Production method for copper-iron diffusion powder

A production method and technology for diffusing powder, applied in the field of powder metallurgy manufacturing, can solve the problems of high bulk density of pre-alloyed powder, easy flaky formation of copper powder, short powder mixing time, etc. The effect of low density and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

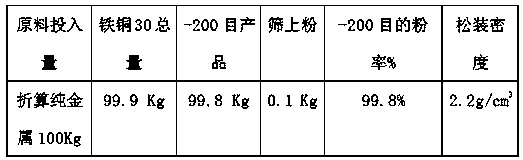

Embodiment 1

[0027] 1) Use -300 mesh copper oxide powder and -300 mesh reduced iron powder.

[0028] 2) Mix the copper oxide powder with industrial engine oil, and the copper content in the copper oxide is 30Kg, that is, the copper oxide is 37.5Kg, and the industrial engine oil is selected as the binder, and the industrial engine oil is 0.6 Kg. The mixing time is 1 hour and 20 minutes. After mixing, it becomes loose and there is no powder phenomenon.

[0029] 3) Put the reduced iron powder into the three-dimensional mixer, and the quality of the reduced iron powder is 70 Kg, and then add the copper oxide powder mixed with industrial oil into the three-dimensional mixer.

[0030] 4) The three-dimensional mixer starts working and mixing, and the mixing time is 2 hours and 40 minutes to ensure that the fine copper oxide powder particles are fully embedded in the iron powder, and different parts of the mixed powder are sampled and analyzed to ensure that each sample in different parts The dif...

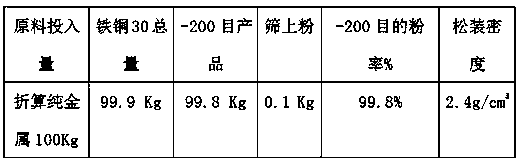

Embodiment 2

[0039] 1) Choose -300 mesh copper oxide powder, choose industrial machine oil as binder, and choose -300 mesh reduced iron powder.

[0040] 2) Mix copper oxide powder with industrial engine oil, and the copper content in copper oxide is 5Kg, that is, the mass of copper oxide is 6.25 Kg, and the industrial engine oil is 0.1 Kg. The mixing time is 1 hour and 20 minutes. After mixing, it becomes loose and there is no powder phenomenon.

[0041] 3) Put the reduced iron powder into the three-dimensional mixer, and the quality of the reduced iron powder is 95Kg, and then add the copper oxide powder mixed with industrial oil into the three-dimensional mixer.

[0042] 4) The three-dimensional mixer starts working and mixing. The mixing time is 2 hours and 40 minutes to ensure that the fine copper oxide powder particles are fully embedded in the iron powder. After mixing, different parts of the powder are sampled and analyzed to ensure that each sample in different parts The differenc...

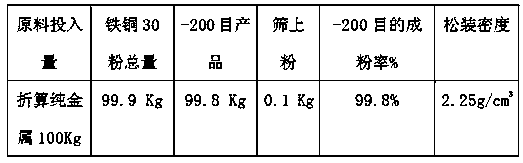

Embodiment 3

[0051] 1) Choose -300 mesh copper oxide powder, choose industrial machine oil as binder, and choose -300 mesh reduced iron powder and nickel powder.

[0052] 2) Mix copper oxide powder with industrial engine oil, and the copper content in copper oxide is 30Kg, that is, the copper oxide is 37.5Kg, and the industrial engine oil is 0.6 Kg. The mixing time is 1 hour and 20 minutes. After mixing, it is loose and there is no powder phenomenon. .

[0053] 3) Put the reduced iron powder and nickel powder into the three-dimensional mixer, and the quality of the reduced iron powder is 60Kg, and the quality of the nickel powder is 10 Kg, and then add the copper oxide powder mixed with industrial oil into the three-dimensional mixer.

[0054] 4) The three-dimensional mixer starts to work and mix the materials. The mixing time is 2 hours and 40 minutes to ensure that the fine copper oxide powder particles are fully embedded in the iron powder. After mixing, different parts of the powder ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com