A kind of hot aerosol fire extinguishing agent and preparation method thereof

A technology of fire extinguishing agent and sol, which is applied in the field of hot aerosol fire extinguishing agent and its preparation, and can solve problems such as high nozzle temperature, low aerosol efficiency, unfavorable fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

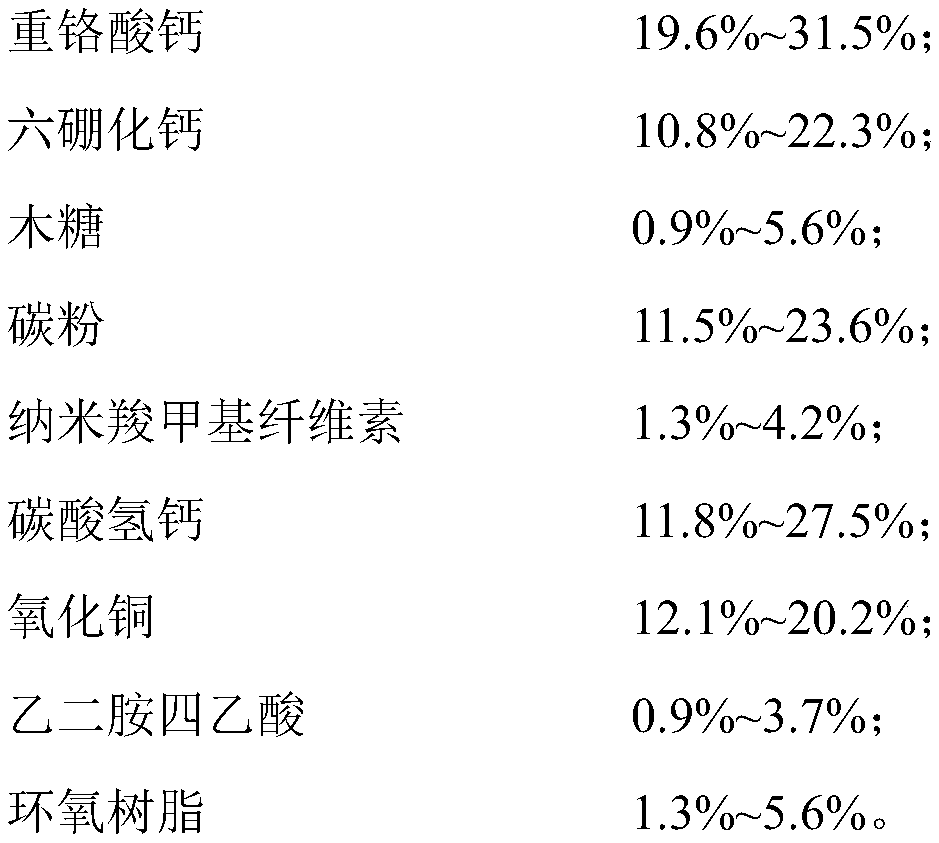

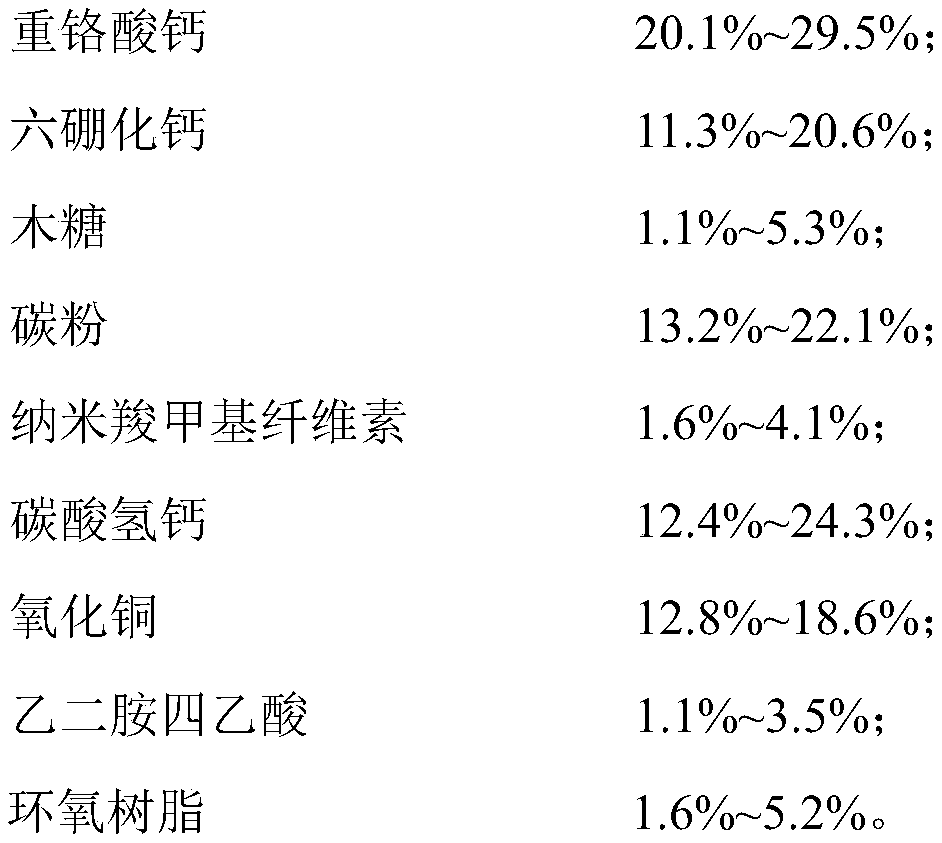

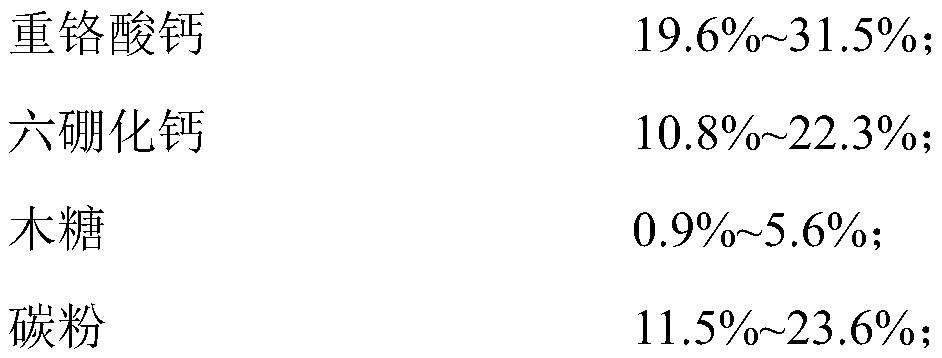

Method used

Image

Examples

Embodiment 1

[0040] The raw material formula of the hot aerosol fire extinguishing agent is: according to the mass fraction, calcium dichromate 21%, calcium hexaboride 15%, xylose 3%, carbon powder 19%, nano carboxymethyl cellulose 3%, calcium bicarbonate 21 %, copper oxide 13%, ethylenediaminetetraacetic acid 2%, epoxy resin 3% (at a mass ratio of 1:1, adding dioctyl phthalate as a thinner for dilution).

[0041] Put the compressed product (with a cartridge) into a small aerosol fire extinguishing device, and install an electric starter (no coolant or compressed gas in the aerosol fire extinguishing device), and the implementation area is 0.1m 2 For the fire extinguishing experiment of the oil pan, the fuel is commercial grade n-heptane. The quality of the product used in the fire extinguishing experiment is 50g, and the experimental results are shown in Table 1.

Embodiment 2

