Water-soluble ion liquid synthesizing method

An ionic liquid and water-soluble technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of process environment toxicity, shortened reaction time, high process cost, etc., and achieve low process cost and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

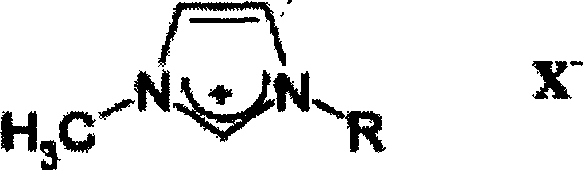

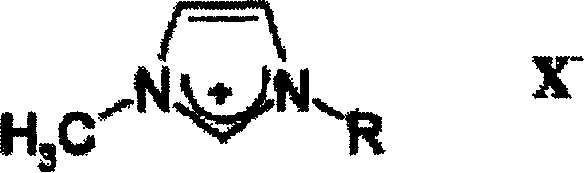

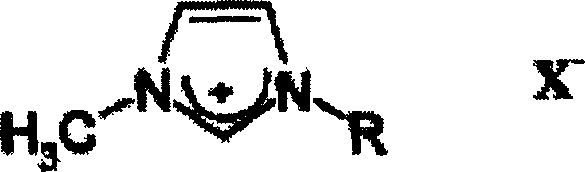

Image

Examples

Embodiment 1

[0018] Example 1 1-butyl 3-methylimidazolium bromide

[0019] Take 1mol each of methylimidazole and bromo-n-butane and add it to a 250ml beaker. The 250ml beaker is covered with a 500ml beaker, and an appropriate amount of water is added inside to make a water bath. The temperature of the water bath is not higher than 80°C. Ultrasonic treatment was performed under the ultrasonic condition of 750W, 99 times per round, each working time was 4 seconds, and the rest time was 5 seconds. After 5 rounds, the liquid in the beaker became clear and transparent, slightly pale yellow. After the liquid was cooled, 200 ml of ethyl acetate was added to extract twice to remove unreacted products. The reaction product was vacuum-dried at 80° C. for 6 hours to obtain about 180 ml of product.

Embodiment 2

[0020] Example two 1-butyl 3-methylimidazolium bromide

[0021] Take 0.2 mol of methylimidazole and 0.2 mol of n-bromobutane and put them into a 100ml beaker. The 100ml beaker is covered with a 250ml large beaker, and an appropriate amount of water is added inside as a water bath. The temperature of the water bath is controlled at 20°C to 60°C. Ultrasonic treatment was performed under the ultrasonic condition of 750W, 99 times per round, each working time was 4 seconds, and the rest time was 5 seconds. After 4 rounds, the liquid in the beaker became clear and transparent. After the liquid was cooled, 70 ml of ethyl acetate was added to extract twice to remove unreacted products. The reaction product was vacuum-dried at 80° C. for 6 hours to obtain about 35 ml of product.

Embodiment 3

[0022] Example three 1-butyl 3-methylimidazolium bromide

[0023] Take 0.3 mol of methylimidazole and 0.33 mol of n-bromobutane and put them into a 100ml beaker. The 100ml beaker is covered with a 250ml large beaker, and an appropriate amount of water is added inside as a water bath. The temperature of the water bath is controlled at 30°C to 80°C. Ultrasonic treatment was performed under the ultrasonic condition of 750W, 99 times per round, each working time was 4 seconds, and the rest time was 5 seconds. After 4 rounds, the liquid in the beaker became clear and transparent. After the liquid was cooled, 100 ml of ethyl acetate was added for extraction three times to remove unreacted products. The reaction product was vacuum-dried at 80° C. for 8 hours to obtain about 50 ml of product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com