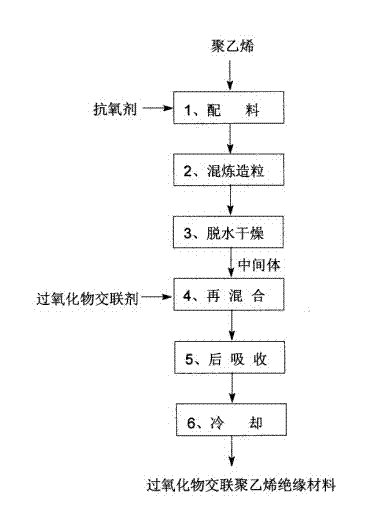

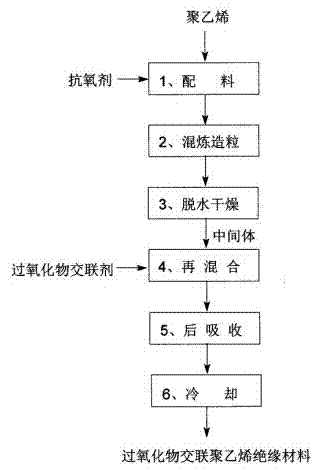

Post-absorption process of peroxide cross-linking polyethylene insulating material

A technology of cross-linked polyethylene and peroxide, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve problems such as high melt viscosity, poor electrical insulation performance, and product quality decline, and achieve control of impurity content, Good electrical insulation performance and the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Main process equipment: the mixing machine is a single-screw extruder, the drying equipment is a centrifugal dehydrator, the filtering equipment is a filter screen, and also includes a mixing silo and a post-absorption silo.

[0025] A post-absorption process for peroxide cross-linked polyethylene insulating materials, which uses polyethylene, antioxidants and peroxide cross-linking agents as raw materials to prepare peroxide cross-linked polyethylene insulating materials, wherein the raw materials are polyethylene, anti-oxidant The weight ratio of the oxygen agent and the peroxide crosslinking agent is 100:0.15:1.6, the antioxidant is powdery No. 300 antioxidant, polyethylene is granular low density polyethylene, and the peroxide crosslinking agent is Filtered liquid dicumyl peroxide, the process steps are as follows:

[0026] (1) Batching: Batch the antioxidant and polyethylene, weigh the antioxidant and polyethylene in proportion, put them into the single-screw extru...

Embodiment 2

[0033] Main process equipment: The mixing machine is a twin-screw extruder, the drying equipment is a fluidized drying bed, the filtering equipment is an industrial filter, and there are mixing silos and post-absorption silos, etc.

[0034]A peroxide cross-linked polyethylene insulating material post-absorption process, which is prepared from polyethylene, an antioxidant and a peroxide cross-linking agent to obtain a peroxide cross-linked polyethylene insulating material, wherein the raw materials polyethylene, anti-oxidant The weight ratio of the oxygen agent and the peroxide crosslinking agent is 100: 0.30: 2.2, the antioxidant is powdery 1010 antioxidant, polyethylene is granular low density polyethylene, and the peroxide crosslinking agent is The liquid double 2 of filtration, 5 vulcanizing agents, described processing step is as follows:

[0035] (1) Batching: Batch the antioxidant and polyethylene, weigh the antioxidant and polyethylene in proportion, put them into the t...

Embodiment 3

[0042] Main process equipment: the mixing machine is a double-stage twin-screw extrusion granulator, the drying equipment is a vacuum dryer, the filtering equipment is a filter screen, and it also includes a mixing silo and a post-absorption silo.

[0043] A peroxide cross-linked polyethylene insulating material post-absorption process, which is prepared from polyethylene, an antioxidant and a peroxide cross-linking agent to obtain a peroxide cross-linked polyethylene insulating material, wherein the raw materials polyethylene, anti-oxidant The weight ratio of the oxygen agent and the peroxide cross-linking agent is 100:0.20:1.8, the antioxidant is powdered 168 antioxidant, the polyethylene is granular low-density polyethylene, and the peroxide cross-linking agent is processed The liquid cumene peroxide of filtering, described processing step is as follows:

[0044] (1) Batching: Batch the antioxidant and polyethylene, weigh the antioxidant and polyethylene in proportion, put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com