Preparation method of difluoroborate

A technology of difluorooxalate borate and hydrogen oxalate, which is applied in the field of preparation of difluorooxalate borate, can solve the problems of unfeasible economy, high cost, and many steps, and achieve the control of metal ion and anion impurity content, The effect of short reaction time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

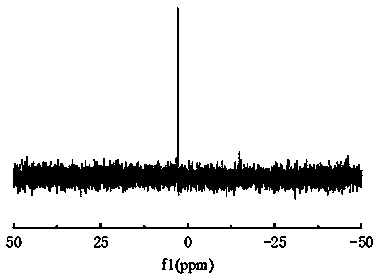

Image

Examples

Embodiment 1

[0025] In a glove box filled with dry argon, add dry lithium hydrogen oxalate (LiHC 2 o 4 ) 48.0g (0.5mol), and phosphorus pentachloride (PCl 5 ) 20.8g (0.1mol), and then add 108g of dry tetrahydrofuran (THF) to the three-necked flask. The flask was taken out from the glove box, placed in a water bath at 35°C and stirred, and boron trifluoride tetrahydrofuran (BF 3 · THF) 73.5g (0.525mol), the reaction started to proceed, the generated gas flowed through the device equipped with sodium hydroxide solution to be absorbed, and the dropwise addition took 2 hours. The solid dissolves slowly, the solution becomes transparent, and is kept at 35°C for one hour, and no gas is emitted from the reaction, indicating that the reaction is complete. Under the protection of argon flow, dichloroethane (CH 2 Cl 2 ) 800mL, stirred slowly at 25°C until crystals precipitated, stopped stirring, after the crystals settled, filtered, and dichloroethane (CH 2 Cl 2 ), and the obtained crystals w...

Embodiment 2

[0029] In a glove box filled with dry argon, add 67.5 g of dry dimethyl carbonate (DMC) to a three-necked flask, and add boron trifluoride dimethyl carbonate (BF 3 DMC) 41.0g, dissolve, then add dry lithium hydrogen oxalate (LiHC 2 o 4 ) 24.0g (0.25mol). The flask was taken out from the glove box, immersed in a 35°C water bath, and kept stirring. Phosphorus trichloride (PCl) was slowly added using a constant pressure dropping funnel 3 ) 13.7g (0.1mol), the reaction began to take place. The generated gas flows into the device equipped with sodium hydroxide solution for absorption. Phosphorus trichloride (PCl 3) took 1.5 hours, and then kept at 35°C for one hour, the reaction solution became clear, and no gas was released, indicating the end of the reaction. The reaction solution was evacuated, while the temperature was raised to 50°C, concentrated and evaporated. Under the protection of argon flow, 800 mL of cyclohexane was added into the flask, and stirred slowly until ...

Embodiment 3

[0032] In a dry argon glove box, add 55.6 g of dry ether (Ether) to the three-necked flask, and then put 24.0 g (0.25 mol) of fully dried lithium hydrogen oxalate and 36.9 g of boron trifluoride ether into the flask, One mouth of the flask was connected to a gas conduit with a valve, and the other two mouths were plugged with stoppers. The flask was taken out of the glove box, immersed in a water bath at 40 °C, and the mixture was continuously stirred. Silicon tetrachloride (SiCl) was slowly added dropwise using a constant pressure dropping funnel 4 ) 11.9g (0.07mol), the reaction began to take place. The generated gas flows into the device equipped with sodium hydroxide solution for absorption. Silicon tetrachloride (SiCl 4 ) for 1 hour, and then kept at 40°C for 1 hour, the reaction solution became clear, and no gas was released, indicating the end of the reaction. The temperature was raised to 40°C, and the solvent was evaporated. Under the protection of argon flow, di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com