Patents

Literature

104results about How to "Control impurity content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation process of TB9 titanium alloy wire with rectangular section

ActiveCN103341520AControl impurity contentSpring cold winding process performance is goodIngotHigh intensity

The invention belongs to the field of processing of titanium alloy, and in particular provides a preparation process of a TB9 titanium alloy wire with a rectangular section, high strength and high toughness as well as a wire and a spring prepared by the process. The process comprises the following steps of: insulating for 1.5-3 hours at 1100-1150 DEG C; adopting a free forging process to forge a TB9 titanium alloy ingot to a TB9 titanium alloy forged rod; insulating for 1-2 hours at 900-1000 DEG C; adopting a hot-rolling process to hot-roll the TB9 titanium alloy forged rod to a TB9 titanium alloy rolled rod; adopting a thermal drawing preparation process at 580-780 DEG C to thermally draw the TB9 titanium alloy rolled rod to a TB9 titanium alloy thermal-drawn wire; and under a beta single phase, adopting a cold drawing process to cold-draw and deform the wire with total deformation of 20-35% under the premise of ensuring 4-10% of deformation of the gate so as to prepare the TB9 titanium alloy cold-drawing wire with the rectangular section. The wire is spirally winded to form the TB9 titanium alloy with the rectangular section.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

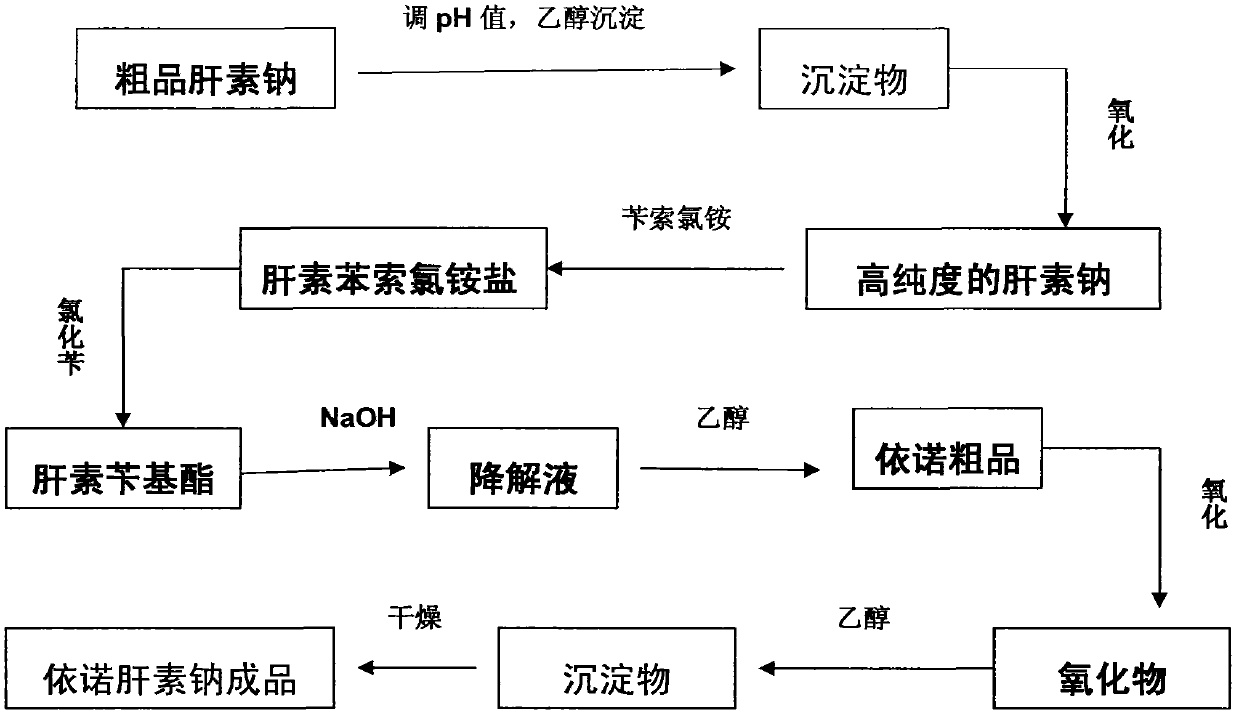

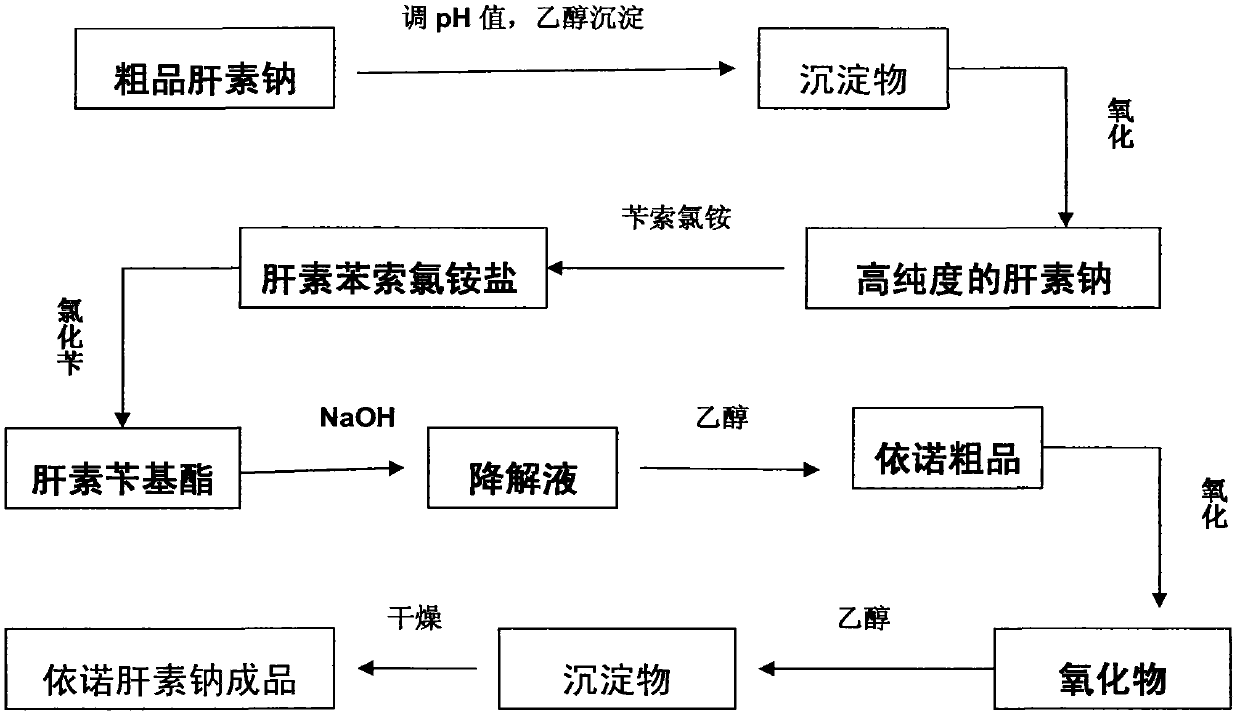

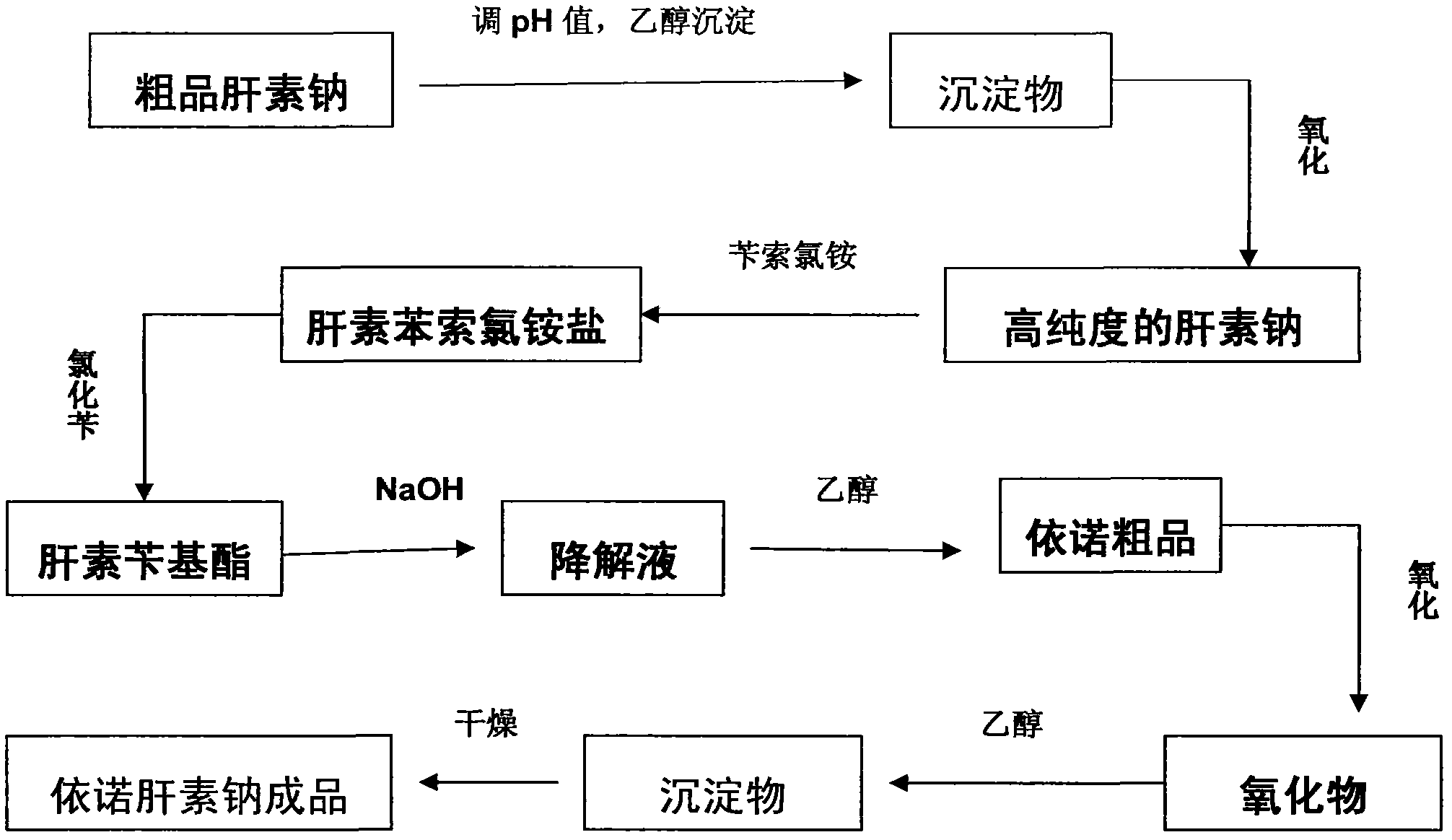

Method for directly producing enoxaparin sodium from crude product heparin sodium

ActiveCN102603925AControl impurity contentReduce intermediate environmentOrganic solventDepolymerization

The invention relates to a preparation method for directly producing enoxaparin sodium from crude product heparin sodium. The preparation method comprises the following steps of: taking the crude product heparin sodium as a raw material, performing fractionated precipitation through an organic solvent to remove most of impurities in the crude product heparin sodium, and then removing part of residual impurity proteins, pigments and other impurities by oxidation through hydrogen peroxide so as to get the high-purity heparin sodium which is in line with the production requirements of the enoxaparin sodium; and taking the high-purity heparin sodium as an intermediate product, preparing a heparin quaternary ammonium salt, preparing heparin benzyl ester, performing alkaline depolymerization on the heparin benzyl ester, neutralizing with an acid, performing alcohol precipitation, refining, decoloring, dehydrating and drying to get an enoxaparin sodium finished product. By adopting the method disclosed by the invention, the use of the organic solvent is greatly reduced, the production efficiency is improved, the influences on the environment are reduced, the enoxaparin sodium finished product which achieves or is better than European Pharmacopoeia 7.0 version is obtained, and the method is simple to operate and can realize industrialized production.

Owner:DONGYING TIANDONG PHARM CO LTD

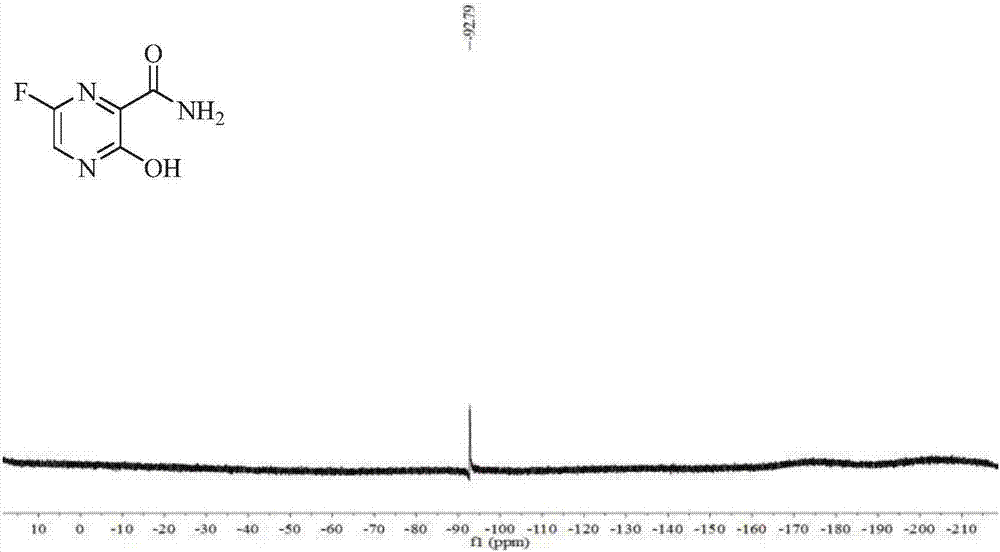

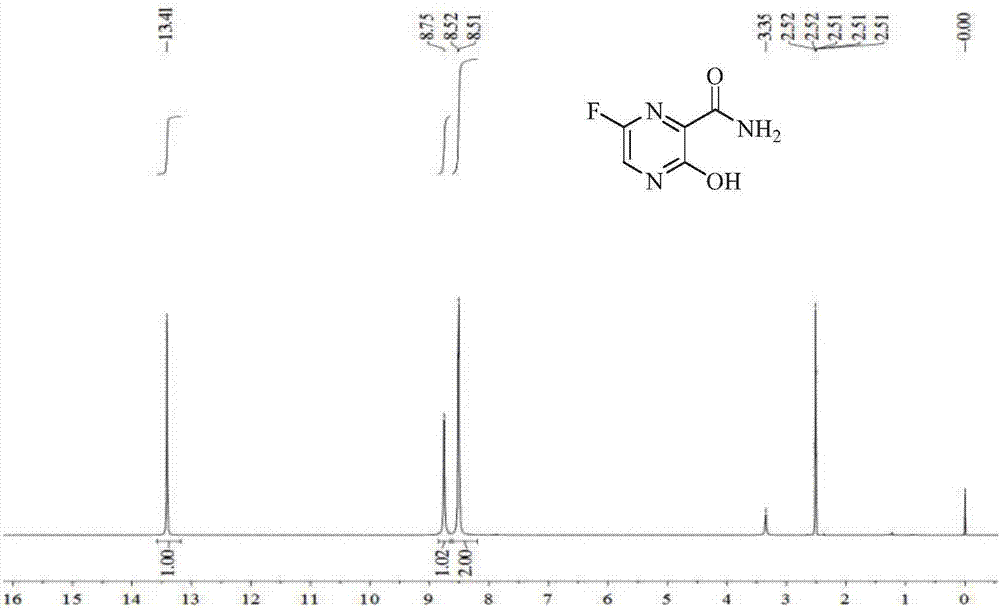

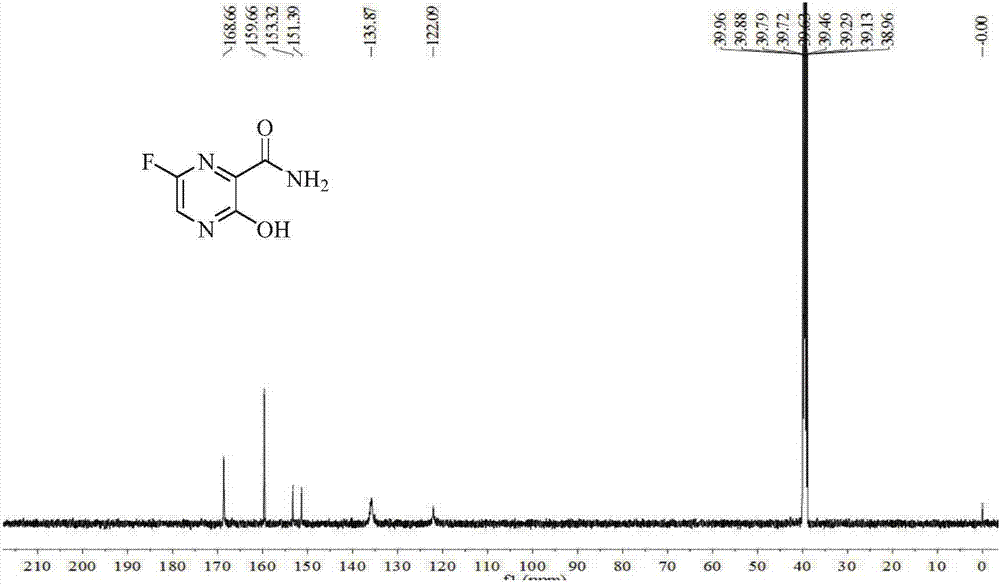

Method for synthesis of favipiravir

InactiveCN106866553ASimple preparation processSimple and efficient operationOrganic chemistryColumn chromatographySubstitution reaction

The invention discloses a method for synthesis of favipiravir. The method comprises an esterification reaction of 3-aminopyrazine-2-carboxylic acid and an alcohol, a bromination reaction, a diazotization reaction, an ammonolysis reaction, a chlorination-dehydration reaction, a one-pot series connection aromatic ring fluorination reaction, a cyan-hydrolysis reaction, an aromatic ring hydroxyl substitution reaction, and purification treatment so that favipiravir is obtained. The method utilizes 3-amino-2-carboxypyrazine as a raw material to synthesize favipiravir through 8-step reactions and has a total yield of 26%. The key intermediates 3 and 6 in the method are purified by recrystallization so that column chromatography separation in the literature is avoided. The final three reactions are finished by a one-pot method so that the operation is simplified. The synthesis method improves a yield, realizes a low cost and green economy and is conducive to industrial production.

