Ultra-pure nanometer silicon carbide and preparation method thereof

A nano-silicon carbide and ultra-pure technology, applied in chemical instruments and methods, carbon compounds, nanotechnology, etc., can solve the problems of high comprehensive production cost and inability to synthesize nano-silicon carbide powder, and achieve the effect of overcoming the complexity of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of ultrapure nano silicon carbide of the present invention includes the following steps:

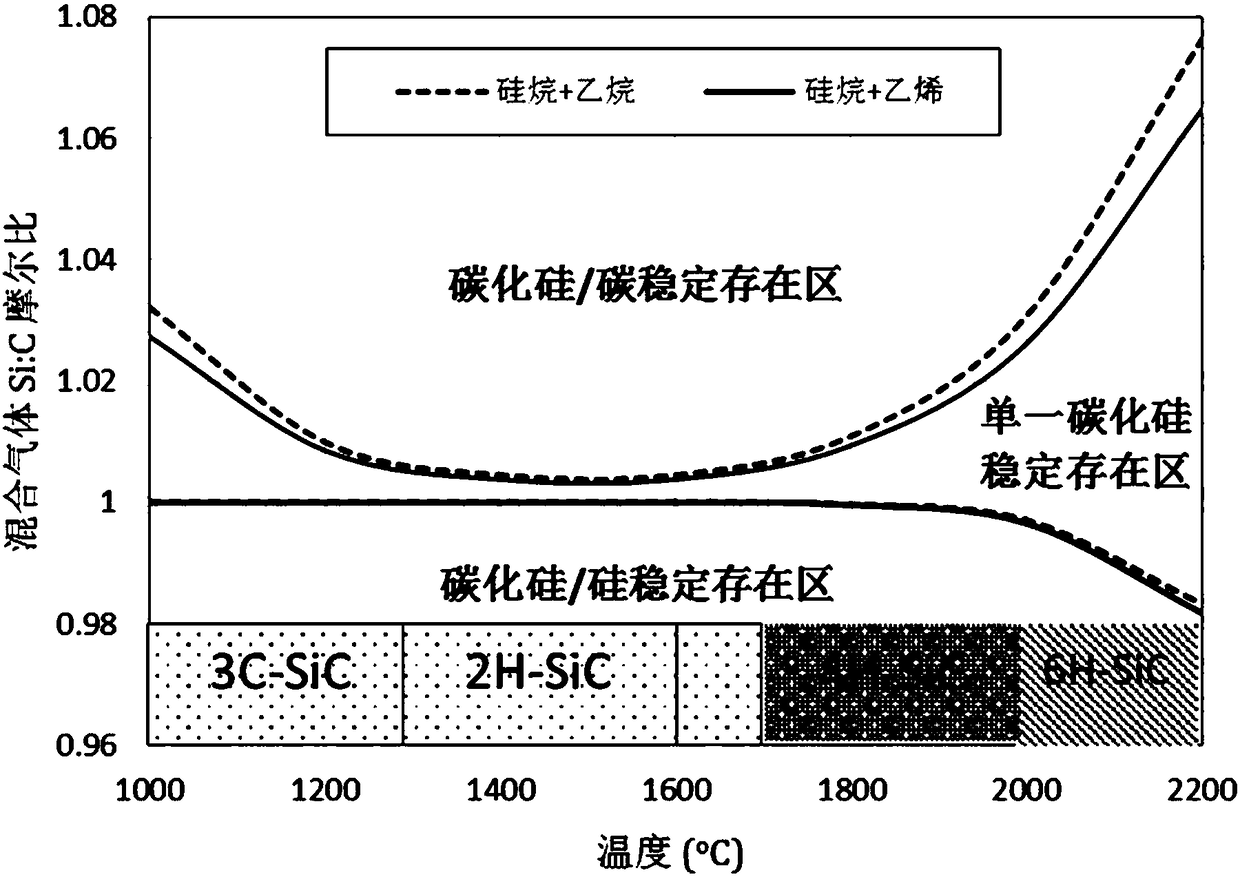

[0025] Preparation of the gas reaction precursor: the carbon-containing gas and the silicon-containing gas are mixed according to the Si:C molar ratio of 1:1.0 to 1:1.06 to obtain the gas reaction precursor;

[0026] Preparation of ultra-pure nano silicon carbide: the gas reaction precursor is introduced into the preheated ceramic reactor, and the gas reaction precursor directly synthesizes nano silicon carbide with a particle size of 50-500 nm in the high temperature zone of the ceramic reactor.

[0027] The method for preparing ultrapure nano silicon carbide of the present invention includes the following steps: introducing carbon-containing gas and silicon-containing gas into a preheated ceramic reactor respectively, and entering the carbon-containing gas and silicon-containing gas in the ceramic reactor The silicon gas is mixed according to the Si:C molar ratio...

