Method for separating and determining glipizide and impurities thereof by liquid chromatography

A technology for glipizide and its determination method, which is applied in the field of separation and determination of glipizide and its impurities by high-performance liquid chromatography, and can solve the problems of poor peak shape of impurities, failure to achieve baseline separation, and influence on integral calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

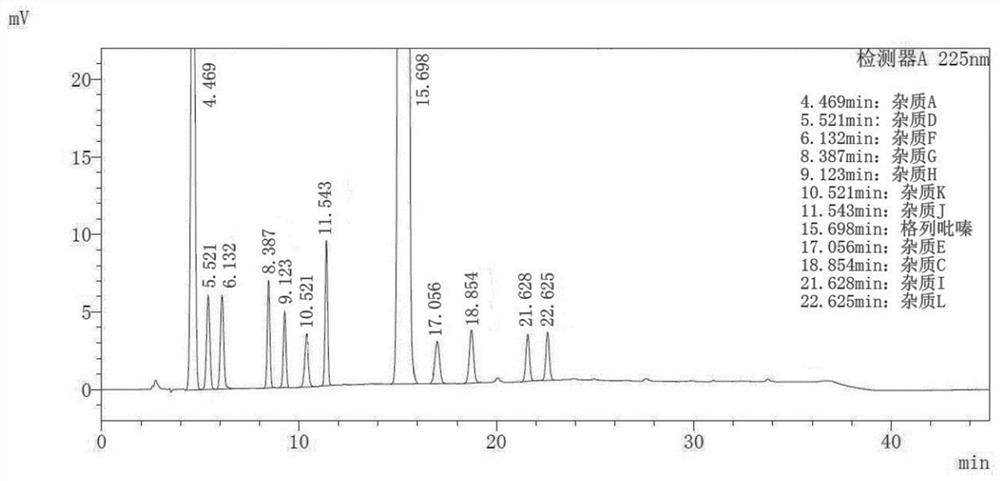

Embodiment 1

[0078] Instrument: Agilent 1260 InfinityII;

[0079] Stationary phase: Agilent ZORBAX SB-C18 (4.6mm×150mm, 5μm);

[0080] mobile phase:

[0081] Phase A: 0.015mol / L potassium dihydrogen phosphate, adjust the pH value to 3.7 with phosphoric acid;

[0082] Phase B: acetonitrile;

[0083] Phase C: Methanol;

[0084] Column temperature: 25°C;

[0085] Injection volume: 20μL;

[0086] Flow rate: 1.0mL / min;

[0087] Detection wavelength: 225nm;

[0088] Preparation of mobile phase:

[0089] Phase A: Take 2.04g of potassium dihydrogen phosphate, add water to dissolve and dilute to 1000mL, adjust the pH value to 3.7 with phosphoric acid;

[0090] Phase B: acetonitrile;

[0091] Phase C: Methanol.

[0092] Mobile phase gradient settings:

[0093] stage V A相 (%)

V B相 (%)

V C相 (%)

Elution time 0 65 25 10 7min 1 50 30 20 5min 2 40 35 25 6min 3 30 45 25 6min

[0094] Solution preparation:

[0095] Diluent: 0.015mol / L ...

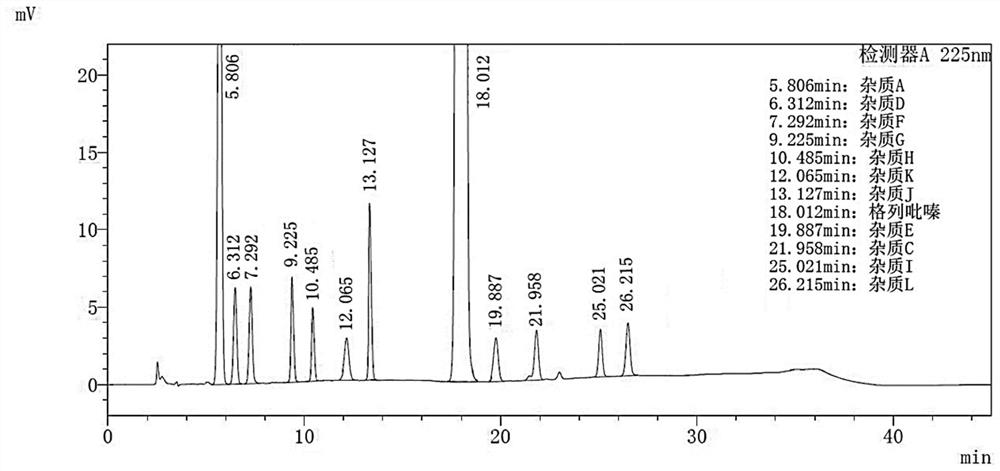

Embodiment 2

[0101] Instrument: Agilent 1260 InfinityII;

