Non-sticking tundish dry material and production method thereof

A technology of dry material and sintered magnesia, applied in the field of refractory material industry, can solve the problems of non-normal application, poor slag corrosion resistance, difficult to unpack, etc., so as to improve the comprehensive utilization rate, improve the anti-sintering performance, and reduce resources. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

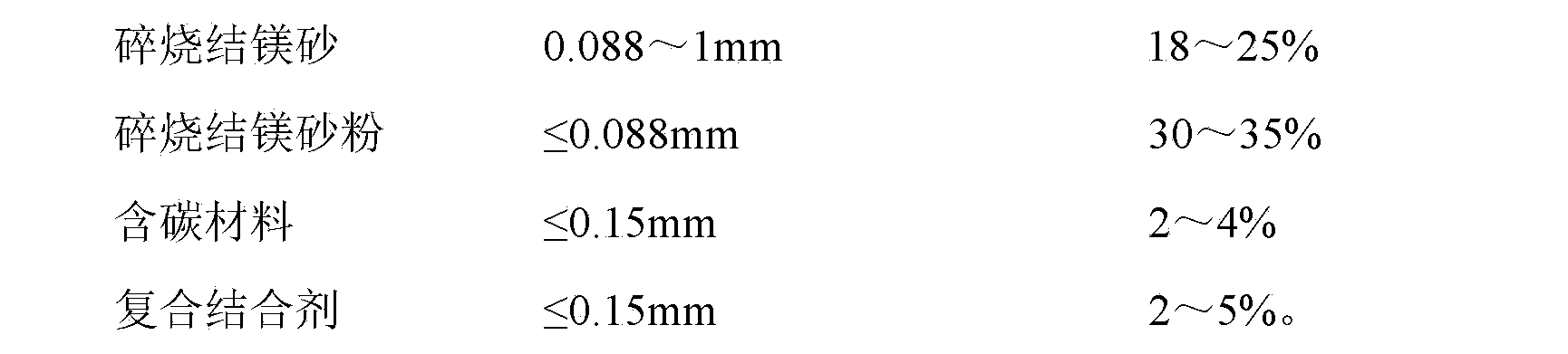

Method used

Image

Examples

Embodiment 1

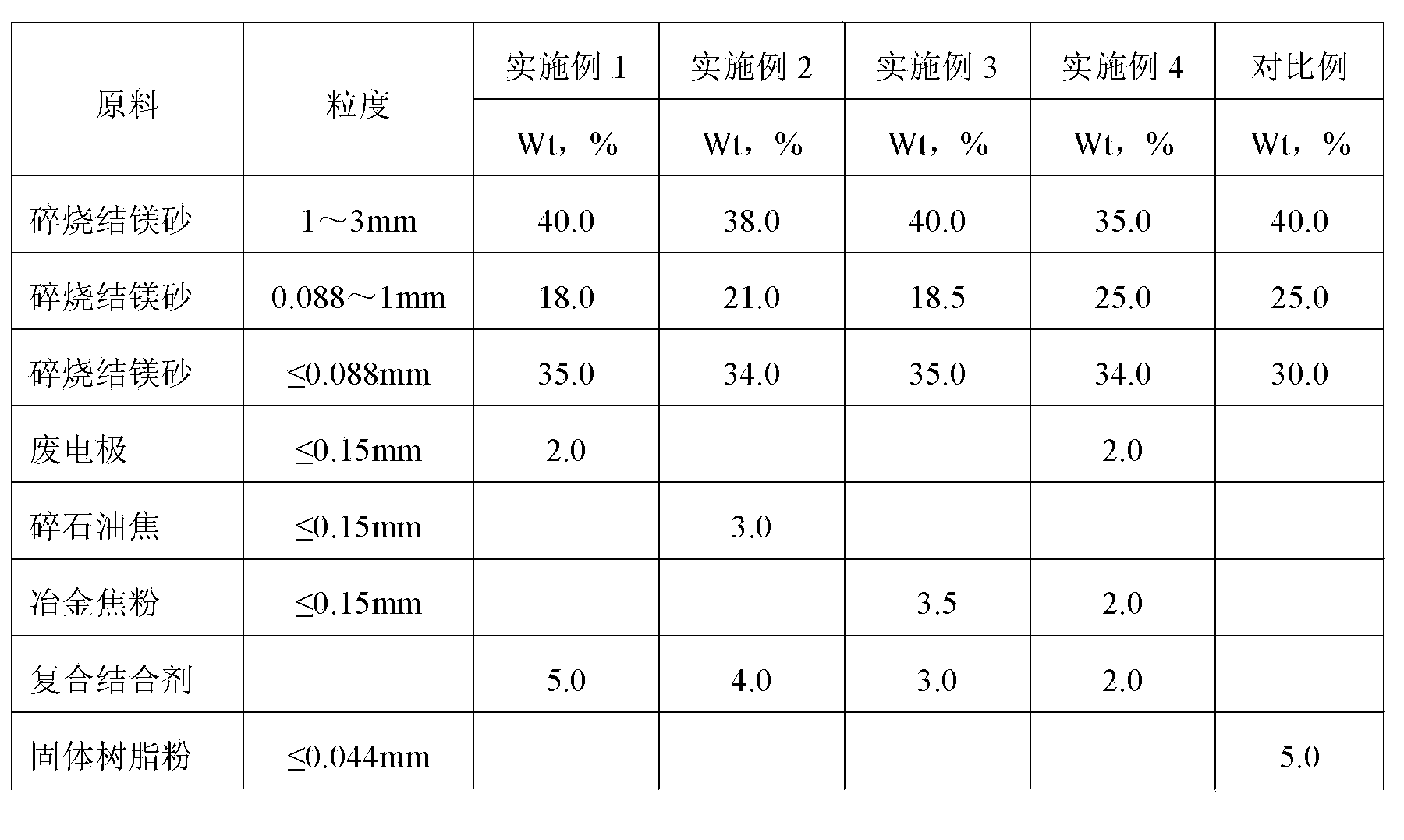

[0024] A non-bonded tundish dry material, the composition of the main material and additives is shown in Example 1 in Table 1, wherein the crushed sintered magnesia contains MgO: 85~90% by weight, SiO 2 :4~8%, Fe 2 O 3 : 1.5~4%, bulk density: 2.8~3.0g / cm 3 . The composite binder is composed of 40% dextrin and 60% solid resin powder.

[0025] The steps of a kind of preparation method of non-bonding tundish dry material are as follows:

[0026] 1. After the crushed sintered magnesia is sieved by 3mm and 1mm sieves, the particle size is 1~3mm and 0.088~1mm (of which ≤0.088mm ≤10%); it is ground into ≤0.088 by ball mill or other grinding equipment mm fine powder; process the waste electrode into 0~0.15mm fine powder;

[0027] 2. Weigh the ingredients according to the composition of the main ingredients and additives in Table 1, add them to the mixer and mix for 8~10min;

[0028] 3. After mixing evenly, bag and pack the finished products that have passed the inspection.

[0...

Embodiment 2

[0031] A non-bonded tundish dry material, the composition of the main material and additives is shown in Example 2 in Table 1, wherein the crushed sintered magnesia contains MgO: 85~90% by weight, SiO 2 :4~8%, Fe 2 O 3 : 1.5~4%, bulk density: 2.8~3.0g / cm 3 . The composite binder is composed of 30% dextrin and 70% solid resin powder.