Owner:CENT SOUTH UNIV

Water-soluble ion liquid synthesizing method

InactiveCN1579609AShort reaction timeReduce processing costsTransportation and packagingMixingAlkaneWater baths

The invention discloses an approach of composing a kind of water soluble ion liquor. Using ultrasonic wave cell smash instrument of 740-760W to process mixed liquor of methylimidazole and bromo carbons whose mol ratio is 1:1.0-1:1.1. The whole reaction is conducted in water bath of 20-80deg.C. Cool after 0.5-1 hour. Use ethyl acetate in same volume to extract for 2-3 times. Obtain water soluble ion liquor after vacuum drying under 60-80deg.C for 6-8 hours. Molecular formula of the production is [RCH3IM] X, thereinto, R for paraffin base of C4, X for Br. The invention has a simple operation and low cost with a short process time. There are little poisonous matters produced at process of producing. Impurities in production are effectively controlled. The production also can serve as medium in catalytic reaction.

Owner:ZHEJIANG UNIV

Method for preparing high-purity vanadium powder

The invention discloses a method for preparing high-purity vanadium powder. The method aims to solve the problem that contents of impurities, particularly contents of O and N, in vanadium powder are high, and requirements of powder metallurgy on purity of raw materials and the like are met. The method includes activating surfaces of a vanadium block by saturated NaO alkali liquor, distilled water and ethanol or acetone sequentially, feeding the vanadium block in a closed container, placing the closed container with the vanadium block in a hydrogenation hydrogen absorbing system, drying and degassing the vanadium block and hydrogenating the degassed vanadium block at the temperature ranging from 200 DEG C to 500 DEG C to obtain high-purity vanadium hydride grains; placing the high-purity vanadium hydride grains in a planetary ball mill for dry grinding; and feeding vanadium hydride powder obtained in the previous step in the closed container for dehydrogenization at a high temperature. The granularity of the submicron vanadium powder prepared by the method can be smaller than 30 micrometers, oxygen content can be controlled to be within 600ppm, nitrogen content is lower than 250ppm, and the problem that the high-purity vanadium powder is prepared difficultly is effectively solved.

Owner:SICHUAN INST OF MATERIALS & TECH

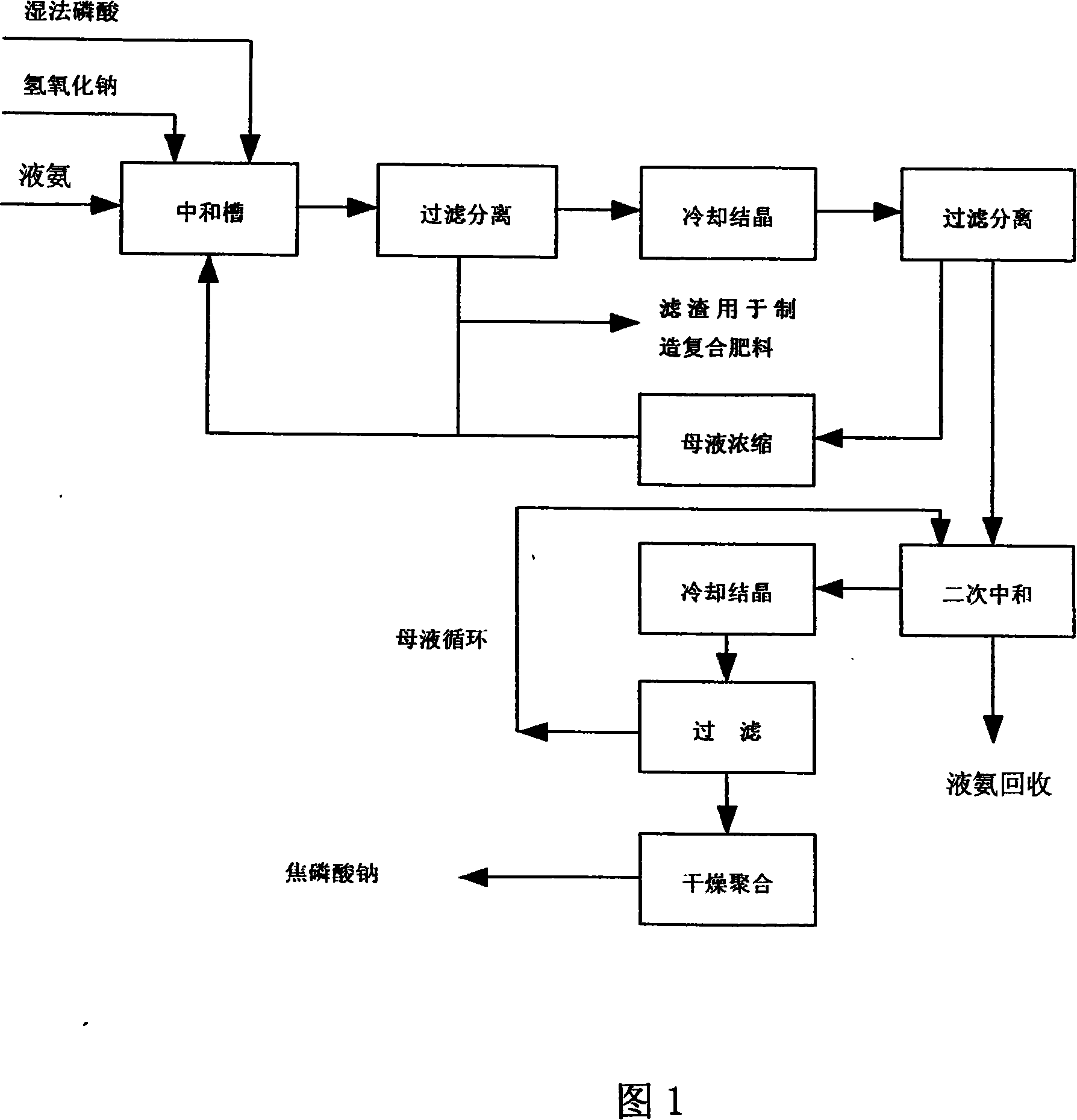

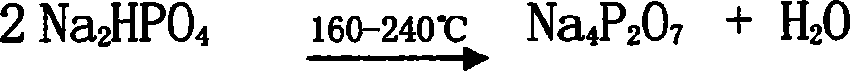

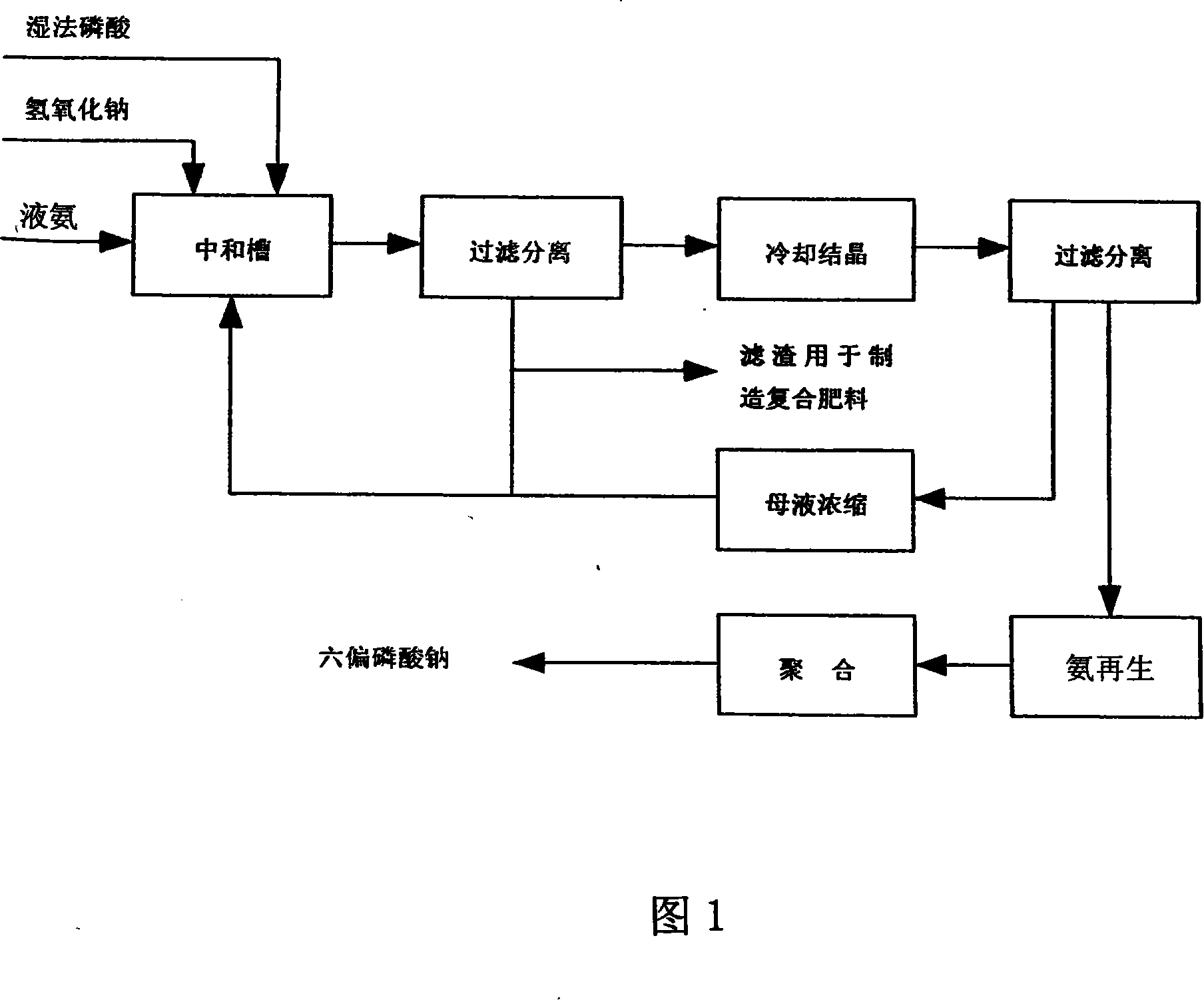

Technique for preparing sodium pyrophosphate from wet method phosphoric acid

InactiveCN101121506AControl impurity contentAvoid easy separationPhosphorus compoundsPhosphoric acidPyrophosphate

