Montmorillonite/ZSM-5 molecular sieve composite material and preparation thereof

A composite material, ZSM-5 technology, applied in the field of new catalytic materials and their preparation, can solve the problems of affecting catalytic performance, prone to sintering, etc., and achieve the effects of good hydrothermal stability, easy separation, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

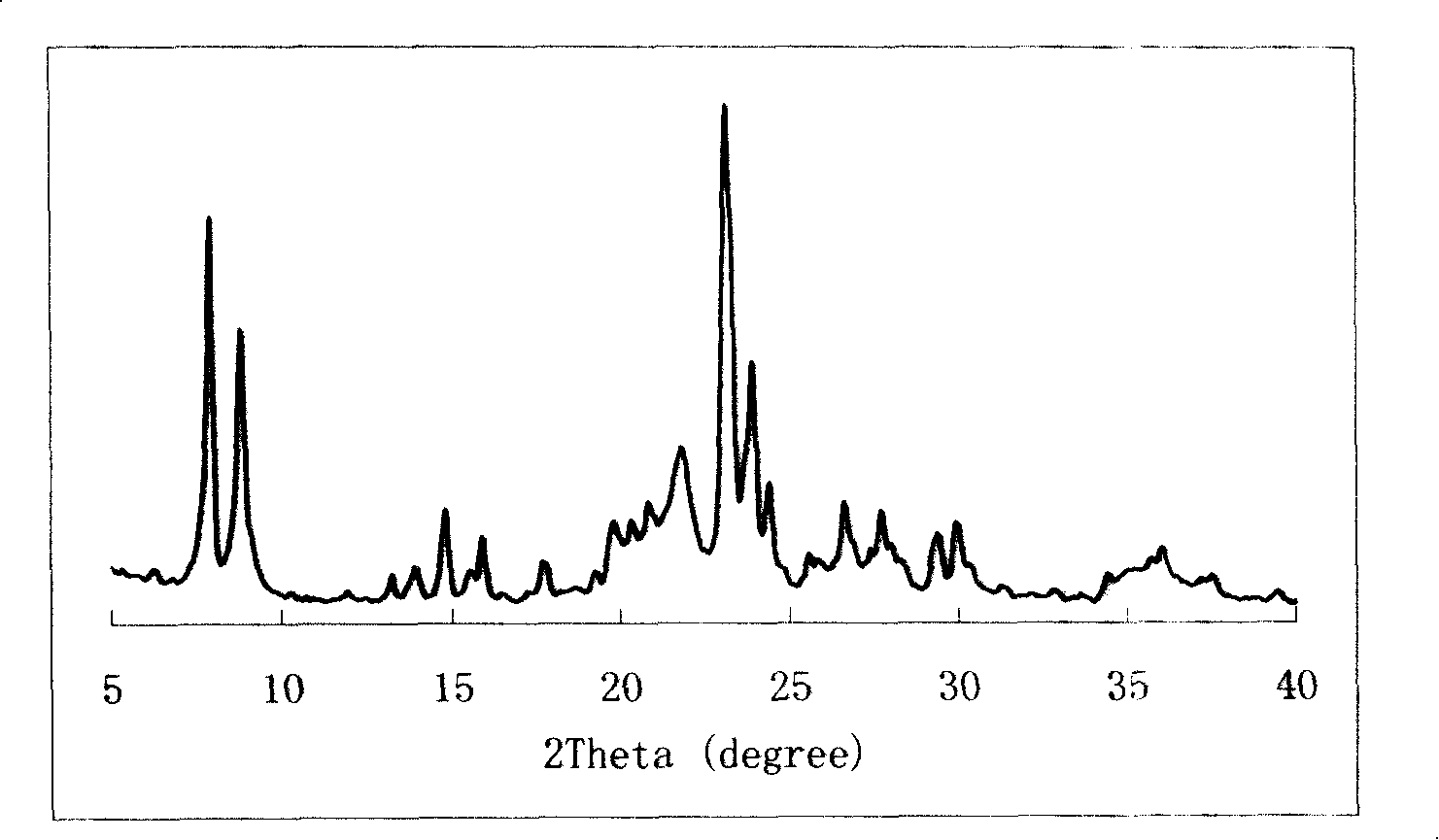

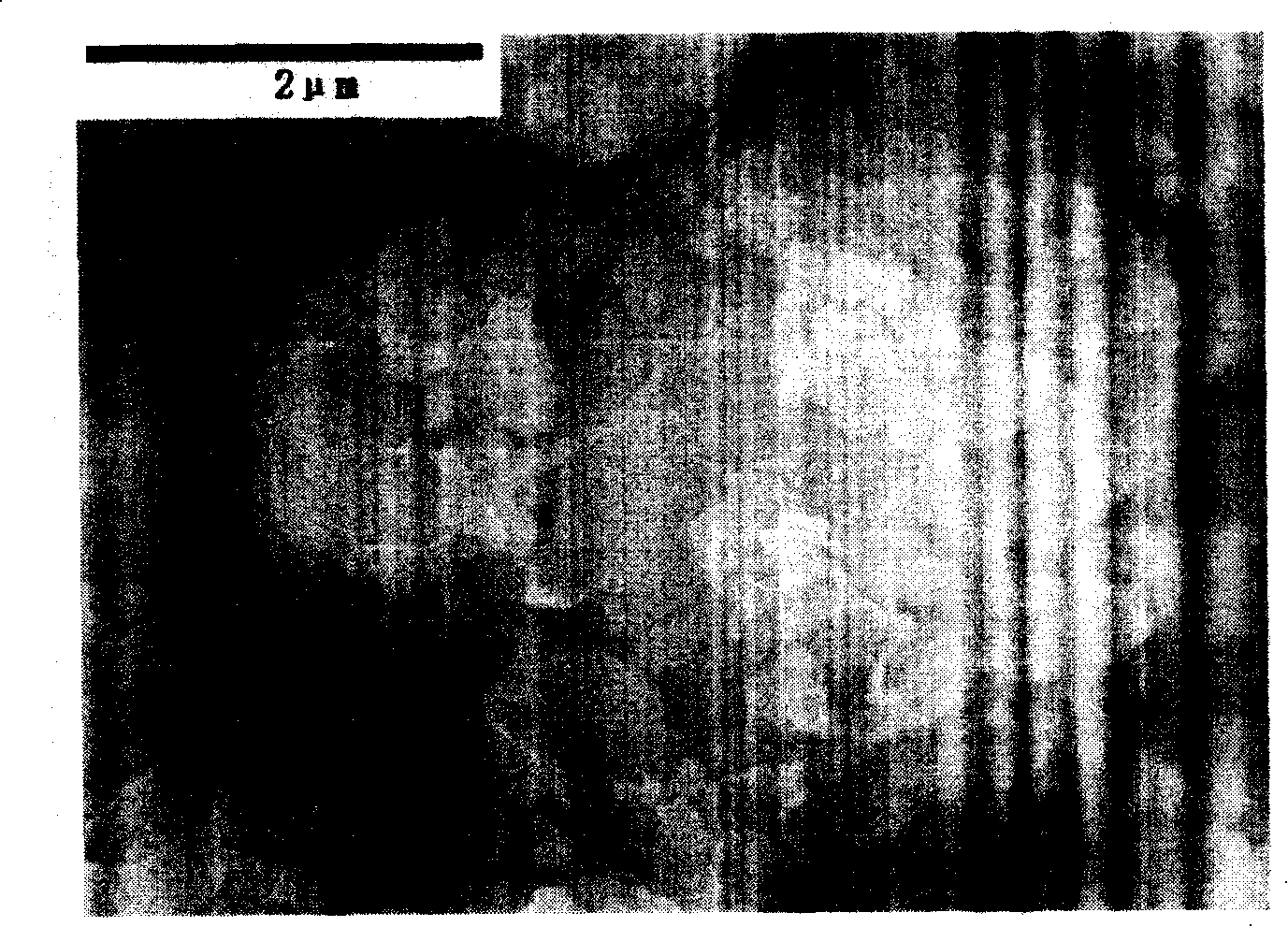

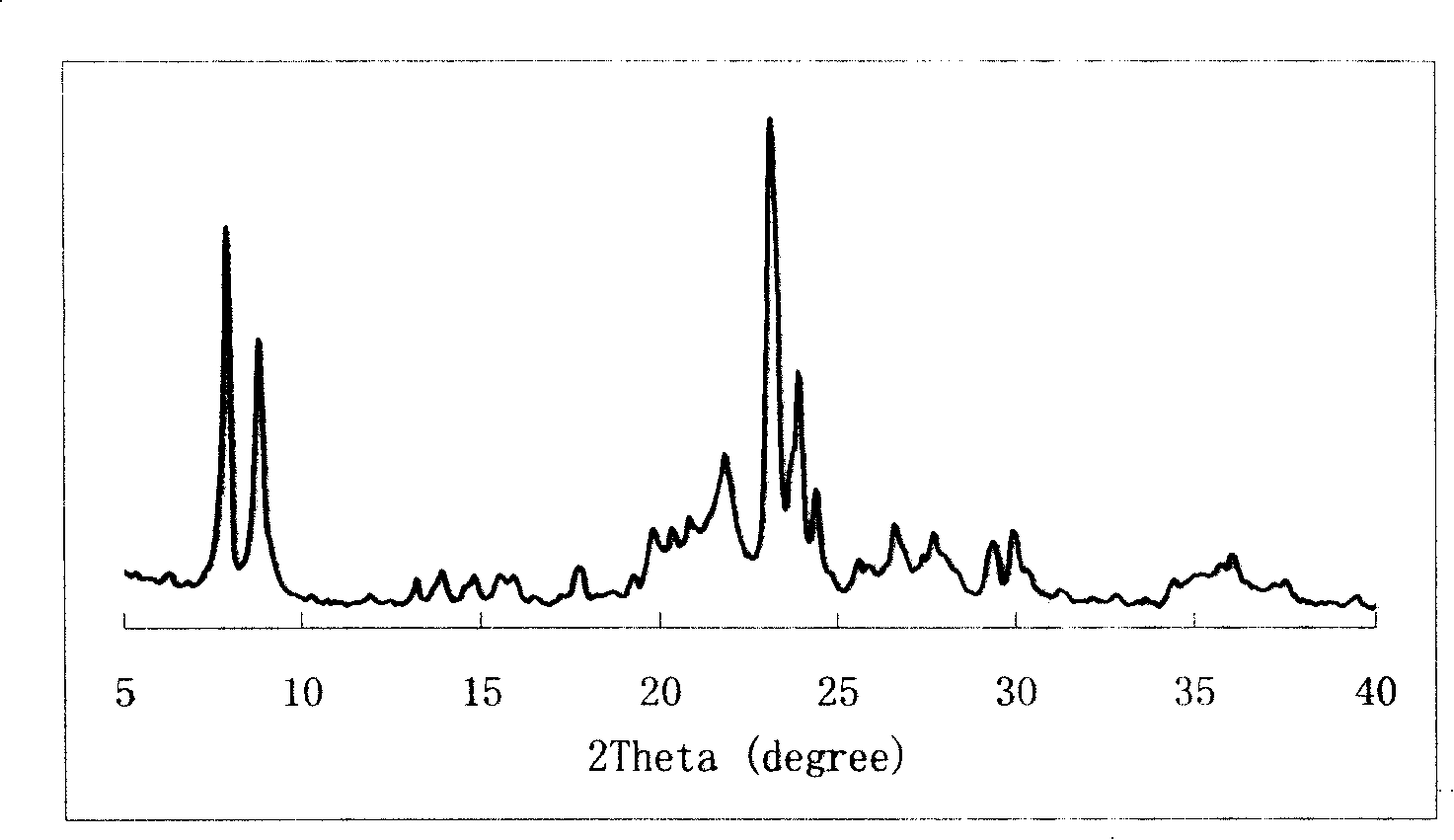

Image

Examples

preparation example Construction

[0023] (1) Preparation of directing agent: Silicon source, templating agent, sodium hydroxide and water according to (8-20) SiO 2 :(TPA) 2 O:(1~4)Na 2 O:(350~600)H 2 The molar ratio of O is mixed at room temperature and under mechanical stirring conditions, and the stirring is continued until the raw materials are evenly mixed, then transferred to the synthetic bomb, and heated at 90-110°C under airtight conditions for 10-20 hours, preferably 16-20 Hours, make the guide agent. Wherein said silicon source is white carbon black, silica sol or silicic acid; said template is tetrapropyl ammonium hydroxide.

