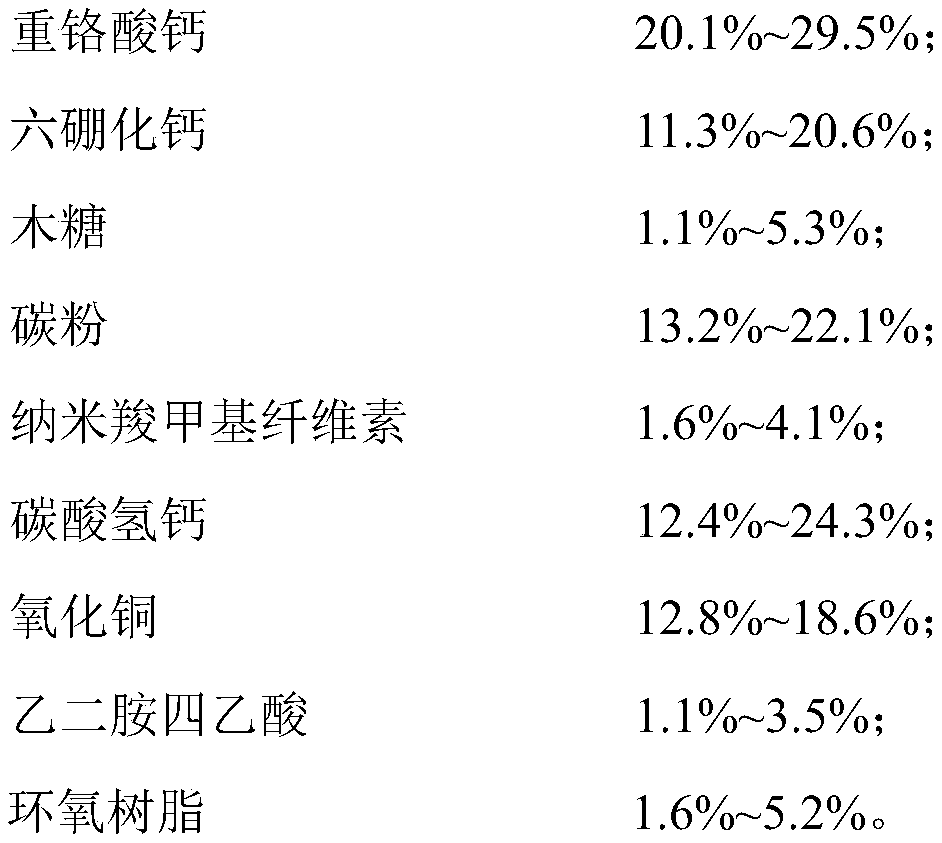

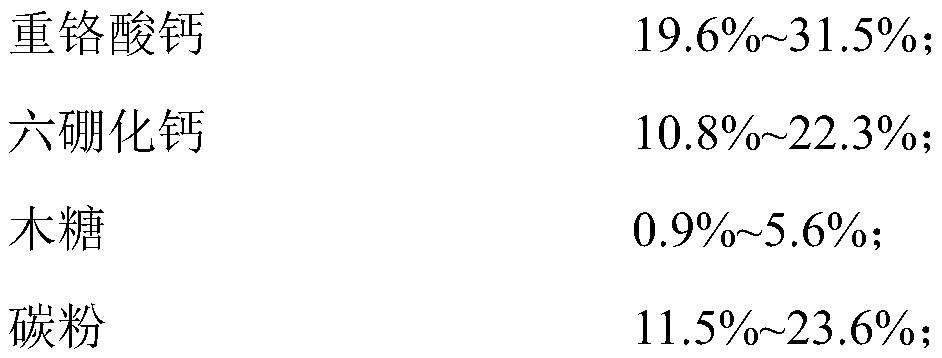

A kind of hot aerosol fire extinguishing agent and preparation method thereof

InactiveCN107694001BLow costImprove fire extinguishing efficiencyFire extinguisherCarboxymethyl celluloseCalcium bicarbonate

The invention discloses a thermal aerosol fire extinguishing agent and a preparation method thereof, which comprises: 19.6% to 31.5% of calcium dichromate, 10.8% to 22.3% of calcium hexaboride, 0.9% to 5.6% of Xylose, 11.5% to 23.6% of carbon powder, 1.3% to 4.2% of nano carboxymethyl cellulose, 11.8% to 27.5% of calcium bicarbonate, 12.1% to 20.2% of copper oxide, 0.9% to 3.7% of EDTA and 1.3% to 5.6% epoxy resin. The components of the aerosol fire extinguishing agent of the present invention have obvious synergistic effects, so that the aerosol fire extinguishing agent has good fire extinguishing ability and fire extinguishing efficiency as a whole, and has the advantages of less dosage, fast fire extinguishing speed, and high fire extinguishing efficiency. For fire extinguishing of oil fire sources.