Owner:SICHUAN HONGDA

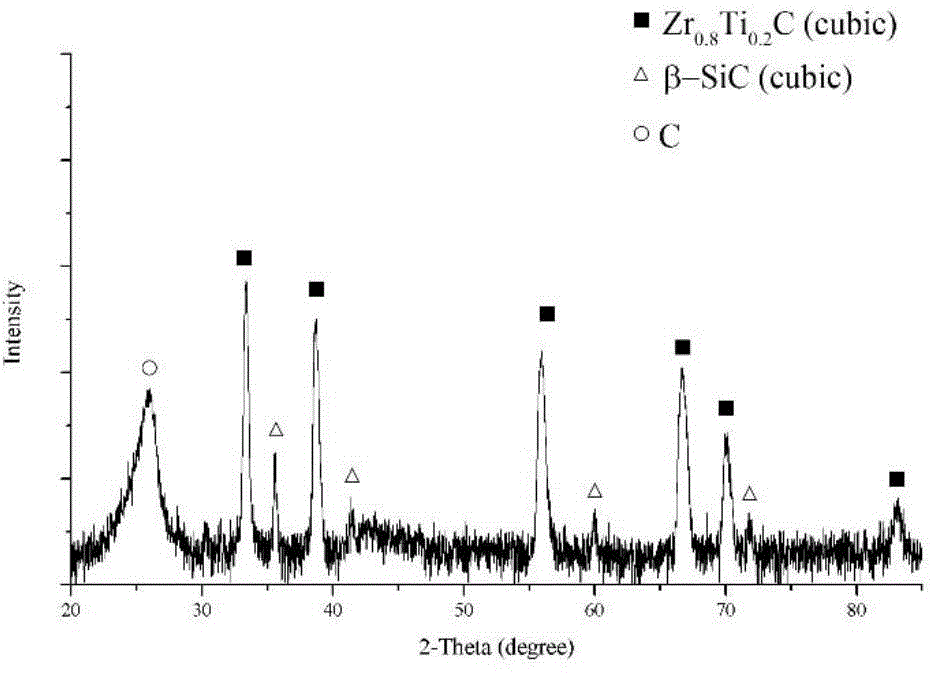

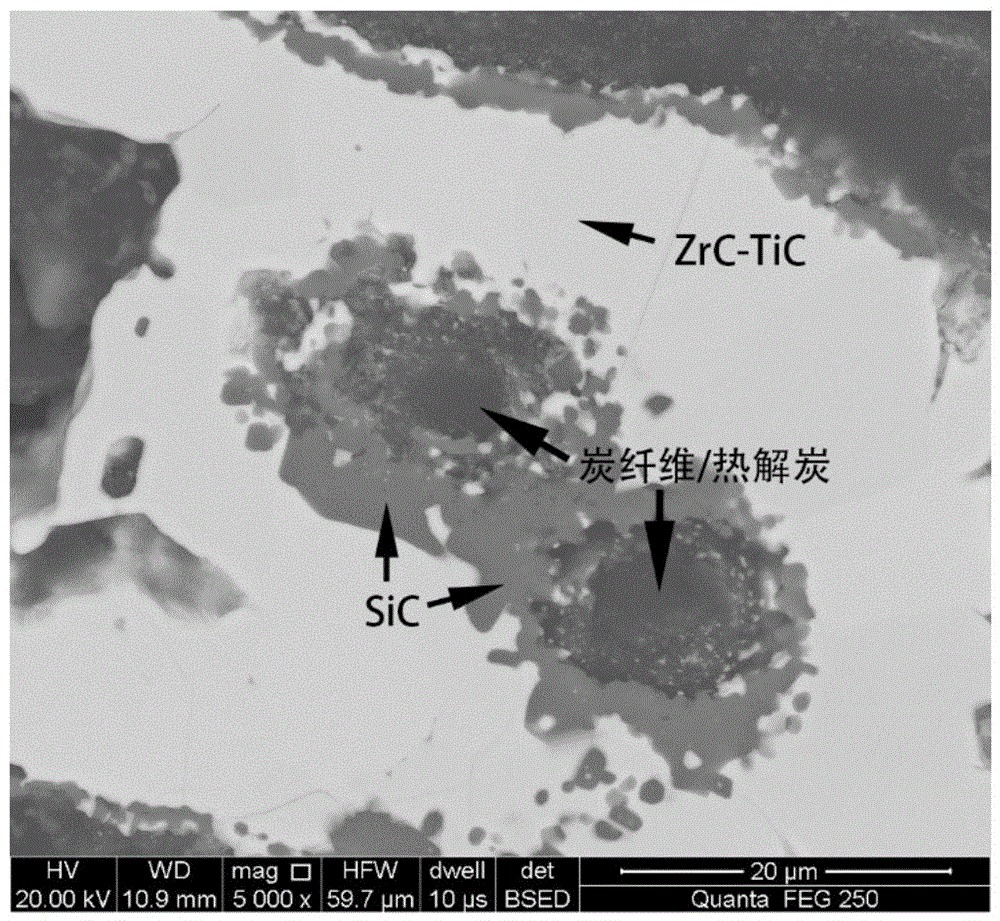

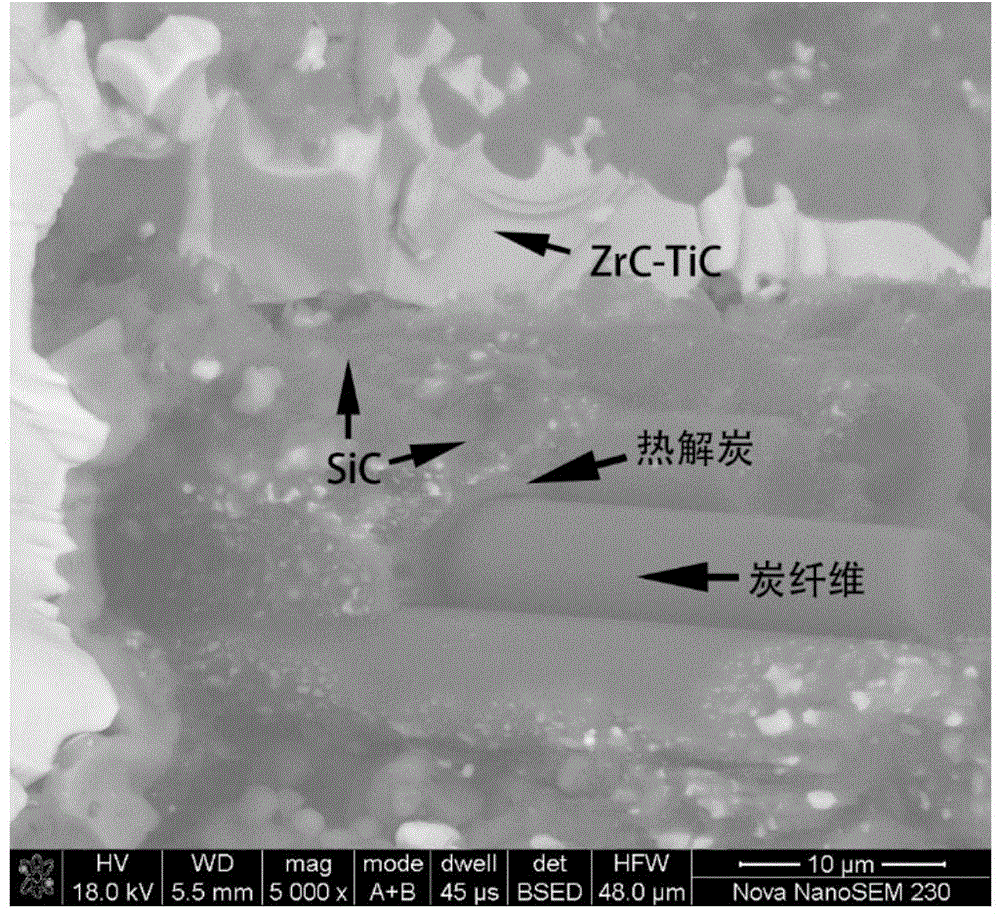

C/C-SiC-ZrC-TiC composite material and preparation method thereof

ActiveCN104671814AReduce thermal mismatchRelieve stress concentrationInterface layerPyrolytic carbon

The invention discloses a C / C-SiC-ZrC-TiC composite material and a preparation method thereof. The composite material is composed of a carbon fibre, a pyrolytic carbon, a main matrix phase ZrC-TiC and a sub matrix phase SiC. The composite material is characterized in that the SiC is used as an interface layer for separating the pyrolytic carbon from the ZrC-TiC. The preparation method comprises the following steps: melting the mixed powder of Zr, Ti and Si, permeating into the inside of the low-density C / C composite material through a capillary action, forming a ceramic phase in a hole through an in situ reaction to obtain the C / C-SiC-ZrC-TiC composite material. The preparation method is rapid and effective and low in cost; the prepared composite material has excellent super-high temperature ablation resistance performance and simultaneously has excellent strength, breaking tenacity and thermal shock resistance.

Owner:深圳金羽先进材料有限公司

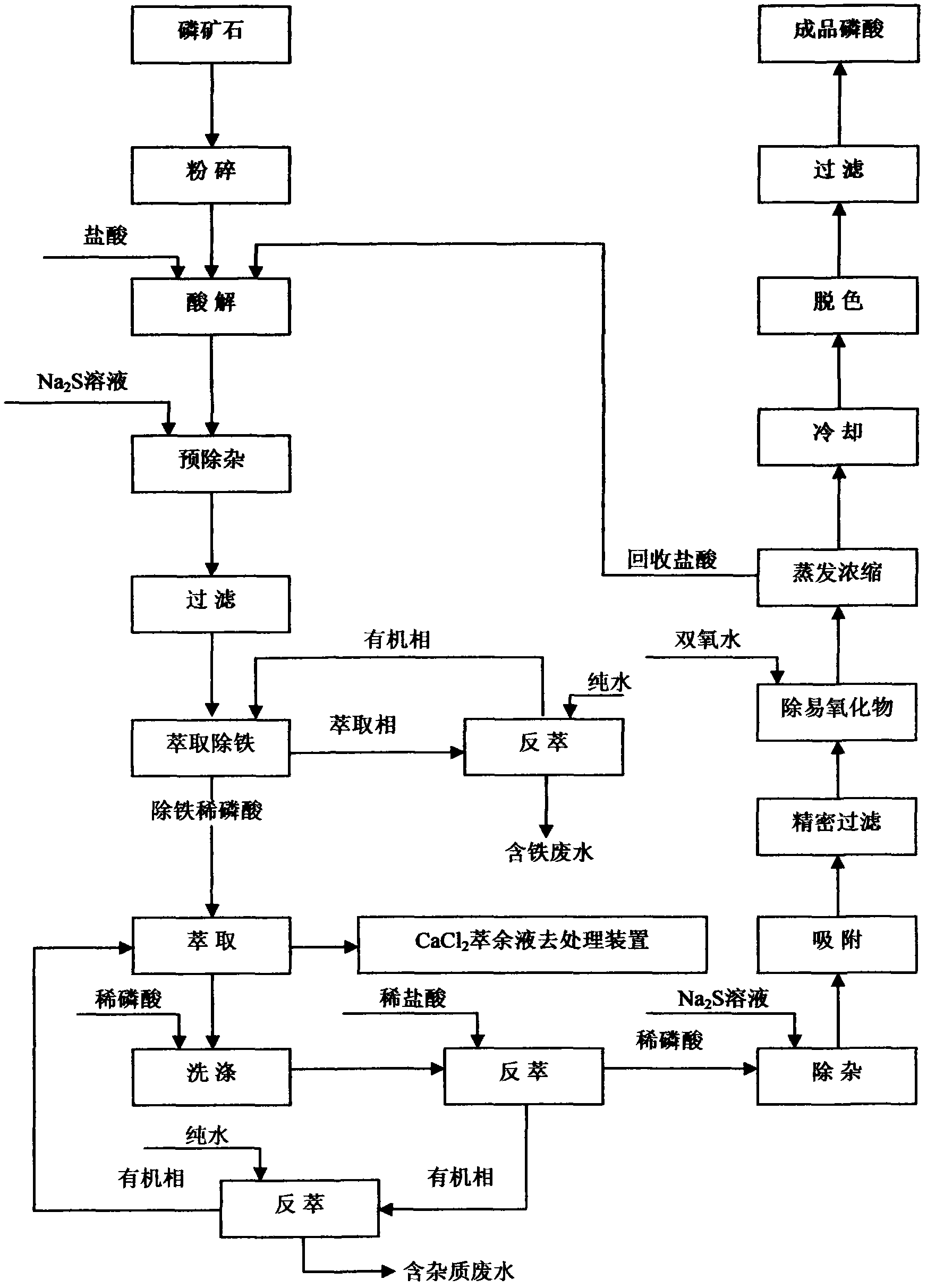

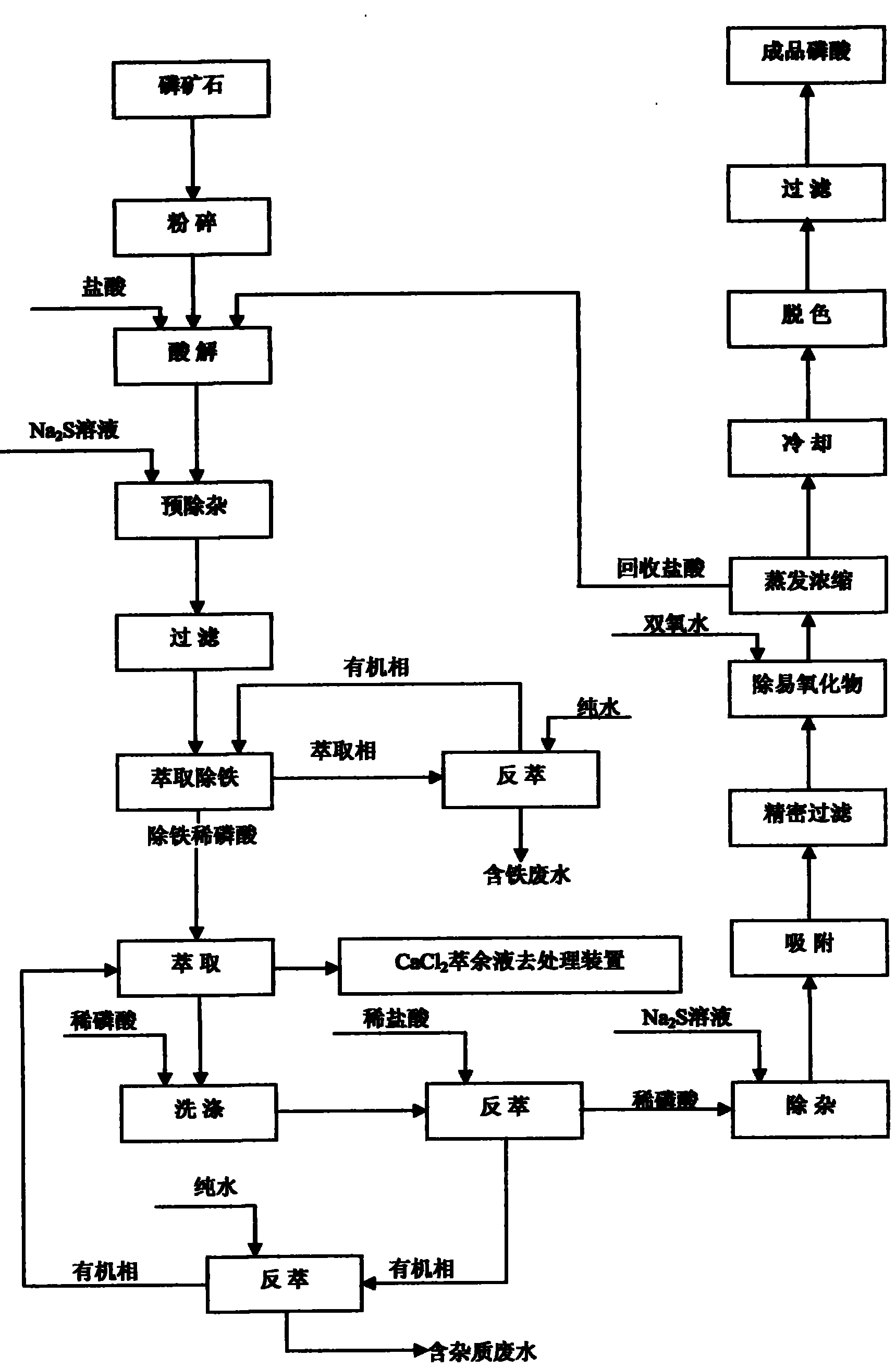

Production technology of food-grade phosphoric acid with hydrochloric acid method

ActiveCN102515134ASimple componentsControl impurity contentPhosphoric acidFood industrySimple component

The invention discloses a production technology of food-grade phosphoric acid with hydrochloric acid method. According to the invention, hydrochloric acid acidolysis process is used as a base, heavy metal impurities are removed by prepurification and subsequent purification, and simultaneously tributyl phosphate with simple components and stable property is used as an extractant to complete extraction, the extraction effect is good, and back extraction process of dilute hydrochloric acid is combined, the utilization rate of the extractant is high. The whole extraction and back extraction are completed at normal temperature, thus the technology is especially suitable for preparing food-grade phosphoric acid in industrial production. The liquid-liquid extraction technology has strong controllability, and high extraction rate and high impurity removal rate. The content of H3PO4 in a finished product of phosphoric acid reaches more than 75 wt%. The finished product of phosphoric acid has good quality and can be used in food industry without purification, and is suitable for lean phosphate rocks or rich phosphate rocks.

Owner:西安君正工程科技有限公司

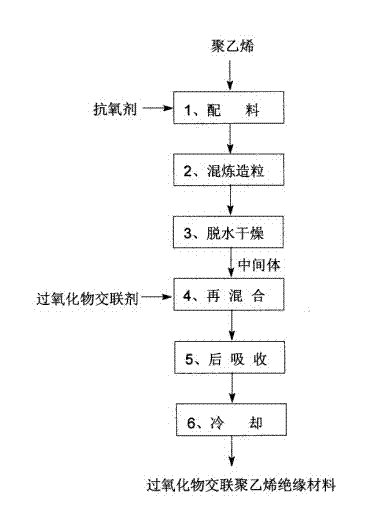

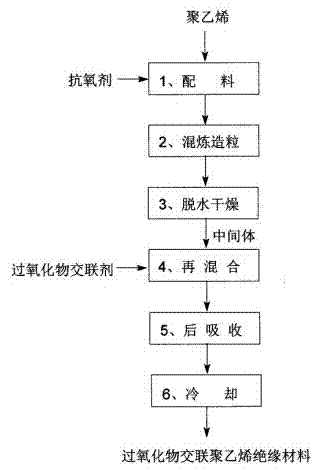

Post-absorption process of peroxide cross-linking polyethylene insulating material

InactiveCN102241848AImprove stabilityImprove reliabilityPlastic/resin/waxes insulatorsPower cableMixed materials

The invention relates to an insulating material for electric power cables, in particular to a post-absorption process of a peroxide cross-linking polyethylene insulating material. The process comprises the following steps of: (1) material blending: antioxidant and polyethylene are blended; (2) mixing and pelletizing: the blended materials are mixed in a mixing roll, and the mixed materials are filtered and then extruded and pelletized; (3) dehydrating and drying: the materials derived from pelletizing in the step 2 are dehydrated and dried to obtain an intermediate; (4) remixing: the intermediate derived from the step 3 is mixed with a peroxide cross-linking agent for 5 to 240 minutes at the temperature from 50 DEG C to 80 DEG C; (5) post-absorbing: the material derived from the step 4 is post-absorbed; and (6) cooling: the material derived from the step 5 is cooled to obtain the peroxide cross-linking polyethylene insulating material. The process in the invention is uniform in mixing, good in post-absorption effect and simple and reasonable in process; and the manufactured insulating material has reliable performances and good quality.

