Gas management method for prolonging life of laser working gas of excimer laser

A technology of excimer laser and working gas, which is applied in the field of excimer laser, can solve the problem of not being able to effectively control the accumulation of impurities in the laser cavity for a long time, and achieve the effect of prolonging the working life and improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

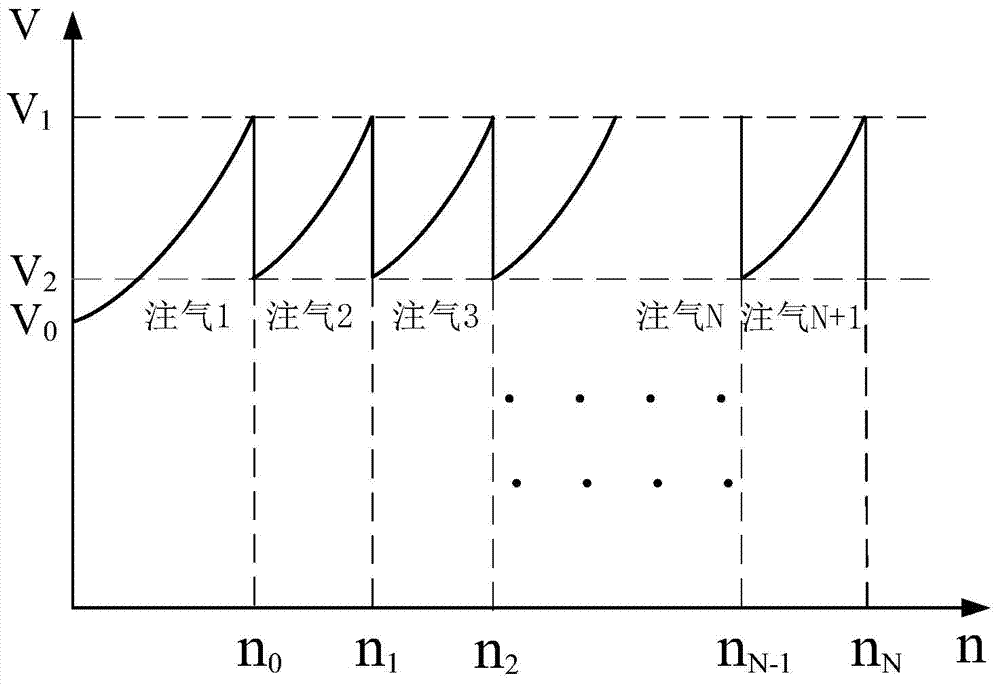

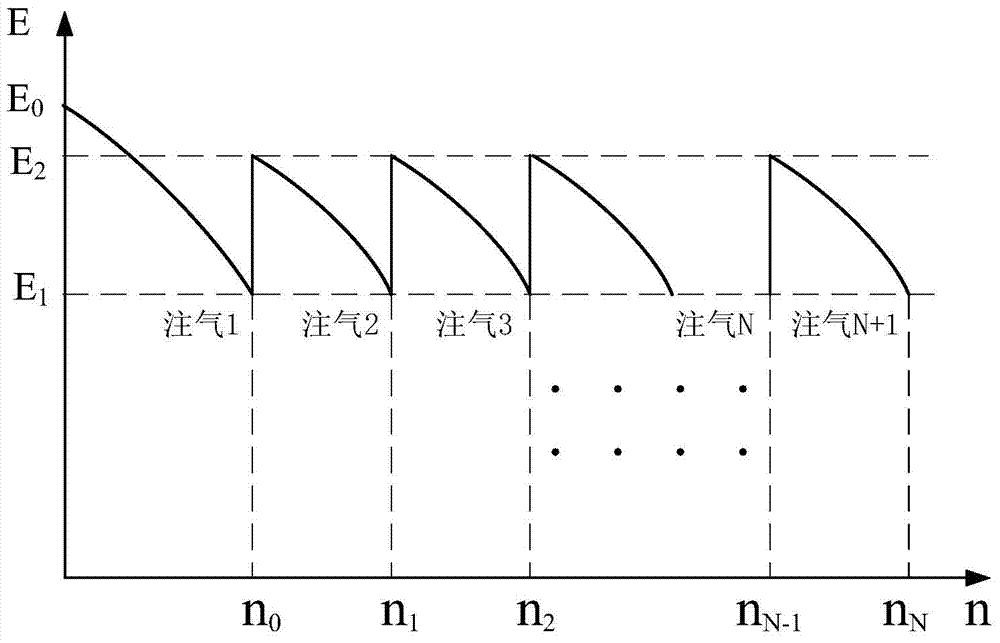

[0015] Such as figure 1 As shown, the operating voltage of the excimer laser in the constant pulse energy output mode increases gradually with the increase of the number of operating pulses. When the operating voltage is changed from V 0 rise to V 1 , the laser cavity F 2 Gas consumption is △F' 1 , the impurity content is C 1 . Impurities in the laser cavity are the F consumed in the laser cavity 2 Gas reacts with other substances to form, and the impurity content is C 1 with F 2 Gas consumption △F' 1 Proportional. At this time, the laser cavity F 2 Gas content F' 1 and impurity content C 1 Can be expressed as:

[0016] F' 1 =F' 0 -△F' 1 (1)

[0017] C 1 =κ·ΔF' (2)

[0018] Among them, F' 0 F in the laser cavity 2 The initial gas content, κ is the proportional coefficient.

[0019] Perform the first partial gas exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com