High-aging-resistance semiconductive shielding material for cables

A shielding material and semi-conductive technology, applied in the field of cable shielding materials, can solve the problem that semi-conductive shielding materials cannot meet the needs of society, and achieve the effects of improving service life, improving flame resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

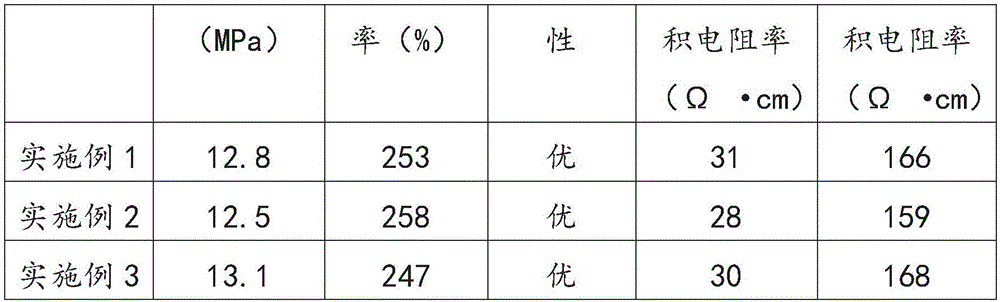

Embodiment 1

[0015] A semi-conductive shielding material for cables with good aging resistance, made of the following raw materials in parts by weight (kg): nitrile rubber 70, butadiene rubber 20, conductive carbon black 40, tricresyl phosphate 15, decabromobiphenyl Ether 3, diformyl peroxide 3, antioxidant 10764, zinc stearate 5, antioxidant MB 2, calcium hexaboride 6, antimony trioxide 2, nano-diamond 4, titanium dioxide 1, carbon fiber 2, ring Oxygenated soybean oil5.

[0016] A method for preparing a semi-conductive shielding material for cables with good aging resistance, comprising the following steps:

[0017] (1) Calcining the nano-diamond and calcium hexaboride at 600° C. for 1 hour, taking them out, adding an appropriate amount of water and stirring evenly;

[0018] (2) Mix and pulverize antimony trioxide, titanium dioxide, and carbon fiber, put them into a banbury mixer, and banbury at 80° C. for 4-7 minutes to obtain a mixture A;

[0019] (3) Preheat the mill to 60°C, add nit...

Embodiment 2

[0022] A semi-conductive shielding material for cables with good aging resistance, made of the following raw materials in parts by weight (kg): nitrile rubber 75, butadiene rubber 25, conductive carbon black 45, tricresyl phosphate 18, decabromobiphenyl Ether 4, diformyl peroxide 4, antioxidant 10765, zinc stearate 6, antioxidant MB 3, calcium hexaboride 7, antimony trioxide 3, nano-diamond 5, titanium dioxide 2, carbon fiber 3, ring Oxygenated soybean oil6.

[0023] A method for preparing a semi-conductive shielding material for cables with good aging resistance, comprising the following steps:

[0024] (1) Calcining the nano-diamond and calcium hexaboride at 700° C. for 1.5 hours, taking them out, adding an appropriate amount of water and stirring evenly;

[0025] (2) Mix and pulverize antimony trioxide, titanium dioxide, and carbon fiber, put them into a banbury mixer, and banbury at 85° C. for 6 minutes to obtain a mixture A;

[0026] (3) Preheat the mill to 65°C, add ni...

Embodiment 3

[0029] A semi-conductive shielding material for cables with good aging resistance, made of the following raw materials in parts by weight: nitrile rubber 80, butadiene rubber 30, conductive carbon black 50, tricresyl phosphate 20, decabromodiphenyl ether 5, Diformyl peroxide 5, antioxidant 10766, zinc stearate 7, antioxidant MB 4, calcium hexaboride 8, antimony trioxide 4, nano-diamond 6, titanium dioxide 3, carbon fiber 4, epoxy soybean oil 7.

[0030] A method for preparing a semi-conductive shielding material for cables with good aging resistance, comprising the following steps:

[0031] (1) Calcining the nano-diamond and calcium hexaboride at 800° C. for 2 hours, taking them out, adding an appropriate amount of water and stirring evenly;

[0032] (2) Mix and pulverize antimony trioxide, titanium dioxide, and carbon fiber, put them into a banbury mixer, and banbury at 90° C. for 4-7 minutes to obtain a mixture A;

[0033] (3) Preheat the mill to 70°C, add nitrile rubber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com