Nozzle structure at bottom of refining furnace and nozzle filling method

A technology of refining furnace and bottom water, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the problems of increasing material cost, waste of drainage sand, lax fit between sprue and plug, and achieve opening and closing Flexible, improve the utilization rate, and the effect of tight shut-off of the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

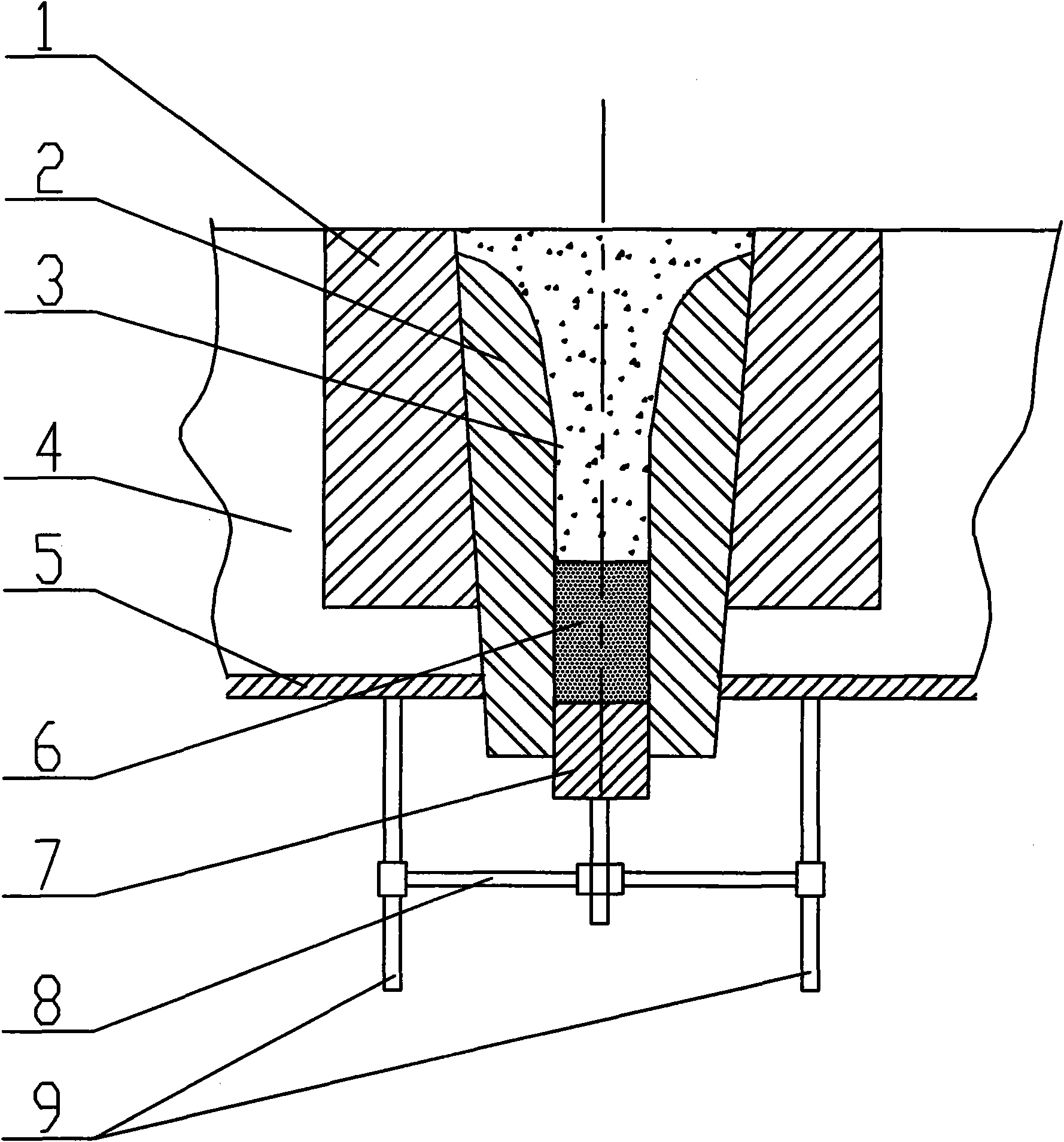

[0013] Refer to attached figure 1 , the nozzle structure at the bottom of the refining furnace of the present invention includes a seat brick 1, a nozzle brick 2, a refractory lining 4, a refining furnace bottom 5, a plug 7, a rotatable bracket 8, and a support 9, and the nozzle brick 2 is produced by Shanghai Taishan Refractory Co., Ltd. It is made of non-fired aluminum-carbon casting mouth brick (aluminum-carbon refractory material with resin as the binder), and the upper chamfer of the inner cavity of the nozzle brick is R58mm.

[0014] The nozzle filling method is as follows: when the lower opening of the nozzle brick inner cavity is blocked and locked by the plug 7, first fill the inner cavity of the nozzle brick with cast iron chips 6 to a height of 100 mm and compact them, and then fill the upper layer of the cast iron chips 6 Drainage sand 3 is tamped to the upper edge of the nozzle brick inner cavity. Drainage sand 3 is made of zirconium drainage sand produced by Hena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com