Owner:JIANGSUSNGSHANG CABLE GROUP

Process for preparing lithium carbonate from spodumene

InactiveCN107640779AControl impurity contentLarge particlesChemical industryLithium carbonates/bicarbonatesHydrogenation reactionFluidized bed

The invention discloses a process for preparing lithium carbonate from spodumene. The process comprises the following steps of crushing, grinding and sieving the spodumene to be 100 to 150 microns, soas to obtain primary raw ore powder; putting the primary raw ore powder into a program control box type electric furnace to carry out crystal form transformation calcination, so as to obtain a primary calcined raw material; grinding the primary calcined raw material, obtaining acidized clinker, carrying out hot processing on the acidized clinker in a fluidized bed reactor, transforming the acidized clinker to be in a dissoluble form used for separating lithium, then filtering, transmitting the filtered acidized clinker in a process pipeline in a manner of reversely flowing with a hot-processgas moved out from the fluidized bed reactor, and enabling the hot gas to be directly in contact with the acidized clinker; introducing a carbon dioxide gas into a hydrogenation reaction kettle to transform the lithium carbonate into a lithium hydrogen carbonate solution, and carrying out a reaction, so as to obtain a carbonated solution; heating the lithium hydrogen carbonate solution subjected to impurity removal to boil, filtering, washing and drying to obtain required battery-grade or high-purity lithium carbonate.

Owner:河北赣锋锂业有限公司

Manufacturing method for high-quality cotton linter

ActiveCN103103841ALow grayscaleLow impurity contentFibrous raw materialsPulp and paper industryImpurity

The invention discloses a manufacturing method for high-quality cotton linter. The processing steps includes that (1) gross cottonseeds of raw material of the cotton linter are purified, stone and dust in the gross cottonseeds are eliminated, and the purified gross cottonseeds are obtained; (2) the obtained purified gross cottonseeds are sent to a delinter to have linter peeled and the impurity content of the purified gross cottonseeds is controlled, so that the cotton linter with low impurity is obtained; (3) the cotton linter with low impurity is sent to a lower linter collecting machine to have the dust eliminated, and the dedusted cotton linter is obtained; (4) the dedusted cotton linter is sent to a shell-linter separator where the linter is effectively separated from the impurities, and the cotton linter without impurity is obtained; (5) the cotton linter without impurity is sent to a cleaning machine where the linter is further separated with the impurities, and the high-quality cotton linter is obtained. According to the manufacturing method for the high-quality cotton linter, the gross cottonseeds are preliminarily purified, the cotton linter with the low impurity content is obtained through the delinter, and then the lower linter collecting machine, the shell-linter separator and the cleaning machine are utilized in sequence, so that the impurities and the dust in the cotton linter are eliminated, and the cotton linter which is low in dust content and impurity content, high in quality and even in mass distribution is obtained.

Owner:邯郸晨光植物蛋白有限公司

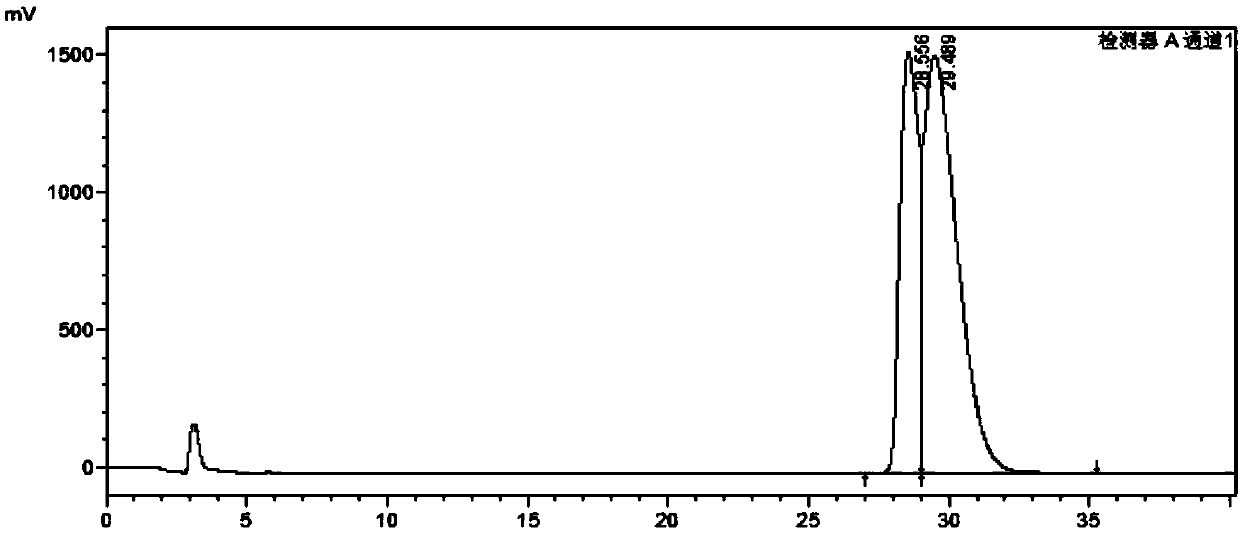

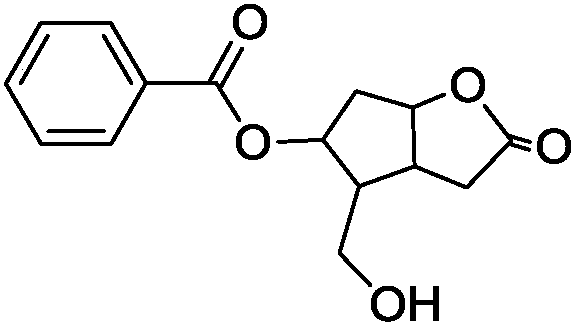

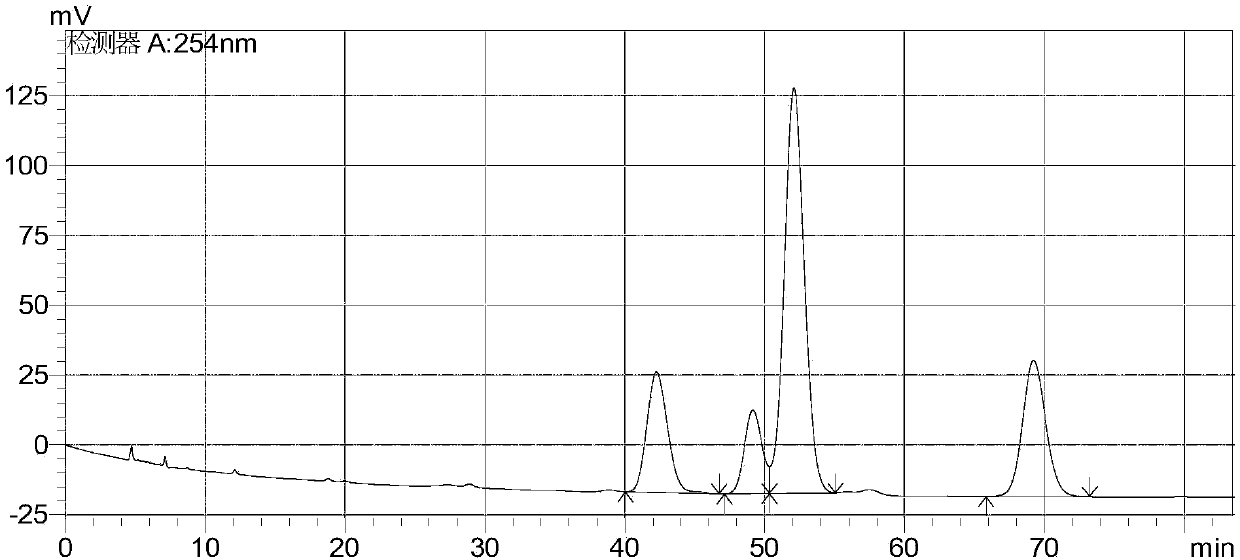

Method for analyzing and separating Corey lactone benzoate enantiomers through HPLC

The invention discloses a method for analyzing and separating Corey lactone benzoate enantiomers through an HPLC by means of a direct-chain starch type chiral chromatographic column with positive phase mixed solvent as the flowing phase. The method can easily, accurately and efficiently analyze and separate the Corey lactone benzoate enantiomers, and therefore the quality of the Corey lactone benzoate enantiomers is controlled. The method can also be used for preparing high-purity single-optical-activity Corey lactone benzoate.

Owner:吉林百纯化学科技有限公司

Carrier material in use for preparing dextran through method of enzyme immobilization

InactiveCN1563374AAdvanced technologyReduce manufacturing costOn/in organic carrierSucroseWater soluble

A carrier material used in producing dextrans with a zyme immobilization method applies complex polymer glues as the immobilized carrier material composed of algae acid or with natural and or synthesized or water-soluble or semi-soluble polymers to immobilize dextran sucrose zymes and produce dextrans.

Owner:HEFEI UNIV OF TECH +1

EFB start-stop battery positive and negative electrode with high charging acceptance capacity and preparation method thereof

ActiveCN109037597AImprove corrosion resistanceReduce voltage dropLead-acid accumulatorsElectrode carriers/collectorsFiberCarbon fibers

The invention relates to an EFB start-stop battery positive and negative electrode with high charge acceptance capacity and a preparation method thereof, belongs to the technical field of EFB start-stop batteries, and mainly solves the problem that the high-temperature life of a battery is reduced due to carbon fibers contained in existing lead paste. The main features are as follows: an anode lead paste formula includes 0.2% -- 0.4% of expanded graphite, 0.08% - 0.12% of short fiber, 0.1% - 0.3% of metal sulfate additive, 0.6% - 1.0% of 4BS seed, 9% - 12% of pure water, 8% - 10% of 1.38 g / cm3sulfuric acid solution and the balance of lead powder; a cathode lead paste formula includes 0.1 to 0.2 percent of carbon nanotube slurry, 0.1 to 0.2 percent of carbon black A, 0.02 to 0.06 percent of carbon black B, 0.08 to 0.12 percent of short fiber, 0.15 to 0.25 percent of organic additive A, 0.08 to 0.12 percent of organic additive B, 0.5 to 0.8 percent of nanometer barium sulfate, 8 to 10 percent of pure water, 8 to 10 percent of 1.38 g / cm3 sulfuric acid solution and the balance of lead powder. The invention has the characteristics of greatly improving battery charging acceptance capacity and further prolonging the battery life, and is mainly used for EFB starting and stopping batteries with high charging acceptance capacity.

Owner:CAMEL GRP XIANGYANG BATTERY

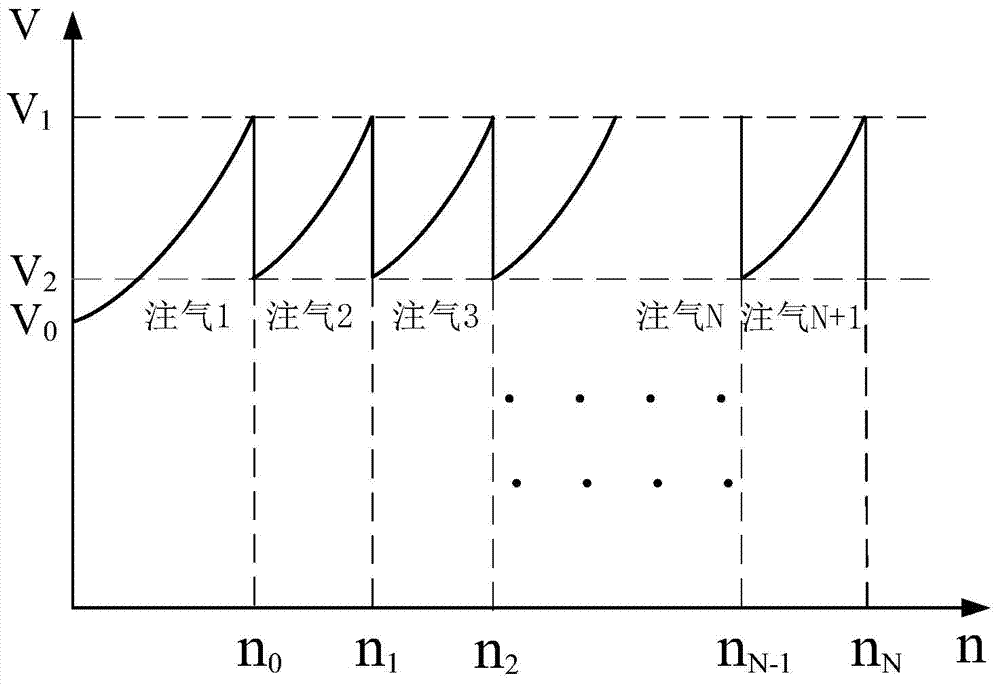

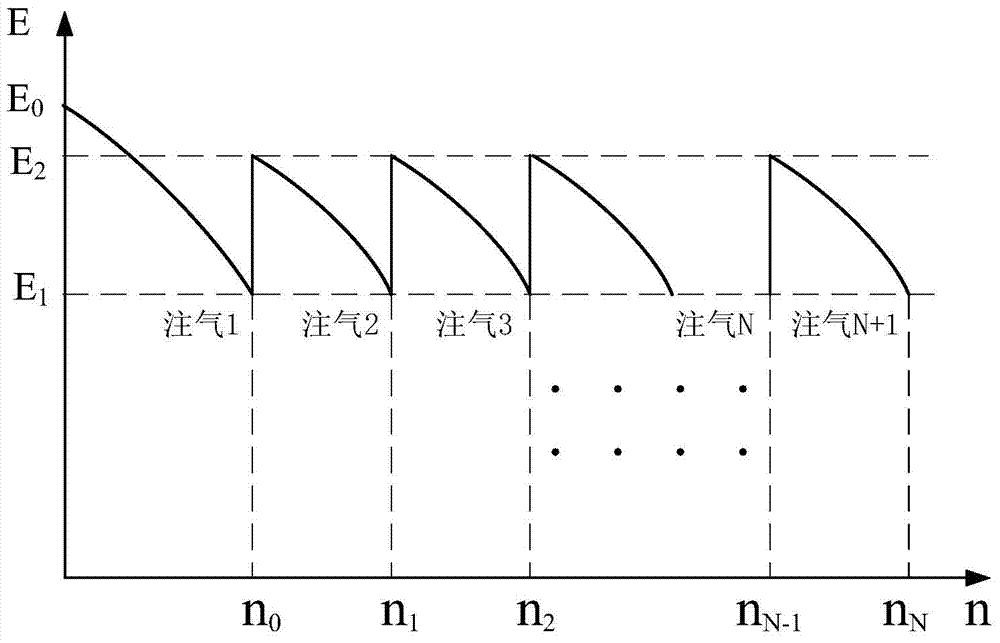

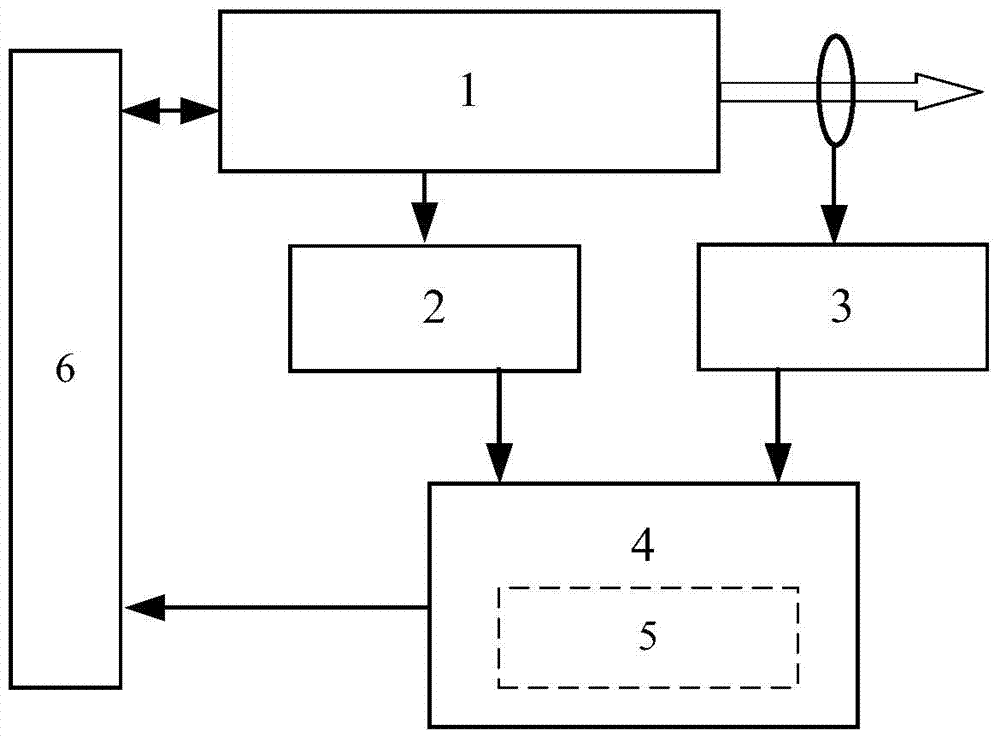

Gas management method for prolonging life of laser working gas of excimer laser

The invention provides a gas management method for prolonging life of laser working gas of an excimer laser. During working of the excimer laser, since the content of halogen gas in a laser cavity is reduced and the impurity content is increased, the pulse energy output by the laser reduces continuously. Through a mode of partially replacing laser working gas in the laser cavity, the halogen gas consumed in the laser cavity can be effectively replenished, and meanwhile the accumulation of impurities is stopped. According to the gas management method, by analyzing the change of the contents of the halogen gas and the impurities in the laser cavity before and after partial gas replacement, the dosage for partial gas replacement and the injection dosage of the halogen gas are controlled, so that the contents of the halogen gas and the impurities in the laser cavity after every partial gas replacement are kept unchanged, and the excimer laser working in a constant pulse energy output mode is maintained to continuously work within a certain working voltage change range or the excimer laser working in a constant working voltage mode is maintained to continuously work within a certain pulse energy change range. The life of the working gas of the excimer laser can be effectively prolonged, and the working efficiency of the excimer laser is improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

