Preparation method for low-cost 3D printing Nb521 alloy powder

A 3D printing and alloy powder technology, applied in the field of powder metallurgy, can solve problems such as difficult and low-cost preparation, environmental pollution, waste of resources, etc., and achieve the effects of controllable impurities, high powder yield, and reduced raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

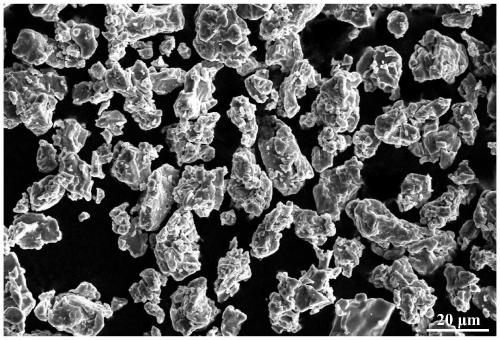

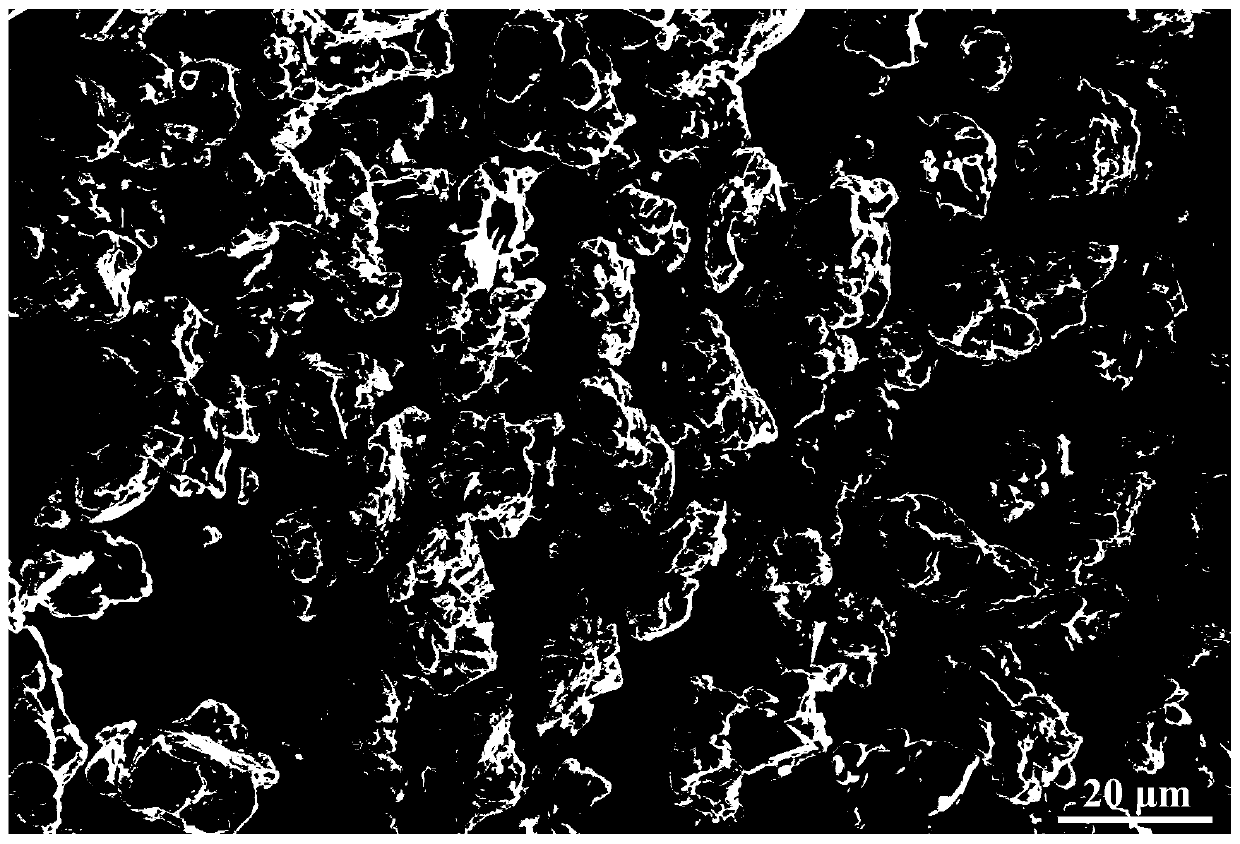

[0018] Cut the Nb521 alloy machining cutting waste into chips with a length of 10-20 mm, put them into acetone and perform ultrasonic cleaning for 10 minutes. Weigh 6 kg of Nb521 alloy scraps into a hydrogenation furnace, feed high-purity hydrogen, and raise the temperature to 700°C at a rate of 20°C / min in a hydrogen atmosphere, and complete the hydrogenation reaction after holding for 5 hours to obtain hydrogenated Nb521 alloy scraps; The hydrogenated Nb521 alloy scraps were taken out, crushed and graded in an argon atmosphere to obtain powders, and then the powders were placed in 2×10 - 3 In a Pa vacuum furnace, the temperature was raised to 750°C at a rate of 10°C / min for dehydrogenation. After dehydrogenation reaction for 2 hours, the temperature was lowered to room temperature, and the powder was taken out under an argon atmosphere; Weigh 0.5kg of Nb521 alloy powder with regular shape and put it into the fluidization equipment, pass argon gas from bottom to top, the flo...

Embodiment 2

[0020] Cut the Nb521 alloy machining cutting waste into chips with a length of 8-15 mm, put them into acetone and perform ultrasonic cleaning for 8 minutes. Weigh 8 kg of Nb521 alloy scraps into a hydrogenation furnace, feed high-purity hydrogen, and raise the temperature to 650°C at a rate of 15°C / min in a hydrogen atmosphere, and complete the hydrogenation reaction after holding for 4 hours to obtain hydrogenated Nb521 alloy scraps; The hydrogenated Nb521 alloy scraps were taken out, crushed and graded in an argon atmosphere to obtain powders, and then the powders were placed in a 1×10 -3 In a Pa vacuum furnace, the temperature was raised to 750°C at a rate of 15°C / min for dehydrogenation. After the dehydrogenation reaction was performed for 3 hours, the temperature was lowered to room temperature, and the powder was taken out under an argon atmosphere; Weigh 1 kg of Nb521 alloy powder with regular shape and put it into the fluidization equipment, pass argon gas from bottom ...

Embodiment 3

[0022] Cut the machining waste of Nb521 alloy into chips with a length of 5-10 mm, put them into acetone and perform ultrasonic cleaning for 6 minutes. Weigh 15kg of Nb521 alloy scraps into the hydrogenation furnace, feed high-purity hydrogen, raise the temperature to 700°C at a rate of 10°C / min in a hydrogen atmosphere, and complete the hydrogenation reaction after holding for 5 hours to obtain hydrogenated Nb521 alloy scraps; The hydrogenated Nb521 alloy scraps were taken out, crushed and graded in an argon atmosphere to obtain powders, and then the powders were placed in a 1×10 -3 In a Pa vacuum furnace, the temperature was raised to 720°C at a rate of 15°C / min for dehydrogenation. After dehydrogenation reaction for 4 hours, the temperature was lowered to room temperature, and the powder was taken out under an argon atmosphere; Weigh 0.3kg of regular shape Nb521 alloy powder and put it into the fluidization equipment, flow argon gas from bottom to top, the flow rate is 0.8L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com