Molecular sieve catalyst for medium and low temperature denitration and production method of molecular sieve catalyst

A technology for low-temperature denitration and production methods, applied in molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve problems such as low denitration efficiency, and achieve high catalytic efficiency, good catalytic activity and diffusion performance, and strong anti-coking ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for producing a molecular sieve catalyst for medium and low temperature denitrification, comprising the steps of:

[0019] (1) the corresponding metal salt manganese acetate powder of a certain amount of active component manganese is dissolved in water, stirs and obtains manganese acetate solution;

[0020] (2) Take a certain amount of USY molecular sieve and impregnate it in manganese acetate solution, stir it at room temperature for 2 hours, dry it in a water bath at 80°C, dry it in an oven at 110°C for 18 hours, and calcinate it in a muffle furnace at 550°C for 4 hours under a static atmosphere , after sieving through a 50 mesh square hole sieve, 6Mn / USY catalysts with different manganese contents were obtained, wherein the ratio of manganese acetate solution to USY molecular sieve was 6% manganese loading.

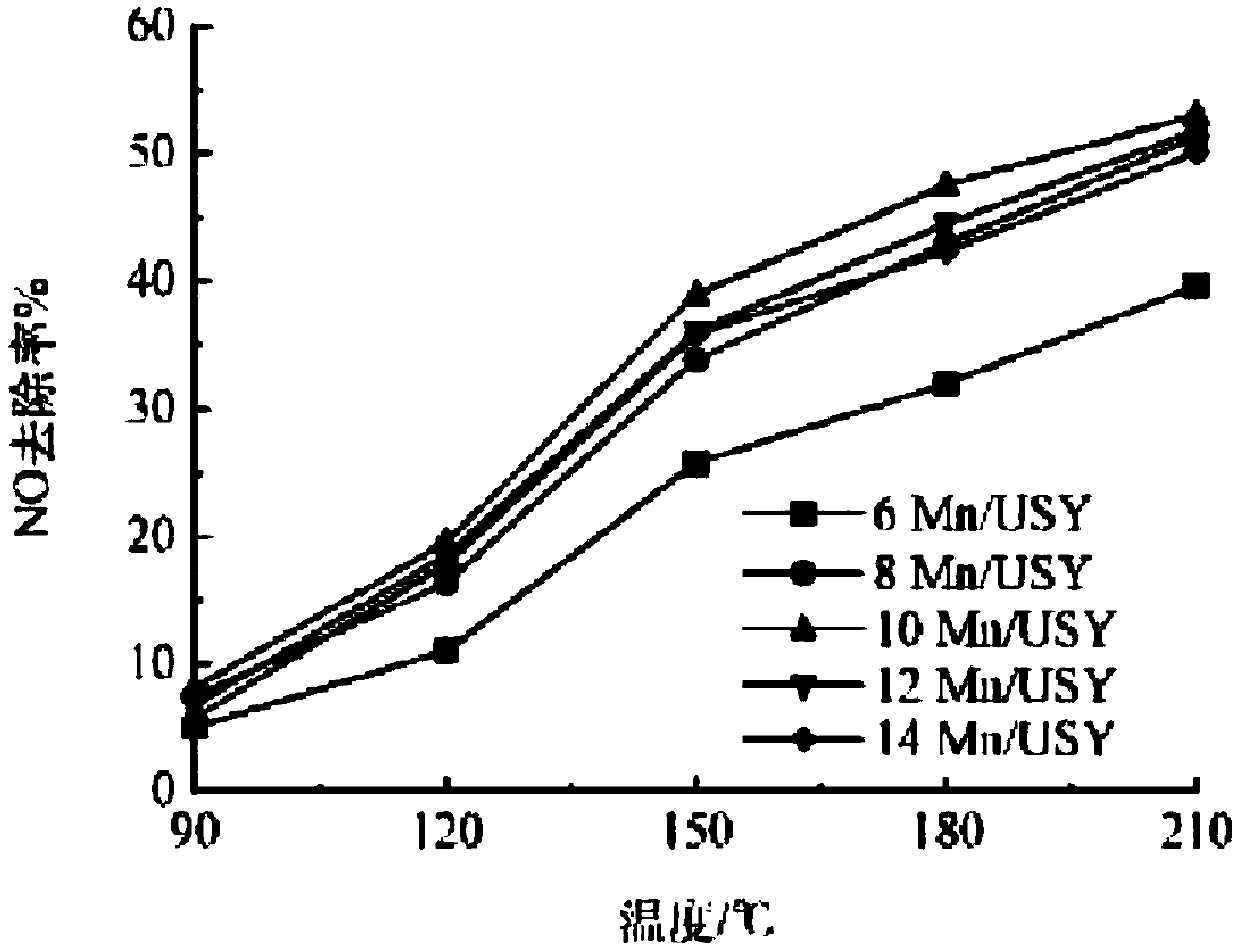

[0021] (3) The NO removal efficiency of 6Mn / USY catalyst was determined by continuous flow stationary reactor. The reaction was carried out in a quart...

Embodiment 2

[0023] A method for producing a molecular sieve catalyst for medium and low temperature denitrification, comprising the steps of:

[0024] (1) the corresponding metal salt manganese acetate powder of a certain amount of active component manganese is dissolved in water, stirs and obtains manganese acetate solution;

[0025] (2) Take a certain amount of USY molecular sieve and impregnate it in manganese acetate solution, stir it at room temperature for 2 hours, dry it in a water bath at 80°C, dry it in an oven at 110°C for 18 hours, and calcinate it in a muffle furnace at 550°C for 4 hours under a static atmosphere , after sieving through a 50 mesh square hole sieve, 8Mn / USY catalysts with different manganese contents were obtained, wherein the ratio of manganese acetate solution to USY molecular sieve was 8% manganese loading.

[0026] (3) The NO removal efficiency of 8Mn / USY catalyst was determined by continuous flow stationary reactor. The reaction was carried out in a quart...

Embodiment 3

[0028] A method for producing a molecular sieve catalyst for medium and low temperature denitrification, comprising the steps of:

[0029] (1) the corresponding metal salt manganese acetate powder of a certain amount of active component manganese is dissolved in water, stirs and obtains manganese acetate solution;

[0030] (2) Take a certain amount of USY molecular sieve and impregnate it in manganese acetate solution, stir it at room temperature for 2 hours, dry it in a water bath at 80°C, dry it in an oven at 110°C for 18 hours, and calcinate it in a muffle furnace at 550°C for 4 hours under a static atmosphere , 10Mn / USY catalysts with different manganese contents were obtained after sieving through a 50-mesh square hole sieve, wherein the ratio of manganese acetate solution to USY molecular sieve was 10% manganese loading.

[0031] (3) The NO removal efficiency of 10Mn / USY catalyst was determined by continuous flow stationary reactor. The reaction was carried out in a qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com