Embodiment 1

[0030] The silane and ethylene were introduced into a gas mixing tank with a volume of 100L according to the Si:C molar ratio of 1:1.01, respectively, to obtain a gas reaction precursor. The gas reaction precursor is introduced into the reactor of high purity alumina that has been preheated and stabilized at 1100°C, and the pressure of the reactor is controlled to 5 atmospheres. A single 3C crystal form nano silicon carbide powder is obtained by reaction synthesis. Such as figure 1 As shown, when the Si:C molar ratio of the driving gas is in the "single silicon carbide stable existence zone" shown in the figure, the reaction product is a single crystal silicon carbide powder.

[0031] The main reaction in the high temperature reactor is:

[0032]

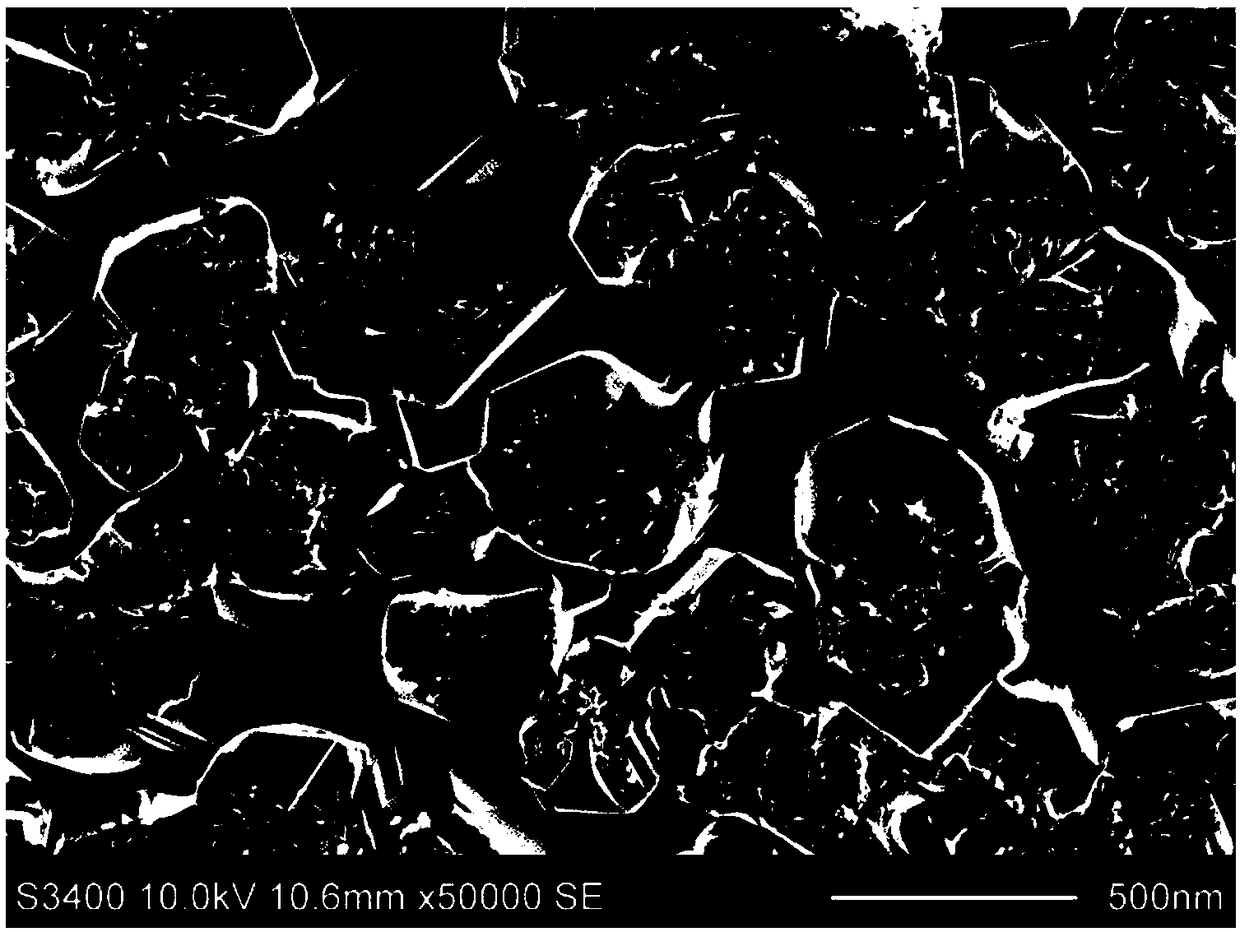

[0033] After the reaction, the silicon carbide powder collected in the reactor has a particle size of 50-300nm and a specific surface area of 25-80m. 2 / g.

[0034] figure 2 This is a photomicrograph of the 3C crystal type nano silico...

Embodiment 2

[0036] The silane and ethane are introduced into the reactor of high-purity alumina which has been preheated and stabilized at 1800℃ according to the molar ratio of Si:C to 1:1.0 under 2 atmospheres at a set flow rate. 4H crystal type nano silicon carbide powder.

[0037] The main reaction in the high temperature reactor is:

[0038]

[0039] After the reaction, the particle size of the silicon carbide powder collected in the reactor is 50-500nm and the specific surface area is 30-50m. 2 / g.

[0040] image 3 This is a photomicrograph of the 4H crystal nanocrystalline silicon carbide obtained by the reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com