[0024] (2) Preparation of ZSM-5 molecular sieve gel: silicon source, aluminum source, sodium hydroxide and water according to (20 ~ 50) SiO 2 :Al 2 o 3 : (2~5)Na 2 O:(800~1200)H 2 The molar ratio of O is mixed at room temperature and under mechanical stirring conditions, and the stirring is continued until the raw materials are evenly mixed to obtain silica-alumina gel...

Embodiment 1

[0038] (1) Preparation of directing agent:

[0039] ①Weigh 13.8g of sodium hydroxide, dissolve it in 710.3g of distilled water, then add 117.0g of tetrapropylammonium hydroxide aqueous solution, and mix well with electromagnetic stirring. ② Take 158.9g of silicic acid and add it into the solution, stir evenly with electromagnetic. ③After magnetically stirring the above solution for 0.5 hours, put it into a synthetic bomb and age it at 100°C for 16 hours to make a directing agent.

[0040] (2) Synthesis of ZSM-5 molecular sieve and its growth on montmorillonite microspheres.

[0041] ① Weigh 867.8g of distilled water, dissolve 10.2g of sodium hydroxide and 10.3g of sodium aluminate, and stir well. ②124g of silicic acid was gradually added into the solution under full stirring, and vigorously stirred at room temperature. ③Add 30ml of directing agent to the above solution, then add 60g of montmorillonite microspheres, and stir at room temperature for 0.5 hours. Hydrothermal c...

Embodiment 2

[0045] (1) Preparation of directing agent:

[0046] ①Weigh 13.8g of sodium hydroxide, dissolve it in 710.3g of distilled water, then add 117.0g of 25% tetrapropylammonium hydroxide aqueous solution, and mix evenly with electromagnetic stirring. ②Weigh 158.9g of silicic acid and add it into the solution, stir evenly with electromagnetic. ③After magnetically stirring the above solution for 0.5 hours, put it into a synthetic bomb and age it at 100°C for 16 hours to make a directing agent.

[0047] (2) Synthesis of ZSM-5 molecular sieve and its growth on montmorillonite microspheres.

[0048] ① Weigh 867.8g of distilled water, dissolve 8.8g of sodium hydroxide and 10.3g of sodium aluminate, and stir well. ② Gradually add 113.1g of silicic acid into the solution under full stirring, and vigorously stir at room temperature. ③ Add 30ml of directing agent to the above solution, then add 40g of montmorillonite microspheres, and stir at room temperature for 0.5 hours. Hydrothermal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com