[0102] Stationary phase: Agilent ZORBAX SB-C18 (4.6mm×150mm, 5μm);

[0103] mobile phase:

[0104] Phase A: 0.010mol / L potassium dihydrogen phosphate, adjust the pH value to 3.5 with phosphoric acid;

[0105] Phase B: acetonitrile;

[0106] Phase C: Methanol;

[0107] Column temperature: 20°C;

[0108] Injection volume: 15μL;

[0109] Flow rate: 0.8mL / min;

[0110] Detection wavelength: 225nm;

[0111] Preparation of mobile phase:

[0112] Phase A: Take 1.36g of potassium dihydrogen phosphate, add water to dissolve and dilute to 1000mL, adjust the pH value to 3.5 with phosphoric acid;

[0113] Phase B: acetonitrile;

[0114] Phase C: Methanol.

[0115] Mobile phase gradient settings:

[0116] stage V A相 (%)

[0117] Solution preparation method and assay method are carried out with reference to embodiment 1, record chromatogram figure 2 . The chromatographic conditions of this embodiment can effectively disti...

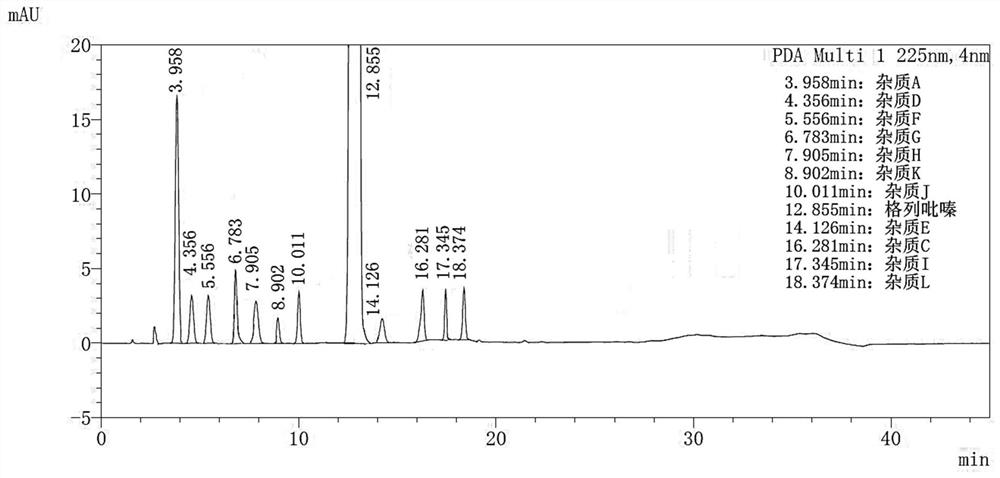

Embodiment 3

[0119] Instrument: Agilent 1260 Infinity II;

[0120] Stationary phase: Agilent ZORBAX SB-C18 (4.6mm×150mm, 5μm);

[0121] mobile phase:

[0122] Phase A: 0.018mol / L potassium dihydrogen phosphate, adjust the pH value to 4.0 with phosphoric acid;

[0123] Phase B: acetonitrile;

[0124] Phase C: Methanol;

[0125] Column temperature: 30°C;

[0126] Injection volume: 30μL;

[0127] Flow rate: 1.2mL / min;

[0128] Detection wavelength: 225nm;

[0129] Preparation of mobile phase:

[0130] Phase A: Take 2.45g of potassium dihydrogen phosphate, add water to dissolve and dilute to 1000mL, add phosphoric acid to adjust the pH to 4.0;

[0131] Phase B: acetonitrile;

[0132] Phase C: Methanol.

[0133] Mobile phase gradient settings:

[0134] stage V A相 (%)

[0135] Solution preparation method and assay method are carried out with reference to embodiment 1, record chromatogram image 3 . The chromatographic conditions of this embodiment can effectively distingui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com