Method for preparing spherical Titanium-Zirconium-Molybdenum alloy powder

A technology of alloy powder and spherical shape, which is applied in metal processing equipment, transportation and packaging, etc. It can solve the problems of low density, poor fluidity and irregular shape of TZM alloy powder, reduce vaporization and burning loss, and improve production efficiency And the effect of product quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

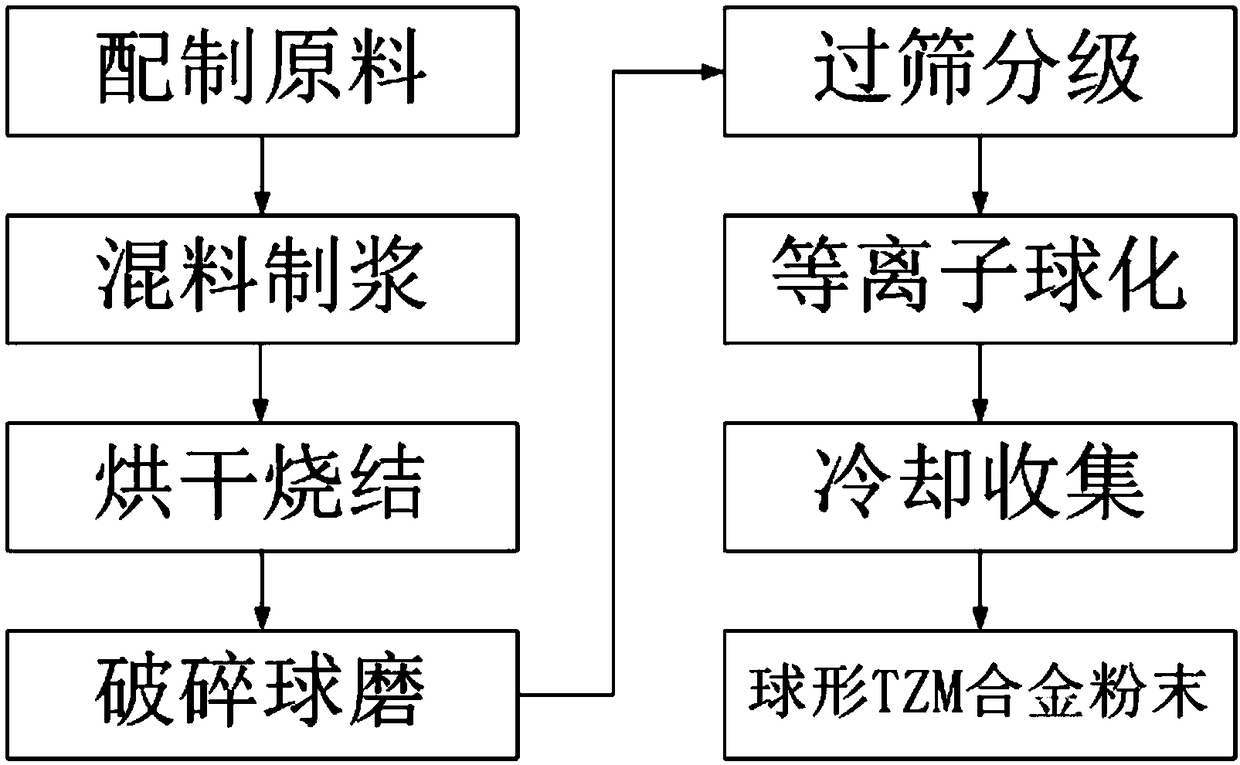

[0041] The low-oxygen spherical TZM (0.4Ti-0.08Zr-0.03C-Mo) alloy powder with a particle size range of 20 μm-45 μm comprises the following steps as figure 1 Shown:

[0042] Step 1: Doping 0.08% (mass fraction, the same below) zirconium hydride (ZrH 2 ) powder, 0.4% titanium hydride powder (TiH 2 ) and 0.03% graphite powder with a particle size of 10 μm-25 μm and a purity of ≥99.9 wt%, to prepare TZM raw material powder with a stoichiometric number of 0.4Ti-0.08Zr-0.03C-Mo.

[0043] Step 2: adding analytically pure absolute ethanol to the TZM raw material powder to prepare a slurry with a solid phase mass percentage of 60%;

[0044] Step 3: Pour the slurry into a molybdenum mixing tank of a three-dimensional mixer, fill the tank with 99.9wt% argon for atmosphere protection, seal the tank, and mix for 3 hours until the slurry is completely infiltrated and mixed evenly;

[0045] Step 4: Use a vacuum drying oven to dry the uniformly mixed slurry under an argon protective atmosp...

Embodiment 2

[0052] The spherical (0.5Ti-0.1Zr-0.02C-Mo) TZM alloy powder with a particle size range of 53 μm-90 μm is prepared, comprising the following steps:

[0053] Step 1: Doping 0.1% (mass fraction, the same below) zirconium hydride (ZrH 2 ) powder, 0.5% titanium hydride powder (TiH 2 ) and 0.02% graphite powder with a particle size of 12 μm-20 μm to prepare TZM raw material powder with a stoichiometric number of 0.5Ti-0.1Zr-0.02C-Mo.

[0054] Step 2: adding analytically pure absolute ethanol to the TZM raw material powder to prepare a slurry with a solid phase mass percentage of 50%;

[0055] Step 3: Pour the slurry into a molybdenum mixing tank of a three-dimensional mixer, fill the tank with 99.9wt% argon for atmosphere protection, seal the tank, and mix for 3 hours until the slurry is completely infiltrated and mixed evenly;

[0056] Step 4: Use a vacuum drying oven to dry the uniformly mixed slurry under an argon protective atmosphere with a purity of 99.95 wt%. The drying te...

Embodiment 3

[0063] The spherical (0.45Ti-0.08Zr-0.03C-Mo) TZM alloy powder with a particle size range of 30 μm-75 μm is prepared, comprising the following steps:

[0064] Step 1: Doping 00.8% (mass fraction, the same below) zirconium hydride (ZrH 2 ) powder, 0.45% titanium hydride powder (TiH 2 ) and 0.03% graphite powder with a particle size of 12 μm-20 μm to prepare TZM raw material powder with a stoichiometric number of 0.45Ti-0.08Zr-0.03C-Mo.

[0065] Step 2: adding analytically pure absolute ethanol to the TZM raw material powder to prepare a slurry with a solid phase mass percentage of 55%;

[0066] Step 3: Pour the slurry into a molybdenum mixing tank of a three-dimensional mixing machine, fill the tank with 99.9wt% argon for atmosphere protection, seal the tank, and mix for 3.5 hours until the slurry is completely infiltrated and mixed evenly ;

[0067] Step 4: Use a vacuum drying oven to dry the uniformly mixed slurry under an argon protective atmosphere with a purity of 99.9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com