[0043] The raw material formula of the hot aerosol fire extinguishing agent is: according to mass fraction, calcium dichromate 22%, calcium hexaboride 12%, xylose 4%, carbon powder 18%, nano carboxymethyl cellulose 3%, calcium bicarbonate 20 %, copper oxide 14%, ethylenediaminetetraacetic acid 3%, epoxy resin 4% (in a mass ratio of 1:3, add dioctyl phthalate as a thinner for dilution).

[0044] Put the compressed product (with a cartridge) into a small aerosol fire extinguishing device, and install an electric starter (no coolant or compressed gas in the aerosol fire extinguishing device), and the implementation area is 0.1m 2 For the fire extinguishing experiment of the oil pan, the fuel is commercial grade n-heptane. The quality of the product used in the fire extinguishing experiment is 50g, and the experimental results are shown in Table 1.

Embodiment 3

[0046] The raw material formula of the hot aerosol fire extinguishing agent is: according to mass fraction, calcium dichromate 21%, calcium hexaboride 12%, xylose 3%, carbon powder 19%, nano carboxymethyl cellulose 3%, calcium bicarbonate 20 %, copper oxide 16%, ethylenediaminetetraacetic acid 3%, epoxy resin 3% (in a mass ratio of 1:2, add dioctyl phthalate as a thinner for dilution).

[0047] Put the compressed product (with a cartridge) into a small aerosol fire extinguishing device, and install an electric starter (no coolant or compressed gas in the aerosol fire extinguishing device), and the implementation area is 0.1m 2 For the fire extinguishing experiment of the oil pan, the fuel is commercial grade n-heptane. The quality of the product used in the fire extinguishing experiment is 50g, and the experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com