[0032] The steps of a kind of preparation method of non-bonding tundish dry material are as follows:

[0033] 1. After the crushed sintered magnesia is sieved by 3mm and 1mm sieves, the particle size is 1~3mm and 0.088~1mm (of which ≤0.088mm ≤10%); it is ground into ≤0.088 by ball mill or other grinding equipment mm fine powder; crushed petroleum coke is processed into 0~0.15mm fine powder;

[0034] 2. Weigh the ingredients according to the composition of the main ingredients and additives in Table 1, add them to the mixer and mix for 8~10min;

[0035] 3. After mixing evenly, bag and pack the finished products that have passed the inspectio...

Embodiment 3

[0038] A non-bonded tundish dry material, the composition of the main material and additives is shown in Example 3 in Table 1, wherein the crushed sintered magnesia contains MgO: 85~90% by weight, SiO 2 :4~8%, Fe 2 O 3 : 1.5~4%, bulk density: 2.8~3.0g / cm 3 . The composite binder is made up of 25% dextrin and 75% solid resin powder.

[0039] The steps of a kind of preparation method of non-bonding tundish dry material are as follows:

[0040]1. The crushed sintered magnesia is sieved by 3mm and 1mm sieves to make particles with particle sizes of 1~3mm and 0.088~1mm (of which ≤0.088mm ≤10%); by ball mill or other grinding equipment, grind to ≤0.088 mm fine powder; process metallurgical coke powder into 0~0.15mm fine powder;

[0041] 2. Weigh the ingredients according to the composition of the main ingredients and additives in Table 1, add them to the mixer and mix for 8~10min;

[0042] 3. After mixing evenly, bag and pack the finished products that have passed the inspecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com