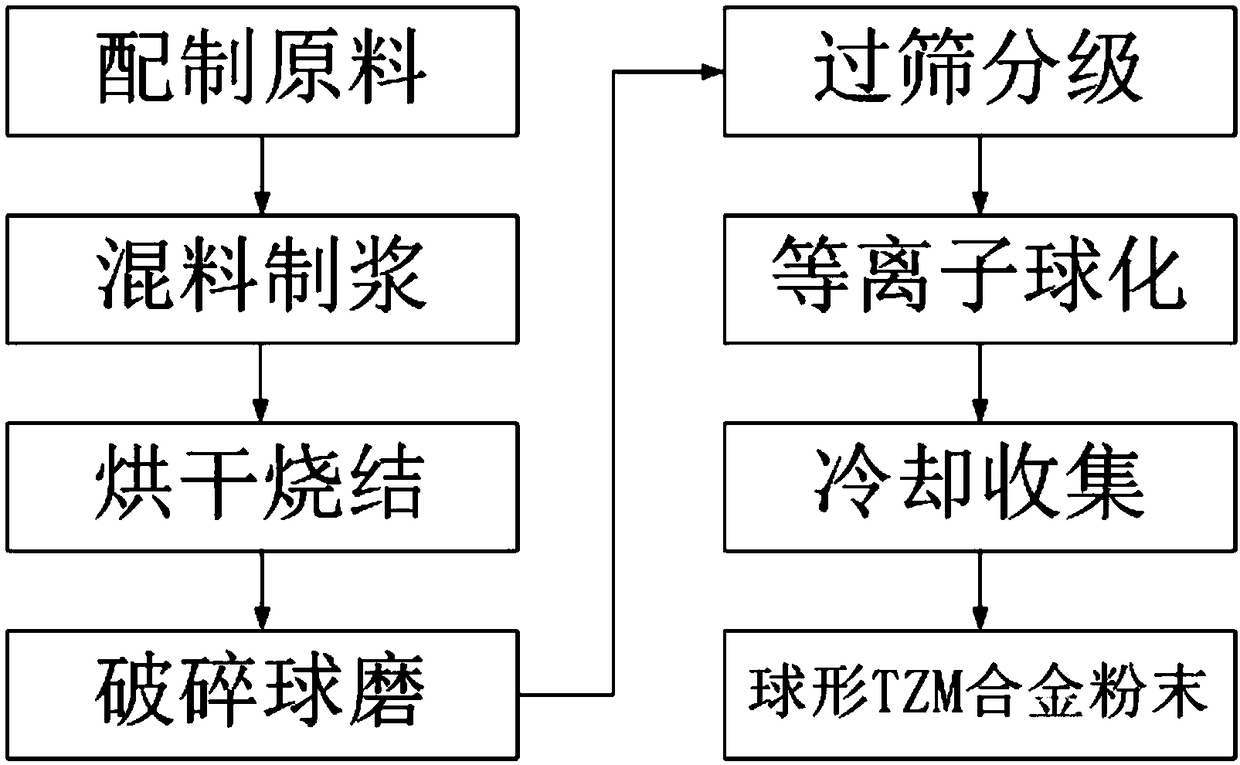

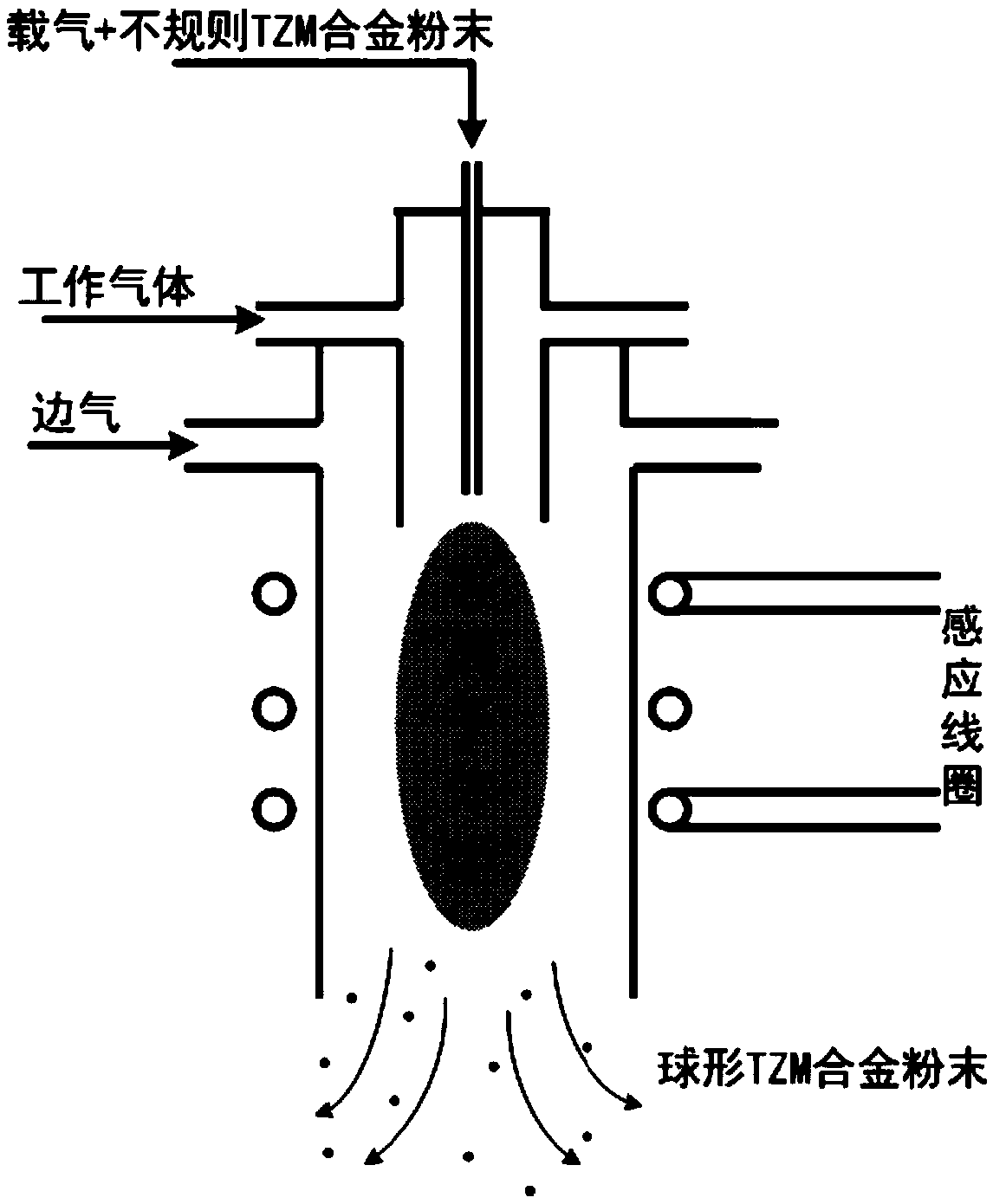

Method for preparing spherical Titanium-Zirconium-Molybdenum alloy powder

ActiveCN109332717ASpeed up meltingPowder state optimizationTransportation and packagingMetal-working apparatusZirconium hydrideTitanium zirconium

The invention provides a method for preparing spherical Titanium-Zirconium-Molybdenum (TZM) alloy powder, and belongs to the technical field of metal powder material preparation. The method for preparing the spherical Titanium-Zirconium-Molybdenum (TZM) alloy powder comprises the steps that reduced molybdenum (Mo) powder, titanium hydride (TiH2) powder, zirconium hydride (ZrH2) powder and graphitepowder are adopted as basic raw materials to prepare raw powder which conforms to the alloy stoichiometry; absolute ethyl alcohol is added into the raw powder to prepare slurry, and thorough stirringis carried out for uniform mixing; the slurry is subjected to vacuum drying, and powder is sintered under a reducing atmosphere; the alloy powder sintered blank is subjected to ball-milling to be sufficiently broken; the ball-milled alloy powder is sieved and irregular TZM alloy powder within a certain particle size range is selected out; the irregular TZM alloy powder is fed into an inductivelycoupled plasma torch, the TZM alloy powder is rapidly melted under a high temperature, and molten alloy droplets form a spherical shape under the action of surface tension; and the molten spherical TZM alloy droplets are separated from a high temperature region of plasma and rapidly cooled under the protection of inert gas to form the spherical TZM alloy powder.

Owner:云航时代(重庆)科技有限公司

Preparation method of lithium tetrafluorooxalate phosphate

InactiveCN109053415AControl impurity contentSimple processOrganic compound preparationCarboxylic acid salt preparationSolventChemistry

The invention discloses a preparation method of lithium tetrafluorooxalate phosphate. The method is characterized by comprising the following steps: (1) dissolving lithium hexafluorophosphate in an aprotic solvent, adding oxalic acid or ammonium oxalate, phosphorus pentachloride or phosphorus trichloride, and carrying out a reaction to obtain lithium tetrafluorooxalate phosphate; (2) adding a poorsolvent to enable the generated lithium tetrafluorooxalate phosphate to be crystallized; (3) filtering, washing, and drying to obtain the lithium tetrafluorooxalate phosphate. The method provided bythe invention is simple in process, non-toxic in raw materials, low in danger coefficient, short in reaction time and high in yield, can effectively control the contents of metal ions and anionic impurities, and can be used for preparing the high-purify lithium tetrafluorooxalate phosphate target product.

