A kind of self-shielded surfacing flux-cored welding wire and preparation method thereof

A technology of self-shielding and welding wire, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problem of low strength of self-shielding flux-cored wire, reduce the generation of pores and cracks, improve uniformity and fluidity, and better The effect of molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

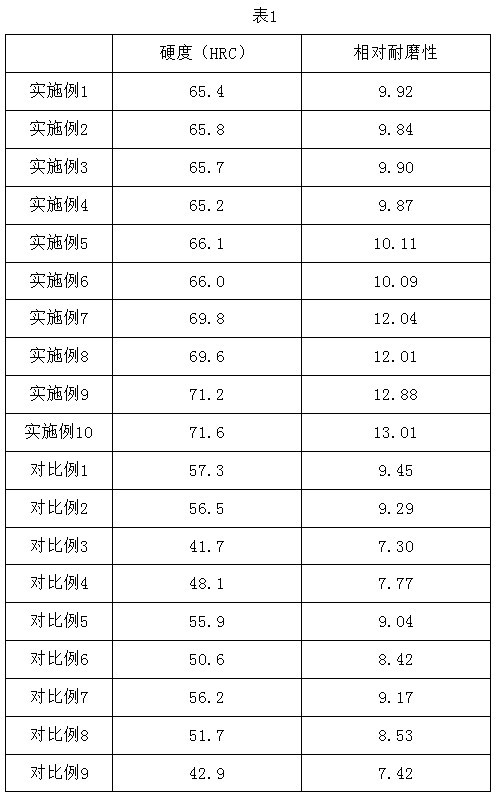

Examples

Embodiment 1

[0065] A preparation method of self-shielded surfacing flux-cored welding wire, comprising the following steps:

[0066] a. Mixing powder: mix the specified amount of 3kg chromium carbide, 2kg ferromanganese, 0.8kg tantalum, 0.8kg tungsten carbide, 0.2kg calcium hexaboride, 0.62kg graphite, 0.1kg cerium oxide, 1.26kg rare earth magnesium ferrosilicon alloy, 0.4kg fluorspar, 0.5kg silica, 0.1kgLi 2 CO 3 , 0.22kg marble for mixing;

[0067] b. Filling: Roll the cold-rolled steel strip into a U-shaped section, and then fill the 10kg powder mixed in step a into the U-shaped metal groove according to the filling rate of 30%, and then seal and roll;

[0068] c. Drawing and forming: the tubular welding wire sealed in step b is drawn, and the filling rate is detected after drawing and forming, which is obtained from the protective surfacing flux-cored welding wire.

Embodiment 2

[0070] A preparation method of self-shielded surfacing flux-cored welding wire, comprising the following steps:

[0071] a. Mixing powder: mix the specified amount of 4kg chromium carbide, 1.5kg ferromanganese, 0.75kg ferrotantalum, 0.3kg tungsten carbide, 0.1kg calcium hexaboride, 0.65kg graphite, 0.05kg cerium oxide, 1.3kg rare earth magnesium ferrosilicon alloy , 0.3kg fluorspar, 0.6kg silica, 0.2kgLi 2 CO 3 , 0.25kg marble for mixing;

[0072] b. Filling: Roll the cold-rolled steel strip into a U-shaped section, and then fill the 10kg powder mixed in step a into the U-shaped metal groove according to the filling rate of 45%, and then seal and roll;

[0073] c. Drawing and forming: the tubular welding wire sealed in step b is drawn, and the filling rate is detected after drawing and forming, which is obtained from the protective surfacing flux-cored welding wire.

Embodiment 3

[0075] A preparation method of self-shielded surfacing flux-cored welding wire, comprising the following steps:

[0076] a. Mixing powder: mix the specified amount of 3.1kg chromium carbide, 1.6kg ferromanganese, 0.76kg ferrotantalum, 0.36kg tungsten carbide, 0.5kg calcium hexaboride, 0.8kg graphite, 0.06kg cerium oxide, 1.5kg rare earth magnesium silicon Ferroalloy, 0.5kg fluorspar, 0.4kg silica, 0.12kg Li 2 CO 3 , 0.3kg marble for mixing;

[0077] b. Filling: roll the cold-rolled steel strip into a U-shaped section, and then fill the 10kg powder mixed in step a into the U-shaped metal groove according to the filling rate of 35%, and then seal and roll;

[0078] c. Drawing and forming: the tubular welding wire sealed in step b is drawn, and the filling rate is detected after drawing and forming, which is obtained from the protective surfacing flux-cored welding wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com