Owner:SHANDONG UNIV OF SCI & TECH

Self-protection surfacing flux-cored wire and preparation method

ActiveCN112872655AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaCeriumBorium

The invention discloses a self-protection surfacing flux-cored wire and a preparation method, and belongs to the field of welding materials. The flux-cored wire comprises a welding wire skin material and welding flux, the welding wire skin material is filled with the welding flux, the welding flux comprises, by weight, 30%-40% of chromium carbide, 15%-25% of ferromanganese, 7.5%-9.5% of ferrotantalum, 3%-8% of tungsten carbide, 1%-5% of calcium hexaboride, 6%-8% of graphite, 0.5%-1% of cerium oxide, 10%-15% of rare earth magnesium-silicon-iron alloy, 3%-5% of fluorite, 4%-7% of silica, 1%-2% of Li2CO3 and 2%-3% of marble, and the filling rate of the welding flux in the welding wire skin material is 30%-45%. According to the flux-cored wire, the hardness and wear resistance of the surfacing metal can be remarkably improved by selecting all the components in the welding flux and optimizing the adding amount of all the components, so that the service life of a repairing material can be prolonged, and the requirements of special fields for the mechanical property of the surfacing metal are met.

Owner:江苏东南焊材有限公司

High temperature resistant paint film for diamond vacuum reduction sintering basket

The invention relates to a high-temperature-resistant paint film for a diamond vacuum reduction and sintering basket. The paint film is prepared from, by weight, 12-15 parts of aluminum oxide fine powder, 5-10 parts of dititanium nitride fine powder, 8-10 parts of calcium hexaboride fine powder, 10-15 parts of chromium trioxide fine powder, 2-4 parts of graphite, 15-20 parts of asphalt and 30-40 parts of gasoline. The high-temperature-resistant paint film prepared through the method and the sintering basket coated with the high-temperature-resistant paint film and subjected to high temperature treatment are resistant to high temperature not lower than 1200 DEG C, are durable and can meet normal use conditions of artificial diamond, and adhesion between metal sintering baskets in the high-temperature state can be effectively prevented. Besides, no influence is caused on characteristics and quality of diamond products, the use effect is very good in hoisting and forking in automatic production, and smooth automatic production can be well ensured.

Owner:ZHONGNAN DIAMOND CO LTD

Worm gear of grain packing machine for processing omega-3 fish oil soft capsules

The invention discloses a worm gear of a grain packing machine for processing omega-3 fish oil soft capsules. The worm gear consists of the following raw materials in parts by mass: 20-25 parts of tin bronze, 30-35 parts of aluminum bronze, 16-20 parts of grey cast iron, 8-10 parts of aliphatic polyketone, 9-15 parts of epoxy resin, 13-15 parts of chromium diboride, 18-20 parts of calcium hexaboride, 22-25 parts of tantalum carbide, 9-16 parts of vanadium carbide, 7-12 parts of magnesium oxide, 9-15 parts of magnesium hydroxide and 16-20 parts of molybdenum disulfide. The worm gear of the grain packing machine for processing the omega-3 fish oil soft capsules has relatively high strength, corrosion resistance and excellent casting property.

Owner:中山百鸥医药科技有限公司

Cervical dilating rod for obstetrics and gynecology

InactiveCN107119212AImprove mechanical propertiesHigh strengthObstetrical instrumentsObstetric historyNiobium carbide

Owner:钟苗

High-temperature-resistant paint film for diamond vacuum reduction and sintering basket

The invention relates to a high-temperature-resistant paint film for a diamond vacuum reduction and sintering basket. The paint film is prepared from, by weight, 12-15 parts of aluminum oxide fine powder, 5-10 parts of dititanium nitride fine powder, 8-10 parts of calcium hexaboride fine powder, 10-15 parts of chromium trioxide fine powder, 2-4 parts of graphite, 15-20 parts of asphalt and 30-40 parts of gasoline. The high-temperature-resistant paint film prepared through the method and the sintering basket coated with the high-temperature-resistant paint film and subjected to high temperature treatment are resistant to high temperature not lower than 1200 DEG C, are durable and can meet normal use conditions of artificial diamond, and adhesion between metal sintering baskets in the high-temperature state can be effectively prevented. Besides, no influence is caused on characteristics and quality of diamond products, the use effect is very good in hoisting and forking in automatic production, and smooth automatic production can be well ensured.

Owner:ZHONGNAN DIAMOND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com