Owner:中山弘毅新材料有限公司

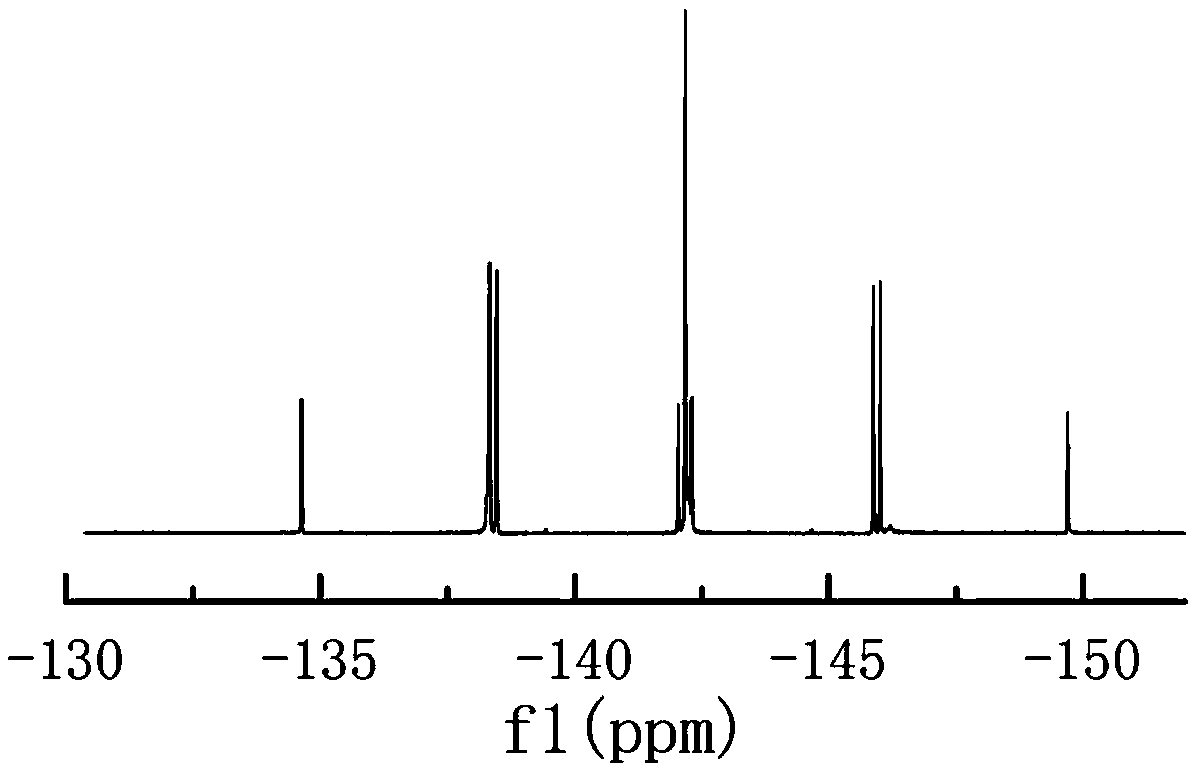

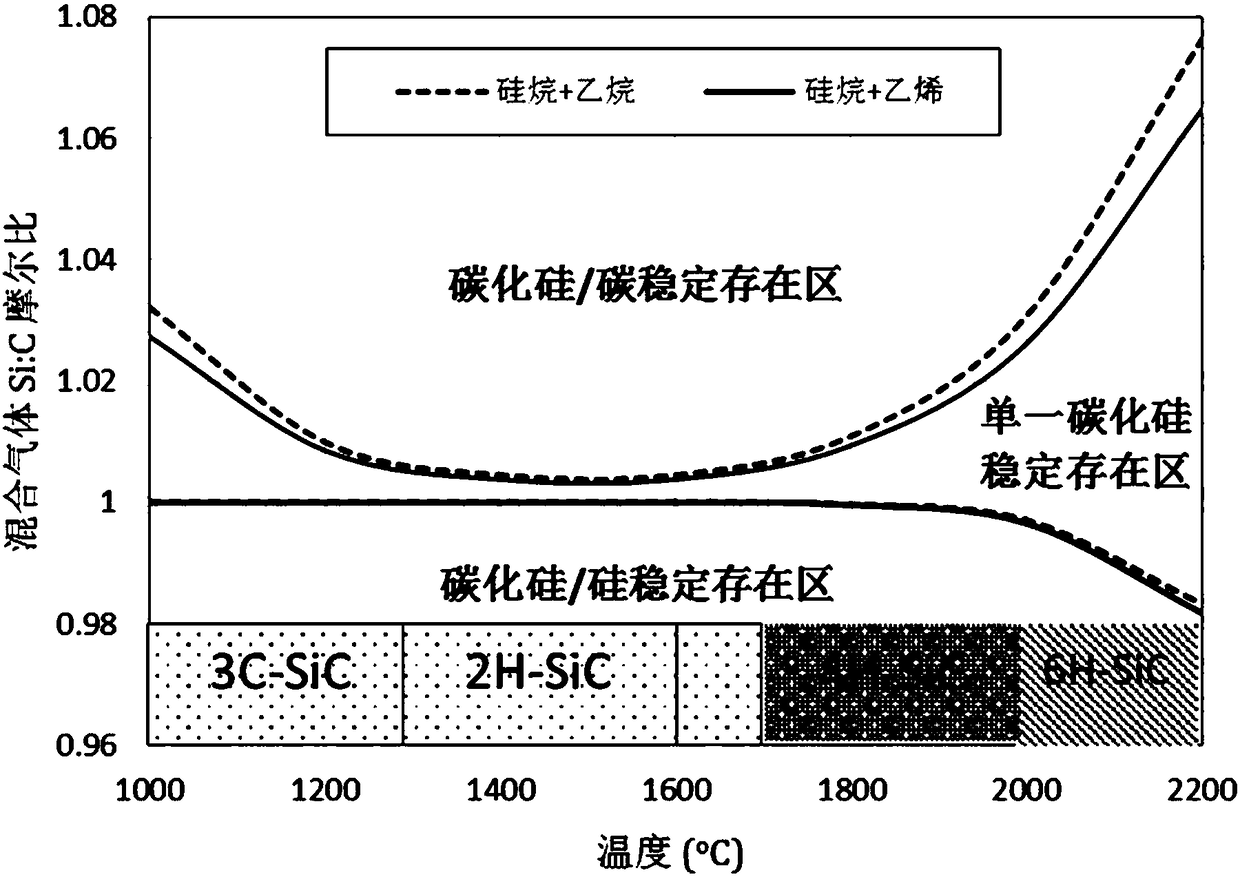

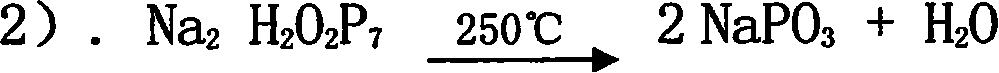

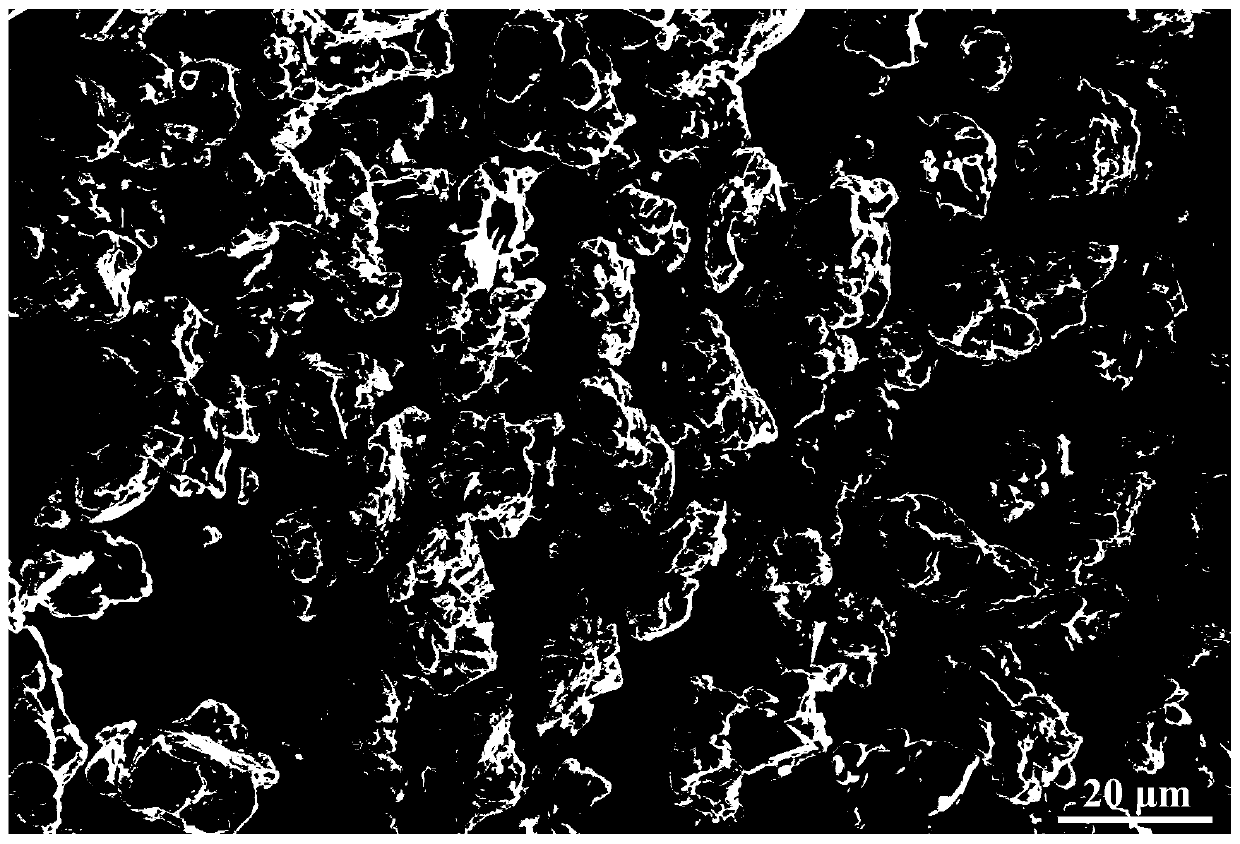

Ultra-pure nanometer silicon carbide and preparation method thereof

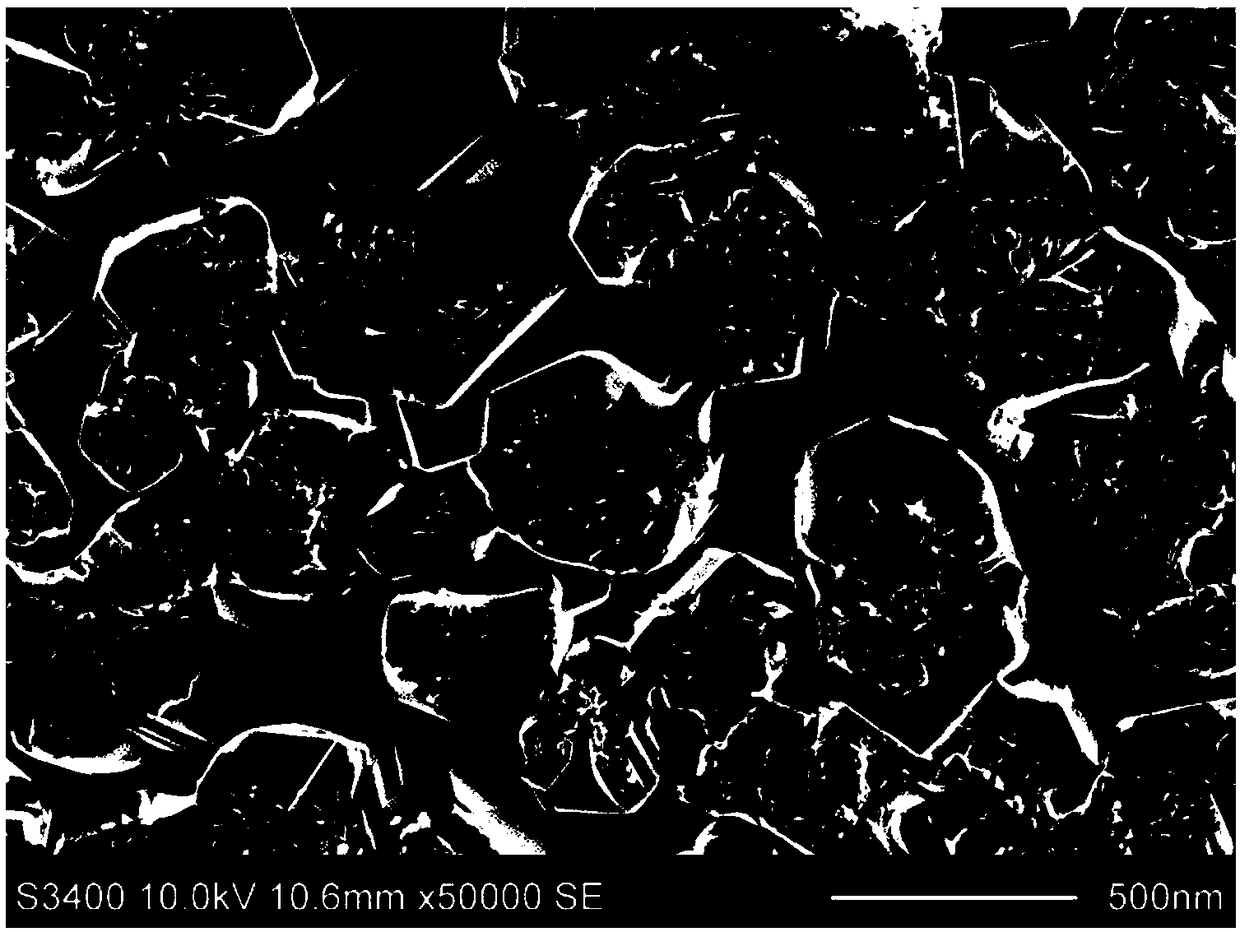

InactiveCN108557823AControl crystal formControl impurity contentCarbon compoundsNanotechnologySingle crystalAtmospheric pressure

The invention provides ultra-pure nanometer silicon carbide and a preparation method thereof. the preparation method comprises the following steps: preparation of a gas reaction precursor: mixing a carbonaceous gas and a silicon-containing gas at the Si:C molar ratio of 1: 1.0-1:1.06 to obtain the gas reaction precursor; preparation of ultra-pure nanometer silicon carbide: introducing the gas reaction precursor into a preheated ceramic reactor such that the gas reaction precursor is directly synthesized in a high-temperature zone of the ceramic reactor into nanometer silicon carbide with granularity of 50-500 nm. Temperature in the preheated ceramic reactor is 1100-2200 DEG C. pressure of the ceramic reactor is 1-5 atmospheric pressures. A single crystal form of nanometer silicon carbide can be synthesized in the invention.

Owner:JIANGSU UNIV

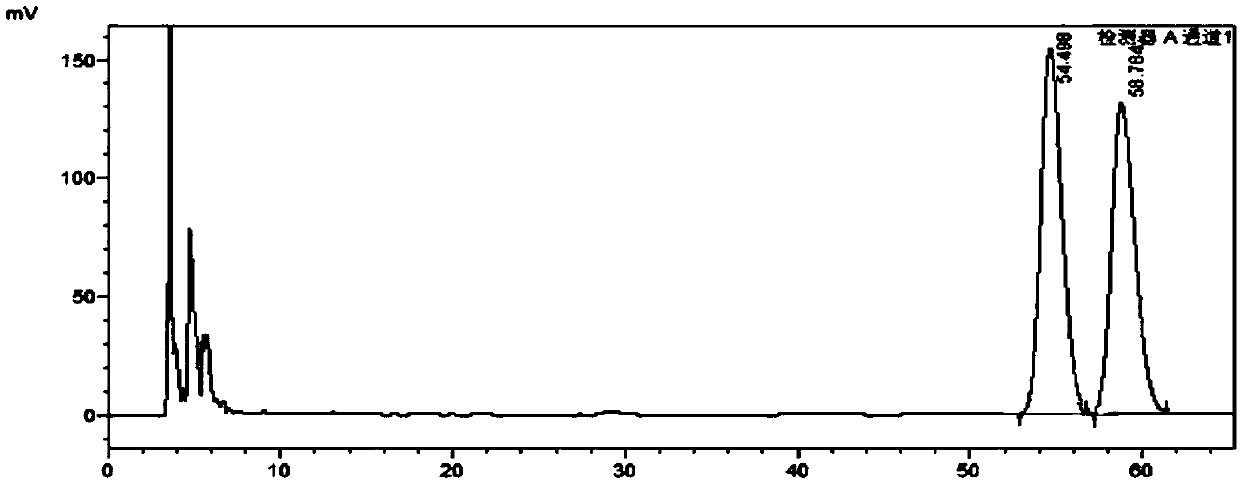

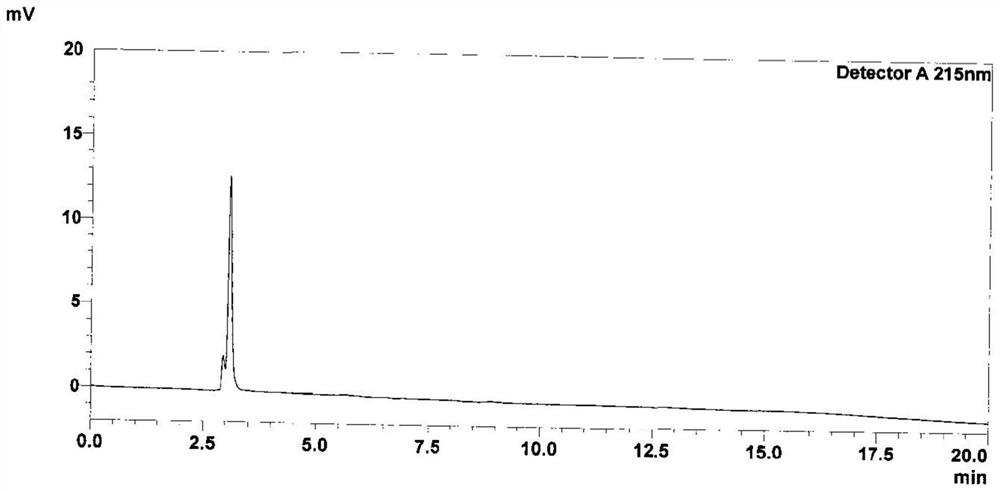

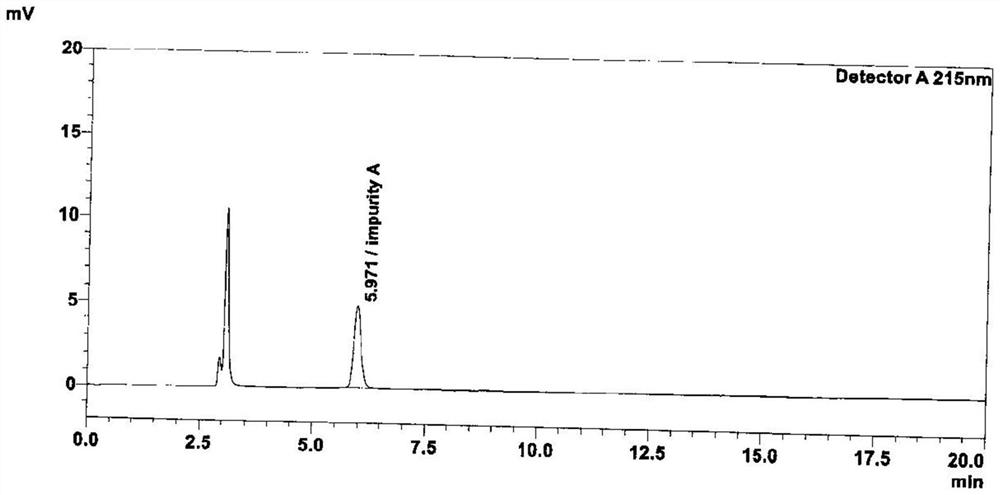

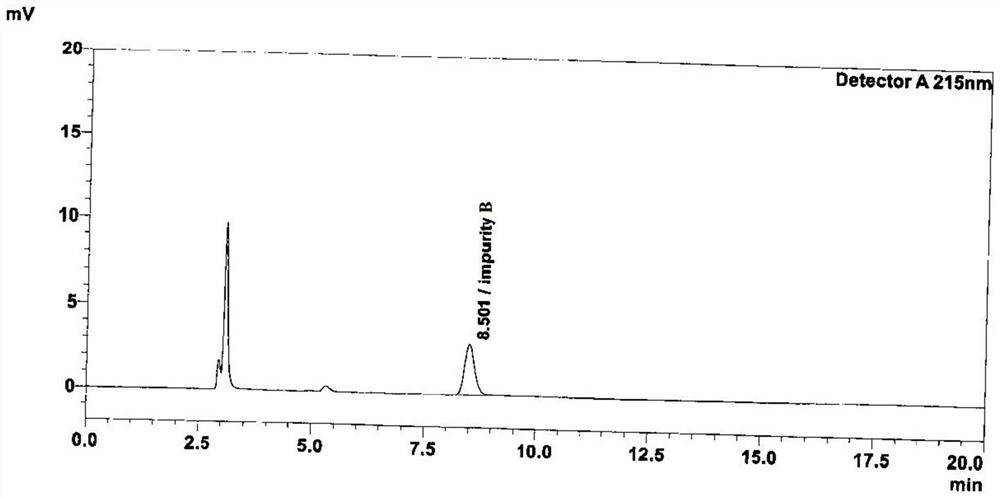

Method for determining peramivir intermediate isomers by using high performance liquid chromatography

ActiveCN111983074AEfficient separationEasy to separateComponent separationChromatography columnHplc mass spectrometry

The invention relates to a method for determining peramivir intermediate isomers by using high performance liquid chromatography. The method is characterized in that an adopted chromatographic columnis a polysaccharide derivative coated chiral chromatographic column; the adopted mobile phase is a mixed solution of isopropanol and normal hexane, and isocratic elution is adopted in a high performance liquid chromatography system; in the mobile phase, the volume ratio of isopropanol to normal hexane is 10: 90 to 20: 80; the flow velocity of the mobile phase is 0.8 to 1.0 ml / min; an adopted detector is an ultraviolet detector, and the monitoring wavelength is 215 nm. The method overcomes the defects in the prior art, solves the problem of analytical determination of the peramivir intermediateisomer, can effectively control the contents of the target product and isomer impurities thereof, avoids the interference of the isomer impurities on the subsequent synthesis reaction, enhances the quality of the subsequent prepared peramivir, and ensures the medication safety. The invention provides an accurate and efficient detection method for determining the isomer of the peramivir intermediate.

