Flame-proof pouring material for hydroted alumina gas suspending roasting furnace furnace liner

A technology of refractory castables and gas suspension, which is applied in the field of refractory castables for aluminum hydroxide gas suspension roasting furnace linings, and can solve problems such as poor volume stability, unsuitability for alumina roasting furnaces, and reduced construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

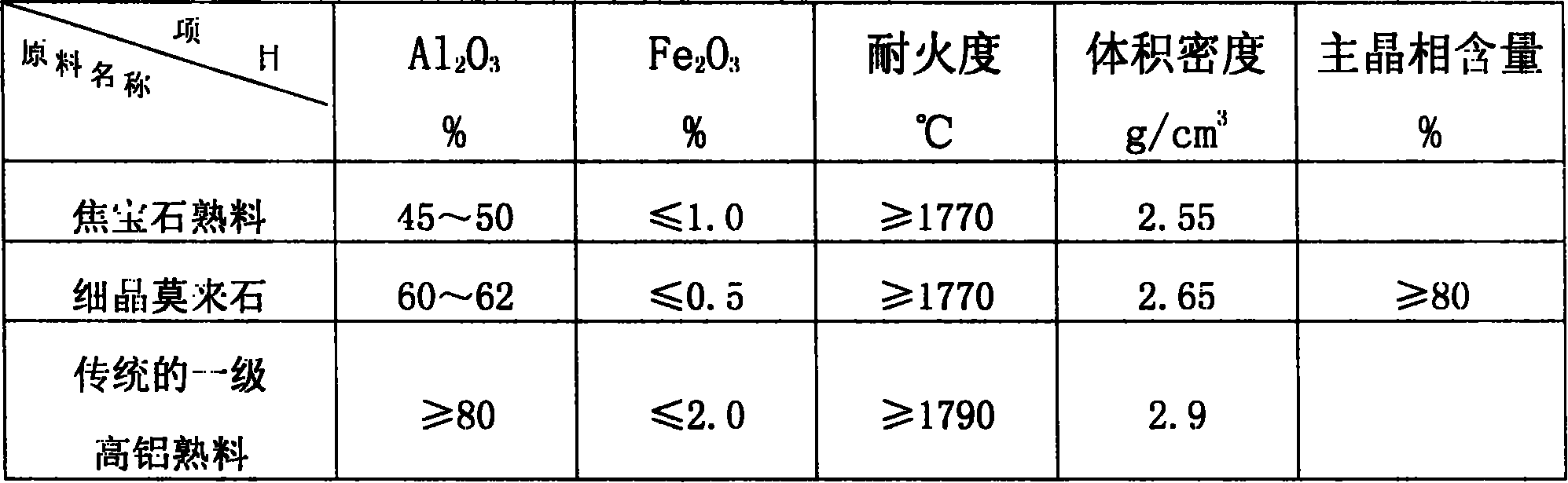

[0028] Strictly select ore sources according to the chemical composition range of each raw material, after crushing-grinding-screening and grading-magnetic separation, raw materials such as burnt gemstone clinker and fine-grained mullite powder with different particle sizes are mixed according to the following weight percentages:

[0029] Burnt gem clinker, particle size <3mm, 30%

[0030] Burnt gem clinker, particle size 3-5mm, 28%

[0031] Burnt gem clinker, particle size between 5mm and 8mm, 10%

[0032] Fine-grained mullite powder, particle size <0.074mm 16%

[0033] ρ-Al 2 o 3 6.8%

[0034] α-Al 2 o 3 Ultrafine powder 5%

[0035] SiO 2 Ultrafine powder 4%

[0036] Sodium tripolyphosphate 0.2%

[0037] Among them, the particle size of ultrafine powder is less than 5 μm

[0038] After adding water and mixing well, the furnace is built-baked-sintered to form a furnace lining. The test results of its performance indicators are shown in Tab...

Embodiment 2

[0040] Operation is with embodiment 1, but the weight percent of its raw material is:

[0041] Burnt gem clinker, particle size <3mm 29%

[0042] Burnt gem clinker, particle size 3-5mm 29%

[0043] Burnt gem clinker, particle size between 5mm and 8mm 11%

[0044] Fine-grained mullite powder, particle size <0.074mm 15%

[0045] ρ-Al 2 o 3 7%

[0046] α-Al 2 o 3 Superfine powder 3.8%

[0047] SiO 2 Ultrafine powder 5%

[0048] Sodium tripolyphosphate 0.2%

[0049] Among them, the particle size of ultrafine powder is less than 5μm

[0050] The test results are shown in Table 3, and the service life is more than twice that of the original.

Embodiment 3

[0052] Operation is with embodiment 1, and the weight percent of its raw material is:

[0053] Burnt gem clinker, particle size <3mm 31%

[0054] Burnt gem clinker, particle size 3-5mm 26%

[0055] Burnt gem clinker, particle size between 5mm and 8mm 11%

[0056] Fine-grained mullite powder, particle size <0.074mm 17%

[0057] ρ-Al 2 o 3 6.6%

[0058] α-Al 2 o 3 Superfine powder 3.2%

[0059] SiO 2 Ultrafine powder 5%

[0060] Sodium tripolyphosphate 0.2%

[0061] Among them, the particle size of ultrafine powder is less than 5μm

[0062] The test results are shown in Table 3, and the service life is more than twice that of the original.

[0063] table 3

[0064] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com