Heavy arenes lightening catalyst and preparing method thereof

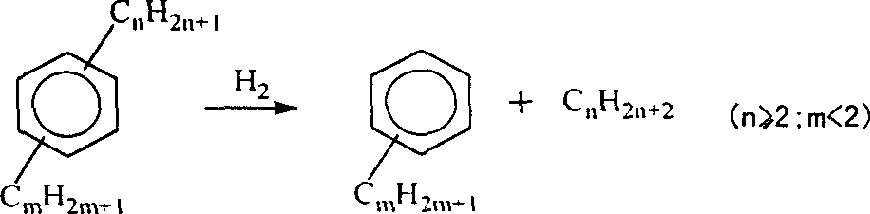

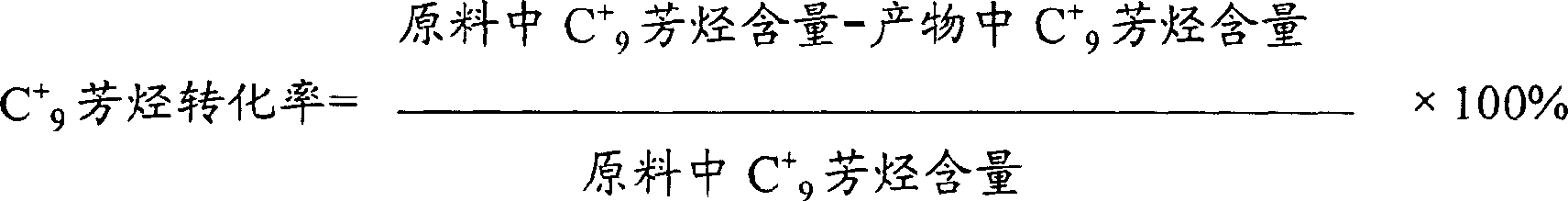

A technology for heavy aromatics and catalysts, applied in the field of heavy aromatics lightening catalysts and its preparation, can solve the problems of low space velocity, technology commercialization limitations, high reaction temperature and pressure, and achieve strong anti-coking ability and activity Improved stability and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of catalyst of the present invention comprises:

[0021] (1) Mix the sodium type ZSM-5 zeolite, mordenite and alumina hydrate in a weight ratio on a dry basis, and then knead, shape and roast to obtain a composite carrier,

[0022] (2) Carry out ion exchange to composite carrier with ammonium salt aqueous solution, make the exchange capacity of the sodium ion in carrier be at least 90%, then wash,

[0023] (3) Formulating an impregnating solution with a group VIII metal compound, impregnating the ammonium-exchanged support, drying and calcining.

[0024] The (1) step of the above method is the preparation of the composite carrier, which is to mix the sodium-type ZSM-5 zeolite and mordenite with alumina hydrate in a predetermined proportion, and then add 25 to 60% of the weight of the mixed powder, preferably 35 to 45%. %, with a concentration of 1 to 5% by weight, preferably 1.5 to 3.0% by weight, of nitric acid aqueous solution kneading and mold...

example 1~6

[0032] Preparation of the catalyst of the present invention.

[0033] (1) Preparation of composite carrier

[0034] An appropriate amount of sodium-type ZSM-5 zeolite (produced by Shanghai Dyestuff No. 7 Plant, with a sodium content of 0.4-0.6% by weight), sodium-type mordenite (with a sodium content of 4.0-8.0% by weight) and HP hydroxide prepared by the method described in CN85100218 Mix aluminum powder, add 40% by weight of powder, and 2% nitric acid aqueous solution, knead, extrude, dry at 110-120°C for 2 hours, and roast at 550°C in air for 4 hours to obtain a composite carrier.

[0035] (2) Ammonium exchange

[0036] Take 10 grams of the above-mentioned composite carrier, and use 0.5N NH at 90±10°C 4 20 ml of Cl solution was used to ion-exchange the carrier for 2 hours, filtered, and washed with deionized water until Cl-free - .

[0037] (3) Introduce metal components

[0038] Predetermined amounts of the precursors of each metal component were prepared as an impreg...

example 7~8

[0044] Get the SB aluminum hydroxide powder that German condea company produces, under the condition of room temperature, liquid-solid ratio 2, use the SnCl that concentration is 10 mg / ml 2 After soaking in the solution for 15 hours and drying at 110-120° C. for 2 hours, aluminum oxide containing 0.48% by weight of tin was prepared. This tin-containing alumina is mixed with ZSM-5 zeolite and mordenite according to the dry weight ratio of 25:60:15, and the method of example 1 is used to mix with HNO 3 After peptization and molding, a tin-containing carrier is made, then ammonium exchange is carried out, and chloroplatinic acid and perrhenic acid with a concentration of 2.86 mg / ml and 11.8 mg / ml are used to prepare an impregnating solution, and the liquid / solid volume ratio is The ratio of 2 was impregnated with the carrier at room temperature for 24 hours, dried at 110-120°C for 2 hours, and calcined at 500°C in air for 4 hours to prepare catalysts G and H. See Table 2 for its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com