Owner:苏州正济药业有限公司

Method for directly producing enoxaparin sodium from crude product heparin sodium

ActiveCN102603925BControl impurity contentReduce intermediate environmentDepolymerizationOrganic solvent

The invention relates to a preparation method for directly producing enoxaparin sodium from crude product heparin sodium. The preparation method comprises the following steps of: taking the crude product heparin sodium as a raw material, performing fractionated precipitation through an organic solvent to remove most of impurities in the crude product heparin sodium, and then removing part of residual impurity proteins, pigments and other impurities by oxidation through hydrogen peroxide so as to get the high-purity heparin sodium which is in line with the production requirements of the enoxaparin sodium; and taking the high-purity heparin sodium as an intermediate product, preparing a heparin quaternary ammonium salt, preparing heparin benzyl ester, performing alkaline depolymerization on the heparin benzyl ester, neutralizing with an acid, performing alcohol precipitation, refining, decoloring, dehydrating and drying to get an enoxaparin sodium finished product. By adopting the method disclosed by the invention, the use of the organic solvent is greatly reduced, the production efficiency is improved, the influences on the environment are reduced, the enoxaparin sodium finished product which achieves or is better than European Pharmacopoeia 7.0 version is obtained, and the method is simple to operate and can realize industrialized production.

Owner:DONGYING TIANDONG PHARM CO LTD

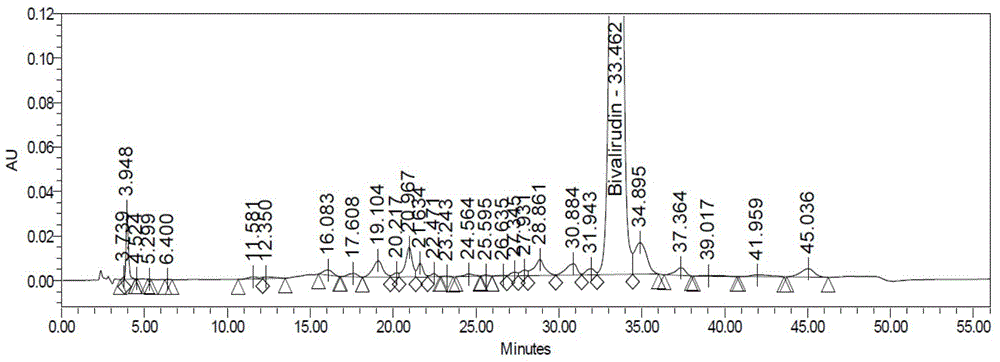

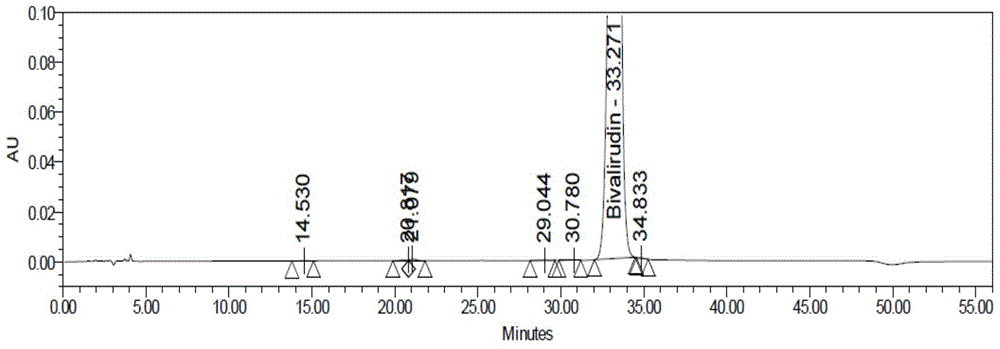

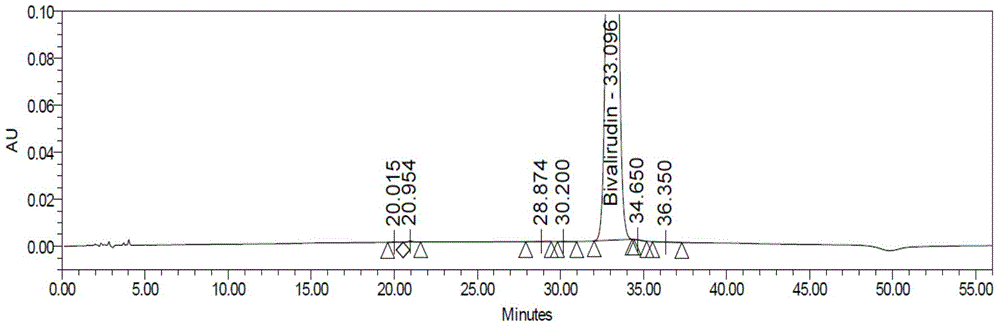

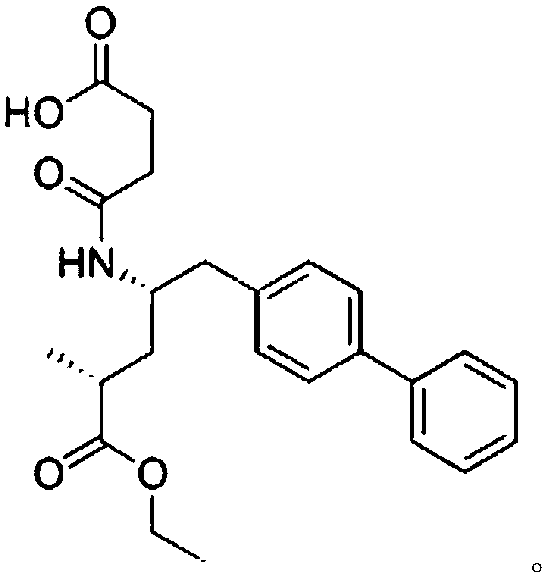

Crude drug bivalirudin purification process

ActiveCN104877024AEfficient removalLow impurity contentPeptide preparation methodsLeech-based protease inhibitorsAcetic acidSilanes

The invention belongs to the field of pharmaceutical synthesis and particularly relates to a crude drug bivalirudin purification process. According to the bivalirudin purification and drying process, two purification systems are combined to complete bivalirudin purification, a chromatographic system for first-time purification (coarse purification) consists of a mobile phase A, namely 0.025%-0.2% of heptafluorobutyric acid solution, and a mobile phase B, a chromatographic column filler is an octadecyl silane bonded silica gel filler with the particle diameter ranging from 45 microns to 75 microns, the purity can be up to 99.8% after gradient elution, a chromatographic system for second-time purification (refine purification) consists of a mobile phase A, namely 0.01%-0.05% of trifluoroacetic acid solution, and a mobile phase B, a chromatographic column filler is an octadecyl silane bonded silica gel filler with 10-microns particle diameter, and the purity of a concentrated solution can be up to 99.8% after gradient elution and twice purification.

Owner:HAINAN ZHONGHE PHARM CO LTD

Preparation method of difluoroborate

InactiveCN108912155AControl impurity contentSimple processGroup 3/13 element organic compoundsBoron trifluorideProtic solvent

The invention discloses a preparation method of a difluoroborate. The preparation method comprises following steps: 1, a boron trifluoride complex is dissolved in an aprotic solvent, a dioxalate and achloride are added, and reaction is carried out so as to obtain a difluoroborate solution; and 2, the difluoroborate solution is subjected to degassing concentration, a poor solvent is added for crystallization precipitation of the difluoroborate, and filtering, washing, and drying are carried out so as to obtain the difluoroborate. The preparation method is simple; reaction time is short; yieldis high; the contents of metal ions and negative ion impurities can be controlled effectively, and the high purity difluoroborate target product can be prepared.

Owner:苏州松湖新能源材料有限公司

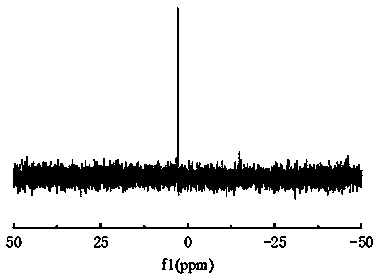

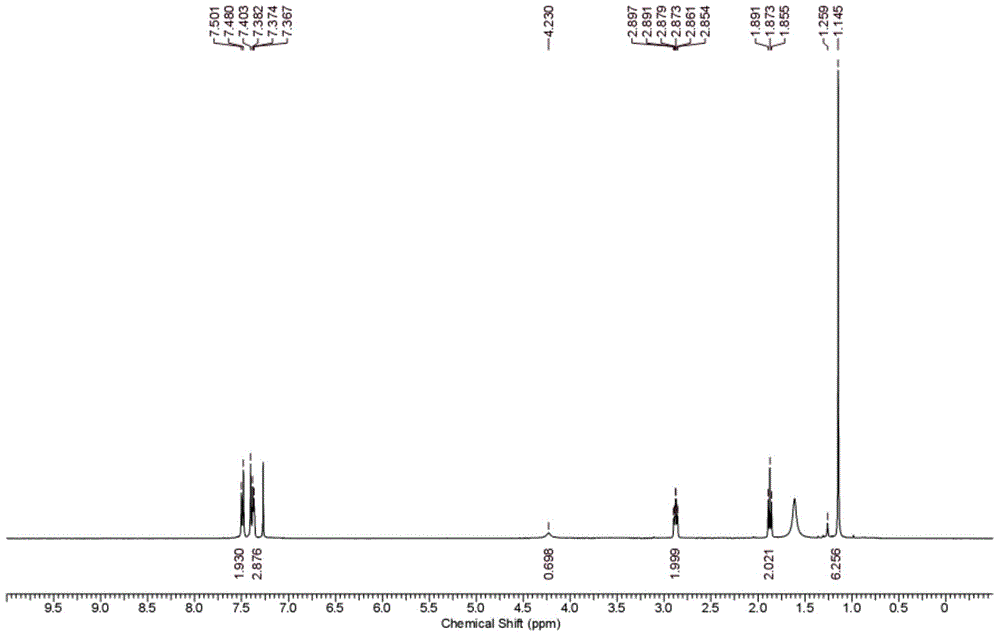

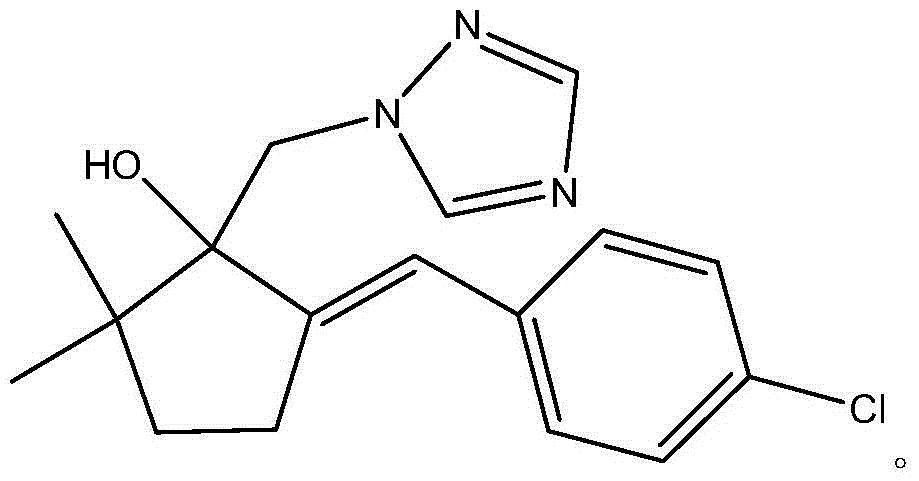

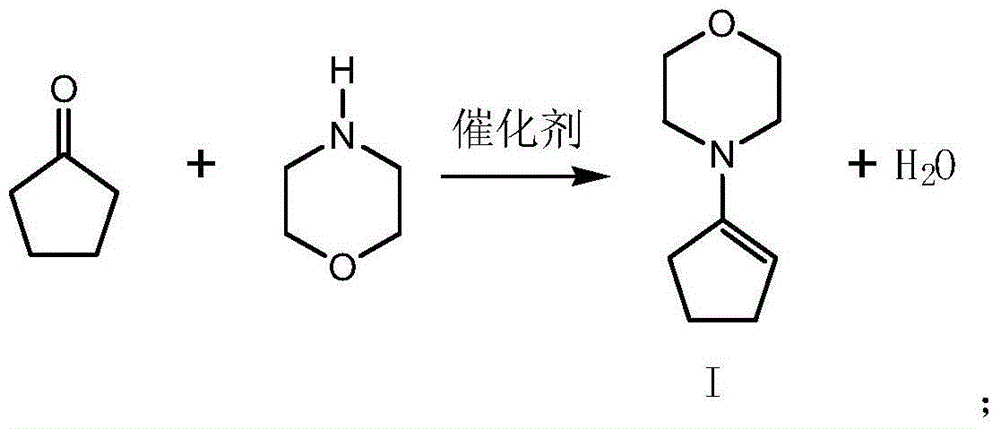

Preparation method for triticonazole intermediate

ActiveCN104130117AControl impurity contentHigh purityCarbonyl compound preparation by condensationAluminium sulfateOrganic solvent

The invention relates to a preparation method for a triticonazole intermediate 5-(4-chlorobenzylidene)-2,2-dimethylcyclopentanone. The preparation method comprises: (1) performing an oximation reaction on cyclopentanone and morpholine in an organic solvent in the presence of p-methylbenzene sulfonic acid at a temperature of 40-80 DEG C, so as to generate an intermediate I; (2) performing a condensation reaction on the intermediate I and p-chlorobenzaldehyde in a solvent at a temperature of 40-80 DEG C, so as to generate an intermediate II; (3) hydrolyzing the intermediate II under an acidic condition to generate an intermediate III; and (4) performing a methylation reaction on the intermediate III and a halogenated methane in a polar solvent in the presence of a strong base at a temperature of 40-80 DEG C, so as to generate 5-(4-chlorobenzylidene)-2,2-dimethylcyclopentanone. The technology is relatively simple, is capable of effectively controlling the impurity content in the product a improving the product impurity, and is low in cost and beneficial for realizing nationalization of triticonazole.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

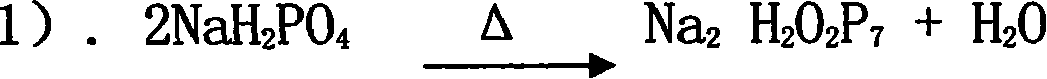

Technique for preparing sodium hexametaphosphate from wet method phosphoric acid

InactiveCN101121507AControl impurity contentLarge crystal particle sizePhosphorus compoundsPhosphoric acidSodium salt

The present invention discloses a sodium hexametaphosphate production technology, taking a wet-process phosphoric acid as the material. The steps are as following: A. Vitriol is added to a phosphorite to produce the wet-process phosphoric acid. B. A sodium hydroxid or a sodium salt is added to the wet-process phosphoric acid to produce a ground paste containing a sodium dihydrogen phosphate. C. The ground paste produced from the step B is filtrated and a clear liquid is collected. D. Ammonia is added to the clear liquid to produce the ground paste containing a composite NaH2PO4.NH3. E. The ground paste is cooled and concentrated to make the composite be crystal. F. The concentrated ground paste is filtrated to collect the composite crystal. G. The composite crystal is heated to make the NH3 in the composite volatilize. The sodium dihydrogen phosphate crystal is produced. H. the sodium dihydrogen phosphate crystal is converged, which produces the sodium hexametaphosphate. The advantage of invention is the low production cost.

Owner:SICHUAN HONGDA

Preparation method for low-cost 3D printing Nb521 alloy powder

PendingCN111168074ALow costImprove resource utilizationTransportation and packagingMetal-working apparatusPowder metallurgyPolluted environment

The invention discloses a preparation method for low-cost 3D printing Nb521 alloy powder, and belongs to the technical field of powder metallurgy powder preparation. The method comprises the followingsteps: taking Nb521 alloy cutting waste as a raw material, and performing processes such as hydrogenation, crushing, dehydrogenation and fluidifying modification to obtain a final product. By recycling the Nb521 alloy waste, the preparation method is low in cost, and further can effectively solve the problems such as resource waste and environmental pollution; the waste is prepared into the Nb521alloy powder through a hydrogenation dehydrogenation process, and the powder is rectified and modified through fluidization treatment, so that fluidity is improved, and the Nb521 alloy powder with oxygen content lower than or equal to 0.01wt%, carbon content lower than or equal to 0.06wt%, a medium diameter (D50) smaller than or equal to 40 microns, and fluidity lower than or equal to 35s / 50g canbe prepared, and therefore, requirements of a 3D printing process can be met.

