Acrylic acid catalyst regeneration method

A catalyst and acrylic acid technology, which is applied in the field of catalysis, can solve the problems of frequent shutdown and regeneration, reduction of catalyst activity, expansion of pore distribution, etc., and achieve the effects of prolonging service life, not easy to sinter, and strong anti-coking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

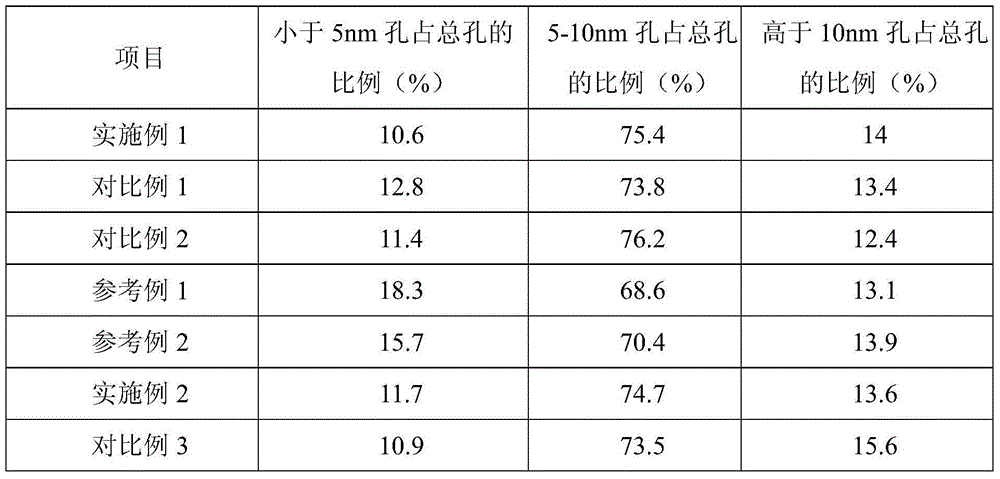

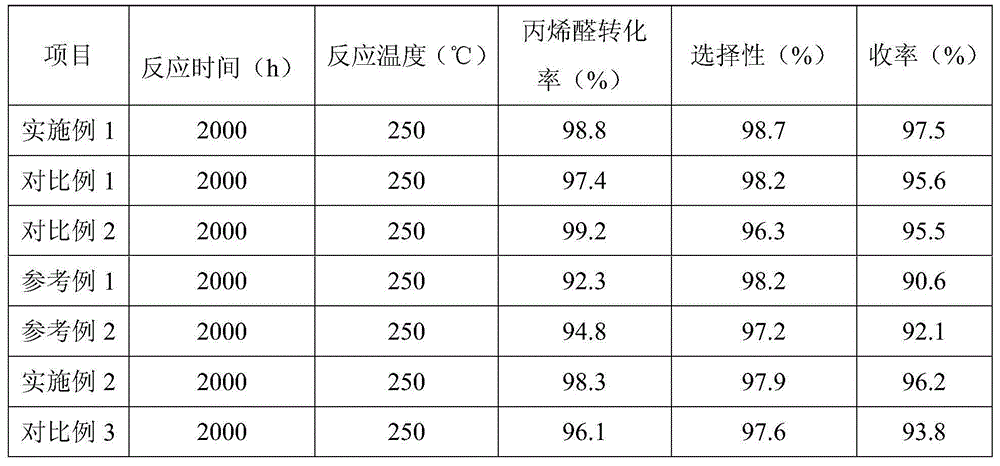

[0028] Embodiment 1: Preparation and evaluation of fresh catalyst

[0029]First, heat 5L of pure water to 95°C, add 135.5g of ammonium metatungstate to it, then add 151.8g of ammonium metavanadate and 916.7g of ammonium metamolybdate in turn, and dissolve it under stirring to obtain an orange transparent solution Add 1.5L of ethanol after the solution is cooled below 40°C, and stir at high speed to form a uniform solution; then add 64.4g of antimony acetate to the above solution to form a black aqueous dispersion; then, dissolve 129.7g of copper sulfate in 833g of pure water , mixed with the above black dispersion to obtain a slurry, which was refluxed at 95°C for 2 hours; ethanol was added at a rate of 20ml / min, and water in the system was separated by distillation. When it is detected that the ethanol content in the distillate is not less than 95%, the slurry is spray-dried, the nozzle temperature is controlled at 140°C, the feeding speed is adjusted to keep the outlet tempe...

reference example 1

[0039] Reference Example 1: Preparation and Evaluation of Deactivated Catalyst

[0040] Put the fresh catalyst into a stainless steel reaction tube with an inner diameter of 25ml, pass through the raw material gas composed of 6.5% acrolein, 8.5% oxygen, 52% nitrogen, and 33% water vapor in molar percentages, at a pressure of 0.2MPa , the gas volumetric space velocity is 1800hr -1 The oxidation reaction of acrolein was carried out under 6000 hours to obtain a deactivated catalyst, and its pore distribution is shown in Table 1.

[0041] Put 100ml of deactivated catalyst into a stainless steel reaction tube with an inner diameter of 25ml, pass through the raw material gas composed of 6.5% acrolein, 8.5% oxygen, 52% nitrogen, and 33% water vapor in molar percentage. 0.2MPa, gas volume space velocity is 1800hr -1 The acrolein oxidation reaction was carried out at a temperature of 250° C., and the reaction results shown in Table 2 were obtained.

reference example 2

[0042] Reference Example 2: Preparation and Evaluation of Traditional Regenerated Catalyst

[0043] The deactivated catalyst prepared in Reference Example 1 was heated up to 390° C. at a rate of 1° C. / hour, and calcined at this temperature for 1 day to obtain a regenerated catalyst.

[0044] Put 100ml of the regenerated catalyst into a stainless steel reaction tube with an inner diameter of 25ml, pass through the raw material gas composed of 6.5% acrolein, 8.5% oxygen, 52% nitrogen, and 33% water vapor by mole percentage, at a pressure of 0.2 MPa, gas volume space velocity is 1800hr -1 The acrolein oxidation reaction was carried out at a temperature of 250° C., and the reaction results shown in Table 2 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com