High-refractive-index optical glass and preparation method thereof

A technology of optical glass and high refractive index, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc. It can solve the problems of high production cost, strong coloring, and poor stability of optical glass, achieve reduced weight and volume, and improve refraction efficiency, the effect of reducing the number of lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

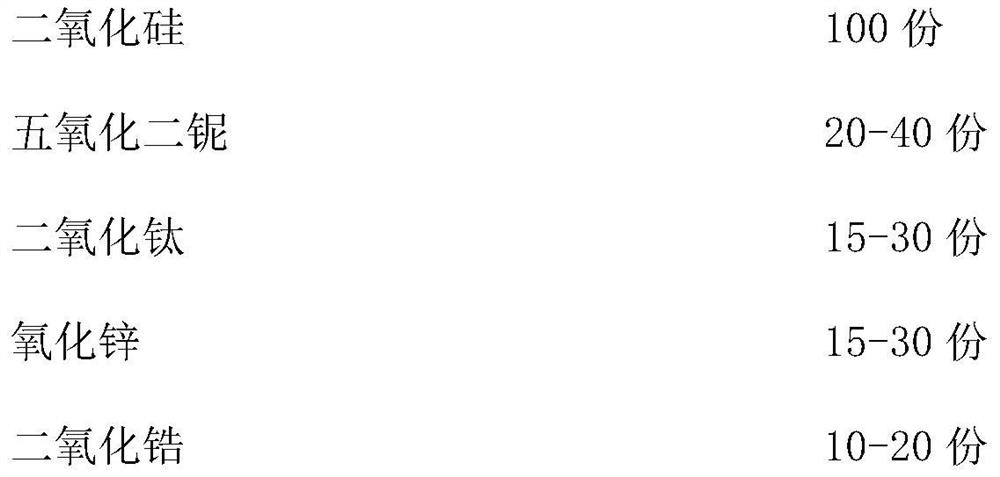

[0029] A high refractive index optical glass is characterized in that it is prepared from the following raw materials in parts by weight:

[0030]

[0031] The preparation method consists of the following steps:

[0032] S1 Mix the silicon dioxide, niobium pentoxide, titanium dioxide, zinc oxide, zirconium dioxide and calcium hexaboride in the formula amount well, then put them into a quartz container to melt and clarify at 1600°C, and perform a smelting. And continue to feed oxygen to obtain molten glass frit;

[0033] S2 Melt the glass frit at 1600°C for 1 hour. During the glass melting process, stir the frit at a stirring speed of 100rpmrpm, and continuously inject argon gas; after the glass is melted, add the frit After the nano-silver of yttrium oxide, zirconium dioxide, gallium oxide, lanthanum chloride and average particle diameter 200nm, leave standstill for 2 hours;

[0034] S3 pouring the glass frit liquid into a preheated mold and annealing to obtain a finished...

Embodiment 2

[0036] A high refractive index optical glass is prepared from the following raw materials in parts by weight:

[0037]

[0038] The preparation method consists of the following steps:

[0039] S1 Mix the silicon dioxide, niobium pentoxide, titanium dioxide, zinc oxide, zirconium dioxide and calcium hexaboride in the formula amount well, then put them into a quartz container to melt and clarify at 1700°C, and perform a smelting. And continue to feed oxygen to obtain molten glass frit;

[0040] S2 Melt the glass frit at 1700°C for 2 hours. During the glass melting process, stir the frit at a stirring speed of 150rpm, and continuously inject argon gas; after the glass is melted, add the frit After the nano-silver of yttrium oxide, zirconium dioxide, gallium oxide, lanthanum chloride and average particle diameter 250nm, leave standstill for 3 hours;

[0041] S3 pouring the glass frit liquid into a preheated mold and annealing to obtain a finished glass product.

Embodiment 3

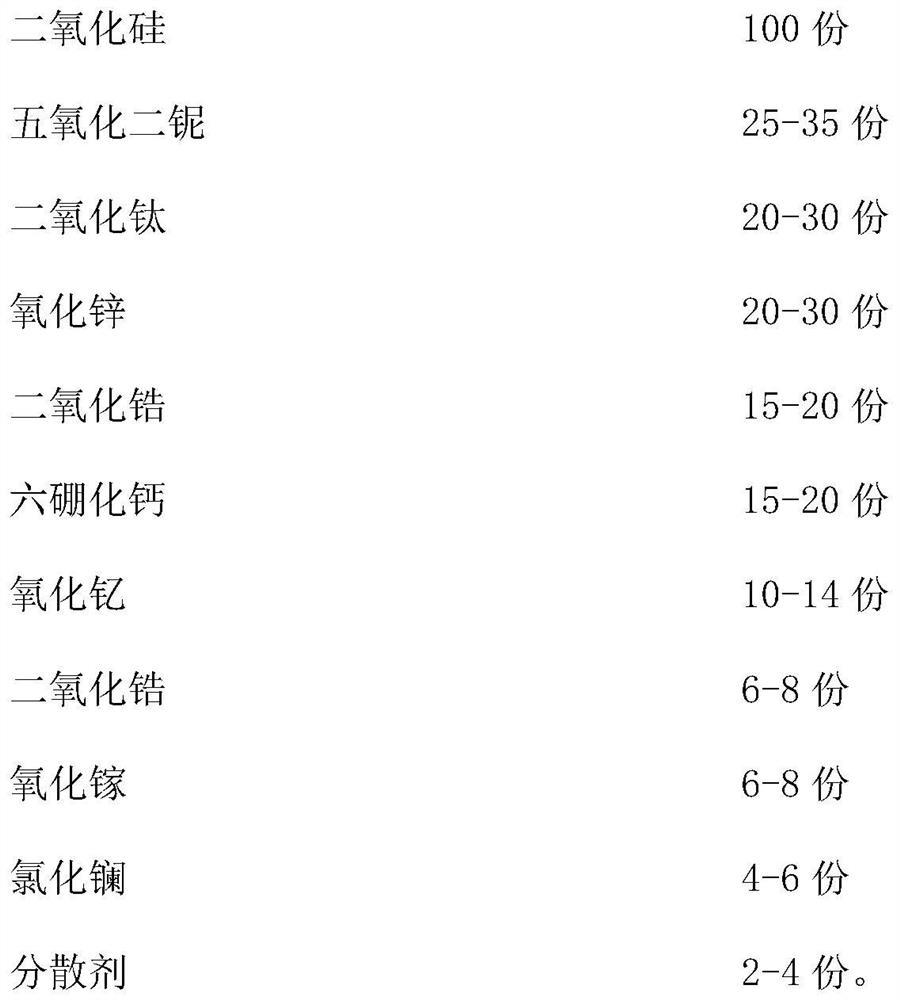

[0043] A high refractive index optical glass is characterized in that it is prepared from the following raw materials in parts by weight:

[0044]

[0045] The preparation method consists of the following steps:

[0046] S1 Mix the silicon dioxide, niobium pentoxide, titanium dioxide, zinc oxide, zirconium dioxide and calcium hexaboride in the formula amount well, then put them into a quartz container to melt and clarify at 1700°C, and perform a smelting. And continue to feed oxygen to obtain molten glass frit;

[0047] S2 Melt the glass frit at 1700°C for 2 hours. During the glass melting process, stir the frit at a stirring speed of 150rpm, and continuously inject argon gas; after the glass is melted, add the frit After the nano-silver of yttrium oxide, zirconium dioxide, gallium oxide, lanthanum chloride and average particle diameter 200nm, leave standstill for 3 hours;

[0048] S3 pouring the glass frit liquid into a preheated mold and annealing to obtain a finished g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com