Owner:UNIV OF SCI & TECH BEIJING

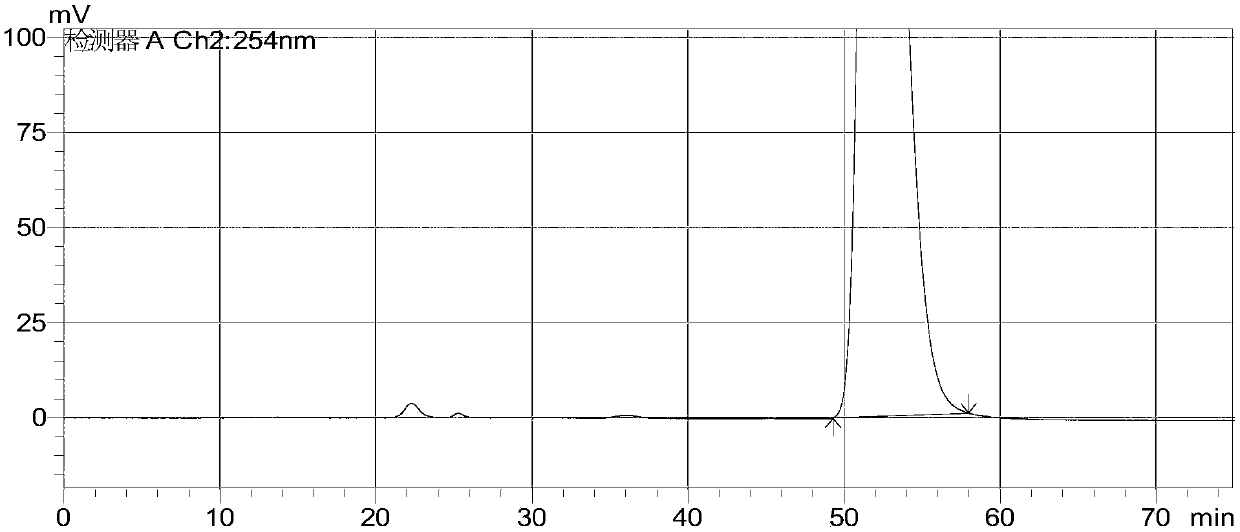

Chromatographic analysis method for AHU377 and AHU377 isomers

ActiveCN109557218AEfficient separationQuality improvementComponent separationOrganic solventTrifluoroacetic acid

The invention provides a chromatographic analysis method for AHU377 and AHU377 isomers. The method adopts high performance liquid chromatography, and uses a bonded chiral chromatographic column as a chromatographic column. Trifluoroacetic acid and other two organic solvents form a ternary mobile phase with a certain ratio, and the flow rate of mobile phase is 0.7-1.0 ml / min. The method can separate AHU377 and three isomers thereof under one condition simply and accurately.

Owner:BEIJING XINLINGXIAN MEDICAL TECH DEV CO LTD

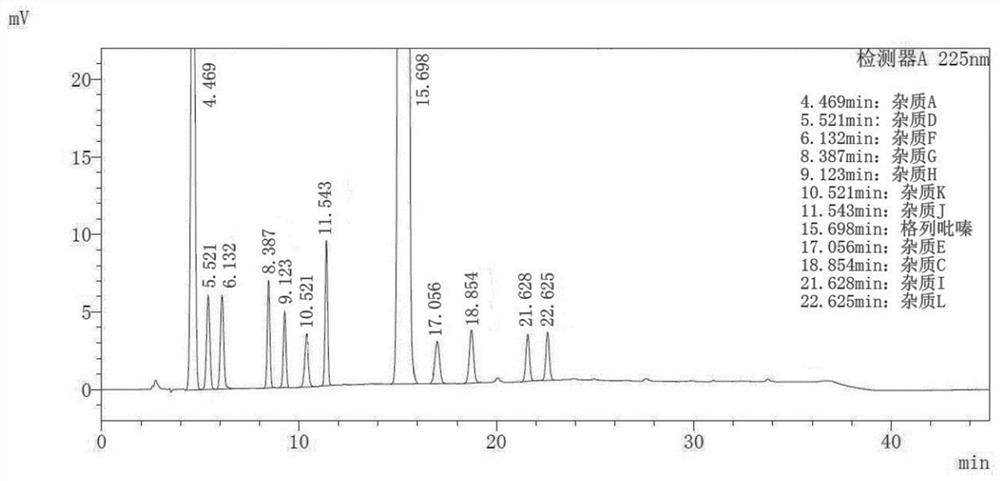

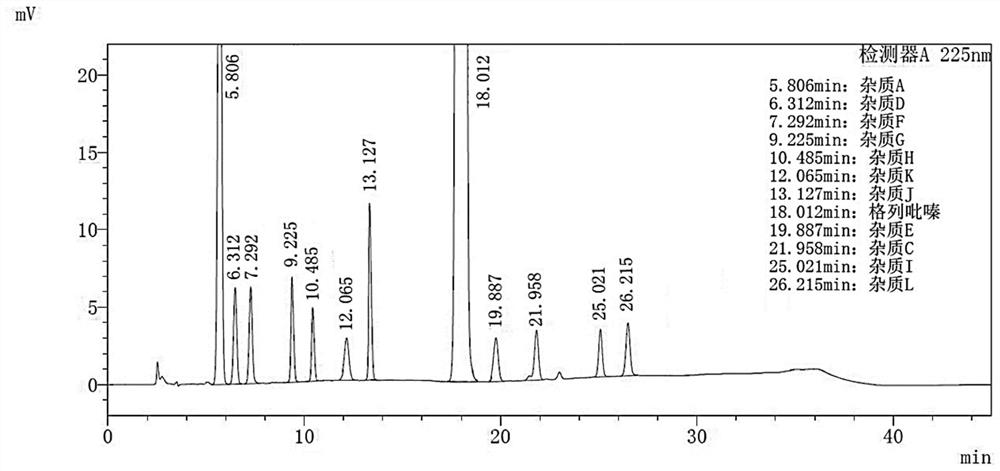

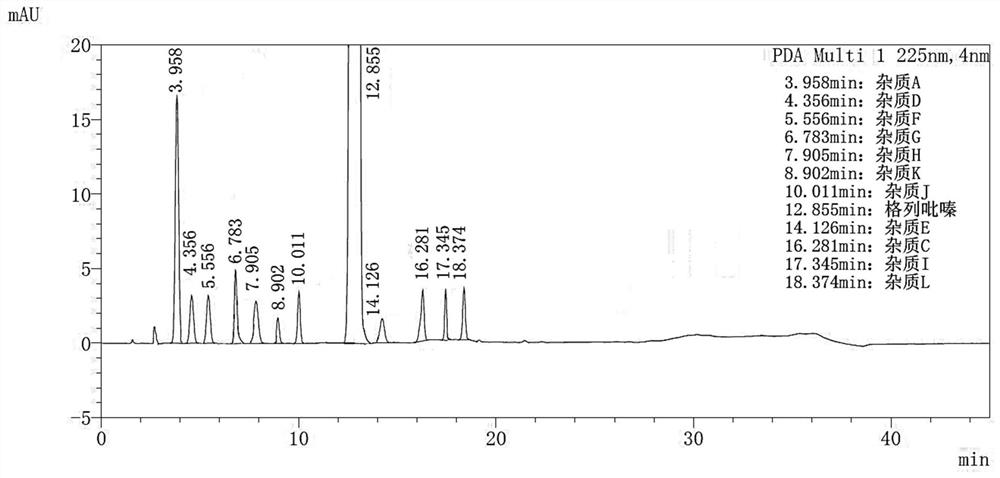

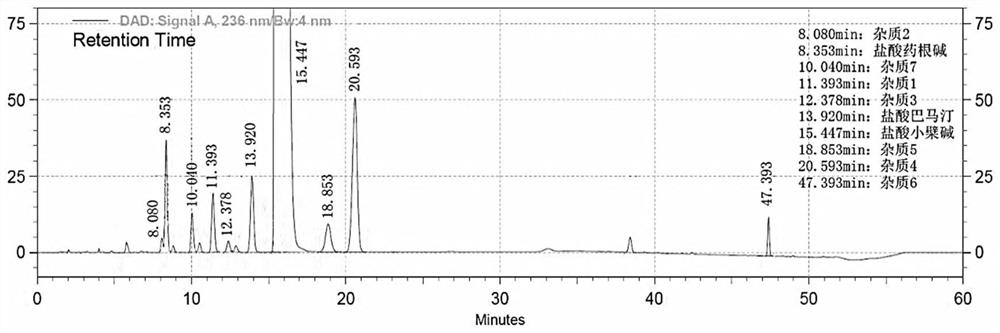

Method for separating and determining glipizide and impurities thereof by liquid chromatography

ActiveCN111679027AAchieve complete separation at the same timeAccurate quantitative analysisComponent separationPyrazinePhosphoric acid

The invention discloses a method for separating and determining glipizide and impurities thereof through high performance liquid chromatography and application. According to the determination method,a chromatographic column taking octadecylsilane chemically bonded silica as a filler is adopted; detection conditions are as follows: chromatographic conditions: the chromatographic column is an octadecylsilane chemically bonded silica chromatographic column; the mobile phase is 0.010 to 0.018 mol / L monopotassium phosphate-acetonitrile-methanol, and the pH value is adjusted to 3.5 to 4.0 by usingphosphoric acid; the column temperature is 20 to 30 DEG C; the sample injection amount is 15 to 30 mu L; the sample injection concentration is 0.0003 to 2 mg / mL; the flow rate is 0.8 to 1.2 mL / min; and the detection wavelength is 225 nm, and gradient elution is carried out. The method disclosed by the invention is high in precision, good in repeatability and high in recovery rate, and can be widely applied to quality detection of glipizide bulk drugs with different sources and corresponding preparations of the glipizide bulk drugs.

Owner:GUANGDONG HUANAN PHARMACEUTICAL GROUP CO LTD +2

Preparation method for spherical monocrystal tungsten powder for thermal spraying

ActiveCN106077696APromote growthControl grain sizePolycrystalline material growthFrom solid statePorosityThermal spraying

The invention discloses a preparation method for a spherical monocrystal tungsten powder for thermal spraying. The preparation method comprises the following steps: firstly adding a certain amount of a mixture of lithium carbonate and sodium chloride in an ammonium tungstate solution as a mother solution, and concentrating to obtain a precursor through heating drying; then selecting a spherical tungsten powder as a mother crystal, adding the spherical tungsten powder in the precursor according to a certain ratio, uniformly mixing, and then placing the mixture in a tubular reduction furnace and carrying out hydrogen gas reduction, and then sequentially carrying out ultrasonic cleaning, vacuum drying and grinding spheroidization to prepare an intermediate; and carrying out airflow classification on the prepared intermediate to obtain the spherical monocrystal tungsten powder. The preparation method disclosed by the invention is simple in process equipment and high in production efficiency; and the prepared spherical monocrystal tungsten powder has a perfect crystal, compact particles, a high sphericity degree, high flowability, a high purity, a high coating hardness, a high powder-applying rate and a low porosity.

Owner:LUOYANG GOLDEN EGRET GEOTOOLS

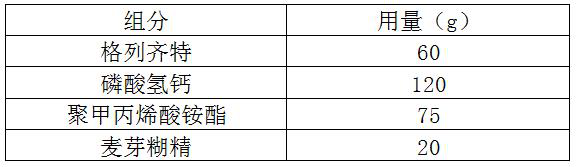

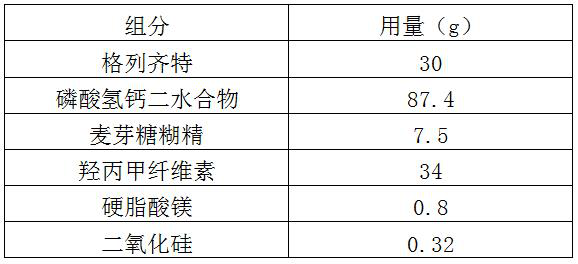

Gliclazide sustained release tablet

PendingCN113116836AControl impurity contentMetabolism disorderSulfonylurea active ingredientsFoaming agentMedicine

The invention relates to a gliclazide sustained-release tablet which specifically comprises gliclazide, a skeleton material, a diluent and a pore-foaming agent, and the skeleton material is methacrylic acid copolymer. The gliclazide sustained release tablet provided by the invention has relatively stable dissolution and release properties, does not have a burst release phenomenon, and has a dissolution curve consistent with that of commercially available drugs; meanwhile, the gliclazide sustained release tablet disclosed by the invention has better quality stability, simple preparation process, low production cost and is suitable for industrial large-scale production.

Owner:BEIJING WINSUNNY PHARMA CO LTD

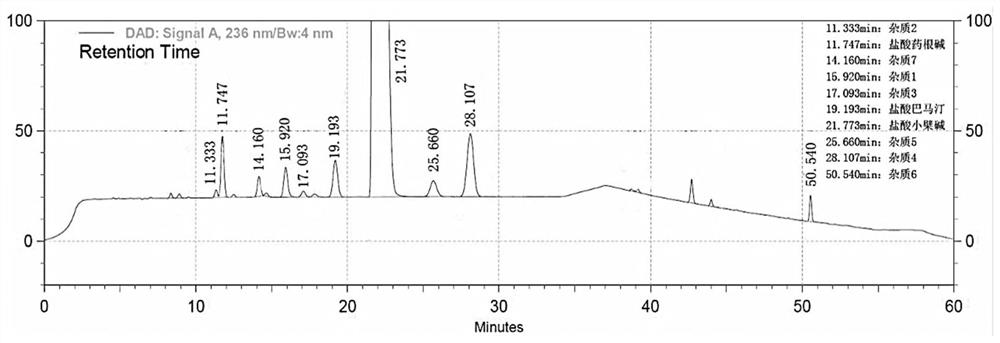

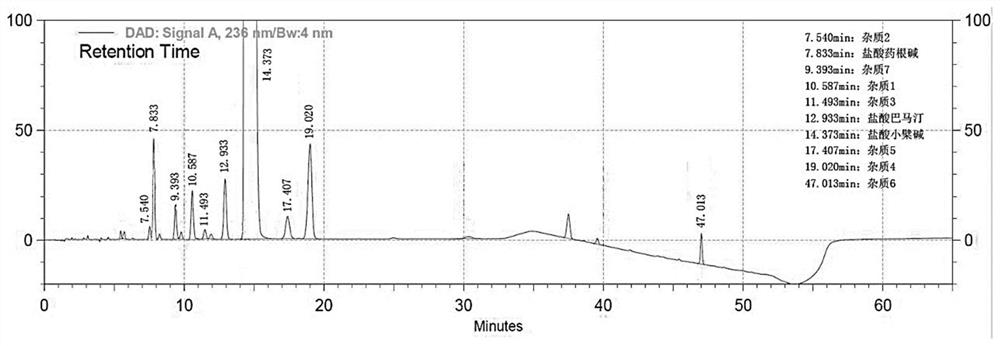

Method for separating and determining berberine and impurities thereof by liquid chromatography

ActiveCN111610272AControl impurity contentAchieve complete separation at the same timeComponent separationSilanesSilica gel

The invention discloses a method for separating and determining berberine and impurities thereof through high performance liquid chromatography and application. According to the determination method,a chromatographic column taking octadecylsilane chemically bonded silica as a filler is adopted; detection conditions are as follows: chromatographic conditions: the chromatographic column is an octadecylsilane chemically bonded silica chromatographic column, the mobile phase is 0.03-0.08 mol / L ammonium dihydrogen phosphate-acetonitrile, the pH value of the mobile phase is 3.0-3.5, the column temperature is 23-28 DEG C, the sample injection amount is 5-15 microliters, the sample injection concentration is 0.0005-2 mg / mL, the flow rate is 0.8-1.2 mL / min, the detection wavelength is 236 nm, andgradient elution is performed. The method is high in precision, good in repeatability and high in recovery rate, and can be widely applied to quality detection of berberine bulk drugs from different sources and corresponding preparations thereof.

Owner:GUANGDONG HUANAN PHARMACEUTICAL GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com